Products

the latest products to help you improve your manufacturing process

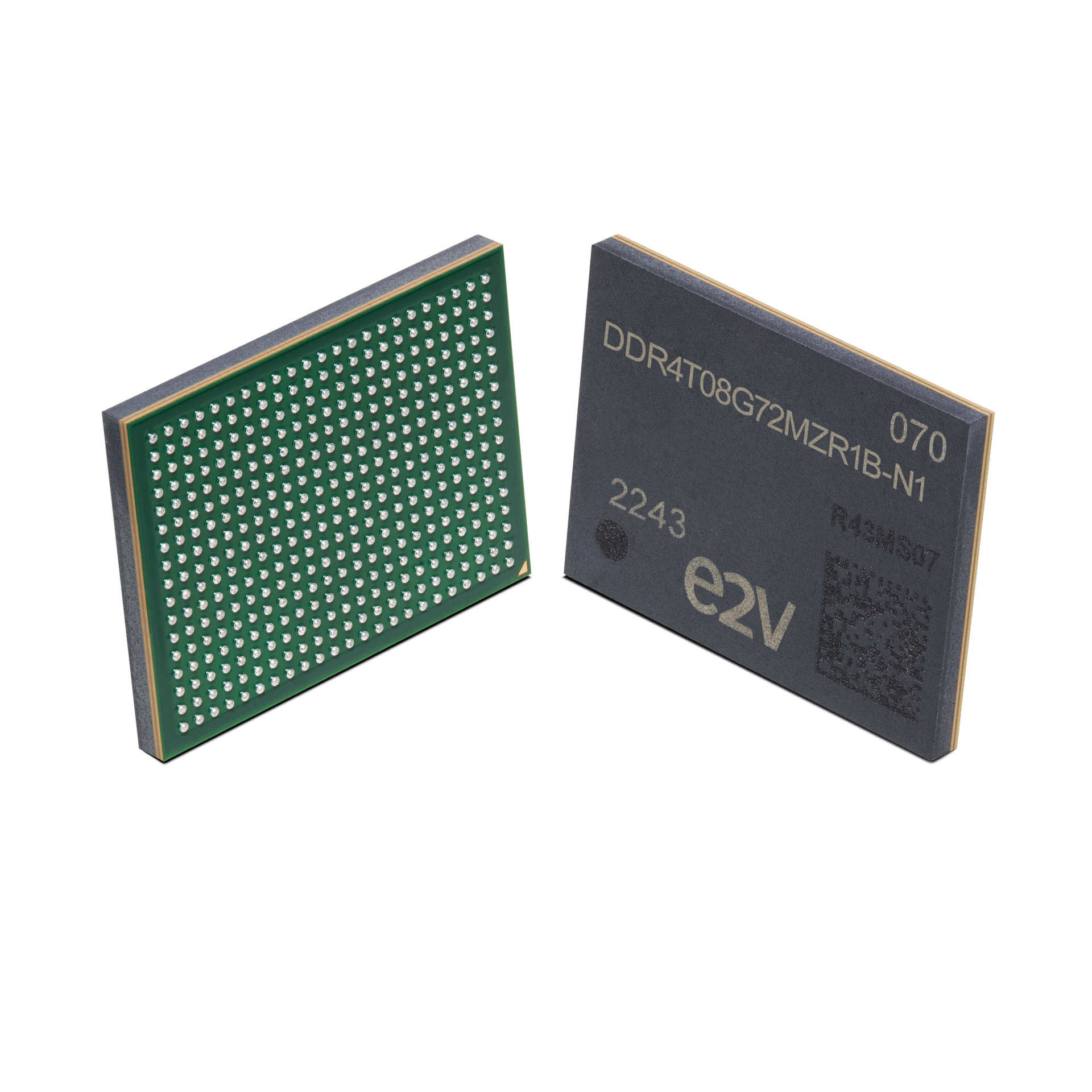

Teledyne e2v 16GB Space-Qualified DDR4 Memory

Teledyne e2v, a leading provider of high-reliability solutions for space applications, announced the immediate availability of Engineering Models for its new 16GB radiation-tolerant DDR4 memory. This high-density addition expands Teledyne e2v’s space-grade DDR4 portfolio—already the most deployed in the industry—with hundreds of 4GB and 8GB flight models delivered to date.

The 16GB DDR4 device maintains the compact form factor of the existing family—just 15mm x 20mm x 1.92mm—and is pin-to-pin compatible with the 4GB and 8GB variants. This compatibility ensures a smooth upgrade path, allowing system designers to scale memory capacity without a complete board redesign.

Fully compatible with all major space-grade processors and FPGAs, including Teledyne e2v’s own LS1046-Space, LX2160-Space, and QLS1046-Space, the memory operates at speeds up to 2400MT/s. It is engineered for robustness in harsh space environments, with a Total Ionizing Dose (TID) tolerance of 100 krad (Si), Single Event Latch-up (SEL) immunity above 60 MeV.cm²/mg, and advanced SEU/SEFI mitigation for reliable, no-data-loss recovery.

“As satellite payloads grow increasingly complex, the demand for higher memory densities becomes critical,” said Thomas Guillemain, Marketing & Business Development, Digital Processing Solutions at Teledyne e2v. “With the release of our 16GB DDR4 engineering models, system architects can begin early validation with confidence, preparing for a seamless transition to flight-qualified versions.”

Engineering Models of the 16GB DDR4 are available now, enabling early-stage development and system validation ahead of full flight deployment. Teledyne e2v supports the integration process with extensive documentation, including the latest 16GB DDR4 radiation report with our customers.

Teledyne e2v

https://www.teledyne-e2v.com/en-us

SVS-Vistek FXO Platform with FXO 25GigE Series Cameras

SVS-Vistek expanded its FXO platform by introducing the new FXO 25GigE Series of machine vision cameras enabled with Remote Direct Memory Access (RDMA) technology.

Combined with the camera's 25GigE interface, the integration of RMDA greatly reduces latency and response times to achieve near real-time image processing. In addition, the use of cost-effective SFP28 optical transceivers, rather than traditional RJ45 connectors, allows data transmissions over cable distances of up to 10,000 meters.

Built on 3rd and 4th generation Sony® IMX global shutter sensors, SVS-Vistek FXO 25GigE Series cameras are available in color and monochrome configurations offering resolutions and frames-per-second (fps) of:

- 1.8 megapixel (1600 x 1140 pixels) x 671 fps

- 5 megapixel (2448 x 2048pixels) x 262 fps

- 8.1 megapixel (2848 x 2848 pixels) x195 fps

- 12.3 megapixel (4096 x 3008 pixels) x182 fps

- 16.2 megapixel (5328 x 3040 pixels) x 144 fps

- 20.4 megapixel (4512 x 4512 pixels) x109 fps

- 24.6 megapixel (5328 x 4608pixels) x 96 fps

This range of options makes the FXO 25GigE Series ideal for diverse applications requiring uninterrupted, stable data flow of extremely high resolutions and frame rates.

Regardless of the FXO 25GigE model, the cameras integrate seamlessly into current network structures, enabling end-users to adapt them without expensive hardware overhauls. The GigE Vision standard ensures compatibility with existing machine vision software and systems, while GenICam 3.0 compliance allows for plug-and-play functionality, reducing complexity.

Rounding out the FS 25GigE's impressive feature set are LUT, binning, ROI, electrical and optical inputs, a 4-channel strobe controller, and an industrial TTL-24V I/O interface equipped with SafeTrigger, logic functions, programmable sequencers and timers, plus an RS232 interface. The milled housing measures 50 x 50 x 100 mm, making it currently one of the most compact industrial cameras with a 25GigE interface in the world. The housing's temperature management also provides excellent image homogeneity.

RMDA works by transferring image data from FXO 25GigE cameras directly to the main memory of a host PC, reducing stress on the operating system and allowing the CPU to perform other tasks by freeing up computational resources. Consequently, CPUs and GPUs can focus on intensive functions like image processing, feature extraction, or neural network computations rather than managing network I/O. In machine vision, where real-time processing of high-resolution images or video streams is critical, RMDA ensures faster decision-making. A firmware update also lets the camera be switched to conventional streaming via GVSP (GigE Vision Stream Protocol).

SVS-Vistek

svs-vistek.com

Proven HBK Force Measurement Technology

Hottinger Brüel & Kjær (HBK) introduced digital connectivity to its U2B and C2 force transducers, now available with an IO-Link interface.

This enhancement makes it easier than ever to integrate tensile and compressive force measurements directly into control systems.

For years, the U2B (tensile and compressive) and C2 (compressive) series have been essential tools in production, monitoring, and testing environments worldwide. With a nominal force range from 500 N to 200 kN, these sensors are known for their reliability and precision.

Now, in addition to analogue outputs (4 – 20 mA and 0 – 10 V), users can opt for a digital output via IO-Link – which ensures smarter data handling and improved system integration.

The IO-Link Integration provides engineers with many benefits:

- Sensor Health Monitoring: Real-time diagnostics compare applied forces and temperature conditions against sensor limits. If thresholds are exceeded, warnings are issued to help prevent damage.

- Enhanced Accuracy: Improved measurement precision and integrated temperature sensing.

- Universal Compatibility: IO-Link is standardized and works seamlessly with all major fieldbus systems.

- Simplified Integration: HBK provides function blocks to streamline sensor setup within control systems.

HBK also offers IO-Link-enabled sensors for torque and weight, expanding the possibilities for smart, connected measurement solutions.

HBK – Hottinger Brüel & Kjær

https://www.hbkworld.com/en/products/transducers/force/c2

https://www.hbkworld.com/en/products/transducers/force/u2b

Teledyne Z-Trak Express 1K5 3D Laser Profiler

Teledyne DALSA introduced the Z-Trak™ Express 1K5 3D laser profiler series. Purpose-built for cost-effective, in-line 3D measurement and inspection, the Z-Trak Express 1K5 is the latest innovation in the Z-Trak family. It delivers high-speed 3D inspection with real-time processing, achieving a maximum profile rate of 5,000 profiles per second across its full measurement range. This makes it ideal for a wide range of industries, including secondary battery production, automotive, lumber inspection, factory automation, and logistics.

Featuring a 1,700mm horizontal field-of-view, the Z-Trak Express 1K5 enables precise measurement and inspection of wide-body objects such as wooden planks, road surfaces, pallets, and automotive body parts, using a single sensor. It also supports the integration of multiple sensors in a variety of topologies, enabling advanced measurement and inspection tasks such as measuring the thickness of moving parts, performing continuous 360° inspections, and extending the horizontal field-of-view, all without compromising Z-resolution. To simplify deployment and reduce costs, the Z-Trak Express 1K5 synchronizes multiple sensors using a data cable and supports content-based triggering for enhanced flexibility.

All Z-Trak profilers are deployment-ready, delivering micrometer level measurements without the need for in-field calibration. To accommodate objects of varying sizes, shapes, colors, finishes, and material compositions, Z-Trak Express 1K5 includes real-time, user programmable profile enhancement functions, two-point HDR, and models with eye-safe red or blue lasers. Like all Z-Trak laser profilers, Z-Trak Express 1K5 performs on-board processing without compromising the profile rate.

The Z-Trak Express 1K5 series comes bundled with:

- Z-Trak 3D Apps Studio – a license for a powerful suite of software tools for in-line measurement and inspection

- Sherlock™8 – a field proven rapid deployment platform for machine vision, enabling seamless communication with PLCs and other devices via industry standard communication protocols such as TCP/IP, MODBUS®, ProfiNet® and more.

Teledyne DALSA

https://www.teledynevisionsolutions.com/products/z-trak-express-1k5/

INSPHERE Intelligent Automation Solutions

Partnering with specially selected integrator Variation Reduction Solutions, Inc. (VRSI), in Michigan, live demonstrations of INSPHERE’s automation cell measurement and control solutions are now accessible to manufacturers and engineers in the region.

INSPHERE has partnered with VRSI in recognition of its innovative, highly committed approach to introducing intelligent automation solutions to support advanced manufacturing. An independent engineering services company, VRSI is dedicated to the integration of the most accurate and effective optical measurement technologies within industry's most advanced automation systems to maximize quality and minimize wasted time and materials.

Advanced manufacturers in North America now have access to INSPHERE’s IONATM robot measurement hardware and ORATM robot control software with localized technical support – a gamechanger for production operations requiring highly accurate, repeatable and flexible activity with the ability to self-correct in-process - reducing interruptions and waste, improving quality and efficiency.

In addition to the VRSI team sharing solutions to improve advanced automation, INSPHERE has a dedicated sales director based in Michigan. Jeremy Burne – US Director Business Development – has extensive experience working within the US automotive sector and is a director with the MIA (Motorsport Industry Association) in Detroit. He works closely with the team at VRSI, industry bodies and manufacturers to share INSPHERE’s innovation in robot cell measurement and control.

Demonstration cells are available at VRSI in Detroit, allowing manufacturers to experience INSPHERE’s automation solutions, and see how efficiencies can be made in reduced downtime, increased production volume, fewer quality issues and lower material waste – all while lowering overall costs.

INSPHERE

https://insphereltd.com

Embedded Vision Kit from Phytec and Vision Components

The phyBOARD for VC MIPI Development Kit from Phytec, in collaboration with Vision Components, is now available in two versions with NXP i.MX 8M Plus and i.MX 8M Mini processor boards. Both versions provide plug-and-play support for Vision Components' more than 50 VC MIPI Cameras. The two embedded vision kits enable users to start development immediately, with cameras ranging from 0.5 to over 20 megapixels resolution, global shutter, rolling shutter, and rolling reset shutter. They can be ordered from both companies and cost 295 euros plus VAT for the phyBOARD-Pollux (i.MX 8M Plus) Imaging Kit and 480 euros plus VAT for the phyBOARD-Polis (i.MX 8M Mini) Imaging Kit. The desired VC MIPI Camera Module can be selected separately.

Both development kits contain all the necessary components for quick and easy setup of an embedded system with integrated image processing. The corresponding V4L2 drivers for addressing the VC MIPI Cameras from own applications or via middleware such as GStreamer, OpenCV, or Halcon are included in the supplied Linux BSP. The scope of delivery also includes adapters and cables for the VC MIPI Cameras and, for the phyBOARD-Polis with i.MX 8M Mini, a 10" display with capacitive touch. The phyBOARD-Pollux with i.MX 8M Plus processor board supports HDMI to connect a standard display.

The embedded vision kits were developed in close collaboration between Phytec and Vision Components with the aim of simplifying the development of custom embedded vision applications for customers through a wide selection of image sensors and seamless integration with processor boards. Phytec's processor boards and Vision Components' MIPI CSI-2 Cameras are characterized by their industrial-grade “Made in Germany” quality, long-term availability, and favorable price-performance ratio. Both companies offer customers comprehensive support in development and integration.

PHYTEC Messtechnik GmbH

www.phytec.de / www.mipi-modules.com

Vision Components

www.vision-components.com

Basler IP67 Camera, Components Solution

Basler AG presents a vision system protected in accordance with the IP67 standard. The system consists of an ace 2 IP67 camera, lens, lens housing, IP67 lighting, and cables. All components are available in numerous variants, which ensures a high degree of flexibility in the system configuration. They are compatible with each other and enable accelerated implementation in the target application. Basler's vision specialists support customers on the path to a customized solution, from needs analysis to commissioning.

The new industrial-grade ace 2 IP67 cameras feature a compact housing, are equipped with an M12 GigE connector, and deliver frame rates of up to 51 fps. Lenses are offered to match the available sensor resolutions up to 24.5 MP and sensor formats up to 1.2". Suitable lens housings are available to protect these lenses in accordance with the IP67 standard. The IP67 lighting includes ring and bar lighting in various sizes and light colors for either continuous or trigger operation. Data and I/O cables with screwable M12 or M8 connections on the camera side complete the IP67 vision system. Basler's reliable supply chain for all components over a period of ten years ensures long-term functioning solutions.

To ensure the intra-operability of the complete solution, Basler validates all other components during the development phase of the camera. Patrick Markiefka, Product Manager at Basler AG, explains: "Customers not only benefit from our broad IP67 portfolio, which in addition to hardware also includes pylon software. They also benefit from the compatibility of the components, which reduces integration and maintenance costs." "In order to achieve a customized system quickly, we offer our customers the option of involving us as vision specialists in the system development," adds Kimberly Matsinger, Application Engineering Manager at Basler Inc. "Our experience shows that this is the most efficient way to implement a tailor-made solution."

Basler AG

www.baslerweb.com/ip67

SmartRay ECCO X 025 Dual-Head Sensor

SmartRay announced the launch of the latest addition to its ECCO X sensors. The ECCO X 025 Dual-Head is the first in the range to offer the full capabilities of the X family, delivering 100% inspection at metrology grade level combined with occlusion-free scanning.

While traditional single-head sensors experience shadowing from raised surface areas when the laser hits the target point but the camera is blocked from viewing it, the ECCO X 025 Dual-Head features a second camera head positioned symmetrically to the first, which significantly reduces occlusions and enables uninterrupted visibility even on complex surfaces.

The dual-head sensor ensures accurate 3D point capture across all parts of the sample without missing data that could occur due to shadowing, as the two cameras overcome this.

The ECCO X 025 Dual-Head is the first dual-head sensor to have X capabilities, which include up to 40 kHz scan rate and 4096 3D points per profile. It also comes standard in lc 3R, with higher scan speeds through shorter exposure times.

It is suitable for a wide range of applications that may be affected by shadowing, including the automotive sector, where the ECCO X 025 Dual-Head can meet the high inspection demands of structural and reflective parts like battery trays. In semiconductors and electronics, high precision is essential for inspecting small, shiny, metallic objects, including conductor wire bonding, BGA and also PCBA, and this new sensor is a game-changer in this process.

Claire Rathsack, ECCO Business Manager, said, “We’re setting a new benchmark for high-precision, shadow-free 3D scanning with the launch of the ECCO X 025 Dual-Head. By integrating dual-head scanning into our industry-leading X platform, manufacturers can now achieve faster, more reliable inspection with precision, especially for challenging, reflective, or complex parts in demanding applications."

Key specifications include a field of view (FOV) of 25mm at mid-field, a typical measurement range of 20mm and a laser wavelength of 450 nm (brilliant blue), the ECCO X 025 Dual-Head offer accurate inspection and precise measurement.

SmartRay

https://www.smartray.com/3d-sensors/ecco-x-025-dual-head/

Siemens Xcelerator Platform

Siemens demonstrates how the enormous potential for optimizing machine tools can be utilized, thanks to the continuous analysis of production data. With the open digital business platform Siemens Xcelerator, IoT-enabled hardware and software, the company demonstrates how the physical world can be connected to the digital world. Such a portfolio accelerates digital transformation and enables flexible and sustainable action both in the building of machine tools and in use.

Siemens recently launched an open, digital business platform called Xcelerator. By doing so, the company seeks to enable customers of all sizes in the fields of industry, buildings, power generation, public utilities and mobility to accelerate their digital transformation and increase value creation. The business platform makes digital transformation easier, faster and scalable. It comprises three cornerstones — a curated portfolio of internet of things (IoT) enabled hardware, software and digital services from across Siemens and certified third-parties; a growing ecosystem of partners; and an evolving marketplace to facilitate interactions and transactions between customers, partners, and developers.

With applications such as Manage MyResources /Tools, Manage MyResources /Programs, Analyze MyPerformance /OEE, Manage MyMachines, Manage MyMachines /Remote and Analyze MyMachine /Condition, as well as the Industrial Edge for Machine Tools platform, Siemens also provides offerings for machine tools via Siemens Xcelerator, both for the machine builder and CNC machine users.

The apps provide intelligent resource management that allows production orders to be prepared smoothly by providing the right tools and NC programs. A central solution at the manufacturing level manages real instances of tools, tool locations and programs for parts production, using the data from the CNC. Workflows in machining environments are optimized, tool circulation and tool inventory are efficiently organized.

The utilization of production capacities can be improved by analyzing overall equipment effectiveness (OEE). All three applications offer innovations, for example, with broader connectivity even for CNC machines that are not equipped with Siemens SINUMERIK CNC, a significant development. This means nothing stands in the way of a shopfloor-wide connection of machines to resource management. In addition, Manage MyResources /Tools can now provide further valuable insights into tool usage, such as the duration of the different life phases for certain tool types.

Also new is the possibility of more efficient tool planning with reservation of tools for a machine or production order or as a standard tool. With the help of unloading lists for balancing, the planning of tool requirements will become even more efficient in the future.

For Manage MyResources /Programs, additional use cases can now be covered by the possibility to add additional file types such as drawings to NC packages. In Analyze MyPerformance /OEE, machine status can now be configured individually. In addition, the app provides detailed insights into workpiece statistics and production progress.

In the new version of Manage MyMachines, it is now possible to examine reports of technical faults even more closely. Also new is the now seamless transition between the two apps Manage MyMachines and Manage MyMachines /Remote, which further improves the user-friendliness and efficiency of service calls. Manage MyMachines is now also available with broader connectivity, which supports machine controllers from other manufacturers.

Siemens openness to partners is demonstrated by the Industrial Edge for Machine Tools ecosystem. Based upon the Siemens Edge Platform, Schunk, the global manufacturer of gripping systems and clamping technology, developed its iTendo Service. By combining sensor data from the tool tip and data from the NC, Schunk wants to help machine tool operators improve the machining process and prevent tool breakage.

Siemens

www.siemens.com

Kassow Robots Sensitive Arm Technology for Enhanced Collaborative Robotics

Kassow Robots announced its Sensitive Arm technology across its complete range of 7-axis collaborative robots. This advanced force control system integrates high-resolution torque sensors into all seven joints of each robot, enabling manufacturers to automate delicate and contact-sensitive tasks with greater precision, safety and flexibility.

The Sensitive Arm system provides real-time, low-latency force feedback while utilizing integrated torque sensors across all joints. With a sensor resolution of up to 0.024 Nm/bit and a control frequency of 30 kHz, the system enables compliant and nuanced motions essential for complex tasks such as assembly, surface finishing, inspection and delicate handling.

"The Sensitive Arm is transforming how manufacturers approach automation of complex assembly and finishing operations," said Dieter Pletscher, Global Sales Manager at Kassow Robots. "Our customers are seeing immediate benefits in applications requiring controlled contact forces from precision assembly to surface finishing while maintaining the industrial strength and flexibility that Kassow Robots’ 7-axis design is known for."

Operators can fine-tune how the robot responds to external forces using a dedicated interface that makes it easy to adjust parameters such as stiffness, damping and end-effector compliance. The system also enables one of the smoothest and most responsive hand-guiding experiences on the market, with minimal resistance and high sensitivity, enabling fast and intuitive programming by demonstration. This significantly reduces the time and complexity involved in deploying new applications.

By eliminating the need for external force and torque sensors, the Sensitive Arm simplifies system integration while improving feedback accuracy. It also improves collaborative safety by enabling faster, more reliable detection of impacts or unexpected contact, creating safer conditions for human-robot interaction on the factory floor.

The Sensitive Arm is available across Kassow Robots’ entire 7-axis collaborative robot portfolio, including new high-payload models, expanding automation possibilities for complex and sensitive tasks. Kassow Robots‘ expanded lineup now offers significantly greater payload capacities while maintaining precision and safety.

Kassow Robots

https://www.kassowrobots.com/

e-con Systems ONVIF-Compliant 4K HDR GigE Camera

e-con Systems® introduced the ONVIF-compliant 4K HDR GigE Camera - RouteCAM_CU86 - built with the Sony STARVIS 2 IMX678 sensor and engineered to provide exceptional image clarity and reliability even in the most challenging lighting environments. This IP67-rated camera is designed for smart surveillance, intersection monitoring, sports and gaming analytics, and dental lighting systems, offering efficient H.264/H.265 compression for bandwidth-efficient 4K streaming over standard PoE networks.

RouteCAM_CU86 integrates the Sony® STARVIS™ 2 IMX678 sensor with e-con Systems’ proven ISP tuning expertise to deliver high-quality 4K video with up to 110dB HDR and remarkable sensitivity down to 0.1 lux. This enables clear visibility in both low-light and high-contrast scenarios such as shadowed parking lot basements, glaring intersection headlights, or brightly lit surgical environments.

This camera is ONVIF-compliant, ensuring plug-and-play compatibility with a broad range of NVRs and VMS platforms for faster deployment and reduced integration costs.

“RouteCAM_CU86 marks our first 4K camera in the RouteCAM GigE series and is built to address imaging challenges in diverse environments. From capturing clear faces in dimly lit industrial spaces and monitoring intersections during difficult lighting conditions, to delivering consistent video quality for outdoor sports and precise details under dental surgical lights, this camera is built for versatility. By leveraging our expert ISP tuning alongside Sony’s advanced sensor technology, RouteCAM_CU86 consistently delivers reliable 4K HDR clarity and low-light performance, all within a rugged, secure and easily integrated solution for next-generation vision systems.” said Suresh Madhu, Head of Industrial Business Unit at e-con Systems.

Additional Highlights of RouteCAM_CU86:

- PTP Synchronization: Enables sub-microsecond time synchronization across multiple Ethernet cameras, critical for precision monitoring and analytics.

- Secure Management with Built-in Cybersecurity: Manages devices through CloVis Central™, a secure cloud platform featuring OAuth2 and JWT-based authentication, TLS 1.2 encryption, private subnets, API gateways, and secure software updates, ensuring end-to-end cybersecurity.

- Digital Pan/Tilt/Zoom: Allows repositioning and scaling within the 4K frame without mechanical lens movement.

- Rugged Industrial-grade design: Built to withstand harsh industrial and outdoor environments, compliant with ISO 16750 and ISO 20653:2013 standards.

e-con Systems offers customization services and end-to-end integration support for the RouteCAM_CU86_IP67 camera, ensuring that unique application requirements can be easily met.

e-con Systems

camerasolutions@e-consystems.com

www.e-consystems.com

Kitov AI 2.9 Automated Software Platform

Kitov AI announced the availability of Kitov AI 2.9, a significant update to its acclaimed software platform. This latest version introduces a suite of powerful features designed to enhance quality, elevate precision, streamline workflows, and deepen integration with manufacturing ecosystems.

"Kitov AI 2.9 is a testament to our commitment to continuous innovation and our dedication to providing manufacturers with the most advanced and intuitive inspection tools available," said Bob Wasilesky, President Kitov AI America. "With the addition of our upgraded AI Engine, Fanuc robot connectivity, advanced multi-sensor capabilities, and a refined user experience, Kitov AI 2.9 empowers our customers to achieve unparalleled levels of quality, efficiency, and flexibility in their production lines."

Key Enhancements in Kitov AI 2.9 Include:

- Kitov AI Trainer Updated to Newest AI Model: Staying at the cutting edge of artificial intelligence, Kitov AI 2.9 integrates the latest advancements in AI models into its AI Trainer. This update has been trained on a significant amount of new real-world defects, ensuring superior defect detection, enhanced learning capabilities, and even greater accuracy in identifying anomalies on complex parts. By future-proofing your AI investment, it guarantees that you and your customers benefit from the newest AI innovations on an ongoing basis.

- Fanuc Robot Connectivity – Premier Robot Partner Integration: This highly anticipated feature establishes Kitov AI as a premier partner with Fanuc, offering seamless and robust integration with Fanuc robots. Manufacturers can now leverage the full power of Kitov AI's inspection capabilities directly within their Fanuc robotic cells, simplifying deployment and optimizing performance.

- All-New Multi-Sensor System: Integrating Enhanced Quality Inspection and Measurement in One: Kitov AI 2.9 introduces a sophisticated multi-sensor workflow that seamlessly integrates a second inspection tool—for deeper evaluation of dimensions, features, or surface roughness, for example, enabling true AI-driven multi-sensor measurements. By combining data from various sensors, this innovation delivers comprehensive inspections and a complete, accurate assessment of product quality.

- AI-Powered Dynamic Measurement of Defects: In an industry first, stop defects in their tracks by detecting them and dynamically building and executing a second-tool robotic measuring plan. This enables in-depth analysis of discovered defects for 100% detection and measurement, including depth, surface roughness, and high-resolution point clouds.

- AI Robot Path Optimization for Difficult Surfaces (Non-Planar or Not Flat): Adjust Coverage for Quality or Efficiency: Addressing the challenges of inspecting intricate geometries, this new optimization allows users to precisely adjust inspection coverage for non-planar surfaces. Manufacturers can now prioritize either exhaustive quality assurance or maximized inspection efficiency based on their specific needs.

- Refreshed User Interface – Easier to Use: User experience is paramount, and Kitov AI 2.9 features a completely refreshed user interface. Designed for intuitive navigation and streamlined workflows, the new UI is lighter and more efficient, which makes it easier than ever for operators to set up, manage, and analyze inspection tasks.

- Digital Twin with QIF: Embracing the power of digital transformation, Kitov AI 2.9 now supports Quality Information Framework (QIF) for digital twin initiatives. This enables seamless exchange of inspection data within a digital twin environment, fostering advanced analytics, model embedded results and measuring plans for MBD and Industry 5.0 PLM.

- CAD-2-Scan - SolidWorks CAD Plugin – Seamless Integration of Kitov AI and SolidWorks: To further enhance design-to-inspection workflows, Kitov AI 2.9 includes a dedicated SolidWorks CAD Plugin. This allows for seamless integration between Kitov AI's inspection planning and SolidWorks design files, drastically reducing setup time and improving accuracy. And more CAD plugins are planned for future versions.

Kitov AI 2.9 is available now to all existing customers for pre-release purchase, as always free to all with an active maintenance plan.

Kitov AI

https://kitov.ai/

Koslow Scientific Alloy Ranger TE-4000

Koslow Scientific introduced the Alloy Ranger TE-4000 — a leap forward in portable alloy sorting and metal verification. Designed for industrial use, the Alloy Ranger delivers rapid, one-handed identification of stainless steels, tool steels, titanium, aluminum, and more — including low alloy and specialty grades. Equipped with Sort-By-Color™ technology, this next-generation thermo-electric sorter eliminates costly metal mix-ups by quickly distinguishing alloys, even when parts are plated or coated. Ideal for aerospace, medical, fabrication, and power generation sectors, the TE-4000 inspects turbines, pipes, tanks, and wire — regardless of size or shape. The lightweight, rugged device features a rechargeable battery, PC-exportable test results, and an intuitive digital interface. Whether you're verifying material before critical welds or inspecting incoming stock for compliance, the Alloy Ranger makes metal testing simple, fast, and accurate — no X-rays, no spark, and no waiting. Koslow invites QA managers, engineers, and material inspectors to experience the new standard in handheld alloy testing.

Koslow Scientific

www.koslow.com

GARDCO RTM Digital Micrometer

Paul N. Gardner USA (GARDCO) announces its new offering the new RTM Digital Micrometer with the comprehensive RT Kit option.

Accurate surface profile measurement is critical for ensuring coating adhesion, corrosion resistance, and compliance with industry standards. The GARDCO RTM Digital Micrometer delivers precision and repeatability, reducing the risk of costly rework and ensuring the long-term performance of protective coatings. Its advanced features and intuitive operation make it an indispensable tool for technical professionals in manufacturing, engineering, and quality assurance

The GARDCO RTM Digital Micrometer, engineered specifically for technical professionals and engineers is built for use with Testex Replica Tape, the industry’s trusted method for measuring blasted steel and textured coating profiles. The instrument streamlines the entire process, from measurement to data management, ensuring reliable, standards-compliant results every time.

“Our new RTM Digital Micrometer sets a new benchmark for precision and reliability in surface profile measurement—making it easier than ever for engineers and inspectors to achieve consistent, standards-compliant results in any environment,” states James Fusco, Product Manager, Paul N. Gardner Company (GARDCO). This next-generation digital micrometer sets a new standard for accuracy, efficiency, and ease of use in surface profile measurement.

Key features and benefits:

- Made in the USA: Designed and manufactured to the highest quality standards

- Custom-designed: Designed to be the optimal tool for measuring replica tape, and makes taking measurements and creating reports easier than ever

- Durable Construction: All-metal housing ensures long-term reliability in demanding industrial environments.

- Efficient Power: Operates on a single AAA battery for maximum convenience in the field.

- Time Required for Replicas: Less than 30 seconds required for most replicas

- Dual-Unit Measurement: Instantly switch between microns and mils for maximum flexibility in any workflow.

- Bright Digital Display: A high-contrast color screen with large numerals ensures visibility in all lighting conditions, reducing operator error and fatigue.

- Robust Data Management: Built-in memory stores up to 250 readings with on-screen statistics. Export data directly to any computer via USB—no software installation required. Data is retrieved in .csv format for seamless reporting and archiving.

- Automated Calculations: Select the appropriate replica tape grade, and the micrometer automatically applies the correct conversion factor and subtracts the 50 µm (2 mils) backing thickness, eliminating manual calculation errors.

- International Standards Compliance: Features an “Average mode” that prompts users to average two readings, fully compliant with ASME B46, ASTM D4417, ISO 8503-5, NACE SP287, SSPC-PA 17, SP5, SP6, SP10, SP11-87T, and more.

- Traceable Calibration: Each unit includes a Certificate of Calibration for quality assurance and audit compliance.

The RT Kit Option is designed to provide technical professionals and engineers with a complete, ready-to-use package for accurate surface profile measurement using Testex Replica Tape. This all-in-one kit includes the GARDCO RTM Digital Micrometer, three cartons of replica tape in Coarse, X-Coarse, and X-Coarse Plus grades, a High Accuracy Burnishing Tool, a classic burnishing tool, an instruction manual, a USB cable for easy data export, a Certificate of Calibration for traceability, one AAA battery, and a custom carrying case for convenient transport and storage. By bundling all essential components, the RT Kit ensures users have everything needed for precise, standards-compliant measurements right out of the box, making it an ideal solution for quality control engineers, inspectors, and technical professionals in the field.

Paul N. Gardner USA (GARDCO)

https://www.gardco.com/Products/Surface-Profile-Testers/Testex-Digital-Micrometer/c/p-102523?variant=15446