CSIA guest column

Dan Blount

CSIA guest column | Dan Blount

Drift analysis is the process of evaluating the instrument's performance over an established period of time.

What Causes Measurement Equipment to Drift?

According to NIST, drift is defined as a slow change in the response of a gage. If your measurement equipment drifts outside of its specifications, it may lead to inaccurate measurement data, impacting critical product performance and ultimately leading to product recalls. Unfortunately, drift can occur over time just by using the equipment like normal.

Some likely causes include:

- Sudden changes in temperature and humidity

- Misuse, mishandling or poor preventative maintenance

- Sudden mechanical or electrical shocks, like dropping a device

- Exposure to corrosive substances or extreme temperatures

- Frequent or prolonged use

- Equipment age and degradation of components

- Improper transportation, shipping or storage

Caption

What is drift analysis?

Drift analysis is the process of evaluating the instrument’s performance over an established period of time. Depending on the instrument type and whether it is adjustable determines the method of evaluation. For adjustable instruments, the preferred way is to compare the As Left values of the previous calibration to As Found of the current calibration. This isolates the interval for the evaluation. If it’s a non-adjustable instrument, such as a ring gage or gage block, you can compare the reported value of the previous calibration to the reported value of the current calibration to evaluate drift.

Whether you are evaluating As Left of previous calibration to As Found of current calibration or As Found to As Found, the important thing to remember is that you want to isolate the time element and then evaluate the instrument’s change or performance over the established interval. By knowing the instrument specifications, you can then establish the probability or likelihood it will fall outside of limits for subsequent calibrations. You can also make a more informed decision about calibration frequency.

The standard provides a systematic approach to sampling without overtaxing resources.

Drift analysis is the process of evaluating the instrument's performance over an established period of time.

Another approach, to identify adjustment trends, would be to perform a quick analysis by comparing As Found to As Left on the current calibration report. You should also evaluate previous calibration reports to look at adjustment patterns or trends over the assigned interval. If the adjustments were made to correct an out of tolerance result, you may want to shorten the calibration interval to ensure that it doesn’t go out of tolerance between calibrations. Adjustments may also be preventative: made proactively in an effort to ensure the instrument will fall inside of specifications at the next calibration. The focus here is the amount of adjustment relative to the specification.

By actively evaluating drift, adjustment trends and establishing effective intervals, you will reduce your risk of using an out-of-tolerance measurement device, which in turn can help to raise the quality of your product. This same approach can also be used in the justification process for lengthening a calibration interval, saving both time and money. If you find that a piece of equipment rarely or never needs to be adjusted and/or the evaluation of drift provides evidence of stability over the lengthened interval, then you likely have all that you need to make an informed decision.

So how do I get started?

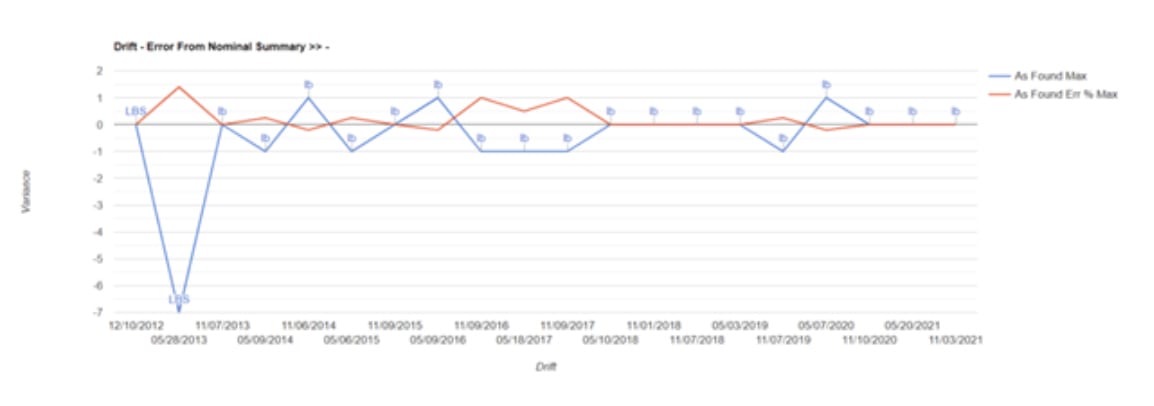

Most calibration software packages use real data from your calibration events to create charts showing your equipment’s’ drift trends over time. These charts can be easily viewed within the equipment record, giving you the information you need to make informed decisions about calibration frequency, maintenance, and eventual replacement.

In addition to helping with calibration frequency, drift analysis can also facilitate predictive maintenance of your gages, extending their useful life, which reduces replacement costs.