Products

the latest products to help you improve your manufacturing process

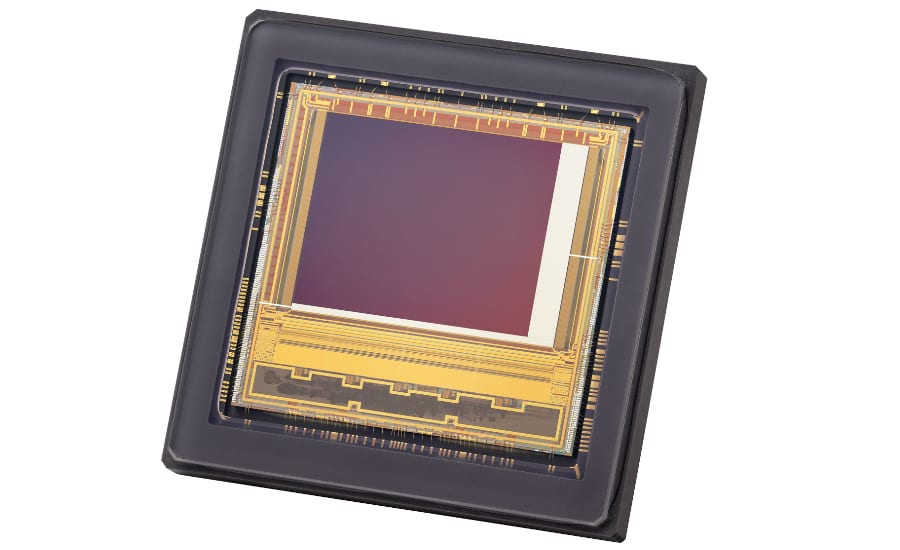

Teledyne e2v Next-Generation CMOS Image Sensors

Teledyne e2v announces OnyxMax™, the next generation of its Onyx 1.3M low light CMOS image sensor. This new sensor has been designed for extremely low light conditions, down to 1 mLux. The combination of sensitivity and image resolution increases its range, allowing even small objects to be detected in harsh conditions. This makes OnyxMax ideal for a wide range of applications including science, defense, traffic cameras, broadcast, surveillance, border control and astronomy.

OnyxMax features 1.3 Megapixels (1,280 x 1,024) and is available in monochrome, as standard, and with CFA arrangements available on request. It has a 10 x 10 µm pixel, designed with Teledyne’s new cutting edge HiRho™ proprietary technology, which enables outstanding Near Infrared (NIR) sensitivity and spatial resolution with Quantum Efficiency (QE) of 58% and MTF of 63% at 850nm wavelength. OnyxMax also provides an SNR of 10 dB at less than 2 mLux and at 60 frames per second and operates in rolling and global shutter modes, providing 75 dB of linear dynamic range. It also has a patented on-chip HDR mode which is capable of handling scene dynamics up to 100 dB.

Teledyne e2v

imaging.teledyne-e2v.com

Olympus Ultra-Thin IPLEX TX II Videoscope

The Olympus IPLEX™ TX II videoscope combines the versatility of a 2.2 mm diameter flexible scope with an ultra-thin 1.8 mm rigid scope in a single package, enabling users to choose the best setup for their remote visual inspection application. The result is a videoscope that offers easier insertion in the smallest spaces, so inspectors can reach their targets fast and acquire the high-quality images they need to make decisions.

The videoscope’s 120-degree field of view and high-pixel CMOS sensor provide high image quality over a wide area, helping inspectors complete their work more quickly. Bright LED illumination and image adjustments—like halation reduction—improve image quality to facilitate confident decision making.

Compared to the original IPLEX TX, the IPLEX TX II has a redesigned flexible insertion tube and shorter rigid section length that makes it easier to maneuver it in small spaces. The rigid insertion tube also has an air injection system that can be used to blow droplets of water or other liquids out of the way to obtain clear images.

The ultra-lightweight rigid scope weighs as much as a ballpoint pen, so inspectors can hold the scope without strain. The extendable grip enables users to grasp the rigid scope close to the insertion point for fine control. Captured images are displayed on a tablet, so inspectors do not have to physically bend down to look through the scope when they are working. Instead, they can position the tablet wherever it is comfortable for them.

The redesigned flexible insertion tube has a new articulation mechanism that eliminates common failure points while metal braiding provides additional crushing and wear protection. In addition, a CMOS imaging sensor on the rigid scope tip enables the system to continue working if the tube is slightly damaged.

Evident Scientific

www.olympus-ims.com/en/rvi-products/iplex-tx-ii/

Zygo Qualifire Laser Interferometer

Zygo Corporation, a business unit of AMETEK, Inc., announces the release of its newest laser interferometer, Qualifire™. Qualifire joins an extensive array of top-end interferometer solutions. This instrument is designed to support and enable the most demanding metrology applications in industries such as semiconductor, lithography, space-borne imaging systems, cutting-edge consumer electronics, defense. Qualifire debuted at SPIE Photonics West in San Francisco on January 30. This interferometer packs significant enhancements and features into a small lighter-weight package without sacrificing performance.

Qualifire brings these features and improvements to Zygo’s laser interferometer product line:

- Smart Accessory Interface—the interferometer can recognize any “smart accessory” installed and automatically apply a system error file and perform lateral calibration.

- Small, Lightweight Footprint—the smallest model of Qualifire weighs approximately 45 lbs (20.4 kgs). It is truly portable, especially for complex and delicate applications in which the interferometer must be moved or adjusted frequently.

- Integrated Phase Measuring Receptacle (PMR)—the PMR is necessary for modulating interference fringes between the test part and reference optic which ultimately creates a quantitative surface map. Its integral design provides:

- Overall mechanical stability and alignment

- Reduces the risk of damage or misalignment

- Ensures consistent performance, reducing the need for recalibration

- Improved User Experience—conveniently accessible power button and kinematic mounting feet make setup easier to use. Large control knobs allow for more accurate adjustments—critical to both alignment and calibration. Integrated handles ensure safe and secure handling.

- Easier service—the sealed optical system and consolidated electronics makes swapping out various components straightforward without exposing the optics to contaminants.

- Flying Spot—an optional module for artifact reduction that includes the autofocus feature.

- Stable Zoom—an option providing a new zoom method which makes perfect image registration possible and diffraction limited image sampling at all magnifications.

Zygo Corporation, a business unit of AMETEK, Inc.

www.zygo.com

Emergent Vision Technologies Plug-ins for eCapture Pro Software

Emergent Vision Technologies introduces new plug-ins that leverage GPUDirect technology, which supports Emergent’s renowned zero-copy, zero-loss imaging approach. The new built-in plug-ins include polarization, H.265/RTMP (real-time messaging protocol), pattern matching, and inference.

Supported by eCapture Pro software, GPUDirect technology enables the transfer of images from the camera directly to the GPU, which bypasses system memory and the CPU, delivering zero-copy and zero-loss imaging capabilities. In addition, Emergent offers optimal flexibility in camera stream routing to any GPU in a system, which simplifies processing distribution. Supported GPUs include NVIDIA RTX A6000, RTX A5000, RTX A4000, RTX 6000 ADA, Jetson Orin, and Jetson Xavier.

“With the tremendous amounts of data that Emergent’s GigE Vision cameras capture, users need a means for processing that data with top performance,” said John Ilett, president and CTO at Emergent Vision Technologies. “Our GPU plug-in technology is supported within multi-camera and multi-server systems for maximum performance and ease of scalability.”

In eCapture Pro software, end users can create their own custom plug-ins or use Emergent’s built-in plug-ins, including a polarization plug-in tool. This tool lets users review the benefits of the characteristic outputs of a standard polarized processing pipeline, such as degree of polarization or direction or angle of polarization. End users can even remove the polarized light or output one of the four orientation options: 0, 45, 90, or 135 degrees.

With the inference plug-in, users can easily add and test their own trained deep learning inference model to perform detection and classification of objects. After training a model in a framework such as PyTorch or TensorFlow, users can add the model to the plug-in, instantiate it on the desired GPU, connect it to the camera, and click “run” to begin, allowing the software to detect and classify objects even while in motion.

To use the pattern matching plug-in within eCapture Pro, the user first creates a pattern template, loads the plug-in, and then instantiates it on the desired GPU. Next the user specifies the path to the pattern template, connects the camera to the GPU, and runs the plug-in to begin matching patterns, including those on moving objects.

Emergent’s eCapture Pro software also offers a plug-in for the H.265 video codec, which is the successor to H.264, delivering up to 50% better video compression while maintaining the same level of video quality, making it an ideal option for high-speed, high-resolution video. In addition, the plug-in supports RTMP streaming, which enables users to stream high-speed video to YouTube and other live streaming platforms. In high camera count systems, this plug-in can help users handle vast amounts of data. In a 48-camera system leveraging a midrange server, a 48-port switch, and two GPUs, for example, all images can be compressed and stored on a single local M.2 drive while one camera from the system streams to an RTMP client such as YouTube.

Emergent Vision Technologies

https://emergentvisiontec.com/ecapture-pro/

LUCID Helios2 Ray Time-of-Flight Camera

LUCID Vision Labs, Inc. announced the series production of the new Helios™2 Ray Outdoor Time-of-Flight (ToF) camera.

The Helios2 Ray camera is powered by Sony’s DepthSense IMX556PLR ToF image sensor and is specifically engineered for exceptional performance in challenging outdoor lighting environments.

Equipped with 940nm VCSEL laser diodes, the Helios2 Ray generates real-time 3D point clouds, even in direct sunlight, making it suitable for a wide range of outdoor applications. The Helios2 Ray offers the same IP67 and Factory Tough™ design as the standard Helios2 camera featuring a 640 x 480 depth resolution at distances of up to 8.3 meters and a frame rate of 30 fps.

LUCID’s proprietary Arena SDK integrates user-friendly controls for all Helios2 ToF cameras. The ArenaView GUI enables users to visualize scene intensity and depth in either 2D or 3D point cloud views, offering real-time manipulation and orientation. Additionally, the software facilitates on-the-fly adjustments, including false color overlay and depth range modifications.

All LUCID cameras conform to the GigE Vision 2.0 and GenICam3 standards and are supported by LUCID’s own Arena software development kit. The Arena SDK provides customers with easy access to the latest industry standards and software technology. The SDK is compatible with the Windows, Linux 64-bit, and Linux ARM operating systems, and supports the C, C++, C# and Python programming languages.

LUCID Vision Labs, Inc.

www.thinklucid.com

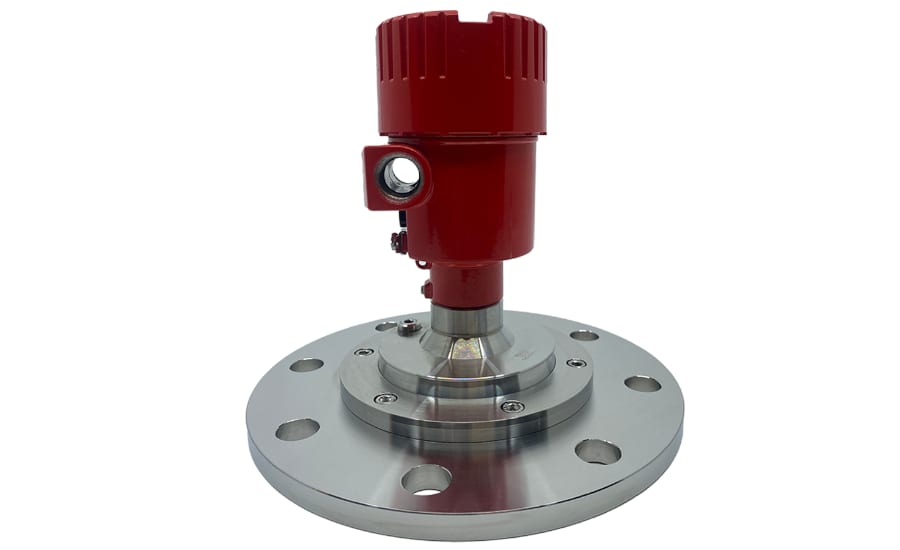

BinMaster NCR-86 Radar Level Sensor

BinMaster introduces the NCR-86, a radar level sensor designed to streamline bulk material inventory management. With unparalleled versatility and innovative features, the NCR-86, paired with BinCloud® software, becomes the singular solution for measuring any solid or liquid commodity across vessels and sites, all accessible through a single login.

- Versatility at its Core: The NCR-86 adapts to any level measurement application, providing 1mm accuracy for solids, powders, or liquids of varying bulk density or specific gravity.

- Quick and Reliable Data: Despite challenging conditions such as dust, foam, steam, or condensation, the NCR-86 ensures rapid data updates, enhancing efficiency in inventory management.

- Effortless Setup: The sensor offers a simple Bluetooth setup using a BinDisc or the BinMaster Sensor App, optionally connected to your phone or PC, facilitating easy installation.

- Cost-Effective Solutions: Utilize wireless and solar gateways, long-range transceivers, and HART consolidator modules to reduce system costs and complexity.

- Comprehensive Inventory Management: Once installed, connect the NCR-86 to the BinCloud system, enabling users to log in, monitor inventory, receive alerts, and generate reports for any commodity, at any site, during any defined time.

- Dependability in Extreme Conditions: Encapsulated electronics make the NCR-86 dependable and safe to operate in extreme environments, withstanding high temperatures and pressures. It is certified to various hazardous approval standards.

- Customizable Options: Choose from plastic, aluminum, or stainless-steel housings, along with various seal materials that suit your specific process requirements.

- Advanced Cybersecurity: The NCR-86 employs advanced technology to combat cyber-attacks, adhering to the highest IT security standards set by the process industry.

- Functional Safety: Designed to standard IEC 61511, the NCR-86 ensures functionally safe operation in any process industry.

- Simplify your commodity management with BinMaster's NCR-86 - one radar, one software, one login, one system. It's time for a seamless and efficient solution.

BinMaster

www.binmaster.com

Teledyne FLIR IIS USB3 Machine Vision Camera Series

The Dragonfly S series combines Teledyne’s expertise in USB and experience delivering embedded camera solutions for industries ranging from life science instrumentation to factory automation.

Teledyne FLIR IIS (formerly Point Grey Research), industry pioneer of the area scan USB concept, is pleased to introduce the new Dragonfly® S USB3 camera series to its machine vision portfolio. The new series is a result of Teledyne’s constant commitment to set and enhance vision industry standards for customer success. It addresses the market’s essential need for a modular, compact, and lightweight camera for at-scale manufacturing, volume-based applications, and multi-camera systems.

Dragonfly S has a modular design to accelerate the inception stage of imaging application development for a diverse range of industrial and non-industrial segments. “This is a first-of-its-kind practical option for factory automation and embedded vision-based device manufacturers,” said Sadiq Panjwani, General Manager at Teledyne FLIR IIS. “The modular concept of the new camera empowers engineers to quickly test, develop, and deliver competitive vision products to market at scale.”

The camera series is ideal for embedded or handheld device applications such as biometrics kiosk solutions, ophthalmoscopy, 3D scanning, automated optical inspection, and more. It is available in multiple configurations, from board-level to a fully-enclosed module in a ruggedized aluminum case. The USB connector is offered in a rear or side orientation with screw-in locking mechanism. These modular options provide maximum flexibility and durability, allowing seamless integration in tight spaces. The cased models are Class B EMC safety compliant as mitigating electromagnetic interference is critical for healthcare and residential applications. Additionally, an onboard image buffer ensures that every captured image frame is reliably transferred to the host CPU.

The first of its series Dragonfly S is now available for pre-order. Additional model releases from VGA to 8MP are planned for 2024.

Teledyne FLIR IIS (Integrated Imaging Solutions), a Teledyne Technologies company

www.teledyneflir.com/mv

Smart Vision Lights RHI200-DO Lightgistics Machine Vision Light

Smart Vision Lights (SVL) introduces the RHI200-DOLightgistics series light, which features 64 LEDs in a 205 mm x 205 mm ring light for intense uniform lighting at long working distances of up to 2000 mm. Equipped with Hidden Strobe technology, the light delivers all the advantages of strobing without the disturbance and disorientation often linked to LED strobe lights.

Hidden Strobe technology allows LEDs to automatically trigger thousands of times per second, pulsating at speeds imperceptible to the human eye and generating the appearance of uninterrupted illumination. The innovative technology helps maximize the abilities of machine vision systems while safeguarding employees from the disorienting effects commonly associated with flashing lights.

Lightgistics lights specifically address the challenges of accurate high-speed barcode reading and optical character recognition (OCR) on highly reflective plastic wraps and shipping bags. Dual OverDrive™ technology utilizes SVL’s new Deca OverDrive™ and standard OverDrive™ engines, which together allow end users to easily attach polarizers that maximize light output in high-speed conveyor systems.

The RHI200-DO is an OverDrive™–only light source with a high-intensity ring light. Its integrated camera mount fits most common machine vision cameras and can be directly connected and controlled through a camera’s trigger output. The RHI200-DO’s onboard charging capacitors ensure powerful bursts of energy while maintaining a low consistent electrical draw. The IP65-rated bright field operates at working distances between 500 mm and 2000 mm with 10-, 14-, and 30-degree lens options.

Smart Vision Lights

SmartVisionLights.com

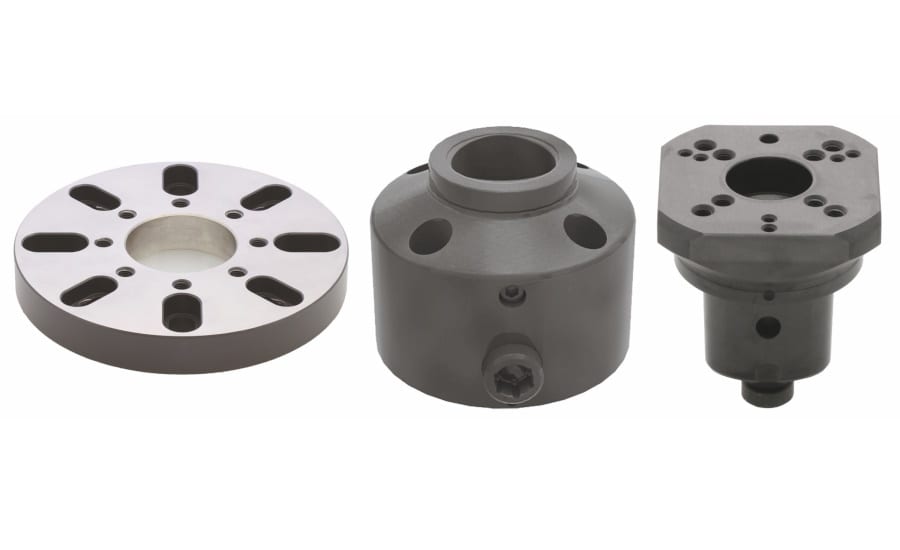

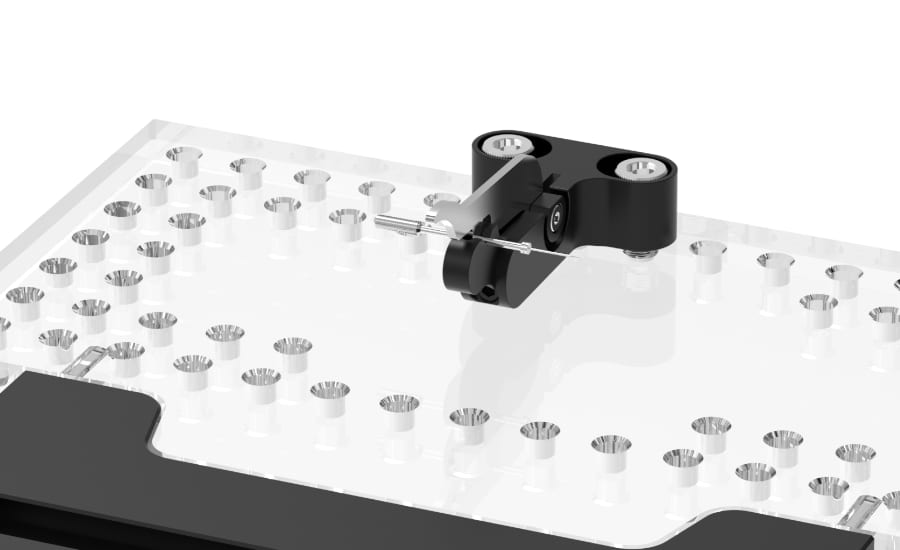

Fixtureworks Quick Zero Setting Devices

Fixtureworks® now offers Quick Zero setting devices. The easy-to-use and easy-to-install devices are used to locate and clamp workpieces to further ensure stability and precise location. The system consists of a mounting plate, base and holder.

The mounting plate, available with a 230 mm diameter, 25 mm thickness/depth with and mounting holes in M10 and M12, is used to mount the base of the Quick Zero System to a T-slot machine table. It is made from 1045 steel, precision ground, with a black oxide finish.

The base component of the Quick Zero setting device system, with a diameter of 115 mm and clamping force of 6,700 lb. attaches to the plate and provides a mount for the holder component. The base can be simply clamped/unclamped from the holder with a hex wrench and tightening/loosening can be completed with less than 180° turn. The cam shaft comes out of the body when the holder is unclamped so the user can visually check if the holder is unclamped or not. The body is made from 4130 steel, carburized hardened, with a black oxide finish. The cam shaft is made from 4135 steel, quenched and tempered, with a black oxide finish.

This square holder, available with a 72 mm in width, and a height of 85 mm including riser, is also part of the setting system. These clamp modules are used to locate and clamp a workpiece in conjunction with the base and plate. This holding clamp secures workpieces by attaching them to holding clamps and custom risers. The holder is secured to the base with a hex wrench. The body is made from 4130 steel, carburized hardened, with a black oxide finish. The clamping screw is made from 4135 steel, quenched and tempered, with a black oxide finish.

In addition to these quick zero setting devices, Fixtureworks also offers myriad workholding components and fixturing accessories including workholding supports, pneumatic flex actuator clamps, nutrunner clamps, quick change pneumatic clamping fasteners, quick action sliding locks spring plunger clamps as well as handles and levers, knobs and grips, equipment handles, hand wheels and cranks, hinges and latches, leveling supports, industrial rubber bumpers, stops and wheels, fixture clamps, clamping locating systems, work positioning elements, vises, grippers and mechanical linear actuators.

Fixtureworks

www.fixtureworks.com

INSPECTIS’ Optical BGA Inspection

INSPECTIS’ BGA inspection systems can now be supplied with optional new XM lenses that offer up to 285x screen magnification, compared to the original standard lens with 200x. The INSPECTIS BGA lens package consists of a lens (standard or XM) plus a probe tip (standard or small).

The new XM higher power lens is compatible with both the Standard and the Small probe tip, which features a 27% smaller footprint.

The new XM LENSES are designated by the following part numbers:

- BGA-004-XM With standard probe tip;

- BGA-005-XM With Small probe tip.

Inspectis offers a wide range of packages/sets covering basic or advanced inspection requirements.

The INSPECTIS BGA Inspection System is available in two system levels, Basics and ProX which includes powerful INSPECTIS BGA Inspection, analysis and documentation software.

INSPECTIS

https://www.inspect-is.com/

B&K Precision Data Acquisition Recorder Line

B&K Precision announced the expansion of its Data Acquisition Recorder line with the DAS1800. This all-in-one unit offers an extensive set of features with an all new user-friendly interface designed to reduce the learning curve and improve overall efficiency. It also raises the bar for performance and configurability.

The DAS1800 provides sample rates of up to 1 MSa/s, a configurable base unit with 10 module slots, large internal solid-state drive of 2 TB, a 15.6” Full HD multi-touch display, and optional internal battery lasting up to 3.5 hours on a single charge. The battery configured model only weighs 15 lbs — making it the lightest all-in-one system in its class and ideal solution for field testing.

Measurement modules available today include:

- Universal: 4-channel isolated universal input module for measuring voltages up to 600 VDC or 424 VRMS, temperature with thermocouples, and current (with shunt) at up to 1 MSa/s/ch

- High Impedance: High impedance version of the universal module with 10 MΩ for ranges ≥ ± 1 V and 25 MΩ for ranges ≤ ± 0.5 mV

- Multiplexed: 8-channel non-isolated differential input module for measuring voltages up to

± 48 V, temperature with thermocouples and RTDs, 4-20 mA current (with shunt), and resistance up to 10 kΩ at sampling rates up to 5 kSa/s.

Save time acquiring, visualizing, and analyzing data using the comprehensive software features available on the DAS1800. Quickly set up channels by storing and recalling sensor information from the customizable sensor library. Visualize data in real-time as waveforms or numeric values, and create custom dashboards. Playback recordings and easily navigate to points of interest using touch gestures such as pinch to zoom and one finger scrolling. B&K Precision also provides free DASpro software for viewing and analyzing recorded data on a PC.

New features are delivered through software and firmware updates via the internet or a USB drive at no extra cost. Additionally, the modular design of the DAS1800 ensures that it can be easily reconfigured as testing needs evolve.

B&K Precision

https://www.bkprecision.com/

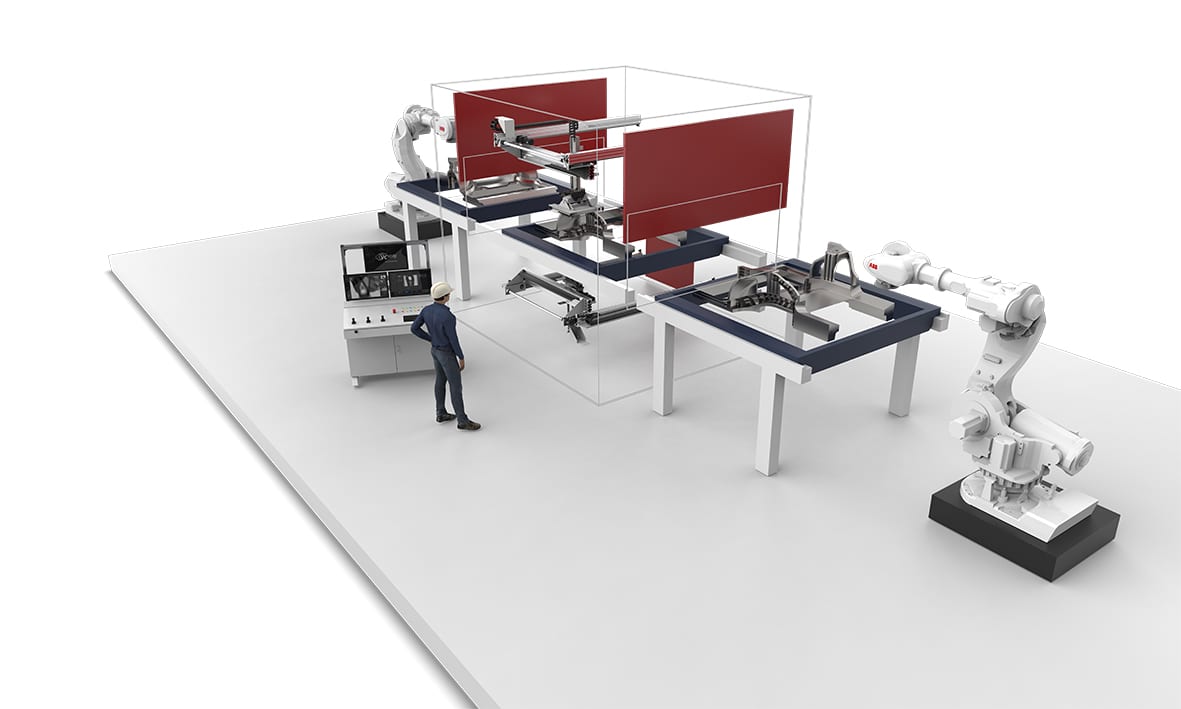

VCxray Inline X-ray Systems

VCxray by VisiConsult is expanding its PRO line x-ray system portfolio with two fast in-line inspection solutions, the PRO FI. and PRO FI. GIGA. Both are specifically tailored for the industrial casting market and various sectors including manufacturing, automotive and aerospace. The new design concept significantly enhances the inspection process by notably reducing the time required per view. Moreover, with the GIGA variant, VCxray has developed a world-novelty allowing for easy rapid and automatic inspection of next-generation gigacasting parts and large battery trays. The new PRO FI. 2D x-ray system range is ADR-ready. Both PRO FI. types can be directly integrated into manufacturing lines or automation cells.

VCxray by VisiConsult enhances its PRO line system portfolio with the PRO FI., enabling a rapid inspection process and offering full flexibility at the same time by inspecting small to large size parts. The inspection area measures up to 1600 x 1000 x 500 mm and the part changeover time is less than six seconds. The robust system is available as PRO FI.160 with 160 kV as well as PRO FI.225 with 225 kV. The manipulator is highly flexible and new inspection programs can be created without requiring programming knowledge. The system can be used manually via joysticks or in fully automatic program mode. An open interface offers versatile integration options into robotic loading cells or manufacturing lines.

With releasing the PRO FI. GIGA, VCxray by VisiConsult fulfils the needs of the transforming casting world facing huge manufacturing and inspection challenges. The current manual bottleneck in the inspection process can be eliminated with this XL version of the PRO FI. combining fast data analysis with easy max-size part inspection inline. The PRO FI. GIGA can also be highly tailored to specific customer requirements. The smart high-speed manipulator ensures that the x-ray inspection can be performed in line with the cycle time of the manufacturing line.

All PRO FI. machines are equipped with the company’s VC.acquire software platform, offering an easy to use Automatic Defect Detection (ADR) functionality. The automation concept provides consistent results, also detecting smaller and harder-to-see defects.

VCxray, a division of VisiConsult

www.visiconsult.de | www.vc-xray.com

Evident Scientific Next-Generation Vanta Handheld XRF Analyzers

The next-generation Vanta™ handheld XRF analyzers—Vanta Max and Vanta Core—deliver improved elemental analysis and material identification using smart and cloud-connected technology. These updated portable XRF analyzers combine the exceptional accuracy, speed, and durability of the Vanta series with improved ergonomics, a refreshed interface, and enhanced connectivity for greater comfort and productivity.

The new ergonomic design includes a balanced handle with an enhanced grip, making the updated portable XRF analyzers more comfortable to hold for extended use in the field or lab. Combined with their proven ruggedness and ease of use, the analyzers can increase uptime in the toughest environments.

A refreshed and intuitive interface enables users to work more efficiently, saving valuable time. Data management is also simplified thanks to the browser-based software option. With a wireless connection, users can review, share and manage XRF results on a PC, tablet or smartphone, enabling seamless data integration into their workflow. Software updates are now automatic, giving users instant access to the latest features. For customer-specific needs, users can take advantage of enhanced application support with the option to add custom analytical capabilities.

Building on the proven performance of the Vanta series, the new models provide reliability and accuracy for portable XRF analysis. The Vanta series is powered by proprietary Axon Technology™, XRF signal processing that uses ultra-low-noise electronics to deliver higher X-ray counts per second for fast, repeatable results. Trusted all over the world in the harshest environments, Vanta analyzers are used by thousands of customers in applications such as scrap recycling, mining, metal fabrication, positive material identification (PMI), environmental assessment, scientific research and education.

The Vanta Max model, replacing the M series, offers the series’ highest analytical capabilities for robust applications, including mining exploration, mineral analysis, soil testing and environmental analysis. The Vanta Core model, replacing the C series, combines value with speed, low limits of detection (LODs) and a wide elemental range, making it the standard choice for fast alloy identification. Vanta Max and Core models are available with optional XRF accessories, including the redesigned field stand, soil foot and holster for greater efficiency in the field.

Evident Scientific

www.olympus-ims.com/en/xrf-analyzers/handheld/vanta/

FRAMOS FSM:GO Embedded Sensor Module

FRAMOS announced the release of FSM:GO – a comprehensive series of deployable optical sensor modules enabling machines to see and think.

FSM:GO offers a curated selection of pre-selected sensors paired with optimally focused lenses to deliver superior Off-The-Shelf image quality. This latest innovation from FRAMOS represents a significant step forward in simplifying the embedded vision development process, making it both cost-effective and time efficient.

Suitable for a broad spectrum of applications, FSM:GO is deployable across many industries including sports and security, as well as enhance the capabilities of conferencing cameras, drones, smart traffic systems, industrial automation, surveying, mapping, and logistics.

FSM:GO is not only a versatile prototyping tool but also stands ready for immediate deployment in mass production. Its introduction signifies FRAMOS's dedication to alleviating the challenges of developing and manufacturing optical sensor modules, enabling clients to concentrate on device design and software development.

Each FSM:GO module is accompanied by a complete suite of necessary hardware components, software drivers, ISP tuning packages and extensive documentation, ensuring seamless integration with prominent platforms such as NVIDIA’s® Jetson™ and NXP i.MX8MP. This compatibility harnesses the power of leading embedded processing platforms to maximize performance.

The integrated FRAMOS PixelMate™ connector, offering an array of connection options such as MicroCoax, FFC, and GMSL, ensures engineers have the adaptability to select the ideal cabling based on system specifications or application demands.

FSM:GO comes initially in three variants, featuring the latest Sony Starvis2 color image sensors with 2MP (IMX662), 8MP (IMX678), or 12MP (IMX676), each with a suite of lens options — from narrow to fisheye. These configurations adapt to multiple fields of view, diverse lighting situations, and varying working ranges, making the modules versatile for a wide array of applications.

FRAMOS

https://www.framos.com/

Renishaw RenAM 500 Ultra Series

Renishaw has expanded its RenAM 500 series with the launch of the RenAM 500 Ultra AM system, cutting build times by up to 50 percent without compromising on quality, and giving metal additive manufacturing (AM) users the tools to produce parts faster.

The RenAM 500 Ultra system includes all the existing benefits of the RenAM 500 series, including industry-leading optical, chamber and gas-flow design, and it adds new productivity-boosting TEMPUS™ technology and advanced process monitoring software.

TEMPUS technology incorporates new scanning algorithms that allow the laser to fire while the recoater is moving, saving up to nine seconds per build layer. The RenAM 500 Ultra’s advanced process monitoring software also delivers detailed insights into the build, equipping users with data and providing in-process visibility.The RenAM 500 Ultra metal AM system is the latest model in the RenAM 500 family, which also includes the Flex system, optimized for R&D work, and the flagship closed-loop powder recirculation model for series production. The entire RenAM 500 family is available with one (500S) or four (500Q) high powered lasers, each able to access the whole powder bed simultaneously.

Renishaw

www.renishaw.com

Phillips Precision Mini-Vise

Phillips Precision unveiled the new Mini-Vise, the latest addition to their acclaimed Inspection Arsenal® system. Aptly named for its exceptional capabilities, it is engineered to provide effective holding for very small parts. In fact, it may set a new standard as possibly the smallest clamp on the market today, showcasing Phillips Precision's dedication to innovation and pushing boundaries in metrology and manufacturing.

Key Features:

- The Mini-Vise boasts an impressive range capacity, accommodating a work piece ranging from .010” to .250” in diameter, catering specifically to the needs of small parts in various industries.

- The Vise features an adjustable spring-loaded mechanism, allowing users to fine-tune the holding force from 0 to approximately 3.1 lbs., ensuring secure and precise holding without part distortion or marring.

- With a focus on adaptability, the Mini-Vise can be seamlessly set up either horizontally or vertically, on imperial and metric Loc-N-Load™ Fixture plates. This unprecedented flexibility in small work holding redefines the possibilities for precision measurement and inspection processes.

- Crafted with precision and durability in mind, the Mini-Vise is constructed from black anodized 6061-T6 aluminum and 304 Stainless Steel, ensuring longevity and reliability.

- The Mini-Vise's retaining crown is impressively slim, measuring just .190" in width, making it an ideal solution for applications where a clear line of sight or space for a touch probe is elusive, yet critical.

Phillips Precision, Inc.

www.phillips-precision.com

Replacement Option for ControlLogix Motion Modules

All three of the Rockwell Automation ControlLogix analog motion modules, 1756-HYD02, 1756-M02AS, and 1756-M02AE, have reached end-of-life and, as of December 2024, will be discontinued and no longer available for sale. Rockwell does not have a replacement option, which leaves a need for a motion solution that Delta Motion is uniquely positioned to fulfill. Rockwell Automation recommends that OEMs and system integrators consider RMC Motion Controllers as a replacement for these modules.

Delta’s RMC Motion Controllers can duplicate the function of the discontinued motion modules. They have the same I/O signals, communicate efficiently with Allen-Bradley PLCs via EtherNet/IP, and connect to all of the same field devices as the ControlLogix analog motion modules. Delta Motion’s sales and support team also has the expertise to support customers in converting from these modules to RMC motion controllers.

Features of Delta Motion’s RMC Motion Controllers include:

- ±10V outputs (some RMCs also have ±20mA and 4-20mA options)

- Connection to feedback devices: Quadrature, SSI, PWM, Start/Stop (analog options are also available)

- Single and multi-axis: RMCs are available from 1 to 50 axes for tightly synchronizing axes

- Command-based programming keeps most control in the PLC, or the RMC User Programs can offload critical motion-related tasks from the PLC

- Easy-to-use and powerful RMCTools software (freely downloadable)

- Analog and load cell inputs for position, pressure or force feedback

- Extensive control algorithm options, including dual-loop position-pressure or position-force control

- Knowledgeable and responsive technical support 24/7/365

To help get the word out about this replacement option, Rockwell Automation welcomed Delta Motion as a Technology Partner in the Rockwell Automation PartnerNetwork™ and arranged for a booth at the Automation Fair in Boston in November.

Additionally, Delta continues to develop and release information designed to make a smooth transition for all applications. With the announcement, Delta has released a complete set of details of using the RMC with an Allen-Bradley PLC, step-by-step instructions, and a video on setting up the communications between ControlLogix and the RMCs, and they plan to record a live webinar during Q1 of 2024.

Delta Motion and Rockwell Automation already share many customers. Rockwell Automation, as a leading global automation company, has a large installed base of its Allen-Bradley Logix platform. Delta’s RMC industrial hydraulic motion controllers are used extensively in conjunction with these PLCs, providing easy integration including exporting of tag names for import into Allen-Bradley PLCs. Now, as a Technology Partner, Delta looks forward to working with more Rockwell Automation customers to achieve the best in industrial motion control.

Delta Computer Systems

www.deltamotion.com