NDT as9102

Inspection

AEROSPACE

By Mari Luke

Remote

Visual

Inspection

How to Simplify your

First Article Inspection Process

AS9102

What is First Article Inspection?

First Article Inspection (FAI) is the process of planning, manufacturing, and verifying a production process. In the aerospace and defense industries in the U.S., most companies conduct AS9102 First Article Inspections. Other industries also use inspections to validate their manufacturing processes, but the format and when in the production process they are completed vary from company to company.

A First Article Inspection Report (FAIR) is the document that certifies that each sample was produced and inspected according to the customer’s specifications.

How to Create an AS9102 First Article Inspection Report

Step 1: Pre-plan your FAI

Before beginning, gather the documentation needed for your First Article Inspection:

● Engineering drawings

● Digital product definition data sets

● Bill of materials/raw materials list

● Specifications

● Manufacturing planning/routing/traveler/work order

● Source/supplier information

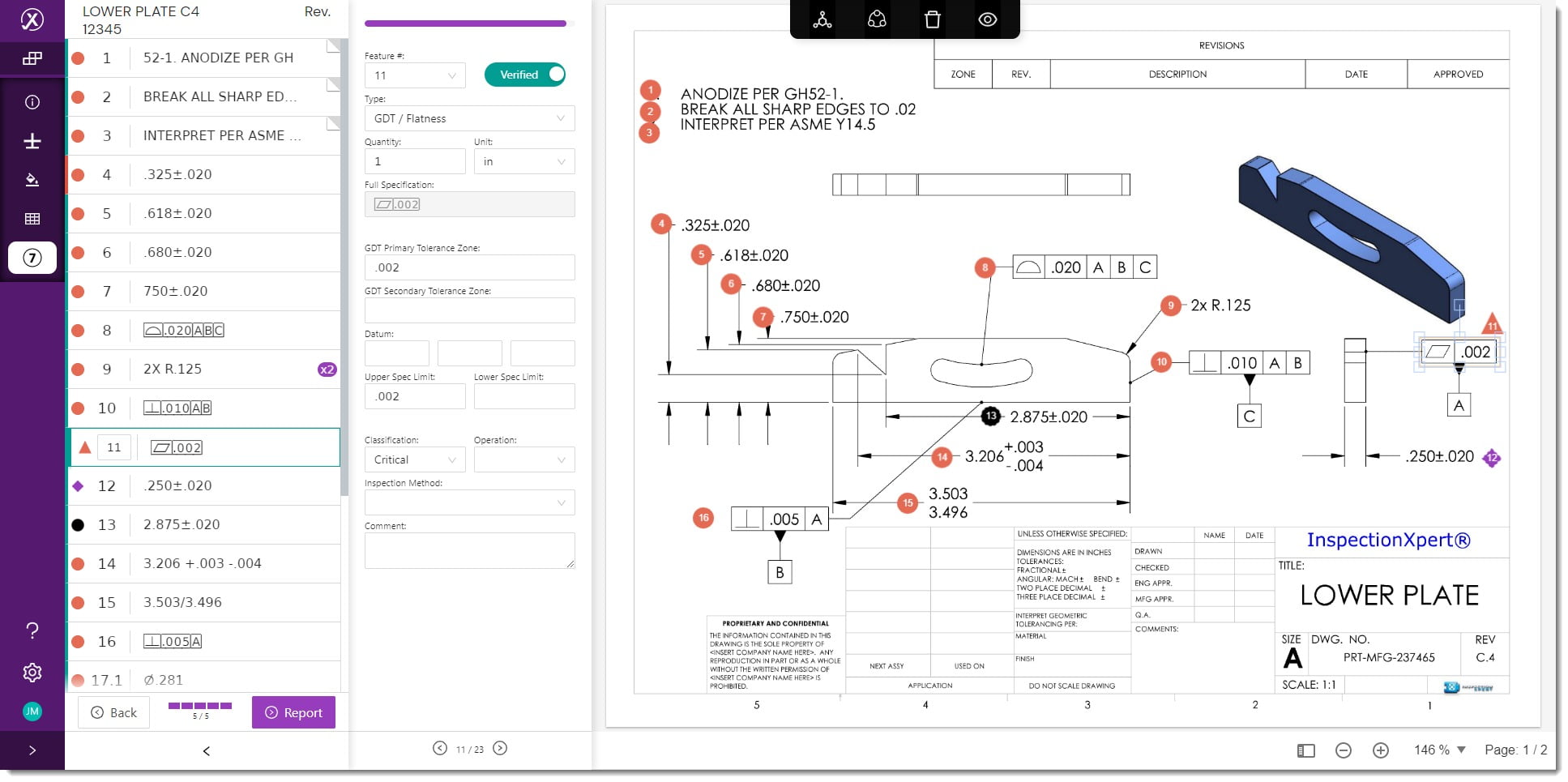

Ballooning a part drawing and verifying feature information in InspectionXpert

Step 2: Create an inspection plan

Balloon part drawing: identify the requirement to be inspected with a balloon number.

● Fill out the AS9102 Form 1 (Part Number Accountability) and Form 2 (Product Accountability) with information from the Bill of Materials and Specifications List

Document reference location of the balloon

Requirements including units of measure, variable requirements with tolerances

Classifications (Critical, Major, Key)

● Fill out the AS9102 Form 3 (Characteristic Accountability) with dimensions, tolerances, notes, and inspection tools to reduce work at the end

Type of tool and the serial number of the tool are often required

Step 3: Manufacture the part

Build the product and ensure you are documenting processing and inspection results for the requirements during the manufacturing process.

● Note: First articles are not necessarily the first part produced, but are from the first production run.

Step 4: Collect data

Inspect the part according to the inspection plan created in step 2.

● Keep track of calibrated, certified inspection tools so that they are traceable back to the person certified to use the tool to perform the inspections/manufacture accurately.

Step 5: Finish reporting

Enter measurement result data into AS9102 Form 3.

● Measured result(s)

● Serial numbers of the tools used to measure the part

● Non-conformance information, if any

● Certificate of Conformance (C of C)

● Functional Test Report

Accessible Anywhere, Anytime

With a cloud based software, your part database is available anywhere, anytime. You don’t have to worry about having the right version of the drawing, or being at the only computer with the right software installed to create a new report.

At a high-mix, low-volume shop with new parts all the time, the need for efficient reporting is critical. Ensuring everyone has the latest version of the drawing and dimensions is necessary for reducing mistakes. Doug Murillo, quality engineer at GrayTech International, a precision machining company in Cleveland, says, “By getting rid of paper drawings and having part information in the cloud, we don’t have to worry about someone finding and using an outdated version.”

Customize Reports for You and Your Customers

With software, you can extract information from your part drawing once and export it to as many different reports as you need. After capturing feature information, you can use the data to create shop floor check sheets, FAIRs, and any other reports or documents required. Manually you’d have to go through a lot of copy/paste and reformatting, but with software, you can set up the reports once and use them for any of your inspections.

As parts continue to get more complex, quality departments are evolving their processes to keep up. The challenge is doing more with the same resources. By using InspectionXpert to simplify their inspection reporting process, Murillo says they’ve been able to do just that. “What used to take four to five hours now takes less than two hours, and we can get full FAIRs done in less than half a day.”

Definitions: Three Forms of an AS9102 FAIR

There are three forms in AS9102 FAIRs: Part Number Accountability, Product Accountability, and Characteristic Accountability.

AS9102 Form 1: Part Number Accountability

Form 1 identifies the part for the FAI and associated sub-assemblies or detailed parts.

AS9102 Form 2: Product Accountability

All material and process specifications, as well as any special processes and functional testing defined as design requirements, must be accounted for on Form 2.

AS9102 Form 3: Characteristic Accountability

All product characteristics such as dimensions, tolerances, notes, etc. must be accounted for on Form 3. An inspection drawing or model is required whereby all inspection characteristics (defined using CAD annotations) are clearly identified with uniquely numbered inspection balloons. The numbers on the inspection balloons must correspond to the characteristic numbers on Form 3.

Image Source: Getty Images and InspectionXpert

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Mari Luke is the director of marketing at InspectionXpert. For more information, visit inspectionxpert.com.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.