=Faro® Technologies, Inc. announced the acquisition of HoloBuilder, Inc.

HoloBuilder brings to Faro its photogrammetry-based 3D platform, which delivers hardware agnostic image capture, registration and viewing to the fast-growing Digital Twin market. With an initial focus on Construction Management, HoloBuilder’s technology platform provides general contractors a solution to efficiently capture and virtually manage construction progress using off-the-shelf 360° cameras.

HoloBuilder’s SaaS platform will add fast and easy reality-capture photo documentation and added remote access capability to Faro’s 3D point cloud-based laser scanning to create the industry’s first end-to-end Digital Twin solution—all without leaving the Faro ecosystem. The combined solution will provide comprehensive scanning and image management capabilities for the Digital Twin market including robotic assembly 3D simulation, construction management, facilities operations and management, and incident pre-planning.

“The high-value that digitalization brings to the AEC and Operations & Maintenance (O&M) industries creates significant market opportunity for Faro,” stated Michael Burger, Faro president and CEO. “The addition of HoloBuilder to our offering accelerates the reality of a true end-to-end Digital Twin solution and advances our strategic objective of increased recurring revenue through market share gains in this large and growing segment.”

“HoloBuilder and Faro together furthers our vision of digitizing the physical world to enable process automation and workflow optimization,” added Mostafa Akbari-Hochberg, HoloBuilder president & founder. “The powerful combination of high accuracy laser scanning with real-time 360° photo capture and collaboration will empower both companies' customer bases with a comprehensive Digital Twin solution.”

Under terms of the agreement, HoloBuilder shareholders received a cash payment of $34 million. As of April 30, 2021, HoloBuilder had $4.0 million in annual recurring revenue with a compounded annual growth rate of nearly 75% since 2019. The transaction closed on June 4 and was funded with available cash reserves. Alantra acted as exclusive financial adviser to HoloBuilder.

For more information, visit www.faro.com or www.holobuilder.com.

Faro Expands Digital Twin Product Suite, Acquires HoloBuilder Inc.

Dean Rob Keynton of The William States Lee College of Engineering has announced that Dr. Ed Morse is the new Director of the UNC Charlotte Center for Precision Metrology (CPM). Dr. Morse is taking the place of Dr. Chris Evans, who retired as CPM Director in December 2020.

“It is my privilege to announce the appointment of Dr. Morse as the new CPM Director,” Dean Keynton said. “Dr. Morse has a long history with the center, both as a faulty researcher and for serving as the center’s Deputy Director since 2010. He is extremely well respected in his field, and has an excellent reputation with CPM industrial affiliate members, students and faculty members.”

Dr. Morse was awarded his Ph.D. from Cornell University, with his dissertation work being in the mathematical modeling of tolerancing for assembly. He joined UNC Charlotte in 1999 as an assistant professor in the Mechanical Engineering and Engineering Science Department. He was granted tenure and promoted to associate professor at UNC Charlotte in 2005, and promoted to full professor in 2011.

"I am honored to have been selected as Director for the Center for Precision Metrology,” Dr. Morse said. “This is an exciting time for the field of metrology, as advanced manufacturing processes require new measurement techniques for process control and conformance evaluation. Also, the closer interaction between computational and physical components (i.e. cyber-physical systems) allows us to apply research in machine learning to investigate how we can reliably perform inspection tasks in the presence of incomplete or uncertain data. I am looking forward to working with my colleagues to continue the growth and success that the center enjoyed under my distinguished predecessors."

Dr. Morse’s current research interests include large-scale metrology, assembly modeling and analysis, machine tool metrology, uncertainty estimation and analysis, tolerance standards and modeling, and various aspects of computational metrology.

Dr. Morse is a member of several ASME standards committees for tolerancing and metrology, and is chair of ASME's B89 committee on Dimensional Metrology, as well as B89's Division 4 for Coordinate Measuring Machines. He is also a Subject Matter Expert (SME) representing the United States in ISO Technical Committee 213 on Geometric Product Specification and Verification.

For more information, visit https://cpm.uncc.edu/.

Dr. Ed Morse is New Director of UNC Charlotte’s Center for Precision Metrology

Hexagon’s Manufacturing Intelligence division announced it will host a Smart Manufacturing Virtual Open House from June 14 – 16, 2021. The jam-packed agenda includes 20 sessions presented by 14 Hexagon speakers covering hot topics from additive manufacturing to reverse engineering to the latest in non-contact measurement. Attendees will learn how data can be harnessed for agile smart manufacturing processes leading to the ultimate form of data leverage – autonomous manufacturing, intelligent machine control, predictive maintenance and more. An interactive showroom will be open from 10 a.m. – 3 p.m. featuring the latest Hexagon technologies supported by local subject matter experts (SMEs) ready to answer user questions. While Hexagon’s offices are safely open for business, the company chose to make this online 3D immersive experience widely available based on the high level of community engagement sparked by their first virtual PC-DMIS user group series. The full agenda and registration to obtain a complimentary ticket can be found here. The press is cordially invited to attend, and should RSVP in advance by responding here.

On Monday, June 14, at 10a.m., Keith Perrin and Sachin Mathur will officially launch the event with a keynote presentation entitled Empowering Smart Manufacturing through Connecting the Virtual and Physical Worlds. Keith Perrin currently leads Hexagon’s Smart Manufacturing initiative. Sachin Mathur was recently named one of the 25 leaders transforming manufacturing by the Society of Manufacturing Engineers (SME). They will delve into the power of connecting data from all functional touchpoints and departments throughout the product lifecycle.

"Our Smart Manufacturing Virtual Open House provides a timely juncture for users and managers to rethink and refresh their approach to smart manufacturing from the comfort of their home or office,” stated Keith Perrin, Industry Director at Hexagon. “This informational event demonstrates Hexagon’s continuous support for customers already on the innovation frontlines and for those ready to pursue the continuous improvements found in a closed-loop system across design, production and inspection. We are excited to provide a virtual space for users who share our same vision and drive for smart manufacturing. This three-day event offers an unparalleled speaker line-up and educational content to help attendees spot the entry points for smart manufacturing in their factories and seize the opportunity to improve their workflow.”

From Monday through Wednesday, Hexagon’s Smart Manufacturing Open House series will cover a broad range of trending industry topics including workflow automation, smart additive manufacturing, evolving measurement standards, next-generation non-contact scanning, reverse engineering, and production optimization with prediction. Also on the agenda are application-specific sessions such as sheet metal solutions, advanced machining toolpath strategies, and virtual simulation technology for assembly. Users will also get a sneak peek of new releases of software for design and engineering, production and quality inspection. During the open house, attendees will have the chance to interact with Hexagon SMEs and discuss pressing challenges standing in the way of digital transformation.

For more information, visit www.hexagonmi.com or @HexagonMI.

Hexagon to Host Smart Manufacturing Virtual Open House

According to a new report from The Reshoring Initiative®, despite COVID, reshoring numbers were up in 2020. Reshoring and foreign direct investment (FDI) job announcements for 2020 were 160,649, bringing the total jobs announced since 2010 to over 1 million (1,057,054). Also of significant importance, reshoring exceeded FDI by nearly 100%, the first beat for reshoring since 2013. Additionally, the number of companies reporting new reshoring and FDI set a new record of 1,484 companies. The initiative asserted that reshoring will continue to be key to U.S. manufacturing and economic recovery in 2021 and beyond.

The Reshoring Initiative’s 2020 Data Report contains data on US reshoring and FDI by companies that have shifted production or sourcing from offshore to the United States. The report includes data for 2020, cumulative data from 2010 through 2020, as well as projections for 2021. The report provides data and analysis in 10 categories, ranging from the number of manufacturing jobs gained, to reasons cited for reshoring, to a breakdown of data by industry, country, region and state.

Top takeaways from the report include:

In 2020, US reshoring set a record of 109,000 jobs and outpaced FDI for the first time since 2013. COVID uncertainty has resulted in companies emphasizing operations in their home countries.

In order to make the U.S. less vulnerable, there are now national initiatives to shorten and close supply chain gaps for essential products. The following industries are most likely to benefit: PPE, medical, tech and defense. Medical equipment and PPE are the first responders of new reshoring and FDI, with cases up nearly 2000% and jobs up 400% from 2019.

President Biden is prioritizing reshoring highly but applying different methods than President Trump. The gaps in Biden’s plans need to be addressed in order to achieve his goal of returning 5 million more jobs.

There is continued growth in efforts by MEPs, EDOs and states to enable reshoring. The Reshoring Initiative is deeply involved in these efforts with its Import Substitution Program (ISP). As a measure of corporate interest, the demand for this service is more than 10 X the rate of 2019.

We anticipate 2021 reshoring + FDI job announcements to be near 200,000, up by at least 25%.

“We publish this data annually to show companies that their peers are successfully reshoring and that they should reevaluate their sourcing and siting decisions,” said Harry Moser, founder and president of the Reshoring Initiative. “With 5 million manufacturing jobs still offshore, as measured by our $900 billion/year goods trade deficit, there is potential for much more growth. We call on the administration and Congress to enact policy changes to make the United States competitive again. Our Competitiveness Toolkit is available to help quantify the impact of policy alternatives, including a stronger skilled workforce, competitive corporate tax and regulatory structures and a lower US dollar.”

To download the full report, visit https://reshorenow.org/blog/reshoring-initiative-2020-data-report/. For more information, visit www.reshorenow.org.

Reshoring Initiative Report: Reshoring Surges to Record High, Cumulative Jobs Announced Surpasses 1M

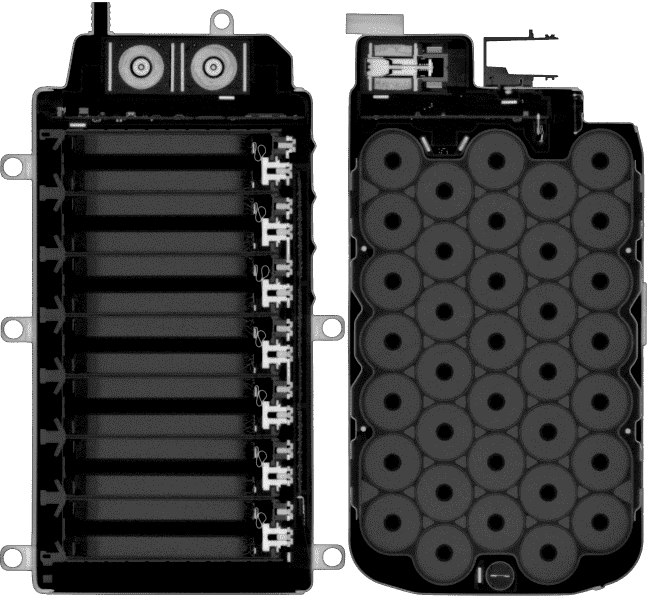

The addition of high energy X-ray scanning at its West Coast facility brings a new level of scanning capabilities to North Star Imaging (NSI). On June 9, Camaron Lemmer, global responsible Level 3 at NSI, will explain the high-energy difference. Using scans of a hybrid car battery, electric motor and gearbox, Camaron will showcase the wide range of capabilities and advancements available with the company’s high-energy systems.

For more information or to register for the event, visit https://4nsi.com/events/high-energy-ct-of-an-electric-vehicle-battery.

NSI to Host Event on High Energy CT of an Electric Vehicle Battery

Hexagon and Plex Systems announced a new strategic partnership. The global partnership will enable Hexagon’s Manufacturing Intelligence division and Plex to co-sell Plex MES to Hexagon manufacturing customers, helping them to take control of the plant floor through full visibility and connectivity and realize the promise of Industry 4.0.

“There’s no question that more connected, data-driven approaches to manufacturing are central to bringing better products to market faster and more cost-effectively with confidence.” said Paolo Guglielmini, president of the Manufacturing Intelligence division at Hexagon. “Plex brings valuable experience to our customers, and its impressive open MES solution augments our technologies offering a path to ramp up shop floor efficiency by bringing together data from siloed processes to solve manufacturing problems faster and more collaboratively.”

Hexagon and Plex share a common vision for smart manufacturing, offering manufacturers an incremental path to achieve greater automation and Industry 4.0 adoption. Using Plex’s robust Manufacturing Execution System (MES) with integrated quality control, Hexagon customers will be able to augment their workflows by streaming quality measurements, engineering data and other manufacturing information into Plex's MES creating a digital system of record in real-time. Manufacturers will benefit from enhanced visibility and control over their inventory and manufacturing processes, while gaining deeper insight, traceability and opportunities for continuous innovation by combining Plex and Hexagon's digital solutions.

“We are thrilled to partner with Hexagon, an organization that is just as dedicated to delivering smart manufacturing solutions as we are and with a global scale,” said Bill Berutti, CEO at Plex. “Smart manufacturing isn’t something that will happen years down the road … it’s real, it’s imperative and it’s happening now.”

Hexagon and Plex will partner in opportunities, initially in Europe and India, where Hexagon prospects and customers have MES needs. The combination of Hexagon and Plex for these manufacturers provides a fully digitalized solution from plant measurement and metrology to managing end-to-end production.

“Smart manufacturers are seeking continuous product and process improvements to ensure that quality is measured, enforced and managed in a closed-loop across design, production and inspection,” said Reid Paquin, research director, at IDC. “This new partnership will enable manufacturers to do just that and on a global level.”

For more information, visit www.hexagonmi.com or www.plex.com.

Hexagon, Plex Systems Announce Partnership to Deliver Smart Manufacturing Solutions

High QA announced a new integration partnership with Verisurf Software to streamline shop floor quality inspection workflows.

The integrated solution automates the measurement, inspection and reporting process providing real-time comparisons of finished parts to 3D CAD models, annotated PDFs and 2D drawings. The High QA flagship product, Inspection Manager, allows for the automatic ballooning of drawings and creation of bill of characteristics in minutes, while CAD-based Verisurf 3D measurement and inspection software provides measurement data collection and analysis, with support for virtually all CAD file formats and all new and legacy CMMs, including portable arms, trackers, scanners, and fixed CNC CMMs.

“Quality assurance is more important than ever,” said Sam Golan, founder & CEO of High QA, “This integration partnership with Verisurf further ensures a streamlined workflow for manufacturers. The more steps in the process you can automate, the less human error that is likely to occur.”

“At Verisurf our focus is on practical measurement and inspection solutions that support the manufacturing enterprise; this requires our software to be open and compatible with ever evolving metrology tools and processes,” said Ernie Husted, president and CEO of Verisurf Software, “Verisurf and High QA share in a common goal to provide customers with measurement and inspection solutions that are flexible, easy to learn, and easy to use.”

For more information visit www.HighQA.com or www.verisurf.com.

High QA, Verisurf Announce Integration Partnership

Scroll Down

Scroll Down