This Case Studies Special Advertising Section features manufacturing companies with real-world challenges using quality equipment, software and services to solve their problems and improve their processes. These problem-solving stories describe myriad manufacturing challenges and how the correct application of a supplier’s product or service made the difference, providing quantitative benefits to quality and manufacturing issues.

The suppliers in this special section present these real-world problems and solutions to help Quality Magazine subscribers who may have similar experiences.

Case Studies

— Special Advertising Section —

GAGEtrak® is the “best control in the company” for Magellan Aerospace.

Magellan Aerospace is a Canadian company with over 80 years of collective knowledge and experience in the aerospace industry. The organization officially adopted the name “Magellan Aerospace Corporation” in 1996, deriving it from the intrepid explorer Ferdinand Magellan. His global exploits established a number of firsts and Magellan Aerospace’s vision is to carry this same legacy into the future of the aerospace industry. Magellan develops and produces complex and integrated products and services that bring value to their customers; they serve the civil aerospace and defense market as well as industrial power applications of aerospace engine technology.

Since 1996, multiple Magellan locations across three countries have chosen GAGEtrak calibration management software to track their gage and calibration data. James Brooks of the Connecticut location started using GAGEtrak in 2007 to track the 3,985 gages and 18,000 annual calibrations for which he was responsible. GAGEtrak was chosen simply because it’s “the best,” Brooks said.

Prior to using GAGEtrak, the company tracked their data by hand on paper; it was clear they needed a more efficient method that would “keep everything at (our) fingertips” and would reduce the likelihood of human error.

Brooks said that GAGEtrak is the “best control in the company” and the company is pleased that GAGEtrak helps them keep their data current and track gage locations.

GAGEtrak is used at thousands of facilities worldwide to improve measurement quality, assure compliance and increase efficiency. Contact us today to learn how GAGEtrak will do the same for your company.

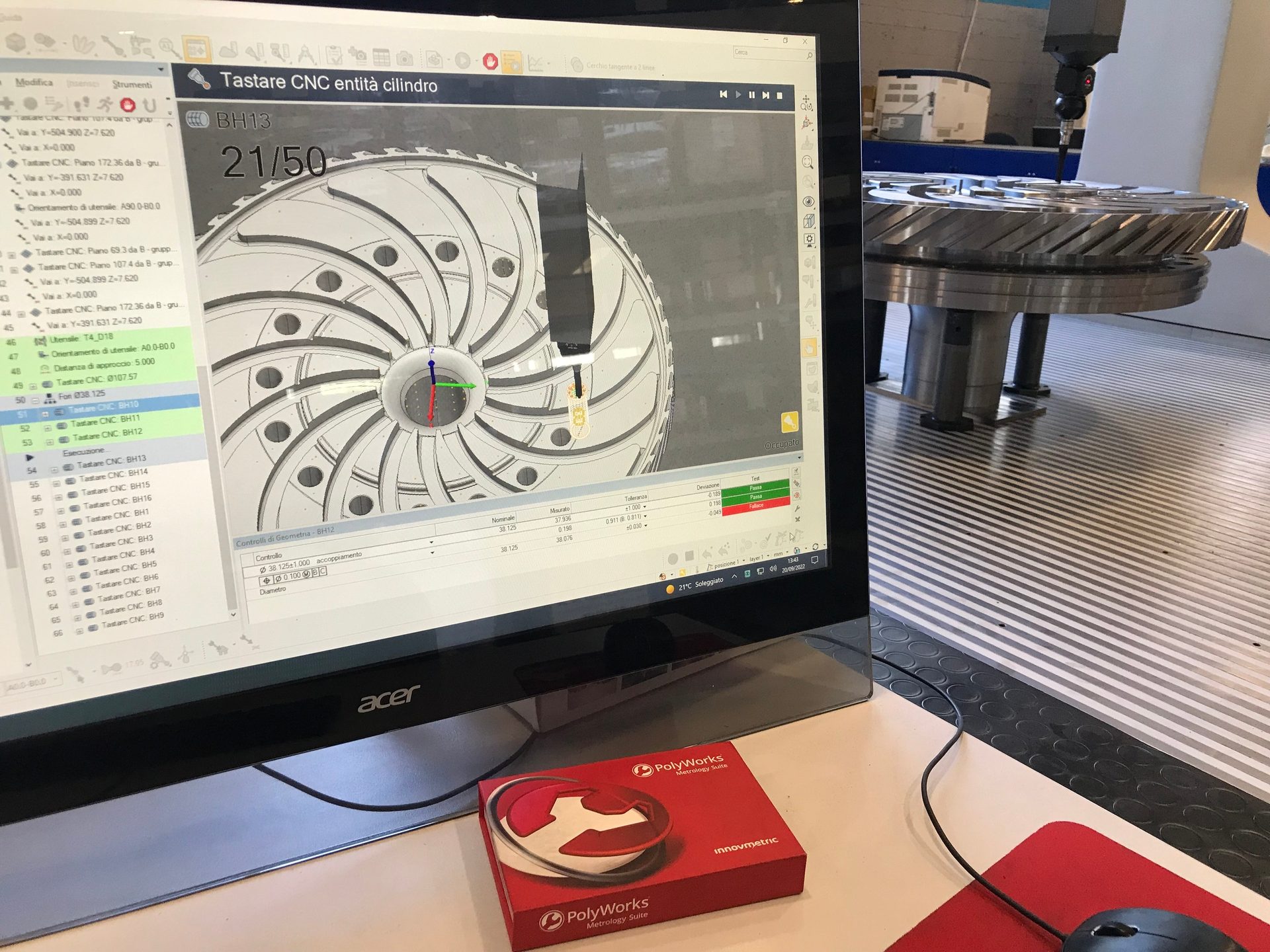

A Single Software Specialized in 3D Measurement and Analysis for all Measuring Devices

When Italian company Bruno Presezzi SpA, a specialist in mechanical machining, decided to add 3D scanning for dimensional control to other systems already being used, it chose PolyWorks® for the convenience of having a single software for all its measuring devices.

In this case study, discover the challenges faced by the company’s team members as they strive to meet increasingly demanding quality standards in their diverse manufacturing operations. Learn how their decision to integrate 3D scanning technology led to the adoption of PolyWorks®, which revolutionized their approach to dimensional control.

PolyWorks enabled them to streamline operations, enhance accuracy, and accelerate processes across their entire production line. From the initial implementation to ongoing technical support, the partnership between Bruno Presezzi and PolyWorks Europa Italia unfolded, driving continuous improvement and innovation.

Draw inspiration from their success and constant desire to exceed customer expectations, to adapt to evolving market demands, and to stay ahead of the competition in the dynamic world of manufacturing.

Manufacturing Case Study

One aluminum manufacturer was having trouble with excess scrap. While there was significant, unavoidable startup scrap, other opportunities to reduce scrap became obvious after some analysis.

While many pounds of finished material were inspected and found wanting before shipment, roughly 40,000 pounds of finished metal was returned each month. Shipping and return costs ate into profitability. Finished metal cost about one dollar per pound. Returned metal had to be chopped up and fed back into the furnace for remanufacture.

Using QI Macros for Excel, it was possible to use PivotTables to analyze and chart ongoing scrap. Control charts showed a stable process producing consistent levels of monthly scrap. Drilling down into the data, Pareto charts showed that one machine out of many was producing most of the scrap. A few hours of root cause analysis with operators of that machine identified simple ways to reduce scrap just by changing the setup and ongoing adjustment process.

Annual savings amounted to over $1,000,000 after only a few hours of analysis.

Million-dollar opportunities lay hidden in data about defects, mistakes, errors, scrap, waste and rework. Using Excel and QI Macros it is possible to mine and find those opportunities—the invisible low-hanging fruit in any company. QI Macros Improvement Project Wizard automates this analysis, creating improvement projects in just minutes.

This analysis works in manufacturing, healthcare, telephony, banking and any industry that tracks waste and rework. Haven’t you waited long enough to find your hidden, low-hanging fruit?

Download a 30-day trial at www.qimacros.com/QualMag2024

Company Name and Contact INfo

www.

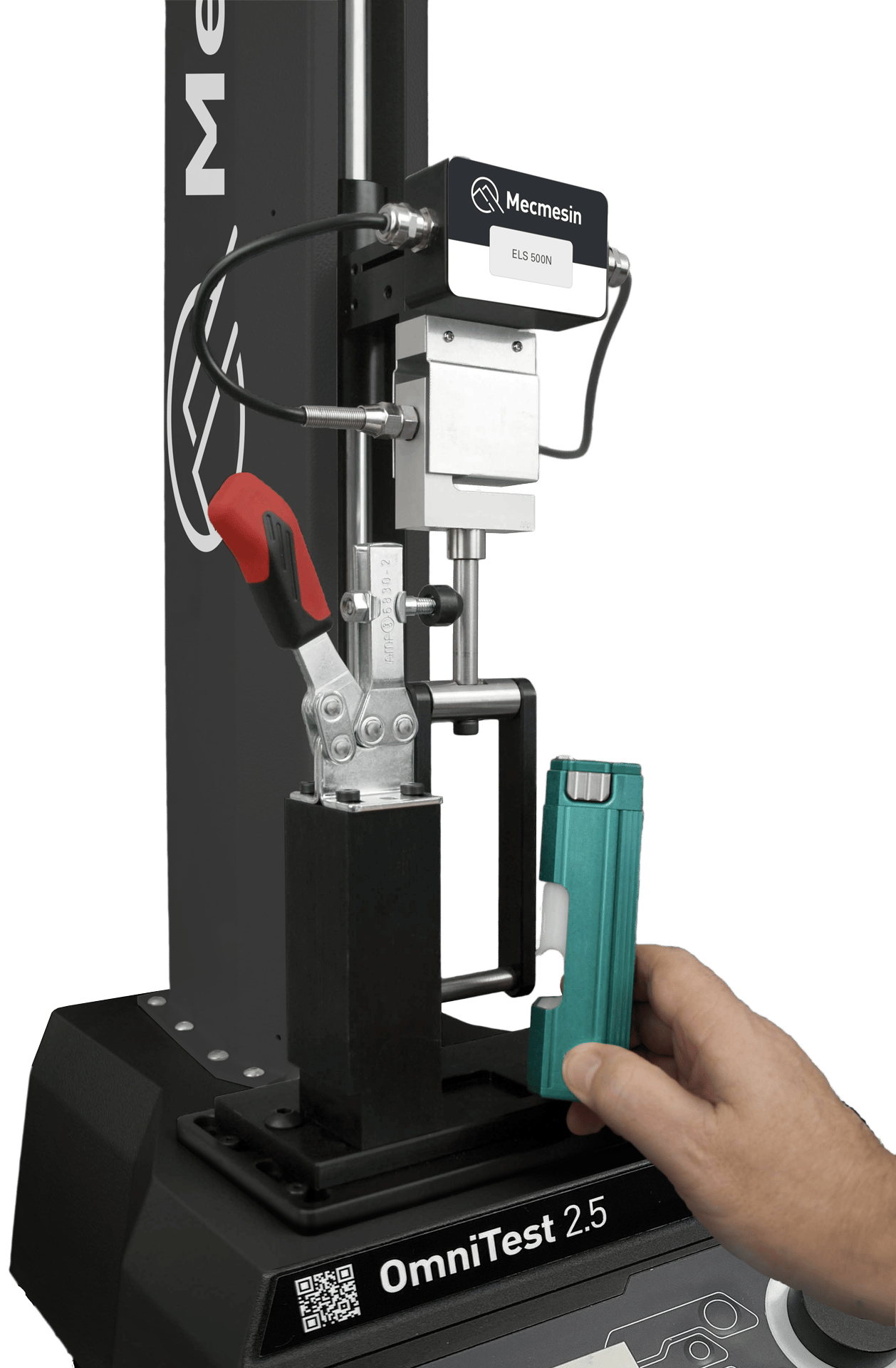

Batch testing the trigger spring strength of biopsy injectors

Bard Limited services Bard® Magnum® biopsy needle injector guns for clients around the world. A prime component in the reusable handheld device is a powerful spring with a dual-action trigger for taking the biopsy sample.

The need for precision: Bard® Magnum® biopsy injectors

Primed by single-finger pressure, the resistance as the cocking slide locks the compressed spring in place must be within design specification. It cannot be too strong for the user’s finger, nor too weak to perform a full, effective insertion and withdrawal. Bard have defined tolerances for the force required to cock the gun and needed a device to measure each unit for continued compliance.

Mecmesin's custom testing solution

Mecmesin supplied two *MultiTest 1-i test stands, each with a custom-designed grip system for the sample. The gun under test is quickly clamped into a secure position, while an upper stirrup engages the cocking slide. Its VectorPro software has been programmed to run batches of tests, displaying real-time characteristic graphs and instant green/red pass/fail indicators. Each unit is referenced, and all results are stored for analysis and reporting.

Biopsy gun spring strength test sample being loaded into the compression UTM

In the medical sector, Mecmesin’s VectorPro software has security modules built on robust architecture to enable organisations to meet FDA 21 CFR Part 11 compliance for electronic signatures and records.

Boosting efficiency and cost savings

The new equipment enables a rapid throughput, consistent testing and accurate reporting, saving Bard significant time and money.

*The current OmniTest UTM range now fulfils this solution.

Dorsey Metrology International- new by 4/10

first paragraph goes here

case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here. case study text goes here.

BELOW Logo with LINK

Company Name and Contact INfo

www.