H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Software & Analysis

The efficiency gains offered by 5-axis CMMs are more than theoretical, they’re measurable. By Scott Knoche

Precision in Motion:

The Rise of 5-Axis CMM Technology

Software & Analysis

H2 Deck Info By Paragraph Style Bold

Headline

In today’s world of advanced manufacturing, where tolerances are tighter and cycle times shorter, precision is more than a goal, it’s a necessity. As complex parts and multi-surface geometries become the norm in aerospace, automotive, energy, and medical device manufacturing, quality assurance systems are under increasing pressure to keep pace. At the forefront of this evolution is the coordinate measuring machine (CMM), and its most recent leap forward—5-axis technology—is proving to be a transformative force.

CMMs have long been the go-to solution for 3D inspection of manufactured parts. Their ability to ensure dimensional accuracy, repeatability, and compliance with engineering specifications has made them a staple on shop floors and in quality labs around the world. Historically, CMMs have operated using a three-axis system (X, Y, Z) to move a touch probe around a part. This traditional setup, while highly accurate, has inherent limitations in speed and flexibility, particularly when inspecting intricate features in hard-to-reach areas.

That’s where 5-axis technology enters the scene, and it’s doing far more than just adding two extra degrees of freedom.

A Leap Beyond the Traditional Three Axes

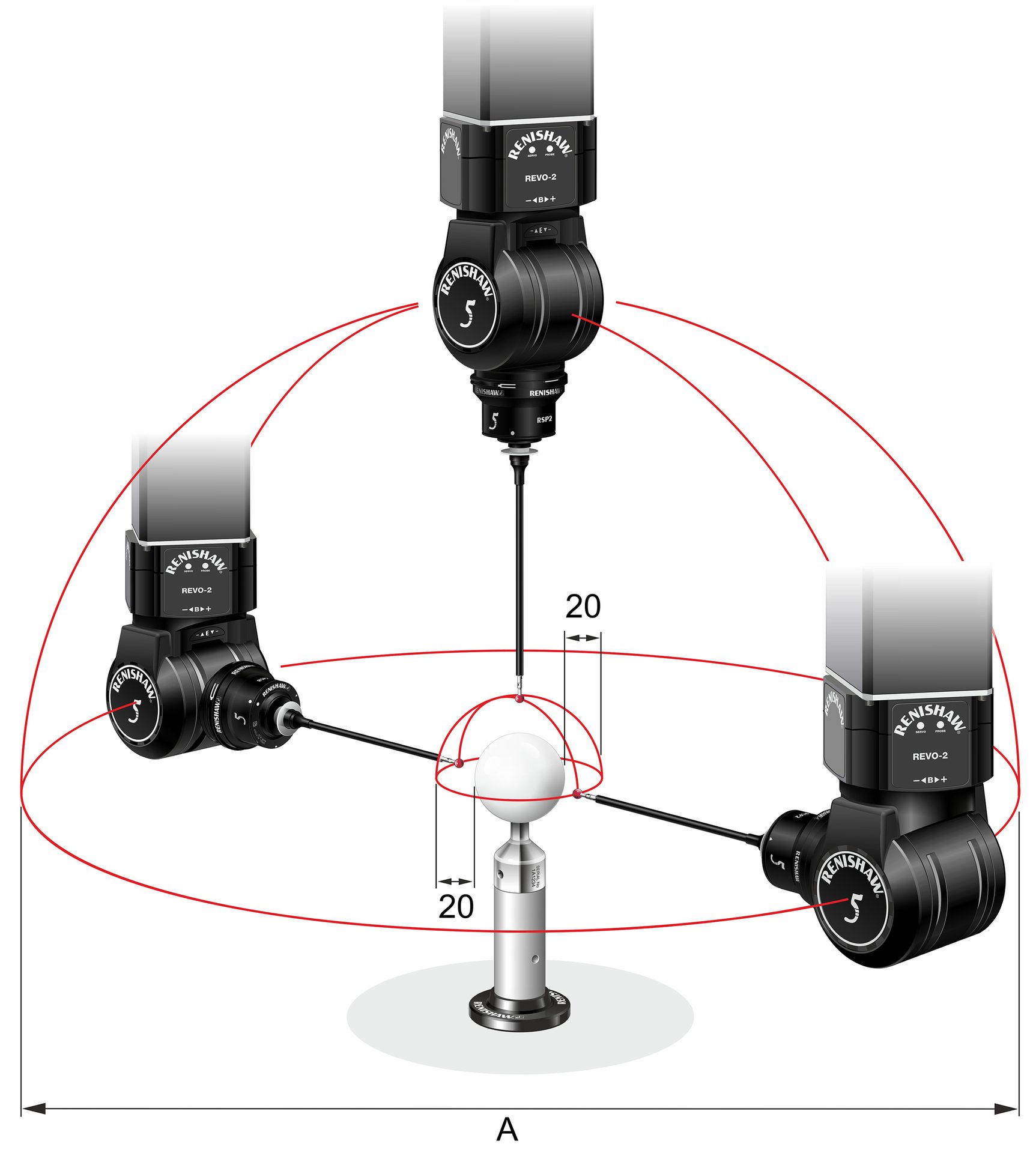

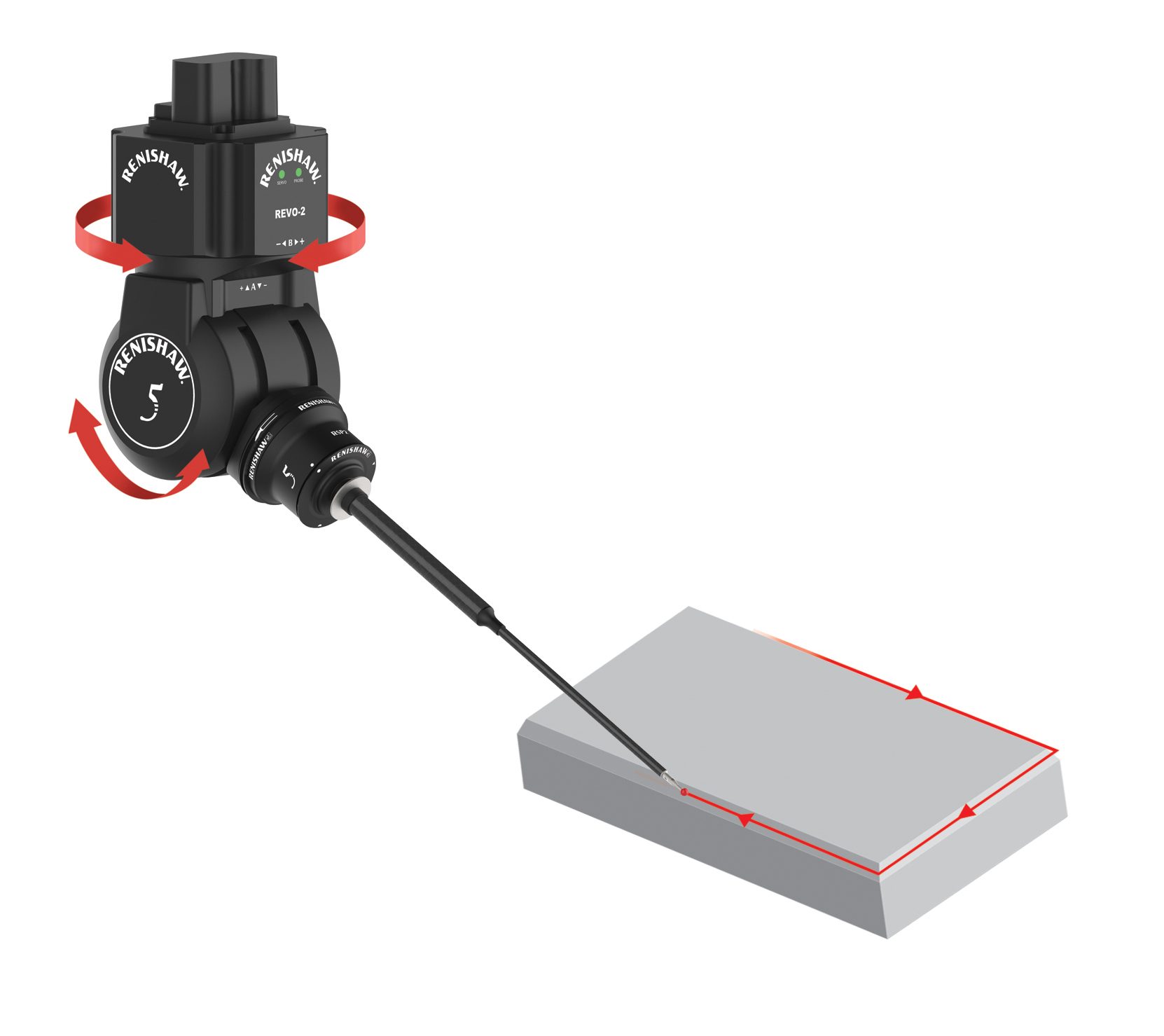

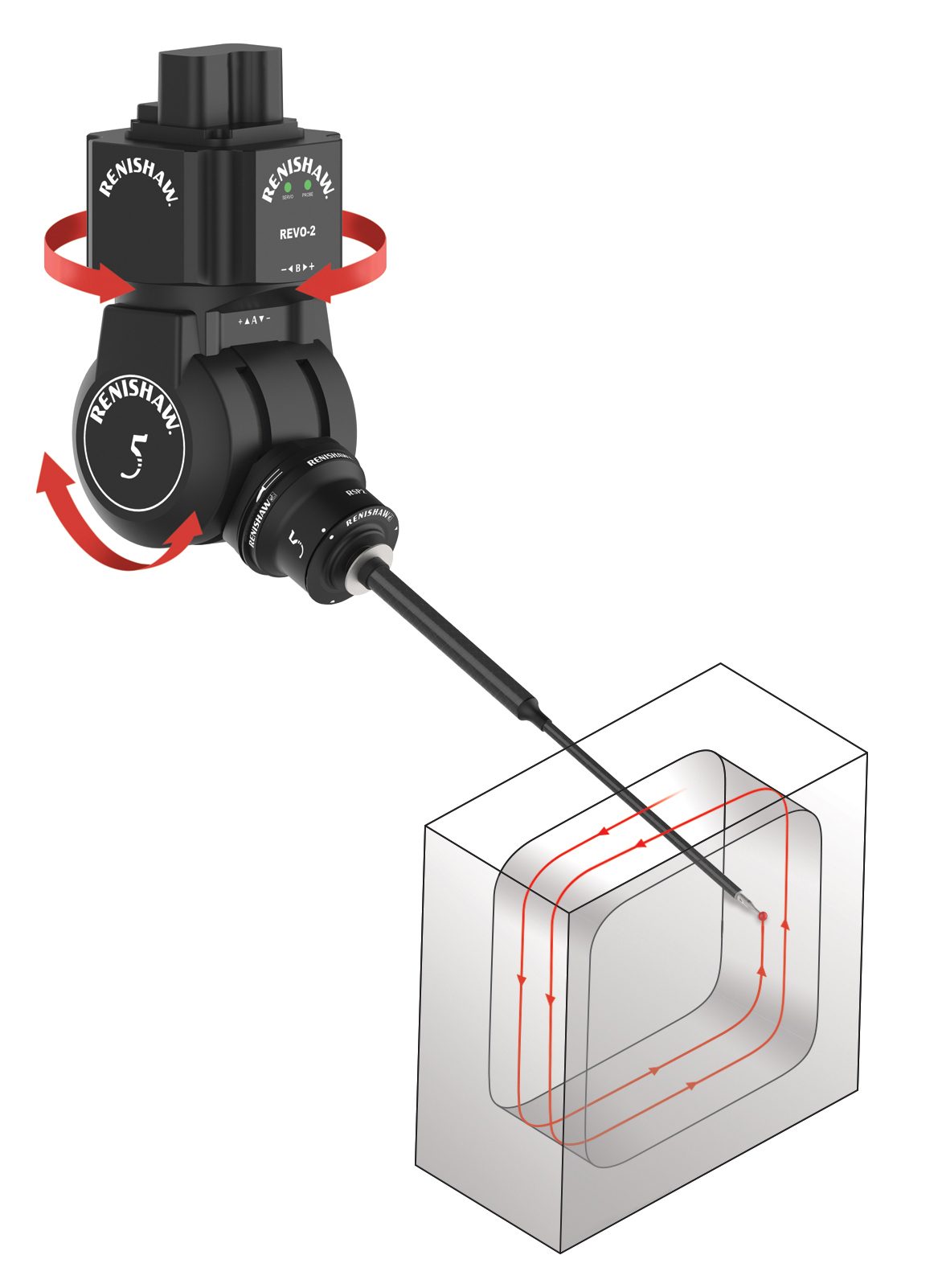

Unlike conventional 3-axis machines, 5-axis CMMs incorporate two additional axes of movement—often referred to as A and B—that are located within the probe head. These motorized rotary axes allow the probe to pivot and rotate with extraordinary dexterity. This innovation means that instead of repositioning the entire machine’s structure to access complex features, the probe head can simply tilt and turn itself into position. It’s a small change in physical motion, but a monumental one in terms of impact.

At its core, 5-axis CMM technology enables what can be thought of as a synchronized dance between machine and head. While the X, Y, and Z axes guide the overall location of the probe, the rotational axes fine-tune the angle, allowing measurements to be made from virtually any orientation, all in one smooth, continuous movement.

Breaking the Speed vs. Accuracy Barrier

One of the most compelling advantages of 5-axis CMMs is their ability to maintain high accuracy even at increased inspection speeds. Traditionally, a CMM operator faced a compromise: speed up the inspection to boost throughput or slow it down to preserve accuracy. With 3-axis systems, accelerating the massive gantry or bridge of the machine introduces dynamic errors due to inertia and vibration.

Renishaw explains it best: “With a 3-axis system, the faster you move, the more dynamic errors are introduced to the system.” This trade-off limits how much cycle time can realistically be saved.

With 5-axis technology, however, much of the probing action is handled by the lightweight, agile head. The main structure of the machine can move more slowly and steadily, while the head performs the fast, precise movements needed to scan or trigger touchpoints. The result? Reduced dynamic error, faster cycle times, and enhanced measurement integrity.

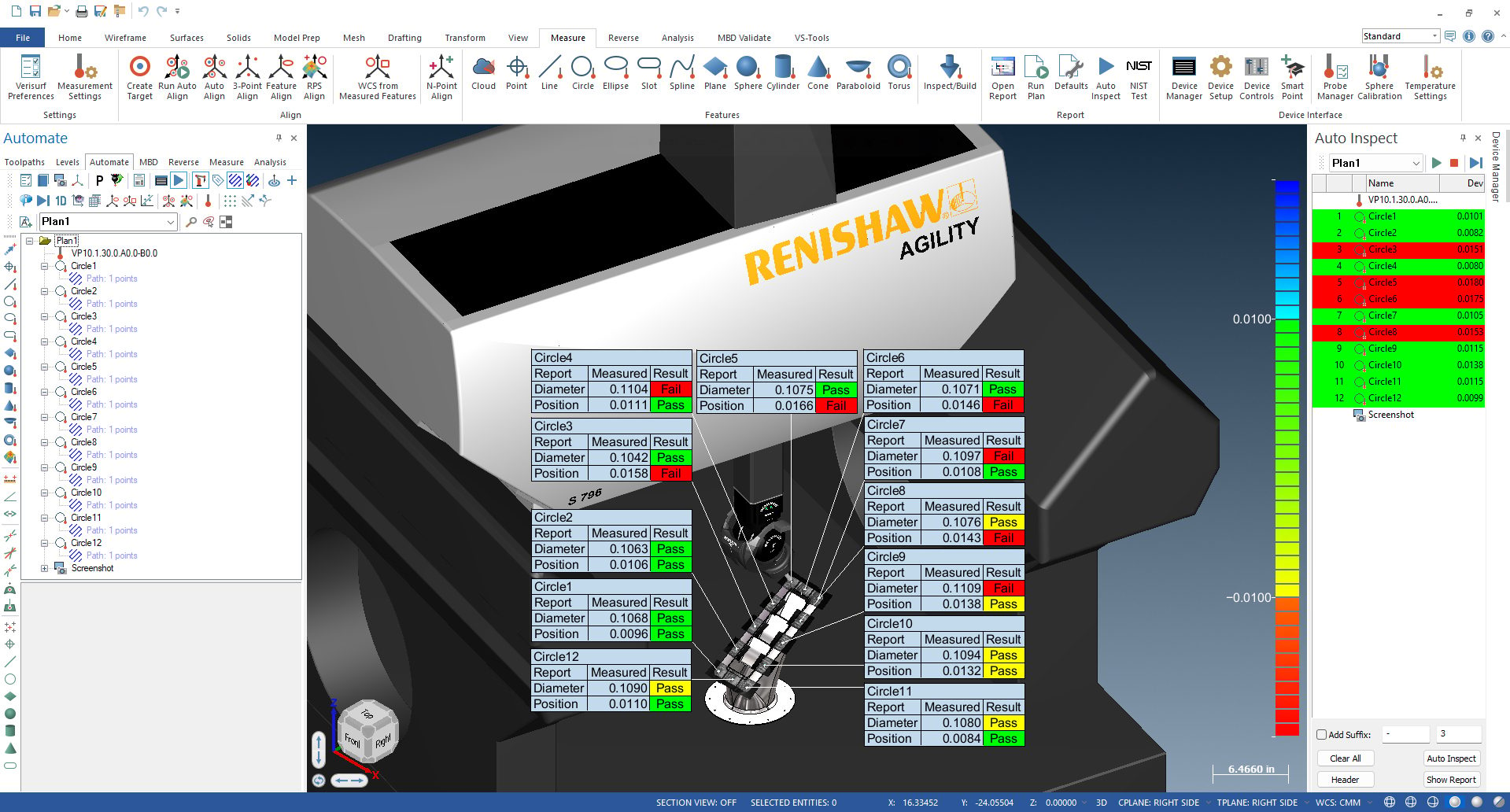

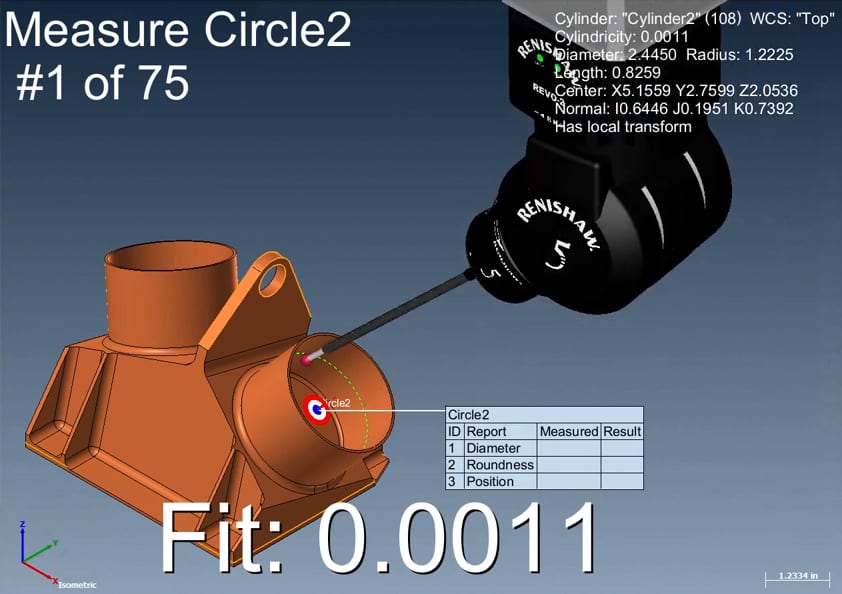

Caption

Probing Without Limits

Accessing difficult features has always been a challenge with traditional systems. Engineers and programmers often resort to elaborate fixturing, reorienting parts multiple times, or using long and delicate stylus extensions, all of which introduce time, cost, and the risk of measurement errors.

With a 5-axis CMM, probe access is significantly simplified. Infinite positioning capabilities enable the head to approach features from virtually any angle, reducing the need for re-fixturing or stylus changes. Entry vectors can be aligned easily within the CMM software, which offers intuitive tools for defining entry and exit paths. Features like Custom Clearance provide real-time graphical feedback, ensuring smooth, collision-free measurement paths, even in tightly spaced geometries.

The Science Behind the "Head Touch"

At the heart of 5-axis systems is a probing method called the “head touch.” Unlike conventional systems that use machine motion (X, Y, Z) to physically push the probe into the part, the head touch relies on A and B axis rotations to guide the stylus into contact. This not only enables faster probing but significantly reduces the wear on the mechanical elements of the machine itself.

Because the probe can be directed by rotating the head instead of moving the heavy machine frame, measurement points can be acquired faster, more precisely, and with less physical strain on the equipment. Over time, this reduces maintenance costs and extends machine life.

Inferred Calibration and Infinite Gains

Another major boost to productivity comes from inferred calibration. In traditional systems, every angle and stylus must be calibrated individually—a tedious and time-consuming process. With inferred calibration, systems determine the head orientation and probe position in a single operation. After initial setup, the probe can operate at any angle with minimal additional calibration.

This innovation drastically reduces preparation time and allows faster deployment of measurement routines, particularly valuable for high-mix, low-volume production environments where new part programs are developed frequently.

Time is Money—5-Axis Delivers Both

The efficiency gains offered by 5-axis CMMs are more than theoretical, they’re measurable. Across multiple categories, 5-axis systems consistently outperform their 3-axis counterparts:

Cycle Time: Higher speeds, fewer stylus changes, and reduced need for re-fixturing mean faster part inspection.

Programming: Simplified path creation and fewer access constraints result in shorter programming cycles.

Setup: Infinite positioning capability reduces or eliminates complex fixturing.

Maintenance: Reduced structural movement preserves machine accuracy and minimizes wear over time.

In comparative time studies, 5-axis systems routinely deliver 30% to 50% reductions in total inspection time. For high-throughput environments, those savings scale dramatically across shifts, machines, and operators.

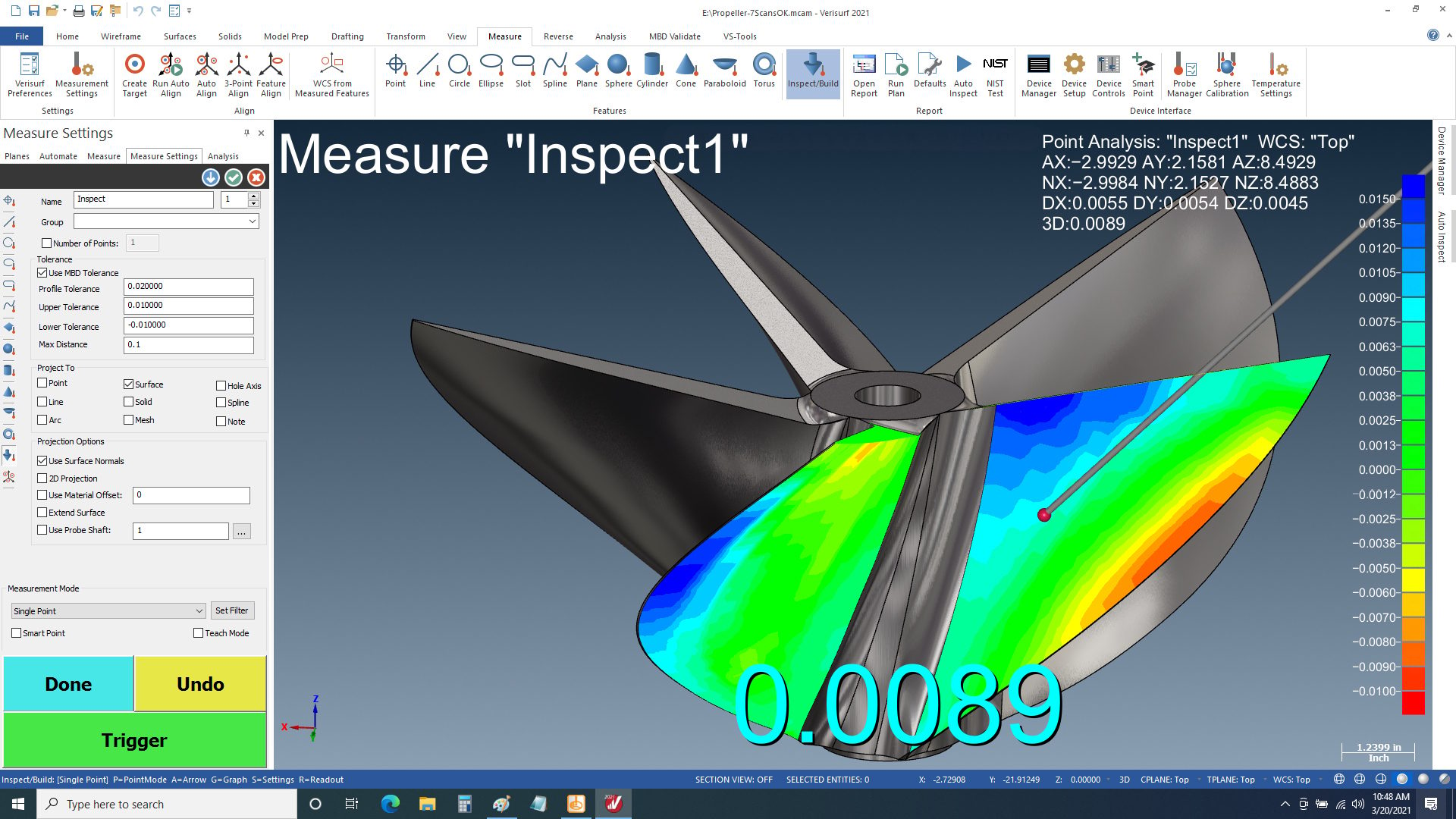

Caption

Real-World Impact: Five-Axis Industries Leads the Way

Few companies illustrate the benefits of 5-axis synergy better than Five-Axis Industries, a precision manufacturing company that was an early adopter of both 5-axis machining and metrology.

“For us, 5-axis capabilities are all about moving the part less and articulating the machine to move around the part,” says a company spokesperson. “We were an early adopter of 5-axis machining; finally, CMMs have caught up and can offer the same productivity gains in measurement and inspection.”

The integration of 5-axis CMM inspection into their workflow has led to a reported 50% reduction in total cycle time—a dramatic improvement that translates directly into increased productivity and profitability.

Is 5-Axis Right for You?

While the benefits of 5-axis CMMs are compelling, the technology isn’t for every shop. Smaller facilities handling low-volume or simple geometries may find that 3-axis systems still deliver the best ROI. However, for companies managing complex parts, tight timelines, or high-volume production, the performance advantages can’t be ignored.

Initial investment in 5-axis technology, particularly tactile scanning systems, can be significant. But with reduced inspection time, fewer hardware requirements, and the ability to win business by showcasing cutting-edge capabilities, the long-term return is clear.

Extra Productivity from Software-Driven Techniques

Pre-programmed control features within metrology software can enable unique measurement techniques that further the speed and accuracy of 5-axis CMMs. Scanning techniques include Circle Scan, Edge Scan, Surface Sweep, Gasket Scan, Helical Scan, and Head Touches. As an example, here are three more software-driven scan techniques:

- Curve Scan – Curve scan automates the measurement and reporting of small transitional surfaces and edges like fillets and chamfers used to reduce sharp edges and stress concentrations.

- Pocket Scan – Pocket scan is used for rapid and automated inspection of isogrid and orthogrid structures that stiffen and save weight on aerospace panels and pressure vessels.

- Spiral Scan – Spiral scan enables CMM programmers to accurately and quickly program and measure turbine blade or propeller surfaces while staying clear of neighboring blades.

The Future of Metrology is Multi-Axis

As manufacturing continues to evolve, the need for speed, precision, and flexibility in quality control will only increase. 5-axis CMMs represent not just an upgrade, but a paradigm shift—enabling more agile inspection processes, faster feedback loops, and greater confidence in part conformity.

When paired with metrology software that supports model-based inspection, real-time feedback, and automation, the 5-axis CMM becomes more than a measurement tool—it becomes an integral part of a connected, digital manufacturing workflow.

In a world where quality and efficiency go hand in hand, 5-axis technology is helping manufacturers achieve both.