With a trained deep machine learning algorithm, manufacturers can perform 100% inspection instead of sample inspection. By Jay Elepano

AI Transforms Patient Safety and Tackles Labor Shortages in Medical Manufacturing

Medical

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Management

H2 Deck Info By Paragraph Style Bold

Headline

A microscopic defect slips through inspection undetected by even the most experienced technician. On the operating table, that mistake could make the difference between recovery and risk. In medical manufacturing, there is no margin for error. Yet, like many sectors of manufacturing, the industry is challenged with labor shortages and rising complexity. Developments in artificial intelligence (AI) offer a solution, acting as an extension of human expertise that allows manufacturers to do more with limited labor and time while also improving patient safety and production resilience.

Addressing skilled labor shortages while reducing human error and subjectivity

Humans possess natural intelligence — a powerful capability that allows us to learn, reason, adapt, and solve problems. While our natural intelligence gifts us the ability to perceive, memorize, learn, reason, create, and understand emotions, it is also deeply tied to biological needs and limitations, leading to variation from one individual to another. One technician may have better eyesight than the other. Fatigue after a long day can cause errors. Another technician may have more training and experience than others. Factors like these contribute to subjectivity and inaccuracies.

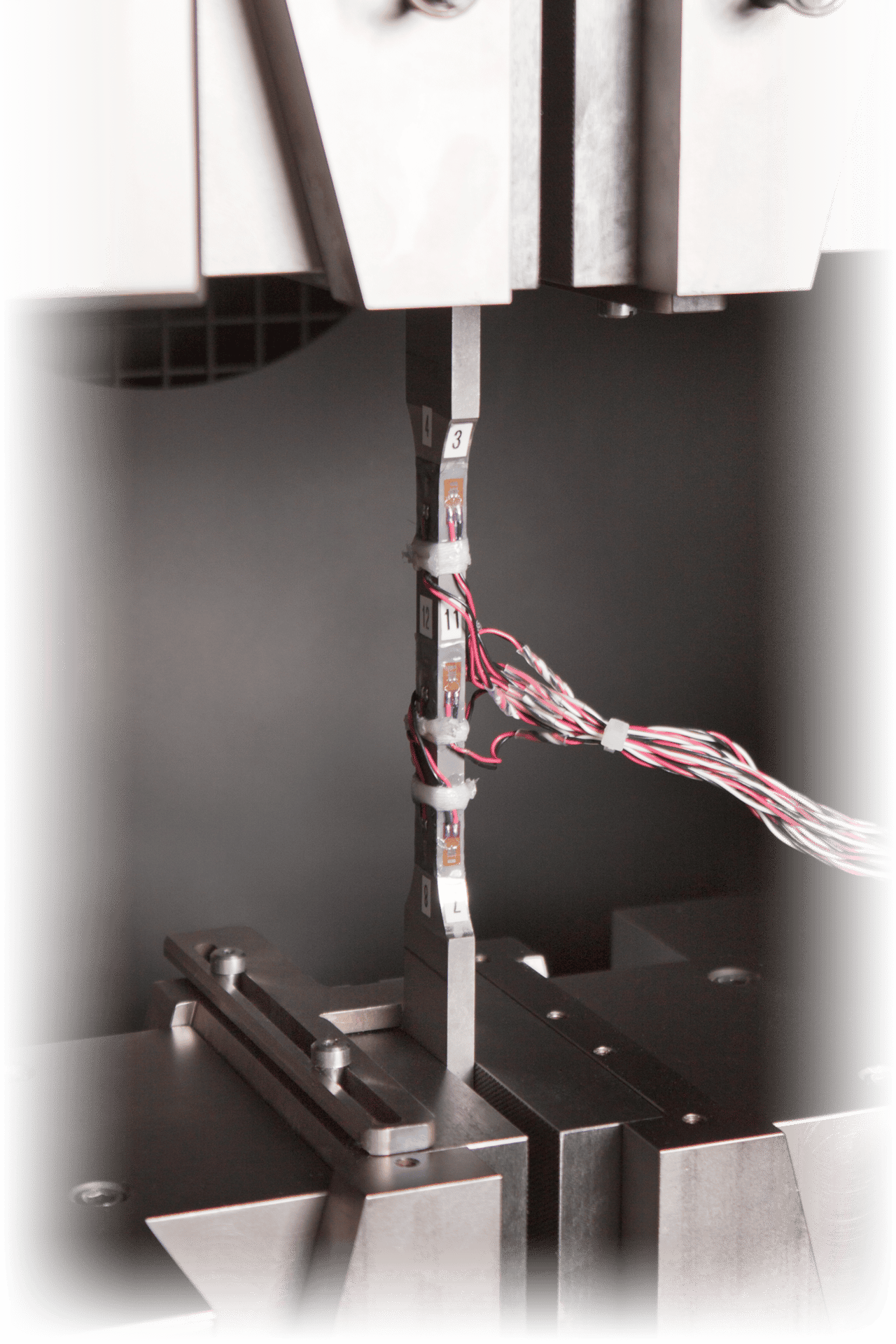

Augmenting inspection with deep machine learning algorithms addresses these issues by recognizing features, colors, and defects automatically. To teach these models, hundreds of sample images are given to software that uses deep machine learning algorithms. These samples train the algorithm to recognize defects and features. The software is also taught why something is not good by learning to recognize a specific defect or discrepancy. Next, samples are put into the algorithm to test its intelligence. In the first iteration, it might be 60% correct. The samples it identifies incorrectly are used to further train the algorithm by teaching it why it was incorrect. This process is repeated until the algorithm meets the application’s needs.

Implementing AI for automatic defect detection has become easier with recent advancements in intelligent inspection software. These developments enable domain experts with no to limited AI expertise to apply a pre-trained algorithm to images without requiring additional training, allowing for a faster ramp-up with fewer resources – a key advantage in an era where a well-trained workforce is scarce.

ZEISS CT scanning technology offers a way to see inside of critical medical components to ensure safety and quality.

ZEISS Automatic Defect Detection (ZADD) augments inspection with deep machine learning algorithms to recognize features, colors, and defects automatically.

Enhancing patient safety through more precise and consistent quality control

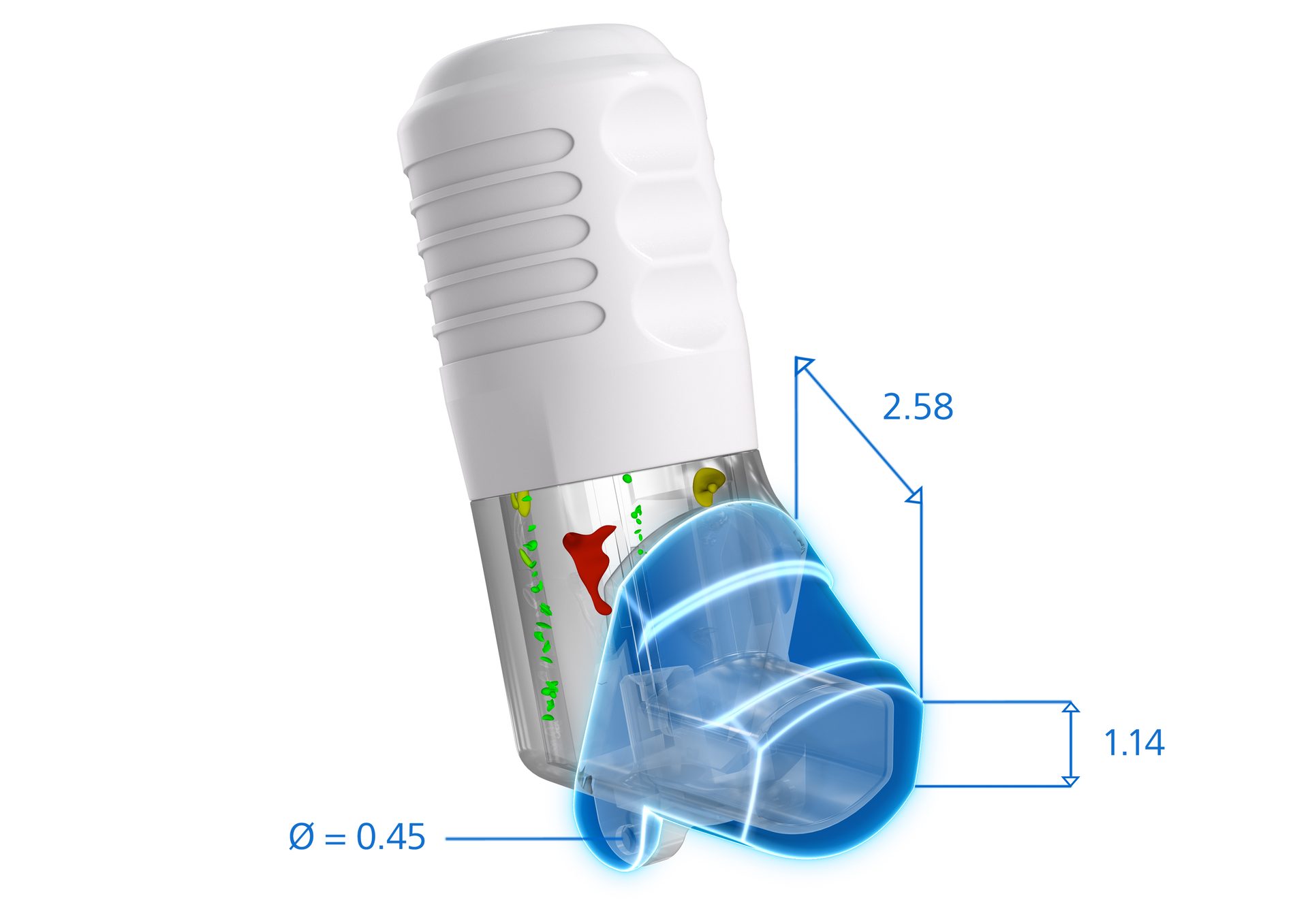

With a trained deep machine learning algorithm, manufacturers can perform 100% inspection instead of sample inspection. This improvement brings life-saving benefits to patients. Consider an inhaler. Inside an inhaler, there are small pouches where medication is stored. As the patient operates the device and takes an inhale, the mechanism clicks over to one of the pouches, and the patient inhales the corresponding medication. Inspecting each inhaler is crucial to ensure that the correct amount of medication is available to the patient when needed.

Internal inspection with a CT scanner confirms whether each pouch contains the correct amount of medication. Feeding CT scan data into a trained deep machine learning algorithm increases inspection speed and efficiency by eliminating the need for an inspector to review each dataset. By increasing inspection speeds through this process, manufacturers gain the capacity to perform 100% inspection instead of sample inspection, thereby increasing patient safety through greater product reliability.

This advantage also applies to syringes. Typically, these medical devices come in a tub with a top that has several holes. The holes contain an empty but fully assembled syringe. Each syringe is hermetically sealed to preserve cleanliness. The challenge is that once the seal is broken, the syringe is no longer sterile. So, how can the manufacturer determine if the syringe meets quality standards and is safe to load medication into?

Historically, manufacturers rely on process stability and check this by inspecting samples periodically. Keeping up with inspection is often a struggle due to the lack of skilled labor and variation from inspector to inspector. However, CT technology enables manufacturers to verify quality specifications, including the presence and condition of the needle and plunger, before filling the syringe with medication, without breaking the seal. Paired with deep machine learning algorithms, this method increases production efficiency and patient safety by enabling fast, 100% inspection prior to the product leaving the facility – a critical advantage in an industry where a recall can be catastrophic.

This benefit also extends to the operating table. Imagine a surgeon goes into surgery. When it’s time to stitch up the patient, the surgeon chooses to use a surgical stapler – a common choice that works well, provided it does not jam or misfire. Assuming that each staple is correctly positioned in the cartridge with the right shape and form, it will perform without malfunction. Once the staple cartridge is sealed, CT scanning technology provides a way to visualize its contents to ensure their safety and quality.

However, hundreds of these surgical staples are manufactured and assembled into cartridges by the minute. This level of volume is a challenge for CT technology alone, but when paired with deep machine learning capabilities, multiple cartridges can be measured simultaneously in the measuring plot. Deep machine learning algorithms can separate this large volume of CT scan data into its individual cartridges, then separate them into individual staples, and subsequently perform measurements and inspections to determine if the staple is bent or present. Manufacturers can instruct the AI-based inspection system to automatically split a large volume of CT data, then apply each set to a coordinate system and slice it according to a specification. Then, the software runs those slices through the algorithm, enabling manufacturers to quickly understand which pass and which fail. This method empowers manufacturers to keep up with production while also achieving a reliable 100% inspection. As a result, surgeons can provide a safer experience without the risk of misfire on the operating table.

ZEISS CT technology paired with deep machine learning algorithms increases production efficiency and patient safety by enabling fast 100% inspection prior to the product leaving the facility.

Dramatically reducing inspection times

AI is also dramatically reducing inspection times, allowing manufacturers to get more done with fewer resources. One example comes from medical implant production. Certain implants are coated with a specific texture that promotes binding to human tissue, facilitating the body’s acceptance of the implant. The coating must meet regulated porosity requirements and undergo regular quality checks to ensure compliance. Traditionally, this workflow requires an operator to manually pick and measure distinct metrics of a sample with a microscope. The operator uses a stereo microscope to take pictures of all the locations where the texture is visible. Then, a trained inspector reviews each of them and determines what passes and what does not. This manual process typically takes 45 to 60 minutes to evaluate a single coating.

An AI-based inspection solution can reduce this process to just seven minutes by extracting the necessary metrics from the data automatically. This improvement allows the process to move from data acquisition to results and report generation up to ten times faster. In addition to increasing throughput and efficiency, it also enables technicians without specialized skills or training to perform this critical inspection work, helping to ease the strain caused by the skilled labor shortage.

ZEISS CT technology allows manufacturers to check quality specifications of drug delivery devices, including whether the needle and plunger are present or bent, before putting medication inside the syringe and without breaking its protective seal.

Conclusion

AI is making improved quality control more accessible in medical manufacturing by automating inspection processes and enabling faster, unbiased decision-making. In doing so, it helps supplement a shrinking pool of skilled labor by allowing less specialized technicians to perform critical tasks. By enhancing quality, AI supports the production of safer medical products, aligning with one of the core goals of quality assurance: ensuring safety. With these advancements, quality is helping to make the operating table just a little safer.