Products

the latest products to help you improve your manufacturing process

Mitutoyo America MF/MF-U Microscope Packages

Mitutoyo America Corporation announced the release of the new MF microscope packages that include the M2 geometric software and touch-screen tablet as well as a retrofit package for D generation MF and MF-U microscopes in the field.

The M2 software is easy to use and allows for graphic-based part view feature construction and generating popular construction types like distances and tangent lines. The software also allows a user to apply geometric tolerances, view deviation results and then export the data and create reports.

Other features with the new MF/MF-U Measuring Microscopes with Metlogix M2 Software and an easy-to-use touch- screen tablet include:

Highest measuring accuracy in its class

Stage travel range up to 400mm x 200mm / 16in x 8in

Quick release mechanism and zero-set buttons on stage controls increase operability when working larger workpieces

Easy to use all-in-one PC Touch Screen Display

M2 Geometric 2D Measurement Software

Camera port is standard on all models

Wide range of objectives available from 1x to 100x

M2 Retrofit package available for D generation MF and MF-U microscopes

Mitutoyo America

https://www.mitutoyo.com/wp-content/uploads/2021/04/MF_wM2-pkgs-lit-npi.pdf

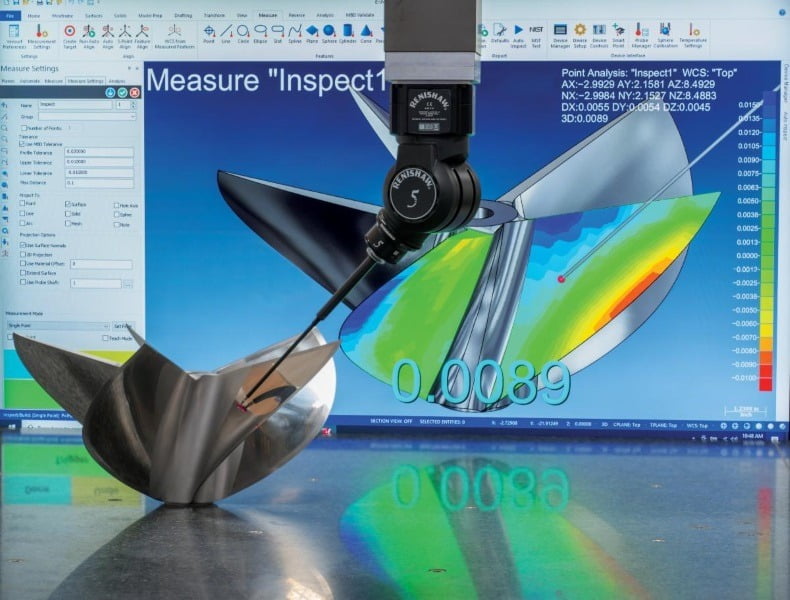

Verisurf 2021 Software

Verisurf Software Inc. announced its new Verisurf 2021 release.

Verisurf 2021 has new and enhanced features that increase measurement and inspection productivity, from CMM plan creation through execution, particularly for Renishaw PH20 5-axis touch-trigger, and REVO 5-axis scanning probes. Users can also look forward to additional CMM controller support, enhancements for GD&T feature control frames and ballooning, and updated Software Development Kit (SDK) for custom user interfaces, integration of robotics, and automating processes across the manufacturing enterprise.

Verisurf measurement and inspection software is dedicated to Model-Based Definition (MBD) and built on a CAD/CAM platform. This enables greater compatibility, workflow integration, and more complete end-to-end solutions customers require.

New Verisurf 2021 highlights include:

5-Axis CMM programing with support for Renishaw PH10, PH20, and REVO heads

External Productivity Utilities provide time-saving tools and shortcuts

CAD Translator V8.0 with new assembly import and management features

Thickness feature for Dynamic Surface Point improves CMM Plan creation

Digital Product Definition compliance – Boeing, PTB, NIST

Custom Clearance CMM Path added to Generate Path tool

Power Surface option to Orient Starter Plane for surface fit

Power Surface is enhanced to support point clouds or meshes in addition to existing wireframe capabilities

Power Surface tools to use starter plane fit options such as least squares, minimum zone, or graphics view, plus an option to use point vectors to help for a better surface fit

SolidWorks Inspection First Article & Balloon Dwg Reports using Verisurf - SOLIDWORKS Inspection added to Report Database output

GD&T Feature Control Frames added to CMM Plans and Measured Features staying current with ASME and ISO protocols

Verisurf Device Interface (VDI) upgrades for new laser trackers and CMMs

Software Development Kit (SDK) Enhancements for communication with other cooperative devices

Feature Align improvements use nominals from the Plan to automatically create a WCS, improving workflow and flexibility

Best Fit feature includes multiple enhancements for automated CMMs and user-prompted inspection routines for manual and portable CMMs

CAD is at the foundation of Verisurf software and 2021 includes new features and improved user experience for model-based inspection productivity.

Verisurf Software Inc.

http://veri.surf/2021

Nikon Metrology NEXIV Series CNC Video Measuring System

Two new models have now been added to Nikon Metrology's latest NEXIV S-range of CNC video measuring systems suitable for in-line, automated dimensional measurement tasks.

The CNC video measurement system NEXIV can automatically measure the dimensions of component features using Nikon's optical and image processing technology. By analyzing the captured image of a component, detecting feature edges at high speed, both accurately and with repeatably, it is possible to quickly measure components with simple and complex features.

With the growth in demand for measuring smaller components with higher performance, and the huge increase in the number of electronic components installed in automobiles, there is a greater need for video measuring systems to measure more components at higher speeds in automated production lines.

The NEXIV VMZ-S series has realized this increased throughput by maintaining and enhancing the performance of the previous model, the NEXIV VMZ-R series. In November 2020, Nikon released the first in the line-up of new VMZ-S systems, the VMZ-S3020, which is part of the fourth generation of the NEXIV series. The VMZ-S4540 and VMZ-S6555 now join and expand this line-up and are perfect solutions for medium and large components or for loading multiple components.

Now that the full line-up of NEXIV VMZ-S series is available it is possible to select the most suitable machine according to a customer’s applications and installation environment. In addition, by utilizing the Remote Control SDK software (optional), multiple NEXIV systems can be fully integrated into the production line and systems can be accessed and operated remotely.

The NEXIV systems obtain the highest level of measurement accuracy using an exceptional stage featuring high-precision linear encoders. The NEXIV VMZ-S series is capable of capturing and processing images at higher speeds than its predecessor the NEXIV VMZ-R series. This has made it possible to reduce the component measurement cycle times without compromise in accuracy or reproducibility.

Nikon has designed an optimized optical system to deliver high quality images and accurate measurement data from within the field of view. With a movable LED ring light and an 8-segment LED illumination, it is possible to resolve and capture the edges of complex shapes. In addition, a high-speed laser, scanning at 1000 points/sec can acquire the cross-sectional profile across a surface and evaluate the relative heights. This meets the surface quality and feature measurement needs across a wide variety of samples.

The measurement software environment of AutoMeasure realizes high accuracy, high speed, and delivers simple measurement functions. A large library of valuable tools is available to use in a user-friendly GUI. For simple components, a support function will automate part of the measurement programming process.

The joystick unit used to move the stage and measurement head has also been redesigned for even greater ease of use for the operator.

Up to 10 NEXIV systems can be controlled remotely by using Remote Control SDK (optional), enabling centralized management and distribution of measurement programs and results all from one place. By controlling NEXIV and measurement programs from a remote location away from the production line, such as a control room or office, manpower can be streamlined, and productivity improved.

With the increasing demand for full automation of the production line especially within the semiconductor industry, the need for automated measurement solution is also increasing. By combining the NEXIV VMZ-S series with in-house or 3rd party automatic wafer loader systems, the process of loading wafers and feature measurement can be efficiently automated.

Nikon Metrology, Inc.

www.nikonmetrology.com

ABB Next Generation Cobots

ABB is expanding its collaborative robot (cobot) portfolio with the new GoFa™ and SWIFTI™ cobot families, offering higher payloads and speeds, to complement YuMi® and Single Arm YuMi in ABB’s cobot line-up. These stronger, faster and more capable cobots will accelerate the company’s expansion in high-growth segments including electronics, healthcare, consumer goods, logistics and food and beverage, among others, meeting the growing demand for automation across multiple industries.

GoFa and SWIFTI are intuitively designed so customers need not rely on in-house programming specialists. This will unlock industries that have low levels of automation, with customers able to operate their cobot within minutes of installation, straight out of the box, with no specialized training.

ABB’s cobot portfolio expansion is engineered to help existing and new robot users accelerate automation amid four key megatrends including individualized consumers, labor shortages, digitalization and uncertainty that are transforming business and driving automation into new sectors of the economy. The expansion follows the Business Area’s focus on high-growth segments through portfolio innovation, helping to drive profitable growth.

GoFa and SWIFTI are engineered to help businesses automate processes to assist workers with tasks including material handling, machine tending, component assembly and packaging in manufacturing, medical laboratories, logistics hubs and warehouses, workshops, and small production facilities.

Users comfortable with operating a tablet or smartphone will be able to program and re-program the new cobots with ease, using ABB’s fast set-up tools. Customers will also benefit from ABB’s global industry and application expertise, which has been developed from installing more than 500,000 robot solutions since 1974 and supported by ABB’s network of over 1,000 global partners.

The new GoFa and SWIFTI cobot families build on the success of ABB’s YuMi family, which has been helping businesses safely automate key tasks since YuMi was launched in 2015. Today, ABB’s YuMi cobots are working alongside people in factories, workshops and laboratories all over the world, performing tasks from screwdriving and assembling electronics and electrical components, to making valves and USB sticks, and testing COVID samples in laboratories.

Every ABB cobot installation includes a start-up package that provides ABB Ability™ condition monitoring & diagnostics as well as a support hotline free for the first six months to access ABB’s expert technical assistance, which is offering support across all industry segments.

FLIR Systems Radiometric Version of Boson Thermal Imaging Camera Module

The Boson® camera core represents the best in FLIR high-performance uncooled thermal imaging technology within a small, lightweight, and low-power package, and now FLIR partners and customers will have the option to purchase radiometric versions that can capture the temperature data of every pixel in the scene.

The new Boson radiometric camera core comes in two versions, 640 x 512 or 320 x 256 resolutions with multiple lens configurations and the ability to capture temperature data for quantitative assessment. The camera core is meant for use in systems across a variety of applications including firefighting, surveillance, security, unmanned systems, industrial inspection, and fixed-asset monitoring.

Featuring radiometric accuracy provides ±5 °C (±8 °F) or ±5% temperature measurement accuracy, the Boson Radiometric cameras include a Spot Meter Accuracy software feature that provides an assessment of how accurate a given temperature measurement appears in the scene. Available as telemetry data accessed through the Boson SDK or the Boson graphical user interface (GUI), this feature provides guidance across five confidence grades offering in-the-moment assessment to help improve temperature measurement confidence.

In addition, the Spot Meter Accuracy software feature gives operators the ability to account for dynamic ambient temperatures, along with the ability to configure measurements prior to operation, including adjusting emissivity and thermal gain settings. These functions are crucial for outdoor environments and the swift movements of unmanned aerial drones and automated ground vehicles. The software also offers inspection and assessment features, including spot meters and windows that pinpoint temperature measurement in the scene that the camera is focused on, and atmospheric correction capabilities during post-processing analysis.

The Boson thermal imaging cores utilize a high sensitivity 12-micron pixel pitch detector that provides high-resolution thermal imaging in a small, low power, lightweight, and turnkey package.

All Boson cores feature FLIR infrared video processing architecture, noise reduction filters, and local-area contrast. The imaging processing capabilities accommodate industry-standard communication interfaces, including visible CMOS and USB.

Flir Systems

https://www.flir.com/products/boson/

Lucid 5.0 MP Phoenix, Triton Polarization Cameras

Lucid Vision Labs Inc., announced that its new 5.0 MP Phoenix™ and Triton™ polarization cameras featuring Sony’s latest Polarsens™ IMX264MZR/MYR CMOS sensors have entered series production.

Sony's next generation of polarization sensors offer high quality polarized imaging at a significantly lower price point. Lucid’s latest Triton and Phoenix 5.0 MP polarized cameras feature the new IMX264MYR (color) and IMX264MZR (mono) polarized CMOS sensors. They use four different directional on-chip polarizing filters (0°, 90°, 45°, and 135°) on every 2 by 2 array of pixels, allowing highly accurate alignment with the pixel array. Furthermore, Polarsens technology has a global shutter read-out, high frame rates, ROI control and trigger modes to further improve the image capture performance.

All Lucid cameras conform to the GigE Vision 2.0 and GenICam3 standards and are supported by Lucid’s own Arena software development kit. The Arena SDK provides customers with easy access to the latest industry standards and software technologies. In addition, the software offers enhanced polarization functionality such as on-camera polarization processing and software visualization tools to accelerate the development for polarized imaging applications. The SDK supports Windows, Linux 64bit and Linux ARM operating systems, and C, C++, C# and Python programming languages. The new polarization cameras Phoenix (PHX050S1-P/Q) and Triton (TRI050S1-P/Q) are now in series production and available for order.

Lucid Vision Labs Inc.

www.thinklucid.com

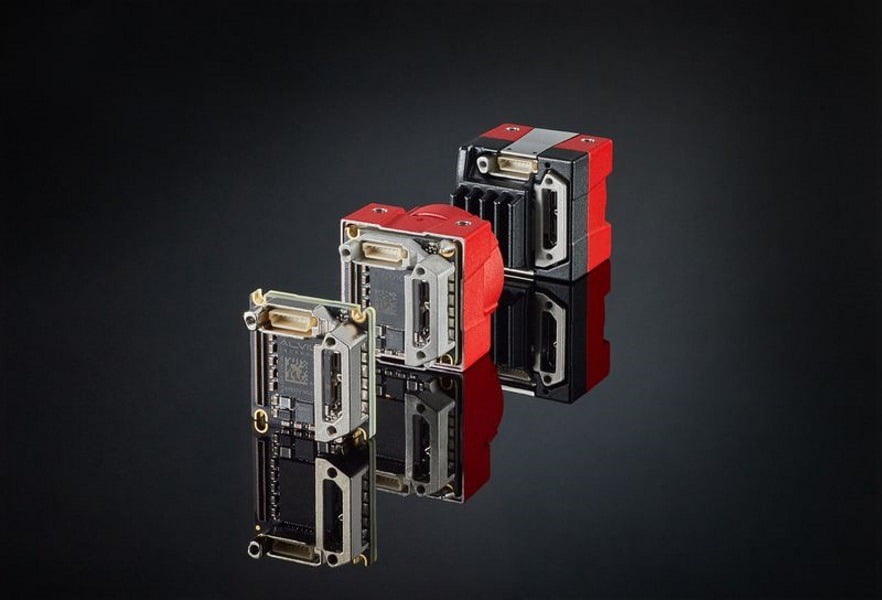

Allied Vision Alvium 1800 USB Cameras

With Alvium 1800 U-2460, Alvium 1800 U-2040, and Alvium 1800 U-1620 Allied Vision adds three high-performance Sony fourth generation IMX back-illuminated CMOS sensors with Pregius S global shutter technology to its Alvium Camera Series. The Alvium 1800 USB cameras combine a compact sugar cube format with large high-resolution sensors and thus offer the highest possible resolution within such a small housing.

Available with both an USB3 and a MIPI CSI-2 interface the Alvium 1800 C/U-2460 delivers images with a resolution of 24.6 Megapixel thanks to Sony’s high-resolution IMX540 sensor. The Alvium 1800 U-2040 is the first model of the Alvium USB3 camera series with a square sensor. It combines a square sensor format with a C-mount in a sugar cube housing and is thus an ideal choice for microscopy applications. It features the 20.4 MP Sony IMX541 sensor enabling a frame rate of 17 fps. Alvium U-1620 is equipped with the IMX542 sensor with a 16:9 wide screen format offering almost twice the resolution of the comparable 2nd generation Sony IMX sensor IMX265 with the same size making it especially attractive for ITS applications demanding high-resolution images.

The three sensors feature an improved back side illuminated pixel architecture that can capture light more effectively, which leads to improved quantum efficiency (QE) compared to 2nd and 3rd generation IMX sensors. High quantum efficiency, lower readout noise and higher spatial resolution result in excellent image quality with high dynamic range. Because of the decreased pixel size of 2.74µm higher pixel densities (i.e. resolutions) for the same optical format are possible.

In addition to the three cameras with Sony 4th generation IMX sensors Allied Vision adds the NIR-enhanced Alvium 1800 U-501c NIR as a color camera to the existing monochrome version. It is equipped with OnSemi’s rolling shutter sensor AR0522 that has a particularly good performance in the NIR region of the spectrum (i.e. above 750nm wavelength). It therefore performs very well in low light scenarios (e.g. at dusk or dawn).

All cameras will be available with different housing variants (closed housing, open housing, bare board) as well as different lens mount options. The USB interface can be located either on the camera back side or left side (as seen from the sensor).

Allied Vision

www.alliedvision.com

JAI Spark Series SP-25000-CXP4A Camera

JAI introduced the Spark Series SP-25000-CXP4A, a new 26-megapixel high performance industrial area scan camera capable of providing full resolution images at 150 frames per second. The new camera is available in monochrome and Bayer color versions, which are equipped with four-channel CoaXPress v2.0 interfaces capable of providing data, transfer at the fastest rate currently supported by the CoaXPress standard – 12.5 Gbps per lane (50 Gbps total).

With its combination of high resolution, high frame rate, and C-mount optical format, the SP-25000-CXP4 is designed to provide an upgrade path for customers using older 12-megapixel or 16-megapixel cameras in applications like automated optical inspection (AOI) or solder paste inspection (SPI) on printed circuit boards, as well as high-speed medical slide scanning, aerial imaging, and other applications where resolution and high frame rates are critical factors. By delivering higher resolution images while maintaining frame rates, which are comparable to the fastest 16-megapixel cameras, these new cameras enable builders of these types of inspection systems to achieve detailed inspections over large areas with fewer cameras or fewer image captures, providing better throughput at lower system costs.

The SP-25000-CXP4 models incorporate the Gpixel GMAX0505 CMOS Global Shutter imager with a resolution of 5120 x 5120 pixels. The 2.5-micron pixel size results in a 1.1-inch optical format supporting the use of C-mount lenses to provide additional system savings in both cost and size.

Standard camera features include both single ROI and multi-ROI modes, which can increase frame rates or reduce data volumes for certain applications. Other notable features include horizontal/vertical image flipping, a 128-index Sequencer function, an auto-level control (ALC) function that intelligently integrates auto-gain and auto-shutter actions, and a lens control capability for transferring commands to lenses connected via Birger Mounts.

The CoaXPress v2.0 interface lets users take advantage of link sharing capabilities for high-speed parallel processing of images that are split across multiple PCs or the same image can be duplicated to multiple PCs with different sub-applications running on each.

Overall size of the cameras is a compact 62 x 62 x 60.5 mm including lens mount and cooling fins.

JAI

Mitutoyo America EJ Counters, LG100 Series Linear Gages

Mitutoyo America Corporation is pleased to announce the release of new EJ Counters and LG100 Series Linear Gages to its expansive sensor lineup of metrology products.

EJ Counters and LG100 Series Linear Gages are designed to be used inline or in measurement cells, enabling real-time measurement and data management in any type of work environment. Features of the EJ Counters and LG100 Series Linear Gages include:

Environmental Resistance: Sliding durability of more than 50 million cycles*, with protection level of IP67G. A highly oil-resistant material is used in the rubber cap and cable sheath, so it can be used even in harsh environments (*10 mm range models)

Reference Point Detection: Reference point signal output functions are featured throughout this series. When incorporating into a device the master setting value is easy to set and is retained after shutdown.

Combines compact size and ease-of-use: High-speed and compact, delivering production site visualization, improved productivity, and information feedback. Up to 8 compact EJ Counters can be linked providing the capacity to connect to 16 gages. On a DIN rail, each unit can be connected directly without using cables to maximize space. All linked units and gages can be driven by a single power source.

CC-Link connection, USB connection: Data can be output through an industrial interface (CC-Link) by linking a compact EJ Counter with an interface unit. Constant data monitoring and positional management are performed. A USB interface is also provided for easy connection with a computer.

Calculation Function: Enables sum difference operations between two gages connected to the same counter. Additionally, functions such as tolerance judgment and peak hold are included.

Mitutoyo America

www.mitutoyo.com

Olympus WeldSight Software

Olympus’ release of its WeldSight™ companion PC software for the OmniScan™ X3 phased array flaw detector provides inspectors with powerful tools to push the boundaries of flaw characterization and sizing. Compatible with conventional UT, phased array (PA) and time-of-flight diffraction (TOFD) acquired data, the software enables inspectors to perform thorough post-inspection analyses that comply with strict validation requirements of international standards.

Experienced PAUT inspectors can perform advanced validation of indications using the software’s weld analysis tools. Inspectors will save time with powerful screening capabilities that cut down the need for cross validation. They can characterize and orient flaws faster, even in complex geometries, by merging distinct scan files and using multiple view options to examine the weld in detail from all sides.

WeldSight software is also equipped with a geometry-based weld gate that generates a C-scan using data from inside the weld only. This as well as other exclusive post-inspection functionalities give inspectors the ability to fully exploit and fine-tune their OmniScan X3 acquired data to accurately pinpoint the areas of interest and precisely size and characterize flaws.

To enable inspectors to comply with the requirements of a specific procedure, application or code, the software’s scan data displays can be dragged and dropped to create a customized layout. Acquisition data integrity can also be validated and improved with the missing data statistics, editable gates, and encoder recalibration tools.

Olympus

www.Olympus-IMS.com

Branson GMX-20MA Ultrasonic Metal Spot Welder

Emerson announces its new Branson™ GMX-20MA ultrasonic metal spot welder, an advanced spot welder that bonds nonferrous metals, including bus bars, foils, switches, and wire terminations in automotive electrical systems, electric vehicles, batteries and battery packs, power storage systems and related applications.

The GMX-20MA metal spot welder is built around an all-new, rigid pneumatic actuator with dual linear bearings and a digital load cell to ensure smoother vertical motion and more precise downforce control for maximum weld quality and repeatability. Actuator travel and tool positioning relative to the welded parts are tracked and measured using a linear encoder. Once tooling/part contact is made, a digital load cell measures and maintains a precise level of actuator downforce on the parts, ensuring that weld energy is accurately delivered and consistent weld quality is assured from one weld to the next.

The programmable controls of the GMX-20MA enable operators to manage the welding process in multiple modes: time, energy, peak power and distance. These versatile weld modes, together with the welder’s advanced digital controls, ensure the added precision required to maintain tight weld process control despite occasional variations in part surface quality or cleanliness. In most cases, the high-frequency, lateral scrubbing action of the ultrasonic tooling eliminates the need to pre-clean parts.

The GMX-20MA is programmed through a user-friendly, touchscreen human-machine interface (HMI) housed in the unit’s Branson 2000Xd power supply/controller. The touchscreen makes creating, editing and recalling stored production recipes fast and simple. The touchscreen HMI also opens up access to the unit’s multiple welding control modes and enables users to configure production- and quality-monitoring solutions.

Throughout the production process, the GMX-20MA power supply/controller continuously compiles and stores extensive weld quality and traceability data. It also conducts amplitude stepping for optimization of weld strength and appearance, with built-in cycle counters to track production. Total cycle time can be displayed in the weld results screen, which allows user to monitor key operating parameters. The unit’s Visual Quality Screen (VQS) monitors and displays real-time quality data so that even small variations can be identified and corrected immediately.

Emerson

https://www.emerson.com/en-us/news/automation/21-02-ultrasonic-spot-welder

OptVol Leak Testing Technology

Manchester-based engineering company VES announced the launch of its OptVol TechnologyTM, a recent innovation in helium leak testing. A helium leak testing system that incorporates OptVol Technology benefits from a small footprint, easily interchangeable tooling for different product variants and a lightweight design for ease of movement between production lines, as production demands change.

The company have completed a formal analysis comparing OptVol Technology with traditional hard vacuum tracer gas systems and have recorded significant improvements across all data points.

74% reduction in footprint

85% reduction in weight

10% improvement in cycle times

92% reduction in power consumption

44% reduction in helium consumption

Scroll Down

Scroll Down