The U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) has awarded $3.7 million in grants to help address current and future barriers to widespread adoption of metals-based additive manufacturing (AM) through measurement science research.

NIST Awards Nearly $4 Million to Support Metals-Based Additive Manufacturing

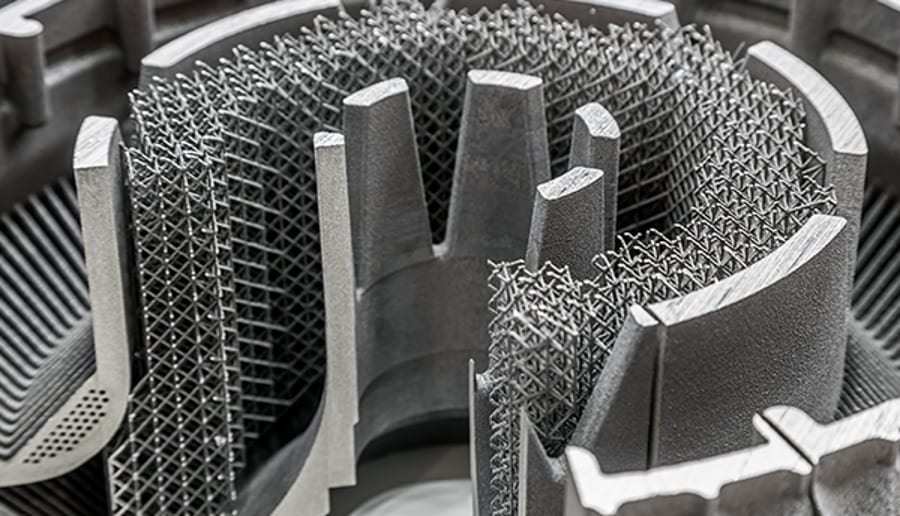

Credit: OlegDoroshin/Shutterstock

“The U.S. can take a leading role in developing the measurements and international standards that will help accelerate adoption of these important 3D-printing technologies,” said Under Secretary of Commerce for Standards and Technology and NIST Director Laurie E. Locascio. “To compete globally, we need to invest in programs such as this that bring together our best minds in industry, academia and government to solve important technical challenges.”

Additive manufacturing typically creates parts and components by building them layer by layer, based on a 3D computer model. Most metals-based additive processes form parts by melting or sintering material in powder form.

“Additive manufacturing offers advantages such as reduced material waste, lower energy intensity, reduced time-to-market, and just-in-time production that could bolster supply chains in the U.S.,” said Locascio. “Accelerating the adoption of new measurement methods and standards will help to advance U.S. competitiveness in this important industry.”

Through its own research and with these grants, NIST is addressing barriers to adoption of additive manufacturing, including measurement science to support equivalence-based qualification and model-based qualification, the characterization of AM materials, and standards to support consistent data exchange/characterizing new advances in AM production systems.

“Accelerating the adoption of new measurement methods and standards will help to advance U.S. competitiveness in this important industry.” —NIST Director Laurie E. Locascio

The following organizations will receive NIST Metals-Based Additive Manufacturing Grants Program funding to be spent over two years:

The Research Foundation for the State University of New York (Albany, New York) — $957,706

The goal for this project is to demonstrate an enhanced nondestructive evaluation (NDE) technique that can determine key material properties such as oxide thicknesses, splatter particle percentage, grain size and defect detection.

Colorado School of Mines (Golden, Colorado) — $956,888

This project will examine new optical metrologies to enable real-time process feedback and control to achieve process-based qualification and certification of metallic parts made by AM.

Auburn University (Auburn, Alabama) — $949,075

The goal of this project is to establish a data-driven framework with computer vision and machine learning for the nondestructive qualification of AM materials and parts for applications that cannot afford failures due to fatigue.

General Electric, GE Research (Niskayuna, New York) — $873,999

GE Research teamed up with GE Additive and the University of Texas at El Paso (UTEP) to establish the Intelligent Stitch Integration for Testing and Evaluation (I-SITE) program to extend existing standardized methods and build correlations between sensor response, material behavior and mechanical properties.

For more information, visit www.nist.gov.

Viking Plastics Continues Streak of Outstanding Quality Performance

Viking Plastics announced it has yet again been honored with receiving the 2021 GM Supplier Quality Excellence Award. The SQEA is reserved only for the top performing suppliers around the world. This special recognition includes 134 suppliers from 16 different countries. The 2021 award is particularly meaningful as Viking Plastics persevered through one of the industry’s most challenging years, showing resilience and reinforcing their commitment to sustainability and innovation.

The company has received this award nine out of the past 10 years. “We are honored to receive the GM Supplier Quality Excellence Award for eight years running now,” says Bob Senz, Corporate Quality Manager. “The dedication of the entire team at Viking Plastics through a difficult year to continue delivering quality processes resulting in quality product is amazing. This award reaffirms our commitment to quality, continuous improvement, and superior customer service.”

For more information, visit www.vikingplastics.com.

Next-Generation OEM Objectives Enable Engineers to Develop the Scientific Instruments of Tomorrow

Evident, a new wholly owned subsidiary of Olympus comprised of its former Life Science and Industrial divisions, released new objectives for OEM integrators and Olympus industrial microscopes that combine a high numerical aperture and long working distance, providing exceptional flexibility in various inspection applications.

Objective lenses are crucial to a microscope’s performance. New MXPLFLN series objectives are manufactured using novel lens polishing technology, so more lenses can fit in each objective housing. This enables users to view high-resolution, high-magnification images at 20X and 50X while maintaining a 3 mm working distance. When inspecting three-dimensional objects—like circuit boards or semiconductor wafers—there is less chance of the objective hitting the sample and causing damage. Four objectives are available in this series: brightfield 20X and 50X and brightfield/darkfield 20X and 50X.

Integrators can choose from a variety of objective and tube lens combinations to simplify their system requirements. For added speed and flexibility, a new 2.5X brightfield/darkfield objective has been added to the popular MPLFLN series. Complementing the objectives, Evident’s lineup of OEM tube lenses has been expanded. Each has different transmittance and other characteristics to accommodate a variety of applications.

Directional darkfield—also called MIX illumination—is a unique observation method that enables users to combine darkfield with brightfield, simple polarized light or fluorescence observation at the same time. The newly released type 2 MIX slider that enables directional darkfield has a removable filter, expanding the variety of lighting colors.

For more information, visit www.EvidentScientific.com.

Nano Dimension Acquires Admatec and Formatec, Creating Metal & Ceramic Additive Manufacturing Portfolio

Nano Dimension Ltd. announced that it has signed and closed a definitive agreement to acquire Formatec Holding B.V (“Admatec/Formatec”), which includes its two subsidiaries - Admatec Europe B.V. (“Admatec”) and Formatec Technical Ceramics B.V. (“Formatec”).

Admatec/Formatec, based in the Netherlands, is comprised of two complementary businesses operating together, which were part of the U.S.-based Precision Surfacing Solutions. It is a leading developer and manufacturer of additive manufacturing and 3D printing systems for ceramic and metal end-user parts. Its industry-grade systems - powered by digital light processing technology - use materials with superior mechanical, electrical, thermal, biological, and chemical properties to produce an array of parts for medical, jewelry, industrial, and investment casting uses. Admatec/Formatec’s industrial production service division is a design-to-production partner for industrial-scale customers via its service bureau platform that combines the advantages of injection molding and additive manufacturing. Both means of production have served as a strategic advantage in working with customers, from early-stage ideas into serial production of end-use parts.

Admatec/Formatec has shown promising financial results under strenuous circumstances of its parent company, indicating that accelerated growth based on its innovative technology can be expected. The business delivered $5.3 million in revenue with a gross margin of 56% in 2021. Nano Dimension has paid a total cash sum of $12.9 million for Admatec/Formatec (net of its cash).

By joining Nano Dimension, Nano Dimension believes that Admatec/Formatec are now poised for even greater success within the Industry 4.0 landscape, which Nano Dimension is at the forefront of transforming with its combination of deep learning-based AI, additive manufacturing, materials science, and robotics. This expertise is planned to enable advanced breakthroughs across the Admatec/Formatec set of solutions and expected to drive tremendous competitive edges for customers.

Nano Dimension’s go-to-market platform is geared to accelerate and broaden the reach of Admatec/Formatec’s products and services to growing markets, particularly in the United States and Europe, where a tailwind of macro trends is driving demand for additive manufacturing (AM) while onshoring and localizing high-mix low-volume manufacturing.

With Admatec/Formatec, Nano Dimension will add two critical aspects to its offering in the AM domain: Materials and new product types. Materials have and will continue to be the bedrock of a successful AM offering. Nano Dimension is already leading in materials science thanks to the breakthroughs in driving additively manufactured electronics with both conductive and dielectric materials. Now, Nano Dimension will also benefit from ceramic and metals – two critical materials for developing applications and end-use parts. To date, Nano Dimension has focused on AME and Micro-AM. As the Company advances, offering new Admatec/Formatec product types will harness the ability for customers to print larger parts – going in size from millimeters to multiple centimeters/inches. This is all further enhanced by the combination of possibilities for Nano Dimension with 3D-Addititve Manufacturing integrated with Metal Injection Molding.

Jaco Saurwalt, chief operating officer of Admatec/Formatec, who is joining Nano Dimension as the head of its Admatec/Formatec Division, commented, “The teams across Admatec and Formatec are excited to become a part of Nano Dimension. We are proud of how we have developed this business and are convinced that we shall be able to expand and accelerate our growth based on our present technology and services. We expect that the combined expertise with Nano Dimension will further establish a leading position in the high-mix-low-volume metal 3D-AM production markets.”

Yoav Stern, chairman and chief executive officer of Nano Dimension, shared, “Admatec/Formatec’s scientists, engineers and other team members, all of whom joined Nano Dimension upon closing of this transaction, are experts and industry veterans in AM 3D-industrial processes. They are going to continue to be led by their present management team.” Mr. Stern added, “Admatec/Formatec’s products and services expand Nano Dimension’s Fabrica Division, adding volume manufacturing capabilities to the high precision micro-mechanical Fabrica 2.0 systems.”

“No less important,” Stern concluded, “is our intention to use our deep learning-based artificial intelligence technologies, from our DeepCube acquisition, to become the “robotic brains” for Admatec/Formatec systems. We expect this will improve yield and throughput and drive a more seamless integration with Nano Dimension’s Fabrica systems. Admatec/Formatec’s machines and services fit the larger picture of Nano Dimension’s vision, aiming to establish “Industry 4.0” solutions, which entail building an AI-based “distributed digital manufacturing application” rather than just machines as capital equipment. The end goal is to reach a capability for maintaining digital inventory of high-end printed mechanical parts in digital form: print them as you need them, where you need them, only the quantity you need, in the best quality at competitive prices, with the highest yield and throughput possible for that point in time, specifically for high mix/low volume scenarios.”

For more information, visit www.nano-di.com.