H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Software & Analysis

Explore how forward-thinking manufacturers are moving beyond AI’s shiny promises to create smarter, more efficient, and proactive quality operations. By Gerben de Haan

From Hype to High Impact:

The Practical Role of AI in Quality Management

Software & Analysis

H2 Deck Info By Paragraph Style Bold

Headline

The manufacturing world today is awash in promises of “AI-powered” solutions. Booths at trade shows, sales emails, and webinars all sing the same tune—AI will revolutionize quality management. But while the buzz is deafening, clarity is rare. What does AI actually mean for manufacturing quality? How can organizations move from empty promises to real value?

This article invites you to move past the buzzwords and focus on what matters: how AI can transform quality management from a compliance-driven necessity to a strategic driver of manufacturing excellence.

The Hype Trap: Tools without purpose

AI, at its core, is just another technology—like databases or front-end frameworks. As users, we don’t select systems based on the underlying technology; we choose them because they solve problems. Yet, too often, vendors position AI as the solution itself rather than focusing on the problems it solves.

The question manufacturers should be asking isn’t “Is this AI-powered?” but “Does this solution deliver measurable improvements?” Whether AI is used to reduce error-prone manual tasks, uncover hidden insights in data, or streamline workflows, its value lies in outcomes, not features.

As a customer once said, “I don’t care if it’s AI, machine learning, or an army of hamsters running on wheels—I care that it solves my problem.”

From compliance tool to strategic partner

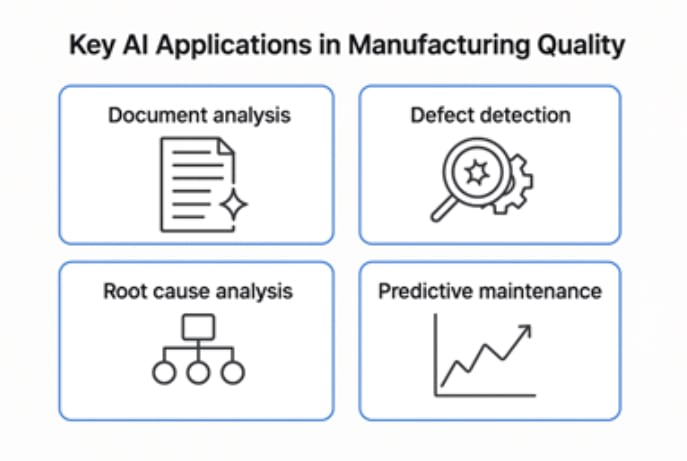

The real promise of AI lies not in its complexity but in its ability to transform quality management into a strategic function. AI-driven systems are evolving from passive data collectors to active participants in the quality process:

- Generative AI offered the first glimpse—drafting procedures, summarizing reports, but lacking context.

- Retrieval-Augmented AI learned to ground its output in real-world data, integrating organizational knowledge into its answers.

- Agentic AI, today’s frontier, doesn’t just respond—it reasons, decides, and acts. Imagine AI systems that proactively identify quality risks, recommend corrective actions, and even prepare for audits, all while learning from every interaction.

In this paradigm, software is no longer just a tool; it becomes a virtual team member—an assistant that knows your processes, adapts to your needs, and supports your team.

Breaking barriers to a Culture of Quality

Traditional QMS solutions often present barriers to broader engagement. Complex interfaces, steep learning curves, and rigid workflows mean only specialists truly leverage them. AI changes that.

With natural language interfaces, users can simply ask, “Show me last quarter’s customer complaint trends,” or “What’s our calibration procedure for mixer #3?”—and get instant, contextual answers. This simplicity:

- Expands participation beyond the quality team to production supervisors, maintenance staff, and operators.

- Reduces resistance by making quality systems intuitive and user-friendly.

- Enhances decision-making by surfacing insights and eliminating manual data wrangling.

Quality no longer needs to be the exclusive domain of specialists. It becomes an organization-wide priority embedded in daily operations.

Laying the foundation: Start digitizing today

Many manufacturing organizations are still managing quality processes with paper-based systems or Excel spreadsheets. This reliance on manual tracking creates bottlenecks, increases the risk of errors, and limits the ability to scale operations or respond quickly to changing requirements.

Digitization is not just a first step—it’s an essential one. Without it, the potential of AI to deliver measurable improvements remains out of reach. Consolidating and centralizing quality data into a single source of truth enables organizations to unlock AI’s capabilities—automating routine tasks, surfacing hidden insights, and proactively addressing risks.

Manufacturers don’t need to overhaul their entire quality system overnight. Start by digitizing key processes, such as nonconformance tracking or supplier document management. Gradually, expand to include broader quality functions and related operational data. This incremental approach builds confidence and creates momentum for further AI-enabled improvements.

If you’re still managing critical quality information with spreadsheets and paper files, now is the time to lay the digital foundation. Digitizing quality processes today sets the stage for AI-driven transformation tomorrow.

Real-World Impact: From data overload to actionable insights

Consider manufacturers wrestling with mountains of unstructured data—supplier certificates, audit reports, customer complaints. Manual processing is time-consuming, error-prone, and demotivating.

AI can change the game by:

- Automating data extraction and comparing certificates against specifications, reducing processing times from 15 minutes to one minute per batch.

- Identifying hidden patterns in deviations and suggesting effective corrective actions, cutting investigation times by over a third and slashing repeat issues by nearly 30%.

- Optimizing audit schedules based on dynamic risk assessments, shifting focus from calendar-based audits to risk-driven priorities.

In each case, the technology isn’t the story—the outcome is: faster, more reliable, more impactful quality management.

Building trust and managing limitations

Of course, AI isn’t perfect. It can hallucinate—producing plausible but incorrect outputs—especially if not grounded in organizational data. That’s why we must approach AI not as an oracle but as a junior team member: one that needs guidance, validation, and oversight.

The key is balance. Use AI to handle repetitive tasks and surface insights, but keep human expertise at the helm to interpret, validate, and decide. Over time, as AI systems prove reliable, we can trust them with greater autonomy.

A journey, not a destination

AI’s role in manufacturing quality isn’t about flashy technology. It’s about continuous improvement, addressing real-world challenges, and driving better outcomes for operations, customers, and employees.

The future-ready quality organization will use AI not as a gimmick but as an enabler:

- From reactive to proactive: AI anticipates risks and acts before issues escalate.

- From siloed to integrated: Quality data connects with operational, supply chain, and customer insights.

- From enforcer to enabler: Quality teams shift from compliance gatekeepers to strategic advisors.

Getting started

If you’re wondering where to begin, don’t overcomplicate it. Identify a specific pain point—whether it’s automating data extraction, surfacing hidden patterns, or improving audit readiness—and tackle it with a targeted AI application. Build trust, measure impact, and expand from there.

As manufacturers, we don’t need to chase the AI trend. Instead, let’s focus on using AI to solve real problems, improve operations, and build a culture of quality that drives our businesses forward.