Products

the latest products to help you improve your manufacturing process

IDS Imaging 10GigE Cameras

In industrial automation, the optimization of processes is often primarily about higher efficiency and accuracy. 10GigE cameras, such as those in the uEye Warp10 camera family from IDS Imaging Development Systems GmbH, set standards here. They enable high-speed image processing in Gigabit Ethernet-based networks even with large amounts of data and over long cable distances. For even more precision, the company is now introducing new models with sensors up to 45 MP that reliably capture even the smallest details.

The new industrial cameras are equipped with the onsemi global shutter sensors XGS20000 (20 MP, 1.3"), XGS30000 (30 MP, 1.5") and XGS45000 (45 MP, 2"). They are primarily used in high-precision quality assurance tasks when motion blur needs to be minimized and data needs to be quickly available on the network. The 10GigE cameras offer up to ten times the transmission bandwidth of 1GigE cameras and are about twice as fast as cameras with USB3 interfaces.

Accuracy and speed go hand in hand when it comes to these models. This has advantages for many applications, e.g. in inspection systems for status and end checks at production lines with high cycle rates–such as semiconductor or solar panel inspection. Users also benefit from the fact that even large scenes and image sections can be precisely monitored and evaluated with these cameras. This proves its worth, for example, in logistics tasks for incoming goods and in the warehouse.

The large format onsemi XGS sensors require correspondingly large optics. Therefore, unlike the previous uEye+ Warp10 models, they are equipped with a TFL mount (M35x0.75). For secure mounting, TFL lenses can be firmly screwed to the cameras. The flange focal distance is standardized and, at 17.526 mm, the same as for the previously available cameras with C-mount. To ensure optimal image quality, IDS recommends the use of Active Heat Sinks. They can be mounted both on and under the models, reduce the operating temperature and are optionally available as accessories.

IDS Imaging

https://en.ids-imaging.com/ueye-warp10.html

B&K Precision Handheld Digital Oscilloscopes

B&K Precision announced its latest iteration of handheld oscilloscopes, the 2510B Series. Comprised of four models, this new line of dual-channel oscilloscopes includes 100 MHz and 200 MHz bandwidth models. For industrial applications, the 2515B and 2516B provide full isolation between all inputs and safety ratings of 1000 V CAT II and 600 V CAT III. For general electronic applications, the 2511B and 2512B provide the same feature set in a non-isolated design and at a more affordable price point.

All models in the 2510B Series offer a maximum sample rate of 1 GSa/s, 12 Mpts memory depth, a built-in 6000-count DMM with dedicated terminals for voltage measurements, and scope/meter trend plot functions for logging measurement data over time. Capture and record up to four voltage or time-related parameters such as period, pulse width, and rise time from the scope input, or plot any one of the DMM’s measurements, including DC/AC voltage and current, resistance, capacitance, diode, and continuity test.

Additional features include a 5.6” color display with refresh rates of up to 100,000 waveforms per second, a sequence mode for capturing pulse waveforms, and serial bus decoding for SPI, I2C, UART, CAN, and LIN protocols. A side panel USB host port is available for saving instrument setups, waveform data, and screenshots to a USB flash drive.

Weighing approximately 3.8 lbs. with the included rechargeable Li-ion battery, non-isolated and isolated models provide up to 5-½ and 4 hours of continuous battery operation, respectively. All models are backed by a standard 3-year warranty.

B&K Precision Corporation

www.bkprecision.com

NewDEL Fiber-Coupled LED sources

LumeDEL LLC introduces the NewDEL™ Fiber-coupled LED sources that are designed to generate high radiant power with spectrally stable output and combining high performance with ease-of-use. NewDEL™ LED sources can be highly effective replacements for lasers and lamps in many applications for scientific and industrial applications such as spectroscopy, optogenetics, photodynamic therapy, fluorescence excitation and photocatalysis.

LumeDEL’s NewDEL™ fiber-coupled LEDs include 17 narrowband models with peak wavelengths from the UV to the near-IR spectral regions, as well as two white light LEDs and a continuum source. The models offer complete configurability, from a continuous operating mode to pulsed or triggered modes, so that users at any level can set up a light source ideally suited to their needs.

A NewDEL fiber-coupled LED is a compact, fully integrated product. Each NewDEL incorporates its own driver and microcontroller circuitry. A separate driver/controller module is not required. Operation of a NewDEL can be performed through a feature-rich Windows-based GUI or personally programmed using distinct serial commands.

LumeDEL LLC

www.lumedel.com

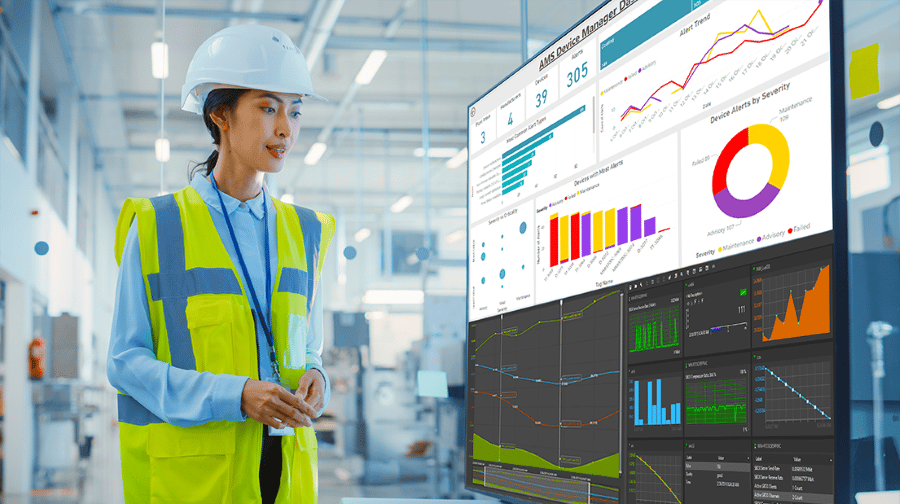

Emerson Data Management Software

Emerson is helping process manufacturers improve performance and sustainability by breaking down the data silos that make it difficult to digitally transform their reliability and maintenance strategies. AMS Device Manager Data Server securely extends intelligent field device data to outside systems to make it easier for reliability and maintenance teams to further capitalize on modern advanced analytics software, providing a step change in operational efficiency and smart manufacturing.

For decades, process manufacturers have relied on asset management software to carefully deploy and monitor plant production assets – like measurement and analytical instrumentation, digital valve controllers, wireless gateways, and others – both within a single plant and across the enterprise. As plants have evolved, they’ve grown their technology stack to adopt a wide range of analytics, historians, machine learning, and advanced modelling to exploit and benefit from historically underused or inaccessible datasets from around the plant. AMS Device Manager Data Server publishes intelligent field device data nearly instantaneously to industrial software analytics solutions already in use by customers, eliminating the need for complex custom data integration and manual workarounds that often cause delayed results and siloed data. This data is relayed via secure industry protocols.

AMS Device Manager Data Server makes it easy to import critical instrument and valve data into common dashboarding tools and applications like Microsoft PowerBI, Emerson software tools such as the Plantweb™ Optics platform, Plantweb Insight, Aspen MTell® and AspenTech Inmation™, plant historians and others.

Emerson

www.Emerson.com

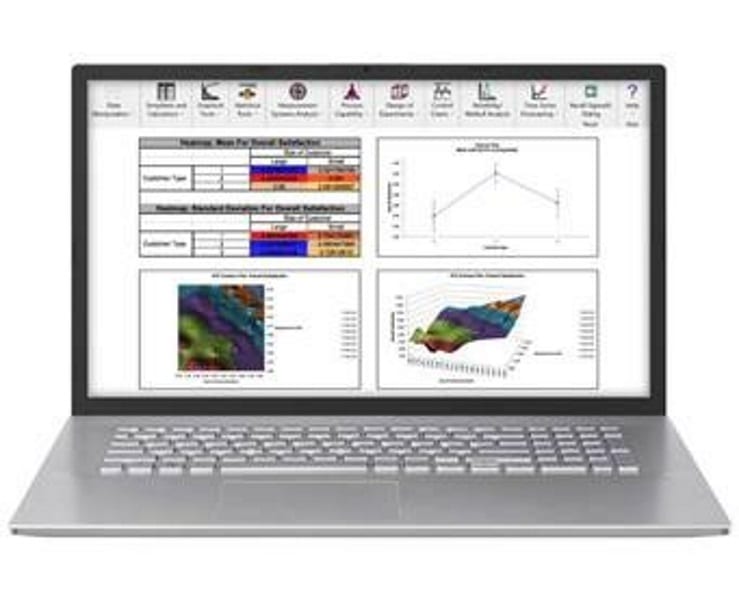

SigmaXL Version 10

SigmaXL was designed from the ground up to be a cost-effective, powerful, but easy to use tool that enables users to measure, analyze, improve and control their service, transactional, and manufacturing processes. As an add-in to the already familiar Microsoft Excel, SigmaXL is ideal for Lean Six Sigma training or use in a college statistics course. Version 10 adds selection guides, powerful new graphical tools and General Linear Modeling.

New features in Version 10 include:

- Graphical Tool Selection Guide

- Hypothesis Test Selection Guide

- Revised Control Chart Selection Guide

- New Data Manipulation Tools

- Convert Raw Data to Frequency (Tally)

- Convert Frequency to Raw Data

- New Graphical Tools

- Heatmap

- Interval Plots and Multiple X Interval Plots

- Empirical/Normal Cumulative Distribution Function (CDF) Plots

- XYZ Contour/Surface Plot

- New Statistical Tools

- Nonparametric Friedman and Friedman’s Exact

- Nonparametric Two Sample Kolmogorov-Smirnov (KS) Test and KS Exact

- General Linear Model (GLM). Extends Advanced Multiple Regression to include:

- New Measurement Systems Analysis (MSA) Templates

- GLM GageRR (Crossed) Metrics with/without Interaction

- GLM GageRR (Nested) Metrics

- GLM GageRR (Expanded) Metrics

- Orthogonal (Deming) Regression

SigmaXL

www.SigmaXL.com

CAPTURE 3D ZEISS ATOS LRX 3D Scanner

CAPTURE 3D, a ZEISS company, announced the ZEISS ATOS LRX—a new large-volume 3D scanning sensor with an ultra-bright laser light source that captures up to 2 × 12 million coordinate points with one scan, quickly delivering precise, full-field data from very large parts. With a measuring area of up to four square meters, the ZEISS ATOS LRX is ideal for applications such as aerospace structural components like fuselage, wings, wing ribs, and tail, MRO, automotive design, tool making, and crash testing, machine building, marine propellers, rotor blades and molds, and wind turbine housings.

The ZEISS ATOS LRX is a complete solution for applications requiring rapid, high-quality 3D data and large-volume measurement beyond what conventional fringe projection systems, laser trackers, and laser radars provide. By delivering large-volume digitalization quickly, the ZEISS ATOS LRX closes a gap in the metrology industry not yet met by current technology. Designed for industrial applications, the ZEISS ATOS LRX includes robust sensor housing to protect against dust and water splash allowing it to work reliably and precisely even in harsh production environments. With this development, industries like heavy casting, shipbuilding, aerospace, automotive and wind energy can now measure very large parts quickly and efficiently.

The ZEISS ATOS LRX draws upon proven ATOS 5X technology by utilizing an extremely bright blue laser light source generated by an advanced integrated laser light compressor, creating a uniform, non-coherent, speckle-free light resistant to ambient light conditions. The light projects over a measuring area spanning 2000 x 1600 mm for short exposure times, even for dark or shiny surfaces. Like existing sensors in the ATOS 5 lineup of blue light 3D scanners, the ZEISS ATOS LRX quickly captures high-resolution data with precision and detail, including complex geometrics and freeform surfaces.

The ZEISS ATOS LRX utilizes a class 2 laser for maximum operator safety. An integrated sensor uses radar to monitor the safety distance to the user, automatically reducing the luminous intensity as necessary if the distance is not maintained or if it detects movement in the critical area. The safe laser protection class 2 allows the 3D scanner to operate without further protective measures. The projector light can also be reduced to utilize interactive features such as a touch probe, live tracking and back projection.

The ZEISS ATOS LRX features the new HyperScale software function designed for fast on-site calibration and the compensation of undesired effects of temperature changes. A calibration cross CC50/2000 that remains folded together for easy setup is included. A single measurement of a DAkkS-certified length standard completes sensor calibration, and the sensor self-monitors its calibration status throughout scanning.

Users complete scanning, inspection, and reporting in the ZEISS ATOS LRX software within GOM Inspect Pro, a part of the ZEISS Quality Suite. The software supports 3D scanning and inspection processes by providing detailed analyses and reporting functions. Users can control the sensor by computer or remote control.

CAPTURE 3D, a ZEISS company

www.capture3d.com

DÜRR NDT DRIVE NDT, D-Tect X

For an optimal digital workflow in radiographic testing (RT), the X-ray inspection software D-Tect X can be integrated with the NDT management software DRIVE NDT. The closely meshed interaction between DRIVE NDT and D-Tect X means that a large part of the process takes place automatically. This not only saves time, but the automatic exchange of data also minimizes the possibility of human error. As all the steps and processes performed are digitally traceable, it additionally provides high levels of transparency.

Once an order is received by DRIVE NDT, the associated inspections can be scheduled. When an RT-D inspection is started in DRIVE NDT, the order data such as order number, customer and location, together with the inspection details such as the test object, measuring point and testing instructions, are retrieved by D-Tect X before the inspection begins. It is also possible to individually submit extra data that is relevant for a specific test report. This way, all the inspectors involved will have all the information they need to carry out the inspection. No doubts remain about who should test what, when, how and with what equipment.

After evaluation of the digital X-ray images in D-Tect X, all the inspection results can be automatically transferred to DRIVE NDT with one click. By linking the imported results with the order data, it is now possible to create a test report effortlessly, which can then be forwarded to the responsible Level 3 for approval.

For new users of D-Tect X it is now even easier for them to become familiar with DRIVE NDT. Each new license offers a test period of one year with DRIVE NDT Lite free of charge. This way means that users can convince themselves of its advantages without obligation. Of course, RT-F inspections can also be managed in DRIVE NDT, but all the benefits of automation can only be fully exploited with digital radiographic testing.

There are now no barriers for digitizing the entire RT workflow, and with DRIVE NDT and D-Tect X, it has never been so easy and efficient.

DÜRR NDT

https://www.duerr-ndt.com

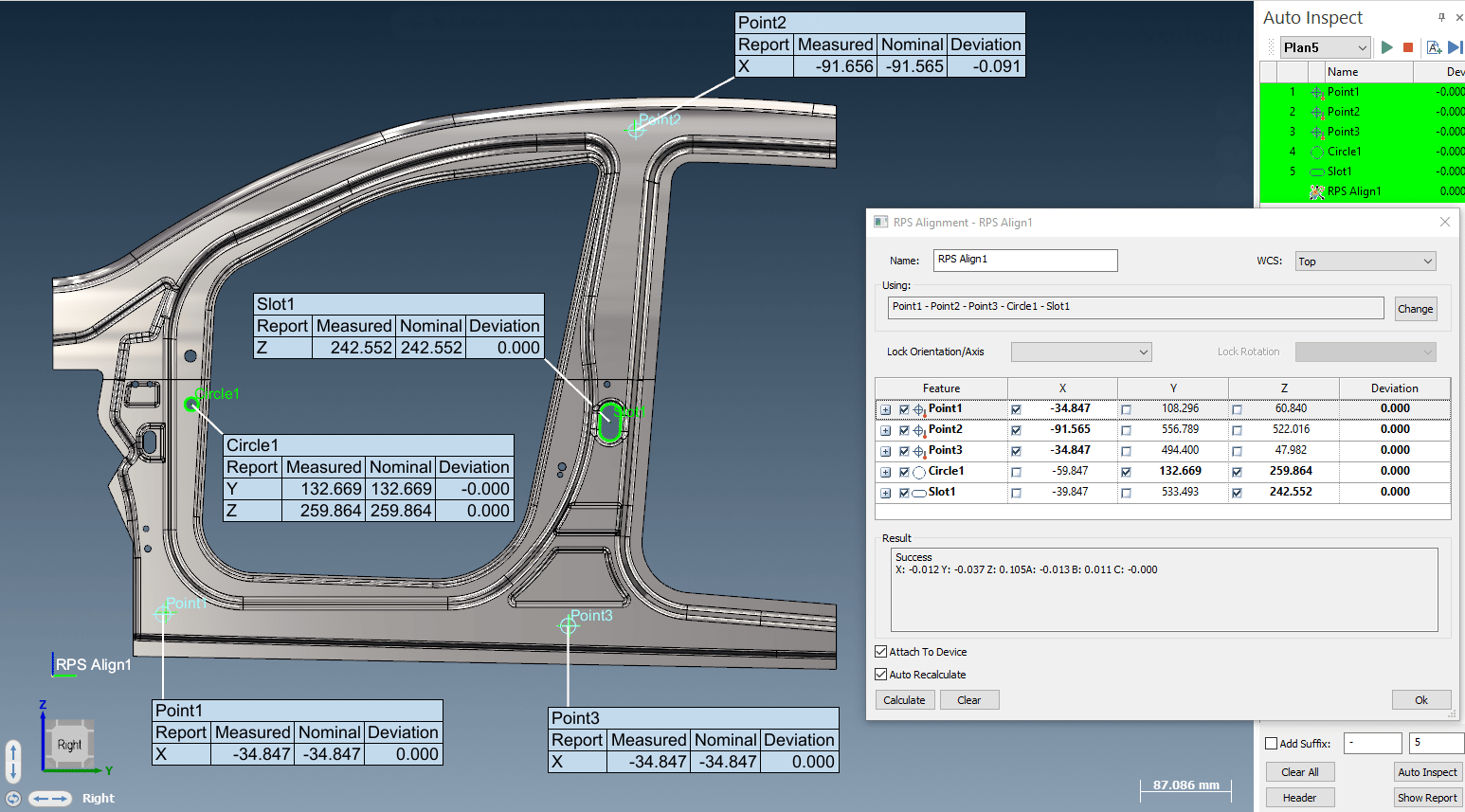

Verisurf 2024 Software

Verisurf Software, Inc., announces its 2024 software release providing new productivity workflows, powerful tools, enhanced functions, and expanded sensor and device compatibility, all designed to better connect metrology and manufacturing for global success. This new release is now available for download directly from the Verisurf Website, where all new and existing customers with current maintenance agreements can access it. With the release of Verisurf 2024, the Company continues its commitment to user-friendliness, stability, flexibility, and intelligent workflows, enhancing efficiency, quality, and throughput while keeping pace with emerging technologies and growing industry requirements.

Verisurf 2024 includes nearly one hundred new productivity workflows, enhancements, and additions. The software empowers users with a universal solution that supports all 3D metrology applications, complemented with expert technical support, training services, and application consulting for seamless integration, optimal process improvement, and better resource utilization.

The new Verisurf 2024 release has many new productivity tools, workflows, feature enhancements, and expanded sensor and device compatibilities; here are a few highlights:

- New RPS (Reference Point System) Alignment accelerates part alignment with precise control, seamlessly connecting measured points to the referenced nominals. RPS Alignment is crucial to complying with alignment strategies often required by the automotive industry.

- New Measure Filters provide real-time outlier removal from tactile scan data, including removal of start and end points, distance, waviness, UPR (Undulations Per Revolution), and Sigma.

- New Extract to Plan is a simple one-button solution to extract geometric features and surface profiles within scanned data. Users can select All Features, Selected Features, or Features Defined by MBD (Model Based Definition) and automatically extract and add the features and surface profiles along with associated GD&T reference data to an Inspection Plan.

- Enhanced Global Register provides quick and robust registrations and refinements of multiple datasets, including Cloud to Cloud, Cloud to Mesh, Mesh to Mesh, Cloud to CAD, and Mesh to CAD.

- Enhanced 3D Mesh Controls support the generation of high-quality Meshes from Clouds, including registration refinements, smoothing, and more.

- New Auto Align Controls enable greater flexibility and power, including alignment to targets in any order, use of gravity plane, and constraining to the highest datum surface target value to comply with industry standards.

- Verisurf 2024 has integrated two additional sensors for the REVO® 5-Axis Multi-Sensor System. The SFP2 (Surface Finish Solution) and RUP1 (REVO Ultrasonic Probe). Verisurf currently supports the RSP2, RSP3, SFP2, and RUP1 REVO 5-Axis Sensors.

Vision Engineering New Generation Mantis Stereo Microscope

Vision Engineering announces the launch of Mantis 3rd Gen of its best-selling and award-winning Mantis range of ergonomic optical stereo microscopes.

The new Mantis generation range (PIXO, ERGO, and IOTA), incorporates Vision Engineering’s renowned patented ergonomic technology along with the latest developments in optics, digital cameras, and fully adjustable LED lighting, keeping Mantis at the forefront of stereo imaging.

New features include: improved optics for both hand-to-eye coordination and excellent depth perception, a 3-position turret to house up to 3 objectives ranging from 3x to 15x, the introduction of an 8x super long working distance lens, five different illumination options providing flexibility to optimize the lighting to view the perfect image, and the Mantis PIXO offers an improved, higher resolution camera for image and video capture. The system also features an option to switch between white light and UV light using a toggle switch.

Mantis PIXO, Mantis ERGO, and Mantis IOTA feature the revered long working distances associated with Mantis which are needed for soldering, rework, and manipulative tasks when tools are required. The new systems are designed with Vision Engineering’s unique eyepiece-less technology that delivers a large, high-quality optical stereo image, making it more comfortable and easier to view than traditional microscopes. Like the generations before, Mantis 3rd Gen is manufactured in the U.S.A.

The Mantis 3rd Gen comes with a range of new stand options and accessories to allow for greater flexibility, stability, and a reduced footprint on the workstation.

Mantis is designed for precision engineering, electronic engineering, medical device manufacture, and a wide range of other applications that require high-quality images and superior ergonomics. Mantis is used in tens of thousands of R&D, manufacturing, and analytical sites around the world.

Mantis 3rd Gen is now available for purchase directly from Vision Engineering or through a network of authorized distributors.

Vision Engineering

https://www.visioneng.us/mantis

OMRON MicroHAWK F440-F 5MP C-Mount Smart Camera

OMRON has announced the launch of the new OMRON MicroHAWK F440-F Smart Camera. This highly configurable smart camera with a 35 frame-per-second 5-megapixel monochrome global shutter sensor brings exceptional performance to virtually any machine vision application.

The F440-F boasts a host of features that make it a standout solution in the industry. Its C-mount lens compatibility and support for external lighting options allow users to optimize their imaging setup. Additionally, the F440-F's compact size positions it as the smallest smart camera in its class, ideal for space-constrained environments. OMRON's intuitive AutoVISION setup tool allows for quick and easy configuration of highly complex applications, empowering users to achieve optimal imaging performance in a fraction of the time.

What sets the F440-F apart is its compatibility with existing systems. It is pin-compatible with the MicroHAWK F430-F smart camera, ensuring a clear upgrade path without the need for complex rewiring. Ensuring seamless integration and connectivity, the MicroHAWK F440-F supports various communication protocols, including Digital I/O, RS-232, Ethernet TCP/IP, EtherNet/IP™, and PROFINET. Power options are equally flexible, with the F440-F supporting both Power over Ethernet (PoE) and direct 24V power supply.

OMRON Corporation

http://industrial.omron.eu