Products

the latest products to help you improve your manufacturing process

Emergent Vision Technologies EROS 10GigE Camera Models

Emergent Vision Technologies is announcing that all models of the groundbreaking EROS 10GigE camera series are now officially shipping. According to the company, originally launched in December 2024, EROS is the smallest, lowest power 10GigE camera in the world.

“Thirty-nine new cameras across color, mono, SWIR, polarized, and UV sensors are now available for our customers to innovate with,” said John Ilett, president and founder of Emergent. “EROS is for the existing 10GigE users who want to modernize, as well as an entry point for those just beginning to need the speed and resolution provided by 10GigE cameras.”

“Best of all, EROS delivers this performance at a price more commonly seen with 2.5 or 5GigE cameras. This opens the door to many applications that were previously limited by not only GigE Vision camera performance, but cost, heat generation, or space requirements,” adds Ilett.

Multi-camera applications were the focus of EROS’ development. Machine vision applications across several industries call for multiple cameras generating high-speed, high-resolution imagery in real-time, such as sports broadcasting, manufacturing inspection, volumetric capture/VR applications, and AI-powered computer vision and deep learning.

Multi-camera applications using EROS can be built in Windows or Linux systems — it uniquely supports both — using Emergent’s eCapture Pro or eSDK Pro software. Both applications use NVIDIA’s GPUDirect to send the data directly to the GPU memory, without copies and without latency. In multi-camera setups, this allows computationally intensive processes such as real-time compression via H.264/H.265 to be mapped directly to the GPU efficiently, with low loss and without detours.

Key Data About the EROS 10GigE Camera Series:

- Compact—Each EROS camera measures just 29 x 29mm. Engineers can replace existing 1, 2.5, and 5GigE cameras with no mechanical changes.

- Energy-efficient—EROS 10GigE cameras only use 4.8 W via RJ45 PoE, 4 W via RJ45 with no PoE, and just 3 W over SFP+ fiber. This is lower than many popular 2.5 and 5GigE cameras.

- Flexible Interfaces—Native support for 10GigE with auto negotiation down to 5, 2.5, and 1GigE. EROS adjusts automatically to network speed.

- Compliant—Certified to the GigE Vision 3.0 and RDMA standards.

- Advanced Sensors for Speed and Resolution—Gen 4 Sony Pregius S CMOS sensors deliver resolutions from 0.5 MP up to 24.5 MP, powering frame rates as high as 711 fps.

- Proven Multi-Camera Capability—The compact, low-power design of EROS makes it ideal for dense, multi-camera deployments. With synchronization accuracy down to 1 µs and support for dozens of cameras in a system, EROS enables engineers to build robust multi-camera systems.

Emergent Vision Technologies

www.emergentvisiontec.com

QxSoft LLC QxAutomation-Manager

QxAutomation-Manager is a turn-key solution to interface between Ethernet based industrial automation hardware and your CMM with CMM-Manager. This Windows Application allows control of CMM-Manager software in a typical industrial automation cell containing a robot and/or PLC.

The automation application can launch CMM-Manager application, calibrate probe tips, send machine to safe load / unload location (home), launch inspection program(s), monitor program running status, monitor robot safe position, report errors from CMM-Manager, report pass / fail status of dimensional report and much more. QxAutomation-Manager is designed to be easy enough for the end user to set up with their own collaborative robot yet comprehensive enough for an industrial integrator to work with their preferred robot or PLC. Integrations ranging from machine tending with a single robot to a full integration within a manufacturing cell is possible with our turn-key solution.

QxSoft LLC

https://qxcmm.com/automation-software/

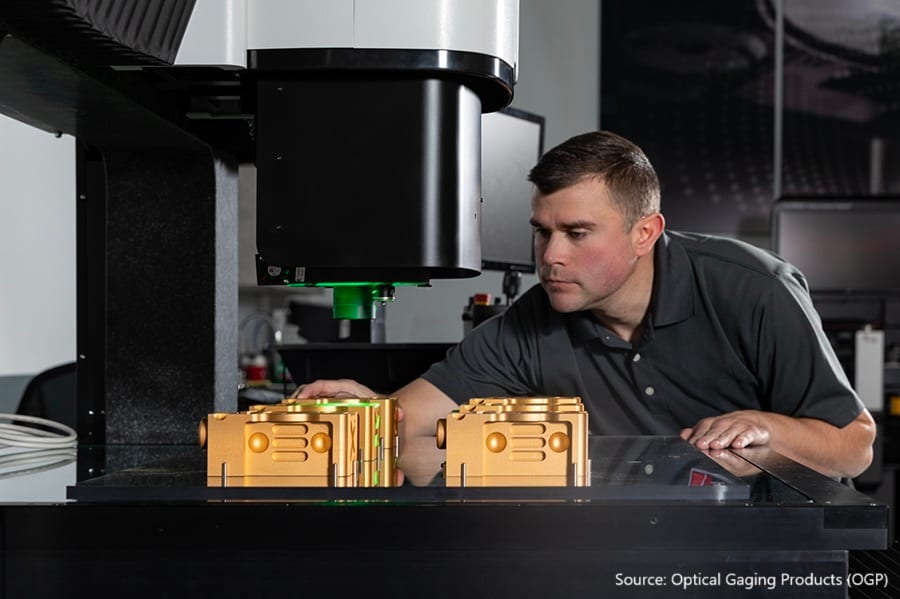

OGP Large Capacity SmartScope M130 M-Series

Optical Gaging Products (OGP®) announced the newest addition to the next evolution of SmartScope® 3D Multisensor Metrology systems: SmartScope M130.

For leading manufacturers crafting large, heavy parts, SmartScope M130 ushers in the next generation of enhancements in image accuracy, optics, and throughput in a new large format 3D multisensor video measurement platform.

Tim Fantauzzo, VP North American Sales, remarked, “The SmartScope M-Series family has quickly been adopted by manufacturers seeking unrivaled confidence in repeatability and reliability. Larger parts obviously can contain many more detailed features. The M130 optical system is truly telecentric with no distortion, so manufacturers making large, heavy parts can achieve more accurate measurements particularly at low magnification with far more part features in the field of view.”

At the core of SmartScope M130 is the patented* IntelliCentric-M Optical System, featuring fixed optics with a 20-megapixel camera and proprietary VIRTUAL ZOOM™ technology. Built from the ground up at OGP headquarters in Rochester, NY, the streamlined IntelliCentric-M optics employ a variety of exclusive technologies allowing for instant magnification changes throughout the same zoom range as a traditional mechanical zoom system, resulting in faster runtime while requiring far less downtime for maintenance.

SmartScope M130 is the ideal choice for manufacturers making large parts that require advanced throughput solutions. The IntelliCentric-M optical system combined with advanced sensors, illumination, and accessories, achieves class-leading optical measurement speeds.

With a robust standard XYZ travel of 790 x 815 x 200 mm, optional 300 or 400 mm Z-axis, and payload capacity of 75 kg (165 lbs), SmartScope M130 offers next-generation M-Series benefits to manufacturers producing large parts. A new innovative base design results in a lower stage height, allowing users to load and unload heavy parts or oversized fixtures with ease.

OGP President Steve Flynn said, “Since 1992, OGP SmartScope systems have helped thousands of manufacturers around the world achieve confidence in their quality programs. With SmartScope M130, we’ve applied the latest evolutions in optics and software in a larger format, creating the next generation of leading metrology solutions for manufacturers making large and heavy parts.

“M-Series systems take full advantage of the advanced edge detection algorithms, parallel processing, and routine optimization found in ZONE3 Metrology Software to deliver advanced throughput and enhanced accuracy for manufacturers in any industry. We are excited for our customers producing large parts that have realized these benefits on their compact format M-Series systems, as well as new OGP users alike, to discover how SmartScope M130 will vastly improve their inspection operations.”

Revopoint INSPIRE 2, MetroY Series 3D Scanners

Revopoint officially pre-launch the INSPIRE 2 and MetroY Series, the newest additions to its 3D scanner lineup. Built for creators, engineers, and professionals seeking portability, accuracy, and simplified scanning workflows, these devices embody a commitment to making 3D technology accessible.

The INSPIRE 2 3D Scanner is Revopoint’s solution to the need for an effortless yet precise scanning experience. Compact and weighing only 190 grams, its reliable performance of up to 0.03 mm precision and 0.05mm+ 0.1mm × L (m) volumetric accuracy makes it an invaluable tool for capturing medium-sized objects for design, 3D printing, heritage documentation, and more.

Blending structured infrared light and multi-line infrared lasers, INSPIRE 2 captures dark or shiny surfaces, even outdoors, in lighting up to 20,000 lux. With a 30% larger scanning area, improved tracking, faster scans, and an optical zoom (1.5x and 2x), INSPIRE 2 is ready to deal with complex scans.

Built-in Wi-Fi 6, optional Power Bank Handle, and real-time screen sharing allow for untethered, on-the-go scanning to meet the need for flexible workflows.

Designed for professionals, the MetroY 3D Scanner and MetroY Pro 3D Scanner are Revopoint’s most advanced handheld 3D scanners yet. Supports scanner-to-PC wireless connections, providing greater freedom of movement when scanning and enabling a scanner-to-PC-to-mobile device streaming system. Using multi-line blue laser scanning technology, both models deliver up to 0.01 mm precision and volumetric accuracy of 0.02 + 0.04 mm × L (m), making them ideal for high-demand applications in aerospace, automotive inspection, reverse engineering, and more.

The MetroY offers three versatile handheld laser modes, and the MetroY Pro boosts that to five, including full-field structured blue light scanning capable of marker-free capture of feature-rich objects at up to 7 million points per second. The Pro also supports an automated Dual-Axis Turntable for ultra-detailed scans.

With thirty (MetroY) and thirty-four (Pro) blue laser cross lines, high-resolution texture mapping, and advanced parallel and single line scanning modes for fine details such as grooves and cavities, the MetroY Series gives you the power to digitize complex geometries with confidence.

Free, powerful, and easy-to-use software comes with every Revopoint scanner. Built from the ground up based on user feedback, the software offers an intuitive workflow from scanning to editing and exporting, all within a single, streamlined platform. The latest upgrades enhance the user interface, improve tracking algorithms, and provide even more flexible post-processing tools to simplify your workflow.

Rovopoint

https://www.revopoint3d.com/

Factory Systems FS.InSpec

Factory Systems introduces FS.InSpec, a smarter, simpler way to collect quality data on the factory floor, whether manually or directly from connected devices. Designed with an intuitive tablet interface, FS.InSpec streamlines the capture of SPC and other key quality data directly at the source. Instantly calculate critical KPIs like Ppk, Cpk, skewness, and kurtosis as data is entered—no delays, no extra steps. Seamless integration with our FS.Net web application means your data is always working for you, powering real-time alerts, Andon displays, dynamic charts, and detailed reporting. FS.InSpec turns data collection into insight—faster and easier than ever before.

Factory Systems

www.FactorySystems.net

Mahr Newly Updated MaraMeter 36B Line of Bench ID/OD Gages

Mahr Inc. announced the launch of its newly updated MaraMeter 36B line of bench ID/OD gages, designed for measuring precision inside and outside diameters directly at the point of manufacture in industries such as bearing production. Created to withstand the rigorous demands of modern manufacturing environments, the enhanced 36B series offers improved configuration flexibility, compatibility with digital readouts, and simplified ordering, while preserving the rugged performance, accuracy, precision, and reliability that have defined the line for more than 75 years.

The latest update modernizes the platform for today’s digital manufacturing landscape, simplifying the ordering process and enabling customers to easily select the best digital indicator for their specific application. The new 36B models maintain the same ranges and configurations as previous models, including 2-point measuring ID/OD bench gages for true diameter (36B-10 and 36B-20) and 3-point measuring ID/OD bench gages for parts with odd lobbing conditions (36B-9 and 36B-19). All four gages are supplied with a complete set of three jaws, equipped with adjustable contacts to accommodate various application heights. Optional contacts from Mahr’s 844T portable ID/OD are available for measuring ID/OD grooves or gear pitch diameters.

Key features of the updated MaraMeter 36B line include:

- Easy-to-adjust jaws for setting diameter against a comparative master

- Adjustable retraction and gaging force

- Friction-free reed spring transfer mechanism for optimal repeatability

- Adjustable base for setting the gage at any angle for 0 to 90° operation by the user

Additionally, the updated 36B models are sold without the integrated indicating readout. This allows users to configure the gage to meet their specific needs, via numerous readout options including Mahr Millimess dial and digital comparators as well as Marcator digital indicators. This modular approach provides a better application match while streamlining the ordering process, allowing for faster delivery from stocked inventories.

"In today’s manufacturing environment, customers demand gages that can withstand the harsh environments at the point of manufacture. The Marameter 36B ID/OD bench gaging system has proven its effectiveness in meeting those requirements in both inspection rooms and shop-floor environments for decades," said Dr. Farzad Azimi, Precision Gage Product Manager at Mahr Inc. "The redesigned and upgraded Marameter 36B measuring systems offer more display flexibility and configuration options from stocked items, making gaging available when it's needed."

Mahr Inc.

www.mahr.com

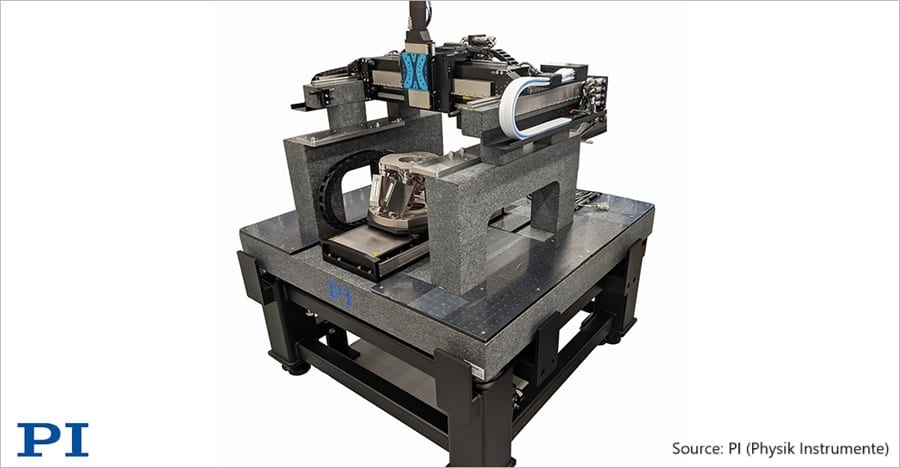

PI USA Engineered Precision Gantry Positioning Systems

PI (Physik Instrumente) offers custom precision gantry motion systems, engineered for high-accuracy industrial applications like inspection, metrology, laser processing, micro-assembly, and high-end 3D printing. Designed and fabricated by PI’s US operation in Hopkinton, MA, this system reflects PI’s commitment to highly reliable, locally manufactured, precision automation solutions.

With three standard gantry product lines (A-341, A-351, A-352), including air-bearing and mechanical-bearing designs, PI’s engineering team can quickly modify and optimize gantries for specific customer applications. All designs leverage FEA-backed development to ensure structural rigidity without unnecessary mass — addressing one of the seven core engineering challenges in gantry systems: maintaining stiffness across long spans.

Equipped with absolute linear encoders delivering 1nm resolution, PI’s precision gantry systems eliminate time-consuming homing cycles and ensure outstanding positional accuracy. The ironless, friction-free, cog-free motor architecture delivers smooth, vibration-free motion with fast acceleration and exceptional velocity control.

Modern precision gantry systems must address complex coordination issues — especially racking caused by drive mismatches in dual-driven bridges. PI solutions mitigate such errors through ACS motion controllers that support gantry-alignment routines to compensate for angular misalignments using virtual rotation axes. Special gantry yaw control algorithms also allow for active rotation (Theta-Z) while locking the linear axes when the gantry is equipped with flexure joints.

Capabilities include:

- Typical Travel Ranges: 300mm to 2m

- Number of Axes: From 2 axis to 10+ axes. Integration of hexapods, piezo nanopositioning stages, etc.

- Top Speed: Up to 2m/s on the cross-axis

- Advanced Features: Dynamic error mapping, optional water-cooling, drag chain cable carriers for high-duty applications

- Z Axis Options: Choose between ball-screw or linear-motor-based vertical motion, with magnetic or pneumatic counterbalance for load balancing and smooth vertical dynamics

Timing precision is critical when coordinating motion with process steps like imaging or laser activation. The hardware timed outputs, synchronized directly with encoder feedback, ensure flawless event positioning — eliminating image blur or part misplacement. Additionally, thoughtful cable management, including specialized drag-chain routing for clean environments, assures reliable repeatability.

PI Americas

www.pi-usa.us

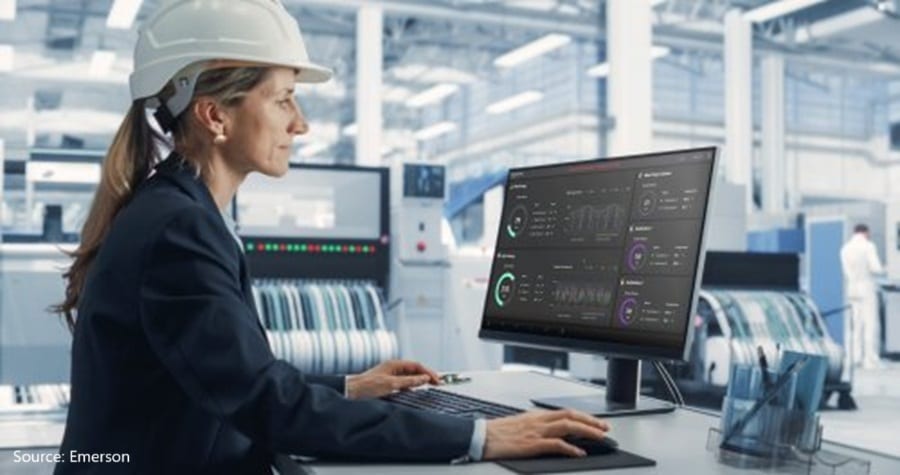

Emerson HMI/SCADA Software

Emerson has announced the release of Movicon.NExT™ Version 4.4, a modern human-machine interface (HMI) and supervisory control and data acquisition (SCADA) platform. Movicon.NExT HMI/SCADA empowers users to create interoperable automation architectures for discrete and process manufacturing applications in the commercial, industrial, and municipal/utility industries. This update delivers enhancements boosting functionality, performance, and flexibility, with an emphasis on user-centric improvements to maximize development efficiency.

Updated industrial communication protocol drivers—for OPC UA, EtherNet/IP, and others—provide support for multi-station, advanced arrays, and more. A new DNP3 driver enables Movicon.NExT HMI/SCADA to integrate seamlessly with power industry and electrical utility networks. Optimized I/O operations more efficiently aggregate read/write tags for greater throughput, and open connectivity helps users easily connect with digital assets.

Native support within Movicon.NExT for Python runtime scripting enables custom, cross-platform logic, so developers can create sophisticated strategies while building on proven work. Updated user interfaces, new graphical properties for controls, and streamlined license management (both local and network-based) enhance and simplify the overall user experience, while accelerating project development.

New support for TimescaleDB in the historian offers improved storage efficiency and higher performance, especially with large data volumes. Other enhancements increase data precision and SQL database compatibility, while recipe and alarm management are performed through a centralized connection. Movicon.NExT is built to meet the increasing demand for data to support visualization and analytics.

A full migration to .NET 8 for core Movicon.NExT applications, and unified and encrypted password management applied across the entire platform, are just two examples of built-in security to help users defend their digital systems and achieve regulatory compliance. CFR21 compliance has now been enhanced with the addition of user group information logged alongside usernames.

Additional Movicon.NExT modules, such as Pro.Lean™ and Pro.Energy™, are also revised to v4.4, with updates such as an improved user interface and navigation, new library symbols, and the addition of grouping and overview screens.

The release of Movicon.NExT v4.4 strengthens this HMI/SCADA’s position as an open, high-performance, and integration-ready platform, while maintaining a focus on ease-of-use. Movicon.NExT is the foundation of a solid automation architecture, helping end users, systems integrators (SIs), and original equipment manufacturers (OEMs) create innovative automation solutions.

Emerson

https://www.emerson.com/en-gb/automation/control-and-safety-systems/movicon/movicon-next

LK Metrology SURFACER Surface Roughness Probe

Coordinate measuring machine (CMM) manufacturer LK Metrology, whose manufacturing facility is in Derbyshire, UK, has announced the introduction of the SURFACER SRP. It is a plug-and-play probe having a resolution of one micron for seamlessly analyzing the roughness of the surface of a component as part of a CNC measuring cycle on any CMM, provided it has an industry-standard probe head.

The sensor eliminates the need for secondary surface roughness inspection, either manually using a hand-held instrument or automatically at a separate metrology station. Manufacturers are able to conduct comprehensive inspection on a component in a single setup in a CMM environment, resulting in significant savings in time and cost. Engineered for ease of use and versatility, the equipment comes with its own downloadable application software, facilitating integration and eliminating the need for third-party software.

Effortless swapping between touch probes, tactile scanning probes, non-contact laser scanners and the roughness probe gives users extended multi-sensor capability. The SURFACER SRP mounting is compatible with change racks, including the new versions introduced recently by LK, enabling automated sensor changing and enhanced operational efficiency.

At the heart of the roughness probe lies a special body that accommodates three interchangeable, skidded, stainless-steel probe modules. One evaluates flat, conical and cylindrical surfaces, another measures concave, convex and spherical surfaces, and a third is for inspecting grooves more than 3 mm wide by less than 10 mm deep, or steps of similar height.

The CMM positions a stylus so that it is in contact with the part, after which the machine axes remain stationary while the probe moves the stylus across the surface under investigation. Wireless communication with the CMM computer via a Bluetooth 4.0 adapter provides seamless data transfer for analysis, simplifying installation.

The skid plays a key role during measurement, acting as a straight-line datum that guides the stylus across a surface to ensure probe stability. The stylus travels independently of and slightly in front of the skid, with surface deviations recorded as the difference in the relative movements of the two elements in the Z-axis. The design ensures that even minute surface irregularities are captured with exceptional accuracy.

Further enhancing the precision of the SURFACER SRP is an integrated preload mechanism, which during stylus operation isolates it from the CMM kinematics, guaranteeing accurate and consistent results regardless of external vibration or machine movement. The force exerted by the stylus tip, which has a radius of 5 microns, is less than four thousandths of a Newton, avoiding surface deformation. Measurable roughness range is 0.5 to 6.5 Ra, which is the average roughness between the profile and the mean line.

Dave Robinson, LK's marketing manager, said, "By integrating surface roughness measurement directly onto the CMM, we are providing manufacturers with a powerful tool to streamline their inspection processes, reduce costs and enhance product quality. The ability to perform multiple metrology functions on a single platform eliminates the need for time-consuming transfers of components and ensures greater accuracy by maintaining part orientation between measurements.”

Measuring the relative smoothness of the surface profile of a metal or plastic component is fundamental after turning, milling, grinding, spark erosion, broaching or reaming, as it directly correlates to how well the component will function in service. It is the small, fine-scale variations and imperfections in the surface including peaks and valleys that is assessed by LK's SURFACER SRP, rather than larger-scale features like waviness or form.

The texture of a surface, even at a microscopic level, significantly influences its interactions with other parts and its environment. For instance, smoother surfaces minimize friction, which is vital for reducing wear of moving parts and improving efficiency, durability and performance. In applications involving seals, a precise surface finish prevents leaks. Furthermore, surface roughness can impact a component's susceptibility to fatigue; rougher surfaces create stress points that can lead to premature failure.

Beyond mechanical functionality, the degree of surface roughness plays a role in corrosion resistance, as smoother surfaces are less prone to trapping corrosive substances. A smooth surface improves electrical conductivity. Additionally, the ability of coatings or adhesives to bond effectively is heavily reliant on surface texture.

LK Metrology

www.lkmetrology.com