H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Test & INspection

Automated weld inspection can pinpoint the exact size and position of each defect and classify them. By Wayne Pugh

Produce Precise, Reliable, & Repeatable Weld Seams with Automated Vision Inspection

Test & INspection

H2 Deck Info By Paragraph Style Bold

Headline

Manufacturers face a number of production challenges. Among the most vital is maintaining a high level of product quality, supported by consistent production throughput that ensures profitability. A key function in this process is assembly, especially as the demand for more automated sensing and control devices, connectivity, infotainment, and electric vehicle components continue to push the need for more complex assembly requirements.

The need to manufacture more complex assemblies poses challenges for process engineers, particularly as component manufacturers are increasingly mandated by strict requirements to document quality assurance of their manufactured products along each step of production. Short development cycles, safety issues, innovative manufacturing and assembly processes, and new production lines mean constant challenges. This significantly raises the need for more efficient manufacturing processes and quality inspection.

Evolution of Automated Weld-Seam Inspection

Manual inspection of welds in assembly is prone to errors and costly to perform.

Production efficiency can be increased considerably when the inspection of weld seams is fully automated. Automated weld seam inspection has been successfully used since the mid-1980s, particularly in the international automotive and automotive supply industries, including all Tier-1 suppliers and integrators.

The continual evolution of automated inspection technology, combined with advances in robotic assembly and computing capability, have enabled the latest generation of inspection systems to perform with extremely high reliability. Every weld seam is automatically inspected and documented after each manufacturing step to minimize serial defect trends and ensure product quality traceability.

Integrated Inline Inspection

The latest evolution of automated weld-seam inspection technology consists of an inspection cell with a sensor that is installed directly in the welding station at various locations. Because the inspection takes place in the welding line, it is easy to quickly intervene should a component require rework. As a result, defects are quickly and consistently identified, processes are optimized, and down time, reworking, and waste are avoided.

Automated weld seam inspection technology does not require a dedicated station or even a dedicated robot. The vision inspection system can be retrofitted to existing lines, regardless of the welding solution used. Supporting the inspection cell-sensor is high-performance computer processing capability equipped with software for trending and analytics.

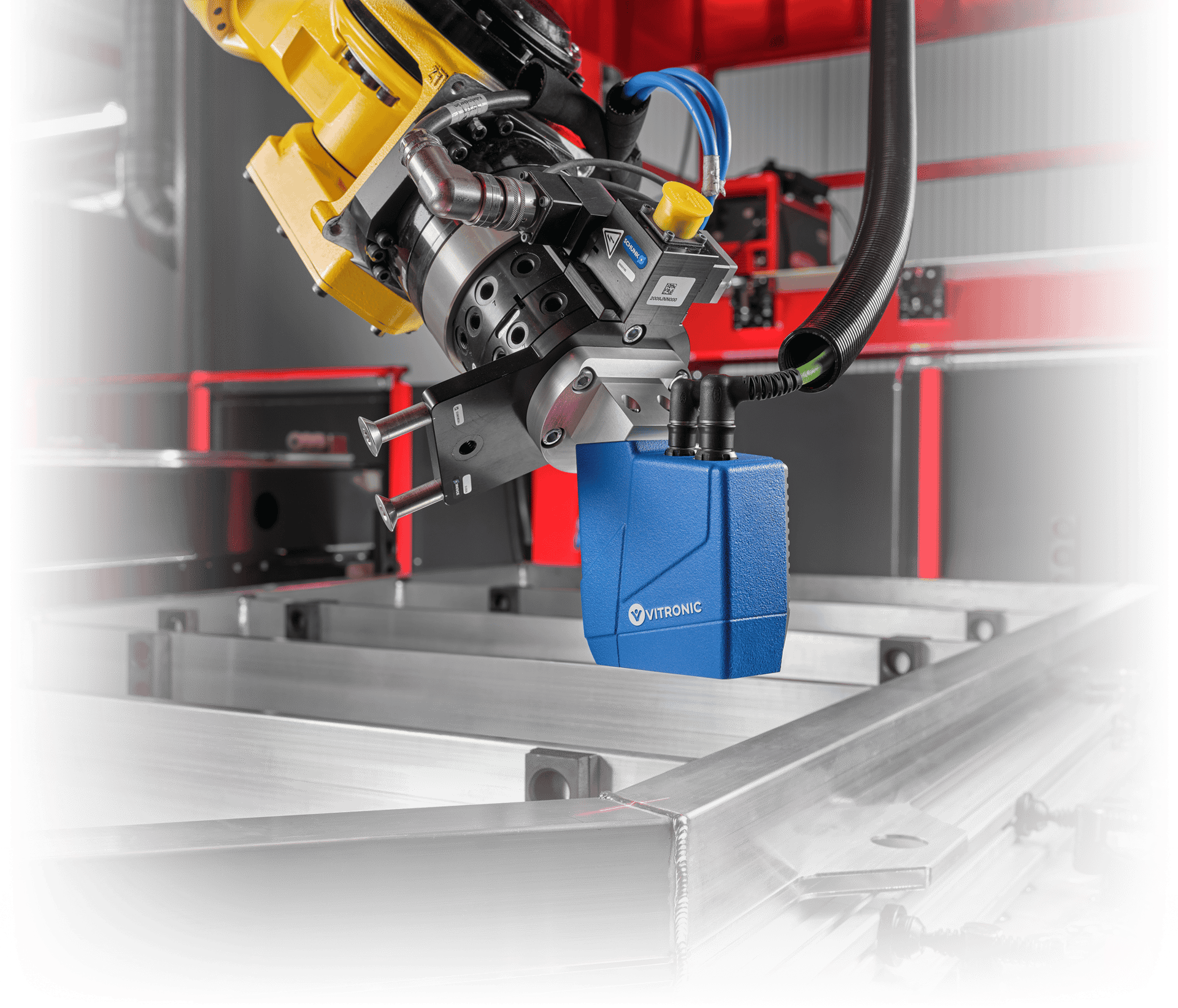

Weld seams are inspected for an automotive manufacturer. Source: VITRONIC

Expanded Inspection Range

Unique to this new generation of automated weld inspection is an exceptionally broad sensing range. The inspection criteria can be configured to suit diverse requirements and applications.

The system is extremely reliable, even when it encounters flat seams, highly reflective materials such as aluminum, seams with differing geometries, and fast image recording speeds.

The automated weld inspection can pinpoint the exact size and position of each defect and classify them. It clearly identifies the tiniest geometric and cosmetic deviations.

Simplified Reworking

All information related to the weld seam inspection is visualized in the software of the latest-evolution weld-seam inspection system, from setting parameters for inspection to the display of defects for reworking. Clear visualization of defects in live operation are displayed as:

a) Real images

b) Precise, detailed inspection images

c) 3D visualization

Defects can be easily analyzed and reworked because of the various visualizations. The software provides detailed instructions for reworking.

The displays are extremely precise, clear, and understandable. Operators can independently access results and rework defects using an integrated touch display or through external visualization stations. In addition to fixing defects with manual reworking, a special classifier also supports automated reworking.

This shows inspection of weld seams on an axle carrier for a Tier 1 auto supplier. Source: VITRONIC

Automated Weld-Seam Inspection Technology

Integrated inline inspection, expanded inspection range and simplified reworking were introduced decades ago and constitute integral functionality of its operation. Vision inspection technologies, and their associated software, have advanced considerably since. These systems are successfully used by leading automotive OEMs and Tier 1 suppliers.

An optical inspection system is a fully automated solution that inspects all weld seams and detects defects as small as 0.1 millimeter, visualizing these for reworking. The sensor uses laser triangulation, which allows laser seams and fine brazed seams to be inspected quickly and with high resolution in 3D. The sensors were specially developed for inspections on reflective materials like aluminum.

As well as being objective and independent of external influences, vision inspection systems consistently follows predefined quality criteria, based on unique specifications and requirements.

Seamless Documentation and Analysis

Using an automated visual inspection solution, all weld-seam inspections are seamlessly documented, stored in an integrated database, and are fully traceable during the entire production process. From this data, operators can quickly identify any potential for production optimization and immediately determine any action that may be required. Completed rework and evaluations of inspection results are then manually entered into the database.

The parameters for quality inspection can then be adjusted during the production process and automatically applied to the next system cycle. This minimizes costly reworking and scrapping of parts.

The inspection data is collected and stored in a database, which enables operators to initiate effective long-term optimizations and implement these on an ongoing basis. This ensures more efficient processes, reduces costs, and continually enhances the quality of the component manufacturing. It also allows manufacturers to house records of parts’ quality for however long they determine necessary for their business records, and the inspection data can be referenced to support parts’ quality years after installation and consumer use.

Weld-Seam Optimization of Critical Components

An automated weld-seam inspection system combined with process optimization software supports manufacturers in delivering components of consistent high quality, while having a direct impact on better managing production volumes and costs.

Automotive manufacturers understand how critical it is to consistently deliver high-quality parts, and using dedicated systems to ensure production quality has been easy to justify ROI. That’s why the automotive industry were the first adopters of this technology nearly 30 years ago. While weld seam inspection technology has been most highly adopted by automotive OEMs and Tier One suppliers, additional industrial manufacturers are adopting automation technologies to streamline their welding production lines.

To leverage weld seam inspection technology, the processes must function reliably. The laser welding process, however, cannot be visually inspected during operation. Defects can only be detected during a subsequent visual inspection of the workpieces. By this point, further rejects have already been produced and the line must be stopped to determine the cause.

Such expensive interruptions can be prevented with an automated inspection system that monitors the welding process in real time. Using a sensor to constantly measure several spectral ranges of light and heat emissions relevant for quality of weld seams in battery production, the latest evolution inspection systems report anomalies outside the tolerances indicating potential quality problems. These parts can be immediately detected, automatically rejected and rewelded. The cause of the defect can be identified and resolved more quickly before further defects are produced.

The latest technology in weld-seam inspection is ideally equipped to ensure that only components with defect-free contacts and cleanly welded modules and housings are manufactured.

Consult a Weld-Seam Inspection Professional

Because weld quality is critical in component manufacturing, it is important to consult an experienced weld-seam inspection specialist who knows the specifics and priorities influencing weld inspection for assembly of components.

Consulting with an inspection specialist early in a project will ensure the most comprehensive and detailed weld inspection technology is utilized and the most optimum procedures have been put into place. This will facilitate manufacturing to achieve the desired production throughput and improve process control while reducing rejects, rework, labor hours and operational costs.