Guest Column

Travis Ellinger

Guest Column | Travis Ellinger

Why the 125-piece study provides improved accuracy and reliability in decision making.

Capability Study Showdown:

30-Piece vs. 125-Piece Explained

In the world of manufacturing and quality engineering, process capability studies are important tools used to determine whether a process can produce parts within specification limits consistently. Two common approaches when analyzing process capability include a 30-piece study and a more comprehensive 125-piece study. Both studies serve the same basic purpose, but they differ significantly in methodology, statistical power, and scope.

In this article, we will explore the background of each study type, and decision-making criteria for selecting the appropriate method. We will also look at why the 125-piece study provides improved accuracy and reliability in decision making.

Background and Purpose of Capability Studies

Process capability studies evaluate how well a manufacturing process meets specification limits by comparing the variability of the process output with design tolerances. Capability studies are typically performed using one of two statistics:

- Cp/Cpk (Process Capability Index): Measures how centered and consistent the process is within the specification limits.

- Pp/Ppk (Performance Capability Index): Similar to Cp/Cpk but includes long-term variation. This is useful for initial process evaluation.

The goals of capability studies include:

- Verify that a process is stable and under statistical control.

- Assess whether a process can reliably produce parts within specification limits.

- Provide a statistical basis for continuous improvement or redesign.

30-Piece Capability Study: A Common Starting Point

The 30-piece capability study is widely used, especially early in the developmental stages or setup. It involves measuring 30 consecutive parts from a stable process and calculating basic statistics such as mean, range, and standard deviation. This is most often used when:

- Time or resources are limited.

- A rapid assessment of capability is needed.

- The process is in its early development stages and under close monitoring.

Advantages:

- Quick and cost-effective.

- Requires minimal sampling effort.

- Sufficient for preliminary or short-run validation.

Limitations:

- Small sample size reduces statistical confidence.

- Limited ability to detect variation trends (e.g., shift, drift, special causes).

- Poor representation of long-term performance.

125-Piece Capability Study: 25 Subgroups of 5

A 125-piece capability study using 25 subgroups of 5 provides more accurate statistical insight. Each subgroup of 5 parts is collected over time (e.g., every hour, shift, or lot), capturing the process’s natural variation more effectively.

Advantages:

- Higher statistical confidence due to increased sample size.

- Subgrouping allows for calculation of within-group and between-group variation.

- Enables more accurate estimates of process standard deviation.

- More reliable detection of special cause variation.

Limitations:

- More time-consuming and resource-intensive.

- Requires a stable process over a longer period of time.

- May be excessive for short-run or low-risk parts.

Comparison of Data Distributions

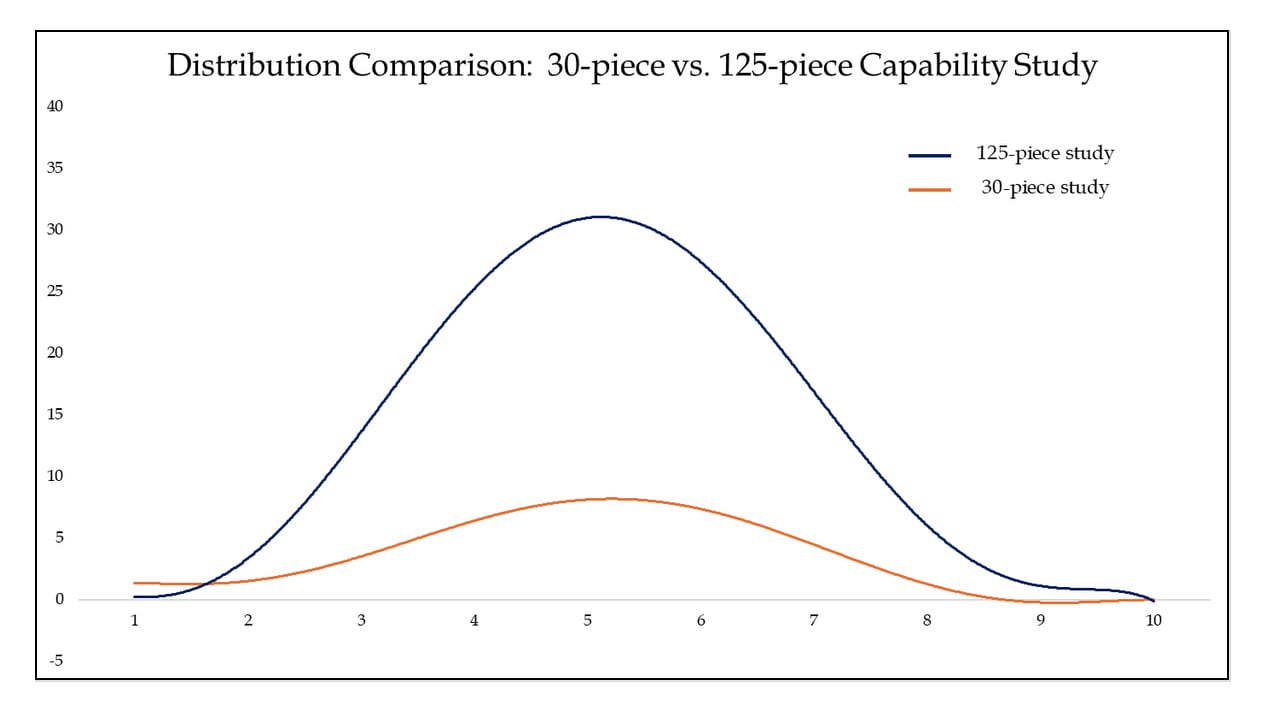

The histogram below shows the distribution difference between a 30-piece study and a 125-piece study. Both datasets are sampled from the same distribution (mean = 5, standard deviation = 1.5), but the larger sample size in the 125-piece study produces a more pronounced and representative distribution:

As shown, the 30-piece histogram is more irregular due to its limited sample size, whereas the 125-piece histogram better approximates a normal distribution, resulting in statistical conclusions that are more reliable.

Why the 125-Piece Study Produces Improved Results

The superiority of the 125-piece study comes from its statistical robustness:

- Improved Estimation of Standard Deviation: A larger sample size allows for more accurate estimates of standard deviation, which directly impact the accuracy of both the Cp and Cpk calculations.

- Improved Process Variability Detection: Subgrouping across different times (hours, shifts, etc.) captures both short-term and long-term variability, allowing the study to differentiate between common cause and special cause variation.

- Control Chart Utilization: The subgroup format enables the use of control charts, such as X-bar and R or X-bar and S charts, which are instrumental in monitoring process stability / drift over time.

- Greater Confidence for Decision Making: Capability studies enable critical decisions such as process qualification, production release, or need for corrective action. 125-piece studies reduce the risk of false conclusions.

- Customer and Industry Standards: Some customers in industries, such as automotive or aerospace, require 125-piece studies (or more) to meet quality standards. You can find these requirements defined in customer specific requirements for industry action group manuals like AIAG’s Statistical Process Control manual (AIAG, 2023).

How well are the quality standards for your organization understood by the people accountable to meet them?

“Pull Quote”

Conclusion

Choosing between a 30-piece and a 125-piece capability study depends on the situation a manufacturer is dealing with, the criticality of the part, and the required confidence level. While a 30-piece study is valuable for quick assessments, 125-piece studies provide significantly more accurate and comprehensive understanding of a process’s capability. In quality-critical industries, where precision and reliability are paramount, the 125-piece capability study is a preferred and often required method.

By understanding the strengths and limitations of each approach, engineers and quality professionals can make informed decisions that balance time, cost, and statistical reliability to ensure the success of their manufacturing processes.

Works Cited:

- AIAG. Statistical Process Control (SPC) Manual. 2nd ed., Automotive Industry Action Group, 2023.

- Montgomery, Douglas C. Introduction to Statistical Quality Control. 8th ed., Wiley, 2020.

- Wheeler, Donald J. Understanding Variation: The Key to Managing Chaos. SPC Press, 2021.