H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

measurement

Today’s manufacturers require more than visual checks or basic dimensional verification. By Chrysee Bollon

Gear Inspection Has Come a Long Way Since the 1920s

measurement

H2 Deck Info By Paragraph Style Bold

Headline

Gear inspection has undergone profound transformation since the early 20th century. What began as rudimentary evaluations for high-precision gears in the 1920s has evolved into a sophisticated discipline defined by standardized protocols, advanced instrumentation, and integrated digital ecosystems. This evolution—driven by industry demands for higher precision, traceability, and automation—continues to redefine quality assurance in gear manufacturing.

From Standards to Smart Systems

In the 1960s, the American Gear Manufacturers Association (AGMA)—established in 1916—formalized quality expectations by introducing gear classification standards. By the late 1980s, these culminated in the American National Standard defining 13 quality classes (Q3 through Q13). These classifications provided a measurable framework for tolerances, ensuring interchangeability, performance consistency, and design reliability.

Today’s manufacturers require more than visual checks or basic dimensional verification. Gears must meet tightly defined tolerances for parameters such as profile, helix, pitch, and runout—parameters essential to ensuring function under load, particularly in automotive, aerospace, and energy applications. Accurate measurement is no longer optional; it is a fundamental requirement in modern production environments.

Caption

CMMs: From Dedicated Tools to Hybrid Platforms

Coordinate measuring machines (CMMs) have played a pivotal role in dimensional metrology since the 1950s. By the 1970s, manufacturers began employing CMMs to measure gear geometries. This shift offered significant advantages: repeatability, flexibility, and the ability to measure both prismatic and gear components. However, limitations persisted—gear-specific measurements often required dedicated machines, and switching between inspection modes could be cumbersome and inefficient.

This challenge led to the development of hybrid CMMs. These systems integrate the precision and flexibility of conventional CMMs with the specialized functionalities of gear inspection equipment. Hybrid platforms offer rotary tables, tailstocks, and advanced software tailored for gear geometries, enabling inspection of gears, shafts, rotors, and prismatic parts within a single, unified environment.

The result: improved efficiency, reduced manual intervention, lower capital investment, and minimized equipment footprint. Such systems are now shop-floor capable, designed to withstand temperature variation and vibration while maintaining micrometer-level accuracy.

Caption

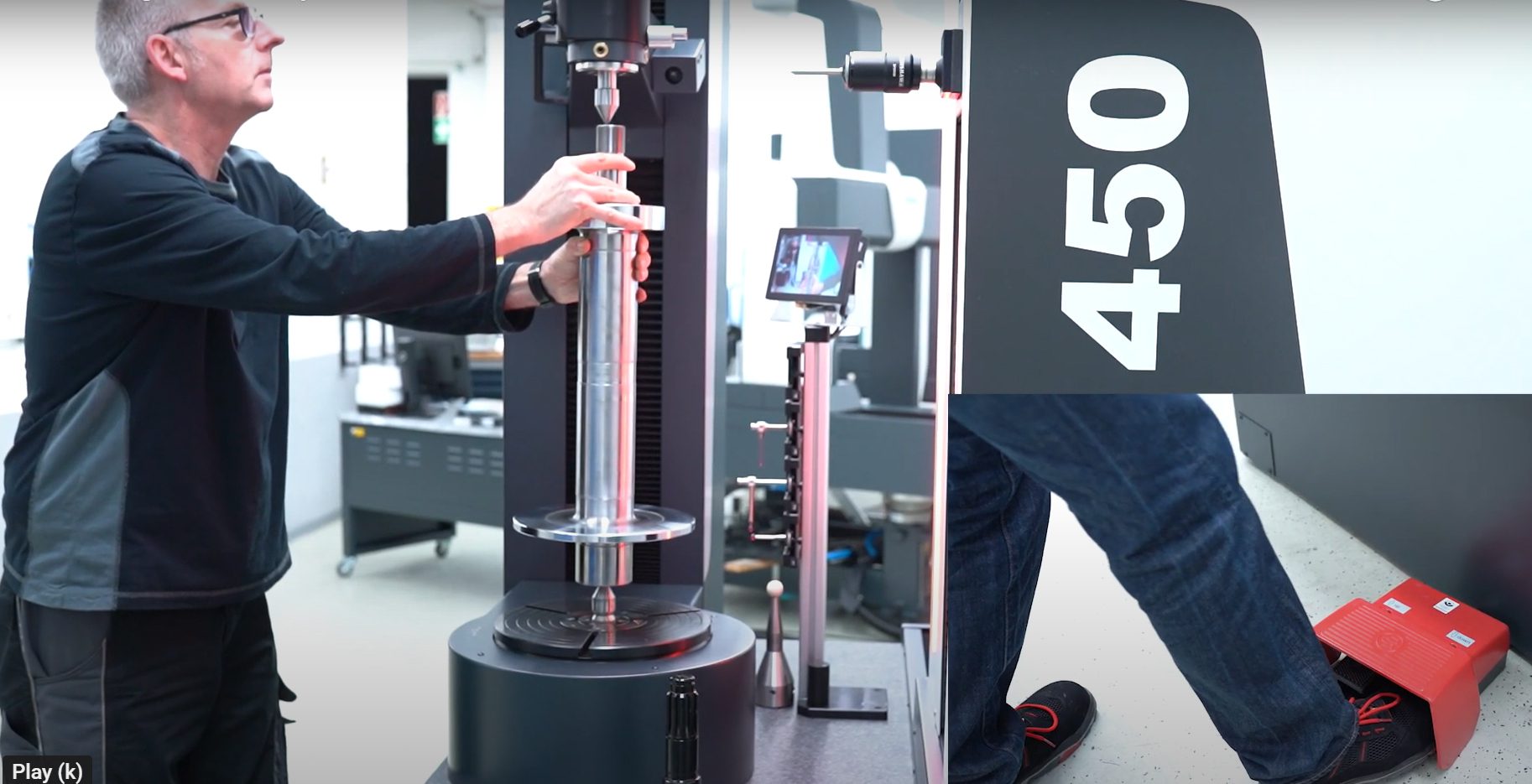

Advances in Dedicated Gear Inspection

While hybrid systems gain traction, traditional dedicated gear inspection machines have also seen remarkable improvements. Enhanced mechanical stability, air-bearing technology, and full granite structures provide thermal consistency and vibration dampening. High-speed scanning, modular architecture, and automated features—such as motorized counter holders and foot-pedal operation—enable these machines to support high-throughput environments without sacrificing accuracy.

Multi-sensor configurations and ergonomic designs have improved usability and serviceability, while intelligent design allows manufacturers to adapt systems to evolving inspection needs. These enhancements are particularly relevant in sectors demanding continuous operation and quick changeover between parts.

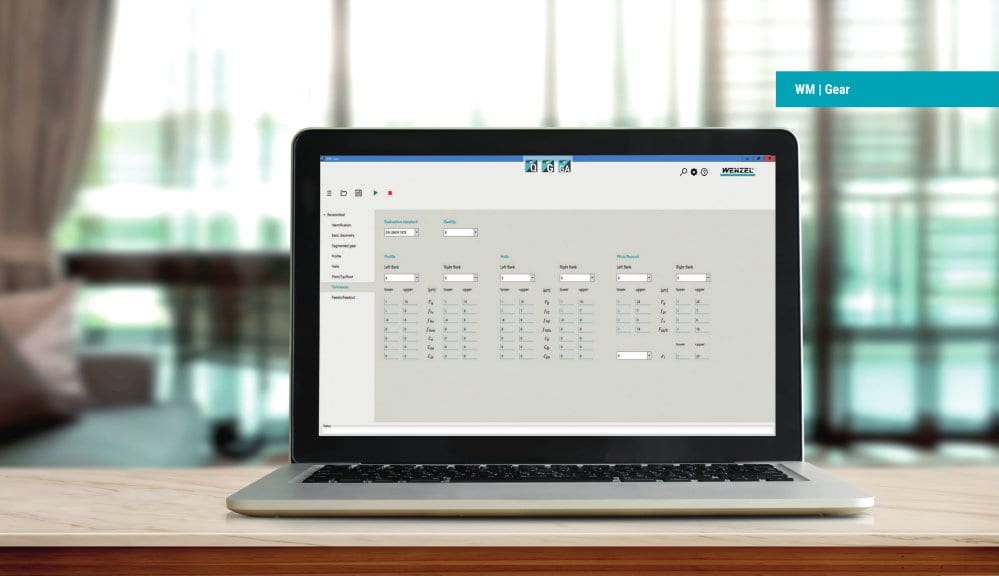

Software: The Brain Behind Precision

Perhaps the most transformative leap has occurred in software. Modern gear metrology software offers intuitive interfaces that support both novice users and experienced operators. It enables simultaneous execution of gear and GD&T (Geometric Dimensioning and Tolerancing) inspection tasks. Integrated evaluation of involute profiles, pitch deviations, and form tolerances occurs in tandem with housing and structural component measurement—all within a single program sequence.

State-of-the-art platforms facilitate real-time trend monitoring, statistical process control (SPC), and remote diagnostics. With capabilities for cloud-based support, machine monitoring, and predictive maintenance, today’s software closes the loop between production and quality assurance.

Further, support for fully automated cells—including robotic part handling and automatic probe exchange—positions gear inspection as a key pillar in the broader movement toward Industry 4.0 and lights-out manufacturing.

Caption

Key Considerations When Selecting Inspection Systems

Selecting the right gear inspection solution involves more than comparing specifications. Manufacturers must evaluate their gear sizes, production volumes, tolerance classes, and integration requirements. Critical questions include:

- Will the system meet throughput and repeatability goals?

- Can it inspect both high-runner production gears and mission-critical components?

- Does it support your team’s training and operational needs?

- Is it scalable and serviceable over a 10–20 year lifecycle?

Evaluating total cost of ownership—including calibration, maintenance, and downtime risk—is essential. So too is assessing the vendor’s commitment to long-term gear metrology expertise and support.

Looking Ahead

As gear inspection evolves, the trajectory is clear: toward greater automation, more flexible platforms, and deeper integration with digital manufacturing ecosystems. Non-contact inspection methods, real-time feedback loops, and AI-enhanced evaluation represent the next frontiers.

We believe that progress in gear metrology is not only about better measurements—it’s about enabling better manufacturing. Whether through hybrid inspection platforms or high-throughput dedicated systems, the tools we build today are helping define the gear performance of tomorrow.