Lighting

Vision & Sensors

V&S

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Management

As inspection speeds continue to get faster, it is important to remember that lighting principles remain unchanged. By Lindsey Sullivan

How to Evaluate Machine Vision Lighting for High-Speed Inspections

H2 Deck Info By Paragraph Style Bold

Headline

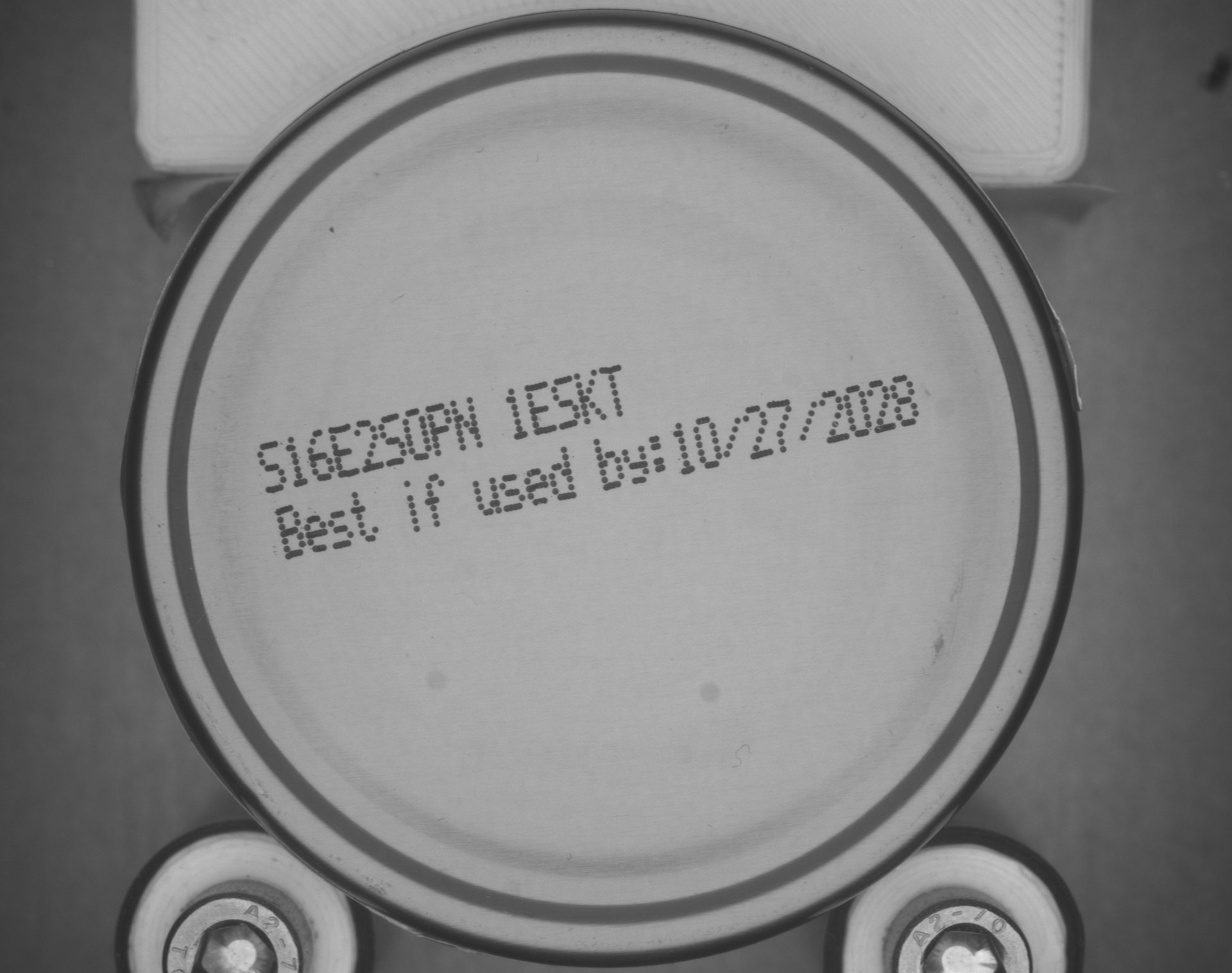

Getting enough light for a high-speed application is not as simple as confirming the lux at a given working distance. Because whether a light is bright enough is more about how much light is reflecting off a sample, not how much light hits it. Are we capturing direct or scattered light? Is the sample going to absorb a lot of light?

Even if the light has a high intensity, the inspection target will still be undetectable if the sample does not reflect enough light to the camera. This challenge becomes even harder in high-speed applications, where lights must be significantly brighter to compensate for short exposure and avoid blur.

There is a common misconception that if a light has enough lux at the distance that it will be installed from the sample, the image will be bright enough. In reality, the way light interacts with a given workpiece means there can be a lot less light actually reaching the camera, and the inspection target may be too difficult to detect as a result. Source: CCS America

The current demands of high-speed applications go beyond what generic lighting is capable of. In recent years, manufacturers have focused on developing lighting solutions that can strobe at the highest intensity possible, for the shortest shutter speed possible. But regardless of whether exposure time is 20 ms or 20 µs, the machine vision system’s accuracy still depends on following the principles of machine vision lighting.

Challenges of high-speed applications

Speeding up operations to increase throughput risks losing accuracy in a vision system if it is not designed to handle those demands.

One of the most significant consequences of high-speed applications is that overdriving lights for short pulses generates heat. Without proper thermal design, lights can degrade more quickly. High-power strobing can also cause shifts in color or intensity over time or between pulses. This can affect color inspections where consistent wavelength illumination is critical. Lights designed specifically with dedicated strobing for high-speed applications focus on getting the highest intensity possible while sufficiently dissipating heat.

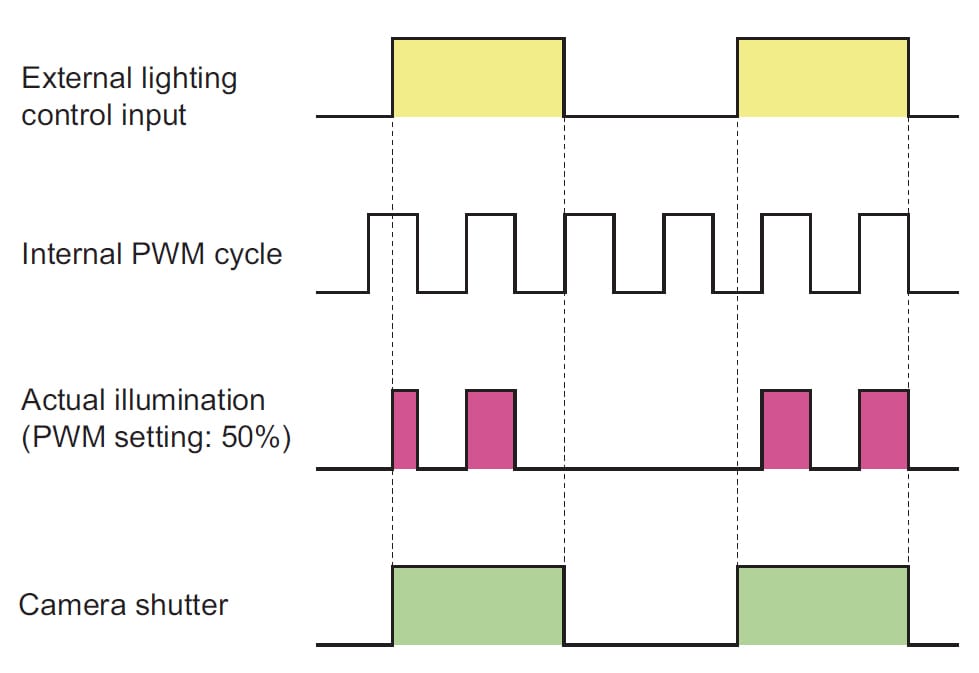

The lighting itself is not the only consideration. With line speeds so fast, it is important to be able to turn the light on and off with the camera exposure, and there is marginal room for error. If the light cannot receive a trigger, turn on, flash, and turn off all within the camera’s exposure time, the image will flicker and have inconsistent intensity. Any jitter in the triggering of light pulses relative to the camera exposure can blur or misalign images. Lighting control needs to be nearly perfect for consistent and precise results.

Lighting control can precisely time light flashes down to the microsecond-level, so that the maximum amount of light reaches the camera within every shutter. Source: CCS America

With lights getting brighter and lighting control improving, machine vision inspections can be performed much faster compared to 20 years ago.

The difference between high-speed flood lighting vs. precision lighting applications

Regardless of whether the sample is stationary or moving, lighting is about creating contrast for the camera so that software can analyze the image repeatably and reliably. Whether to use flood lighting or precision lighting depends on what is required to create contrast.

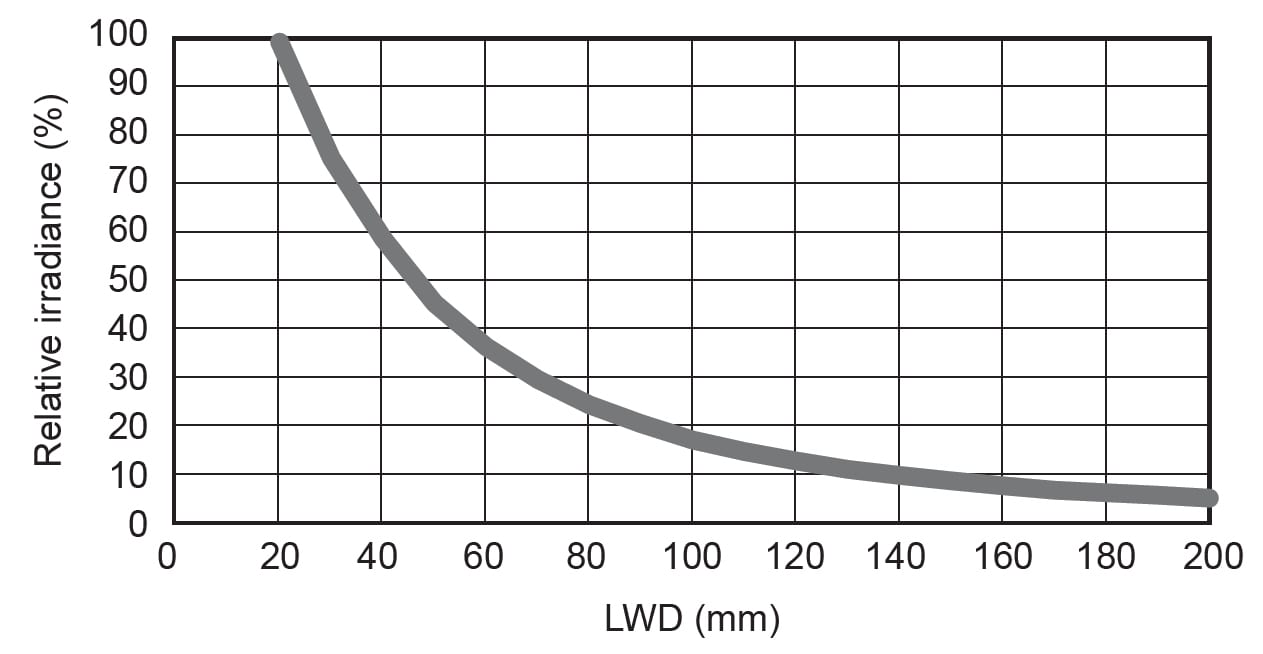

In flood lighting applications, the contrast is there even without lighting, such as a dark barcode on a light background. There is no specific direction or LWD required to see the target information, and the main purpose of lighting is to evenly illuminate the entire field of view.

Barcodes, such as those in logistics applications, already have high contrast. Dedicated strobe flood lighting ensures the image is bright and uniform for code reading, even at long working distances. Source: Effilux

A dedicated strobe flood bar light can provide uniform illumination, so ambient light or other factors do not affect the image day to day. The most common application of high-speed flood lighting is logistics, where thousands of packages need to be scanned every day. Flood lights also provide the intensity needed for high-speed applications that require installing lights at longer working distances.

Inspections that use precision lighting have a specific detail that needs to be seen that has little to no contrast on its own. Engineers must factor in what wavelength, direction, angle, size, and optical accessories will do the most to enhance uniformity for the highest possible contrast, or else the system will not be accurate enough to be reliably deployed.

Sometimes, flooding the FOV with a lot of light makes it harder to see the target information. A lighting solution with a specific lighting geometry, working distance, etc. will clearly highlight the defect and emit enough light, so the image is bright with no blur. Source: CCS America

Since higher intensity lighting may create more harsh specular reflections, especially on curved or shiny parts, precision lighting solutions become even more crucial in high-speed applications. High-speed precision lighting must provide different types of lighting geometries in addition to strobing capabilities, so that there is as little noise as possible interfering when capturing the defect.

How to determine the lighting intensity needed for a high-speed application

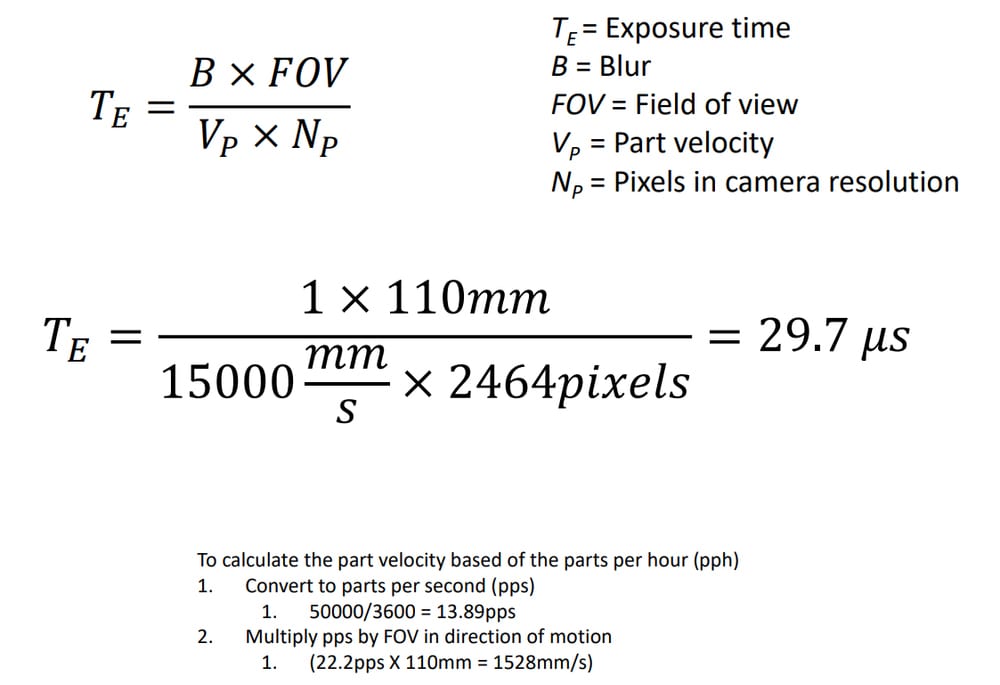

The best indicator of an application’s required intensity is the exposure time. To calculate the exposure time for an application, you need to know blur (B), field of view (FOV), part velocity (VP), and pixels in camera resolution (NP).

This formula is used to calculate exposure time for an application and can help engineers determine if a standard light on overdrive or a dedicated strobe light is the likely solution. Part velocity can be calculated using parts-per-hour (pph) if that is the information the customer provides. Source: CCS America

Generally, if the exposure time is:

- >500µs: standard intensity is usually sufficient

- 100µs - 500µs: application dependent

- <100µs: dedicated strobe required

Testing high-speed applications is about determining how much brighter the light needs to be compared to standard intensity. It might sound counterintuitive, but the most effective way to test a high-speed application is to initially treat it like it is not. When setting up the testing station, start with standard lights and a slower shutter speed. This is because there are more lighting options if the application can be solved with standard lights on overdrive compared to strobe-only lights. It is also easier to start with standard lights because you can test all lights in continuous mode. Otherwise, it will take extra time to set the current rating and strobe time for each light being tested.

Once you have determined the optimal lighting solution, you can then test what type of intensity control is required to properly illuminate the high-speed image: overdriving the light or using a dedicated strobe overdrive light.

Here is a recommended process for testing intensity:

- Set the camera to the required exposure time.

- Overdrive the standard light at its maximum intensity (with respect to the duty cycle and maximum intensity rating).

- Set the strobe time of the light to 85-90% shorter than the exposure time. This ensures 100% of the flash is captured within the exposure time.

- If the image is not bright enough, switch to a dedicated strobe light that is as close to the chosen light form factor and size as possible and set it up in the same way as Step 3.

- Confirm the initial solution works with the new light and intensity control method and adjust as needed.

If a dedicated strobe light is unavailable for testing, you can use the difference between ideal and target exposure time to approximate how much brighter the standard intensity would need to be. Set the exposure time on the camera to whatever it needs to be to reliably solve the application. How far away that is from the target exposure time provides a good idea of how much more light is required.

For example, if the target exposure time is 80µs, but the exposure time for a reliable image at standard intensity is 220µs, the light needs to be around 2.75X brighter than the standard intensity. You can then ask a lighting manufacturer if the light will be 3X brighter or if it can be overdriven at 300%.

In most cases, the intensity will be bright enough with a dedicated strobe light. If brightness is still insufficient, consider slowing the inspection speed or consulting a lighting manufacturer about a custom strobe light to meet the application’s intensity requirements. If you do not have the lighting or controllers needed to test high-speed applications, most lighting manufacturers can either test your sample in their lab or loan you their lights to test in your facility.

As inspection speeds continue to get faster, it is important to remember that lighting principles remain unchanged. Instead of relying solely on illuminance measurements, testing that a light not only reflects enough light to the camera but also gets a uniform image of the target information can save engineers from discovering they have the wrong lighting solution after the vision system is already assembled.