Quality 101

Lean 101:

An Introduction to Lean Manufacturing

Lean is about learning to see opportunities and continually improving them.

By Tim McMahon

Lean manufacturing (or thinking) can help companies gain a competitive advantage. The core idea is to maximize customer value while minimizing waste (and not compromising productivity).

Lean is more than a specific tool, management technique or software package. Lean is creating and implementing processes that are highly responsive to customer demand. Lean paves the way for delivery of high quality products and services, at the right location, at the right time, all in a cost effective manner.

Ideally, the new processes optimize all parts of the value chain so that you do more with less—less labor, capital, and time.

Lean Principles Provide a Framework

Lean Thinking is comprised of five fundamental principles that provide a framework for creating an efficient organization:

Specify Value – End-use customer view

Identify Value Stream – Activities that create value

Flow – Make value flow

Pull – Respond to customer demand

Perfection – Zero waste

Lean is Customer First; what is value in the eyes of the customer? What features do they want? When do they want them and at what price? Without this information, how can you design your ideal system?

This value needs to flow from raw materials through to the consumer. This is Just In Time manufacturing (JIT), producing what the customer wants when they want it!

Next you strive for perfection, improving everything that you can about the product and process.

This is done by all within your organization, Lean values respect for people, and involves everyone to help meet customer value.

Create Value, Eliminate Waste

Lean is a systematic way to see the inefficiencies and address these to grow the business. To make processes more efficient and move closer to the value stream, we use lean thinking.

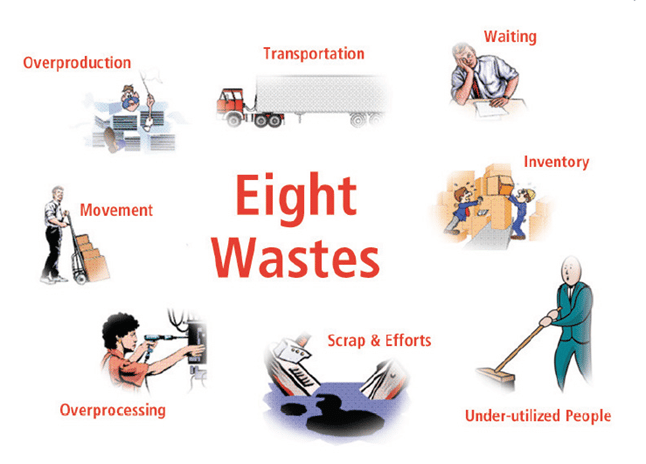

There is a handy acronym for knowing the eight types of waste: “Tim Woods.”

Transportation

Transporting items or information that is not required to perform the process from one location to another. While the product is moving, no value is added to it.

Inventory

Inventory and information queued-up between people and processes that are sitting idle not being processed.

Motion

Excess movement by people or equipment only consumes time and resources without producing value. People, information or equipment making unnecessary motion due to workspace layout, ergonomic issues or searching for misplaced items.

Waiting

Idle time created when material, information, people, or equipment is not ready. No value is added while people wait for product to process or product waits for people or machines.

Over-Processing

Performing any activity that is not necessary to produce a functioning product or service. Doing more than what is necessary to generate satisfactory value as defined by the customer.

Overproduction

Waste from producing product that is not currently needed or product that is not needed at all.

Defects

Products or services that are out of specification that require resources to correct. Defects are the result of executed processes that did not produce value.

Skills

The waste of underutilized intelligence and intellect commonly referred to as behavioral waste. When employees are not effectively engaged in the process.

Source: Tim McMahon.

Lean Rules Create a System

Lean rules provide the guidance to improve, explaining the “why” behind the tools. For everyone in an organization, these rules help structure activities, connect customers and suppliers, specify and simplify flow paths, and bring improvement through experimentation.

The principles of the Lean used to provide value can be summarized into four basic rules:

Activity Rule – Specify all work to content, sequence, timing, and outcome.

Connection Rule – Customer-supplier connections must be direct & unambiguous.

Pathway Rule – Pathways for product/service must be simple & direct.

Improvement Rule – Improvements are made using scientific method (PDCA) at place of activity (Gemba) under the guidance of a teacher (Sensei)

These principles are the building blocks of a Lean production system. They allow organizations to gain maximum efficiency so everyone can contribute at or near his or her potential. When the parts come together the whole is much, much greater than the sum of the parts.

The Benefits of Lean Manufacturing

In most scenarios, Lean can offer manufacturing companies:

Higher-quality products with fewer defects and rework

Lower levels of inventory

Higher levels of stock turnover

Fewer breakdowns of equipment and processes

More output

Better delivery performance

Greater profits

Happier customers

Enhanced and stronger relationships with vendors

More engaged workers

All these benefits are even more critical in the pandemic with the major disruptions to manufacturing.

For me Lean is a thinking methodology for running your business. The goal is to grow the business by adding value to the customer, eliminating waste, and engaging all employees in this process. Lean is about learning to see opportunities and continually improving them.

Opening Image Source: Smederevac / iStock / Getty Images Plus via Getty Images.

Tim McMahon is an operational excellence leader, author, and blogger. As a Lean practitioner, he brings more than 20 years of leadership experience implementing Lean manufacturing. McMahon has held a number of leadership positions within operations management, Lean, and quality disciplines of innovative high tech manufacturing companies. He is the founder and principal contributor of A Lean Journey Blog, a site dedicated to sharing lessons and experiences regarding Lean thinking, improvement practices, and leadership. By drawing on his experience in Lean, Six Sigma, and Quality Management Systems he co-authored ASQ's Lean Handbook, an educational reference guide to support Lean Certification.

Scroll Down

Scroll Down