H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Management

Hexicurity faced a recurring challenge in wire crimping quality. By Jon Boucher and Andrea Van Landingham

Theia Lens Improves Wire Crimping Accuracy, Enabling Automation via Machine Learning

Case Study

H2 Deck Info By Paragraph Style Bold

Headline

Hexicurity in Boerne, Texas, develops high-security access integration solutions for doors, turnstiles, and elevator systems, designed to work seamlessly with existing access control infrastructure. Within its own operations, Hexicurity manufactures wire crimps for their verifier and distributor components that integrate into their TransVerify System. These crimps are critical to their operations with roughly 100 crimps per system.

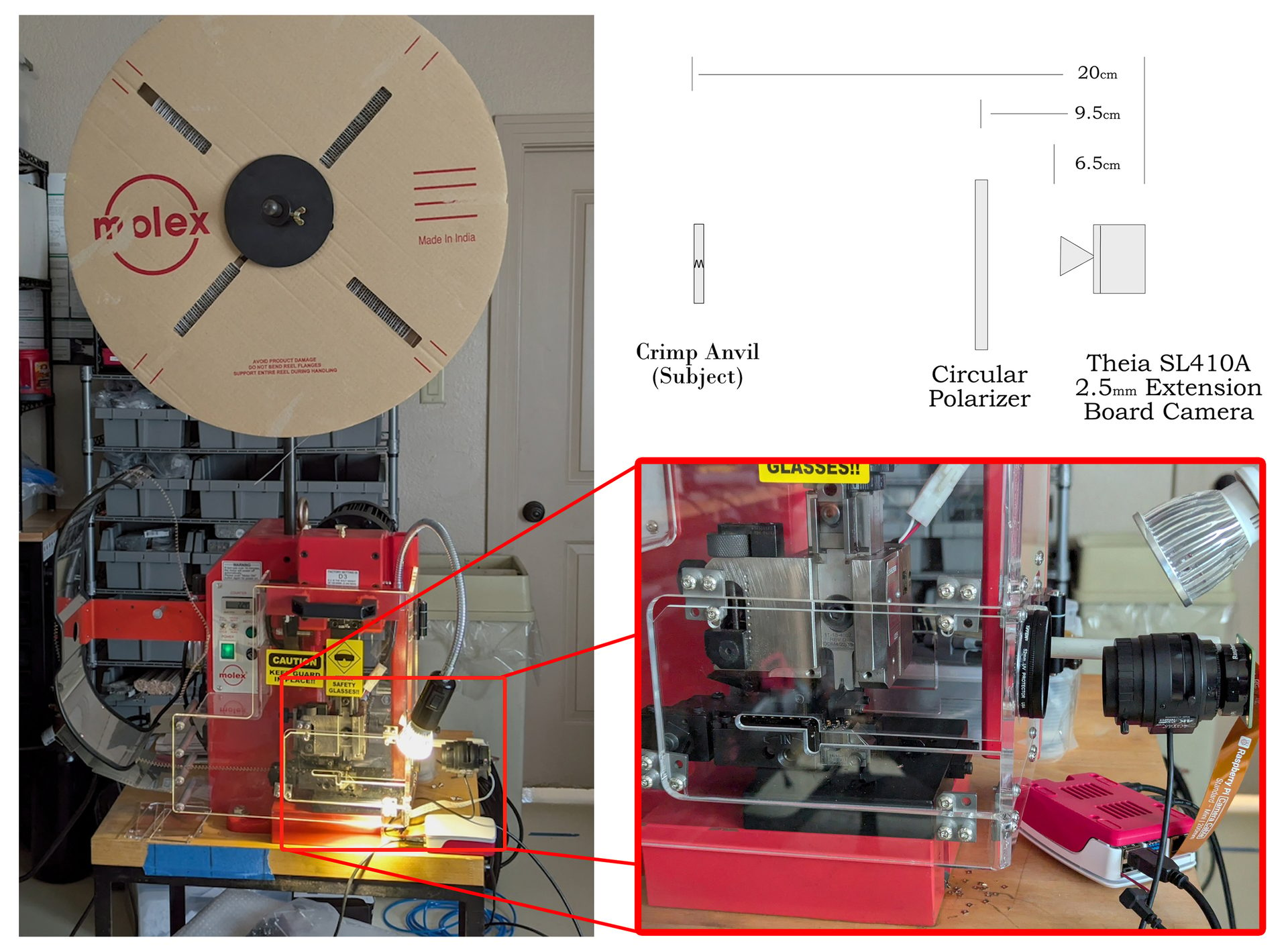

Hexicurity faced a recurring challenge in wire crimping quality. The company purchased a precision crimping machine from Molex, a leading maker of electronic connectors. While the machine performed well when the wire was positioned perfectly, its design blocked the operator’s view of the crimp point (Fig. 1). This created a situation where even skilled operators could misalign the wire— too close, and vital insulation is crushed in the press jaws; too far, and the crimp remains insecure. Despite encountering only two faulty crimp incidents in its history—one resulting in a cross-country service call with significant travel expenses and an associated customer delay—Hexicurity recognized the importance of addressing the issue proactively to prevent future occurrences.

Fig. 1 Molex Machine showing a detail of the optical chain from Theia Lens to wire crimp anvil.

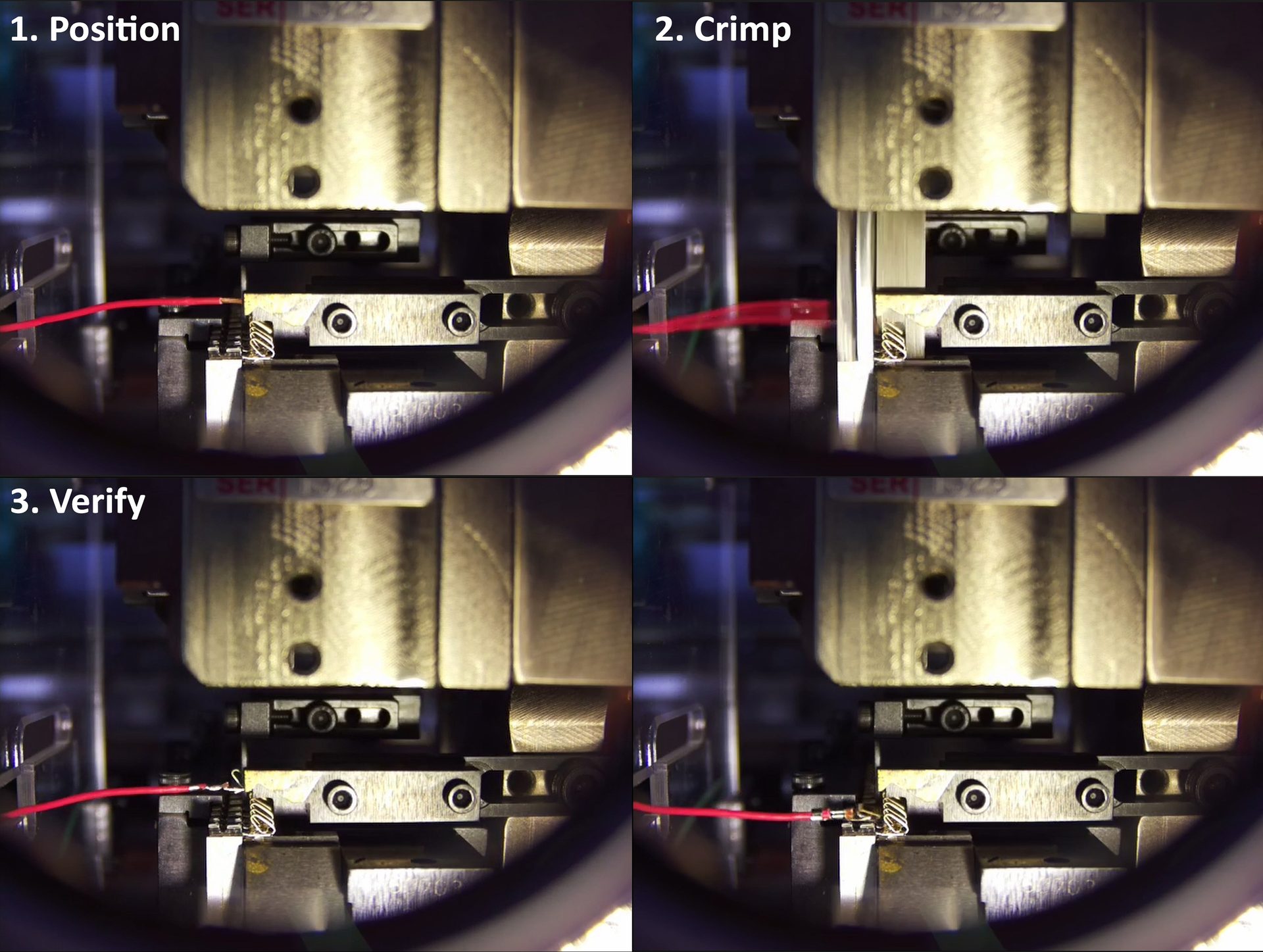

So they embarked on a project to solve the crimp vision problem, with the goal of giving the operator an unobstructed, magnified view of the wire just before the crimping operation and to record each crimp for traceability. This objective has been achieved, with the system now providing operators with the visual clarity they need to ensure proper placement (Fig. 2).

Fig. 2 Theia’s SL410A lens helped Hexicurity image the crimp press with enough resolution to greatly reduce errors and maximize successful crimps, as seen here.

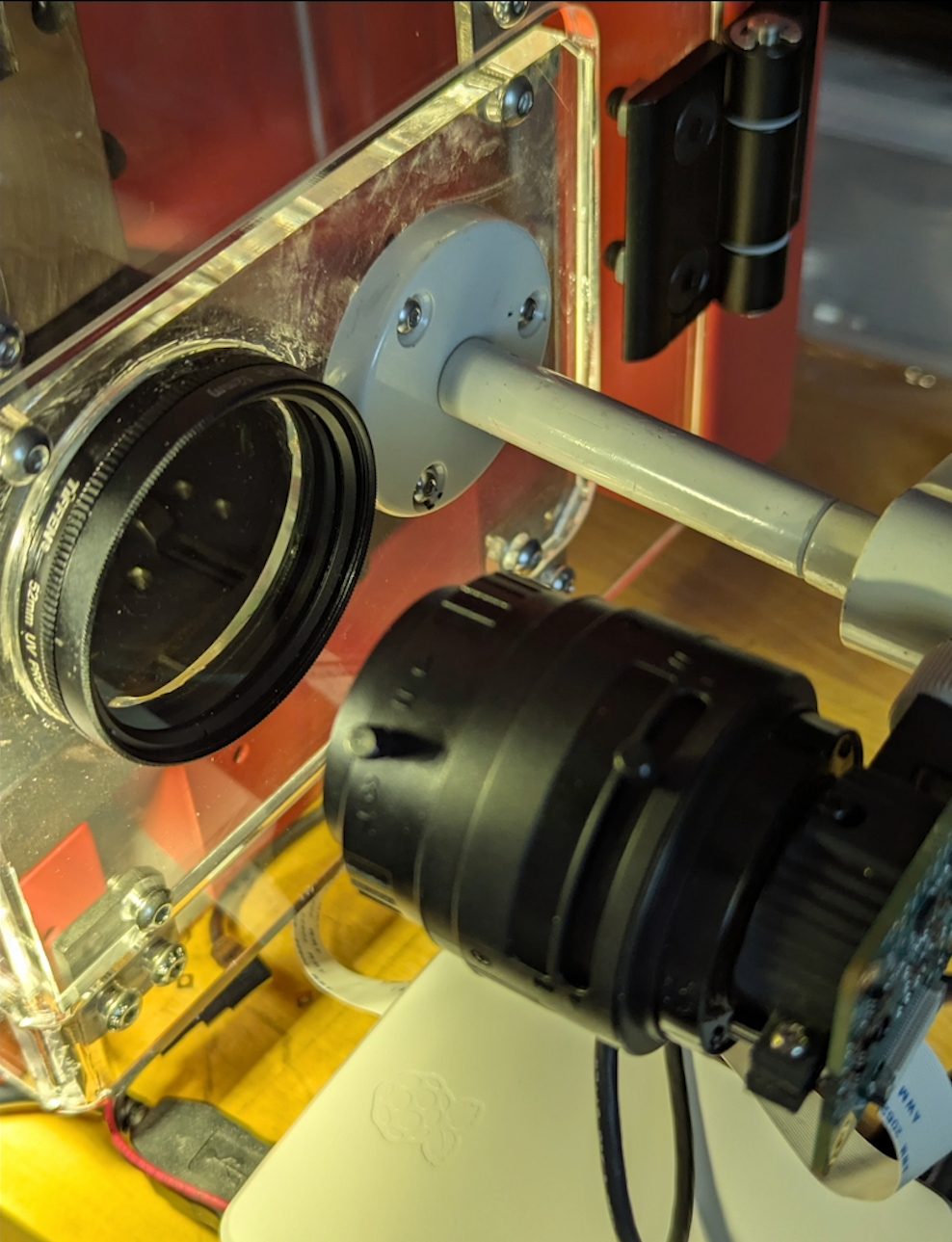

At the core of this optical solution is a Theia Technologies SL410A 4-10mm varifocal lens which was made for the 1.55µ size pixel and provides 300lp/mm resolution. The Theia lens is focused on the crimping anvil with a circular polarizer mounted in between to reduce glare and specular reflections from bright metal surfaces (Fig. 3). The imaging system includes the ArduCam B024001 camera with a 4K+ (4056×3040) Sony IMX477 1/2.3” sensor, connected to an IoT processor via a 15-pin FPC cable.

The company has now upgraded to a Raspberry Pi 4K High Resolution camera to gain locking back-focus adjustment capability, improving image quality. Further improvements include adding a 2.5mm extension tube using the back-focus adjustment.

The lens is set at the 6mm focal length which provides 61 degrees HFOV and sits approximately five inches from the target, capturing high resolution detail critical for both operator viewing and machine learning analysis. The SL410A CS-mount lens is also available in C mount and motorized versions for remote zoom and focus capability.

Fig. 3 Theia’s SL410A on a ArduCam B024001 shooting through a Polarizer.

Theia’s SL410A provided the resolution necessary to capture the intricate details of wire strands and crimp deformation, while maintaining consistent sharpness across the frame—ensuring reliable data for AI training. The 4K lenses also allow for digital zoom which will assist in training machine learning algorithms, verifying quality control crimping with 100% accuracy.

According to George Mallard, system designer and vice president of engineering for Hexicurity, “compared to the other available lens choices, (the SL410A) lens offer less color distortion and a flatter image. Since we intend to run our image-processing pipeline on a modest processor, consistent image quality reduces processor load.”

The impact of this system has been immediate. Operators now have the visibility required to position wires correctly on the first attempt, reducing rework and improving consistency. In addition to improving process flow, it also reduces production cycle time.

Long-term, Hexicurity plans to introduce automation into the process, using machine learning to detect when the wire is in the correct position and to trigger the crimp semi-automatically or automatically. This will require hundreds of recorded examples of both correct and incorrect crimps to train the model effectively. Another long-term goal is to extend the same machine learning process to provide 100% quality control, inspecting every crimp and rejecting any that fails to meet specifications.

The high-resolution, glare-free images are forming the basis for a dataset that will power the next phases of automation. In the future, Hexicurity expects to deploy a trained machine learning model to the IoT controller, enabling fully automated go/no-go decisions before the crimp occurs and ensuring that every crimp meets quality standards without slowing production.

Mallard notes that Theia’s contribution was indispensable, “Theia’s SL410A lens gave us the clarity and accuracy we needed. Without this level of resolution, the AI model simply wouldn’t have enough reliable data to learn from.”

The integration of Theia’s high-performance optics into Hexicurity’s crimping process has transformed a visibility challenge into a foundation for advanced automation, paving the way for both improved quality and greater efficiency in electronic manufacturing.