xxxxxx xx

xxxxxxxxxx

Case Study

NDT

NDT

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Modern ADR platforms may incorporate artificial intelligence and machine learning. By Camaron Lemmer

High-Throughput DR Aerospace and Automotive Inspection with ADR | And a Time and Detection Rate Comparison Study

2D Digital Radiography (DR) is a powerful modality within the field of nondestructive testing (NDT), offering high-resolution inspection capabilities for complex components in aerospace and automotive manufacturing. Combined with Assisted Defect Recognition (ADR), these systems streamline defect detection, reduce inspector burden, and improve overall quality control. This paper explores the technical merits of 2D DR and ADR integration with a specific case study and time trials, as well as applications in safety-critical industries, and the evolving role of digital imaging in high-throughput manufacturing environments.

In performance-critical sectors such as aerospace and automotive manufacturing, the demand for high-throughput, high-resolution inspection continues to rise. Structural integrity, weld quality, and assembly verification across components ranging from turbine blades to electronic control modules are important to the overall safety of the final system. The integration of ADR with DR tools further advances this capability by enhancing interpretation efficiency and consistency.

While computed tomography (CT) has garnered attention for its volumetric imaging capabilities, 2D DR remains a faster and more cost-effective option for many production environments. As component complexity and production volumes grow, DR systems with automated image processing provide an effective and efficient solution for quality assurance workflows.

Background Principles of 2D Digital Radiography

2D DR relies on the transmission of X-rays through a component and the capture of the resulting image by a digital detector array. Unlike film radiography, which requires chemical processing, DR provides real-time imaging with high dynamic range and resolution, enabling immediate assessment and post-processing.

Flat-panel detectors (FPDs) are central to DR systems and offer pixel sizes allowing for resolution of minute variations in X-ray transmission. When coupled with optimized exposure parameters, these detectors provide high-fidelity imaging of structural features, including welds, voids, porosity, and inclusions.

The radiographic sensitivity (often denoted as the ability to detect a defect of given size relative to the component thickness) is influenced by factors [1] such as:

- Source energy and spot size

- Detector resolution and noise performance

- Geometric magnification

- Contrast

With appropriate calibration and system configuration, DR can detect sub-micron defects in metals, composites, and hybrid assemblies.

Applications in Aerospace

Aerospace components demand stringent inspection standards due to the criticality of flight safety. 2D DR is routinely used in the inspection of:

- Welded titanium and aluminum airframe structures

- Engine turbine blades and vanes

- Composite structures for delamination or foreign object detection

- Fuel system and hydraulic manifold assemblies

- Additively manufactured parts

A significant advantage of DR in this context is its ability to image through high-density alloys with minimal distortion while offering rapid image acquisition suited to in-line or batch processing.

When paired with ADR, the inspection of repetitive geometries—such as cooling holes in turbine blades—becomes more reliable and less labor-intensive, particularly during serial production.

Applications in Automotive

The automotive industry benefits from 2D DR in the inspection of:

- Weld seams in chassis components

- Die-cast transmission housings

- Battery modules in electric vehicles (EVs)

- Additively manufactured parts

The demand for lightweighting has led to an increase in aluminum usage, which is well-suited for X-ray transmission. In battery modules, 2D DR allows the detection of weld integrity issues, foreign object debris, or misalignments within stacked cells—critical for preventing electrical shorts and potential fires [2].

High-speed DR systems integrated into production lines enable inspection of hundreds of parts per hour, a necessity for automotive environments where cycle time affects the bottom line.

Assisted Defect Recognition (ADR)

Manual DR image interpretation can vary from inspector to inspector (and shift to shift) depending on a number of factors including overall experience, expertise within a certain industry or with a specific component, or even inspector fatigue. ADR systems address these limitations by using algorithms to pre-screen images and highlight regions of interest based on learned defect patterns or rule-based logic. These tools are not intended to replace certified inspectors but to assist them by:

- Reducing false negatives

- Improving throughput

- Standardizing evaluation criteria

Modern ADR platforms may incorporate artificial intelligence (AI) and machine learning (ML), trained on vast libraries of annotated radiographs to improve detection of common flaws such as lack of fusion, porosity, or undercut in welds [3].

An example of this in practice is the application of ADR to weld inspection in aerospace brackets, where the system flags variations in grayscale density for further evaluation, allowing the inspector to focus on critical areas while maintaining productivity.

Technical Integration and Data Workflow

A key advantage of modern DR systems is their interoperability with digital workflows. Image data can be:

- Automatically stored in DICONDE format for traceability

- Analyzed via ADR in real time

- Flagged for review using automated defect grading logic

Moreover, DR systems can be configured with robotic part handling to further increase throughput and reduce human exposure to radiation, as is done in some aerospace casting inspection cells [4].

Limitations and Considerations

While 2D DR offers high-resolution imaging, it is limited by superposition effects—i.e., the inability to distinguish depth. Complex internal geometries or overlapping features may require CT imaging for full evaluation.

Additionally, successful ADR implementation requires sufficient training data and validation. Overreliance on unvalidated ADR systems could result in missed defects or overcalls, leading to unnecessary part rejection.

To mitigate these risks, best practices include:

- Cross-validation with manual interpretation during rollout

- Periodic retraining of ADR models

- Adherence to industry standards (e.g., ASTM E2737, ASTM E2698) for system performance checks [5]

A Time and Detection Rate ADR Study

Samples

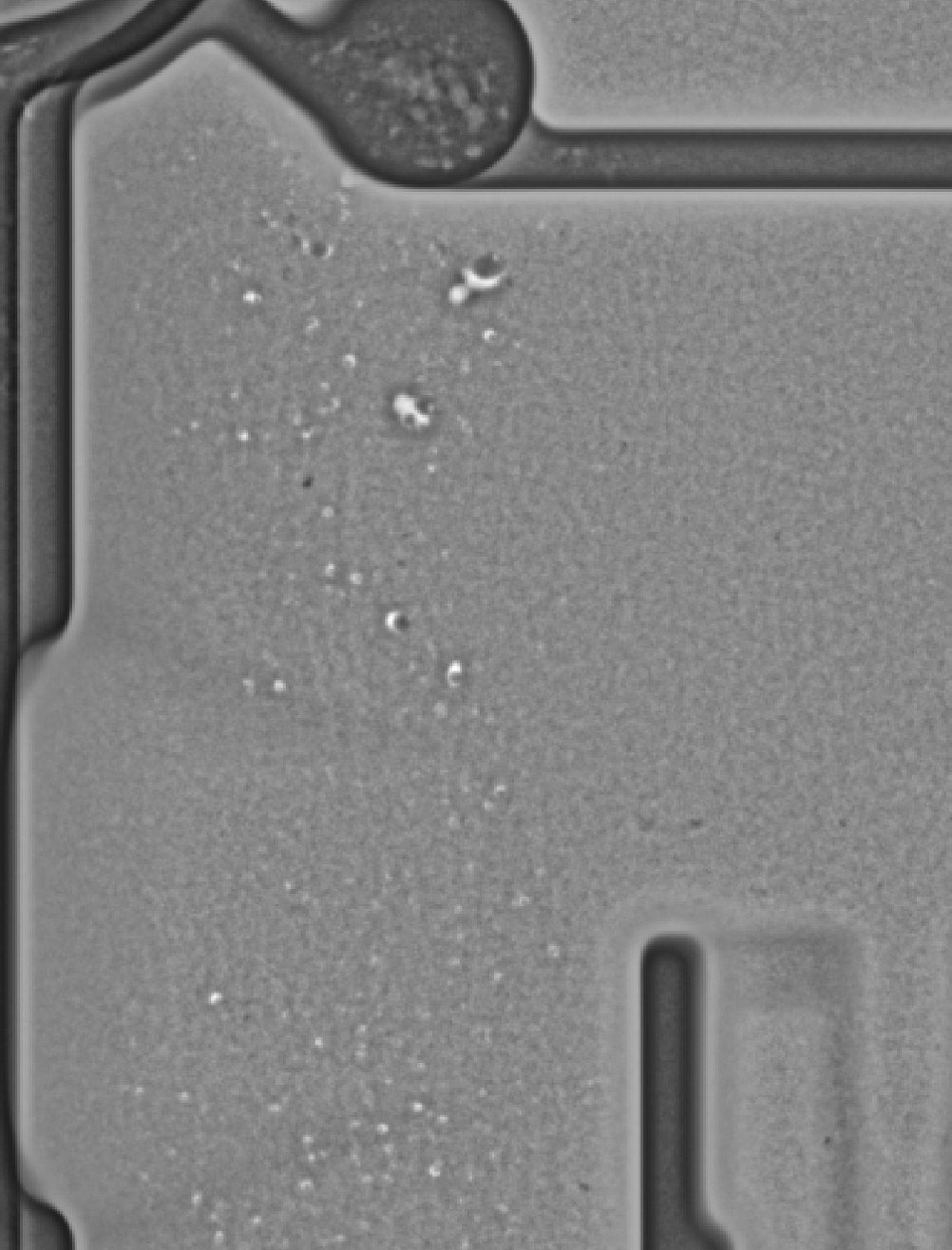

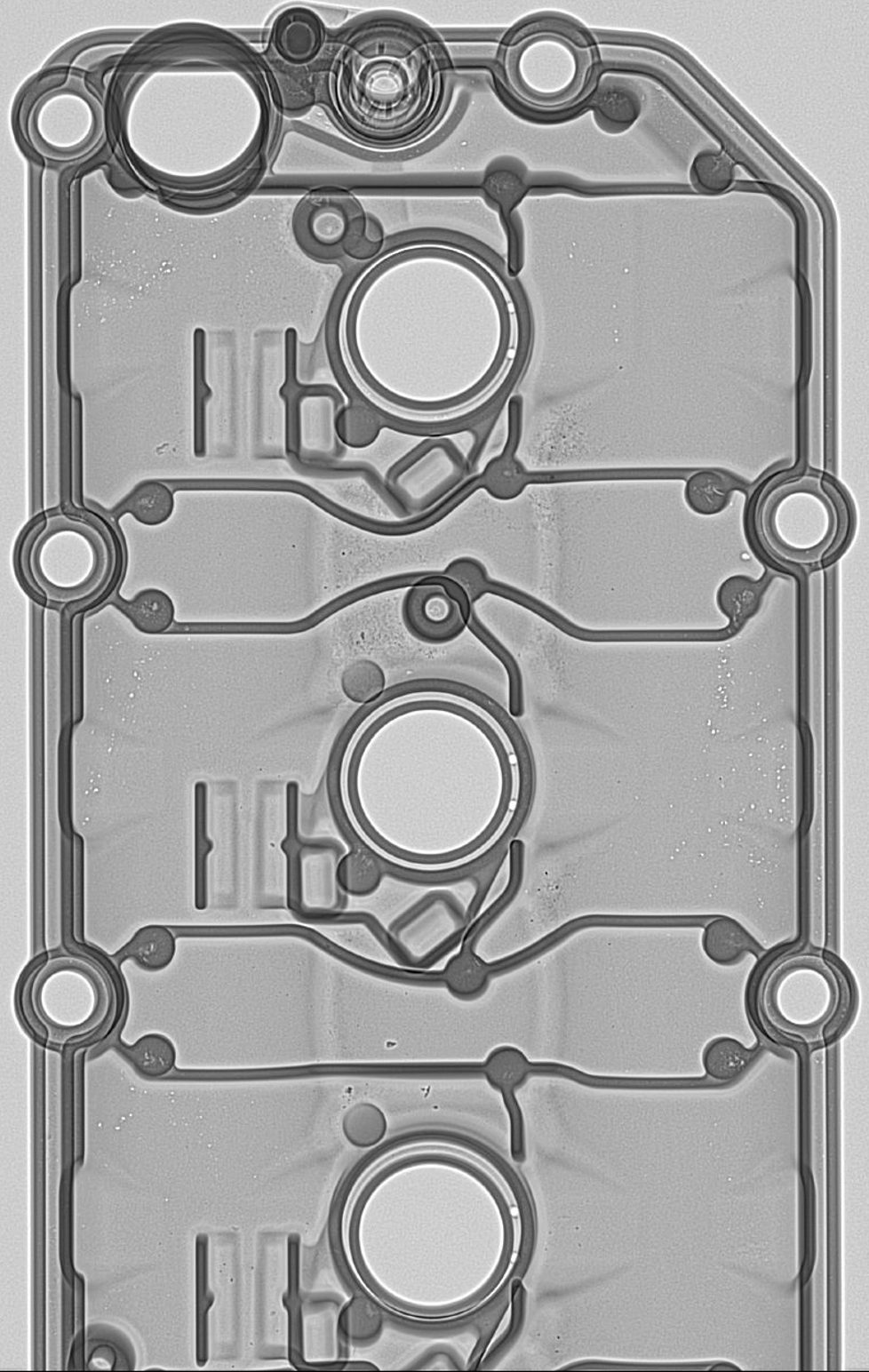

The study utilized three aluminum cast valve covers from a V10 engine [Fig. 1], selected for their relevance to casting industry challenges in both aerospace and automotive. These parts exhibited natural defects such as gas porosity, shrinkage, inclusions, and dross, while simulated cracks were introduced across varying wall thicknesses—from thin to thick zones—to test detection limits. This diversity ensured a robust evaluation of the system’s capabilities.

Time Study

In order to capture the potential real value of ADR in a high throughput environment, a time study was performed [6]. Across the images captured it took an experienced manual operator roughly 60 seconds to evaluate and annotate each image, while the ADR platform utilized in this study (efX-ADR) processed each image in roughly 1.5 seconds. The program evaluated the indication regions found in the image based on specific evaluation criteria as determined by the user and in this case, we used maximum area.

Fig. 1: Aluminum cast valve covers from a V10 engine with a specially designed fixture.

Manual + ADR Interpretation

In the digital radiographic process, image evaluation is generally considered the bottleneck for time. When adding the efficiencies gained from ADR we can see a reduction in overall image evaluation of up to 30%, potentially increasing daily radiograph assessments from 480 to 624, or 36,000 more annually per interpreter. This efficiency gain transforms production capacity.

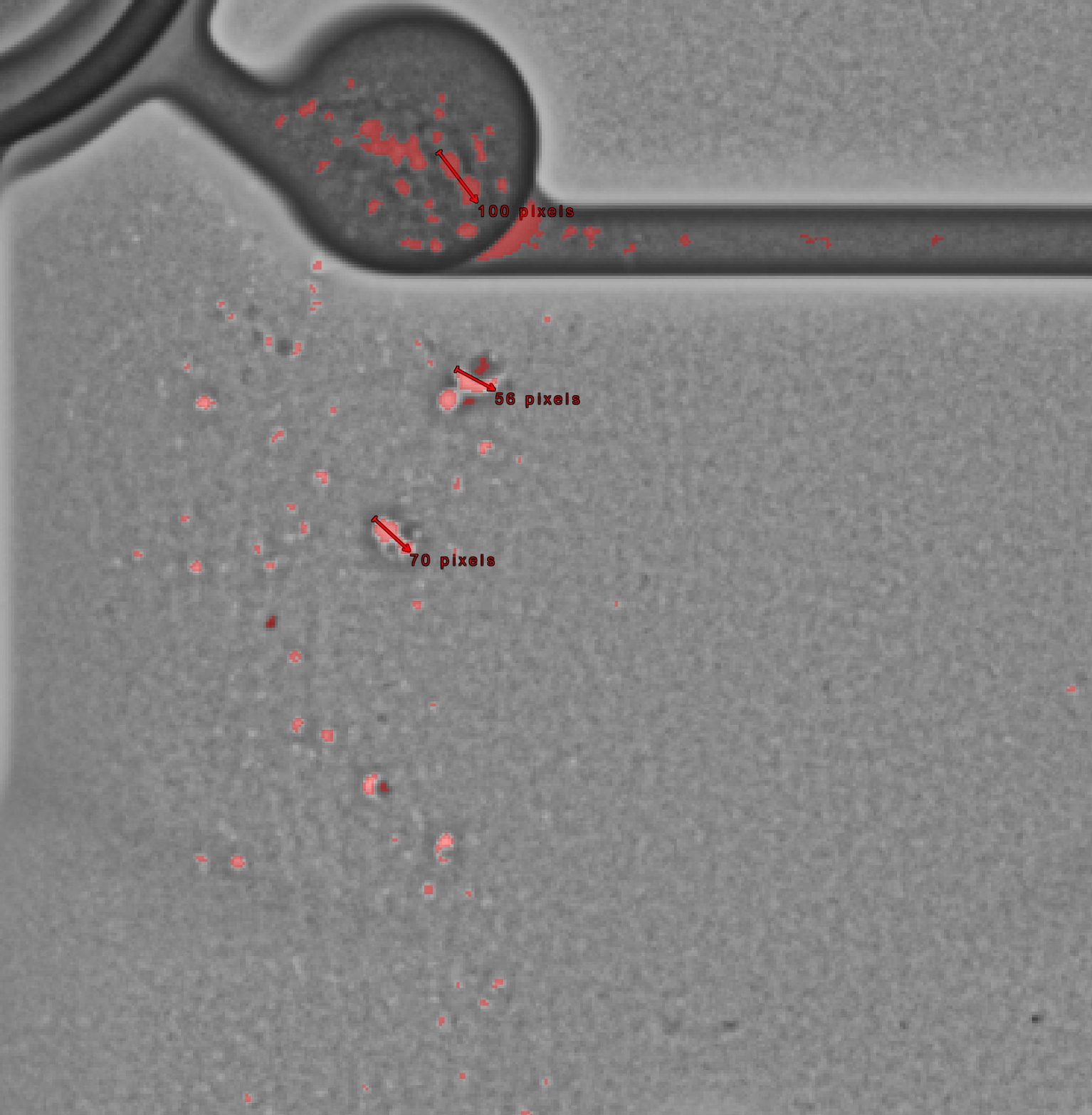

Detection Rate

In a small case study, we evaluated the repeatability and reproducibility of detecting specific indications in castings using a 60-second motion program, conducted over three days. Parts were unloaded and reloaded between each run to test reproducibility. The study focused on detecting four indication types as shown in Figure 2:

- Foreign material (inclusions)

- Shrinkage

- Gas porosity

- Simulated cracks

Detection of inclusions, shrinkage, and gas porosity achieved repeatability and reproducibility of 99% or higher. Simulated cracks were more challenging, particularly in material thickness transition zones. A rule-based image processing chain was configured to identify all four indication types.

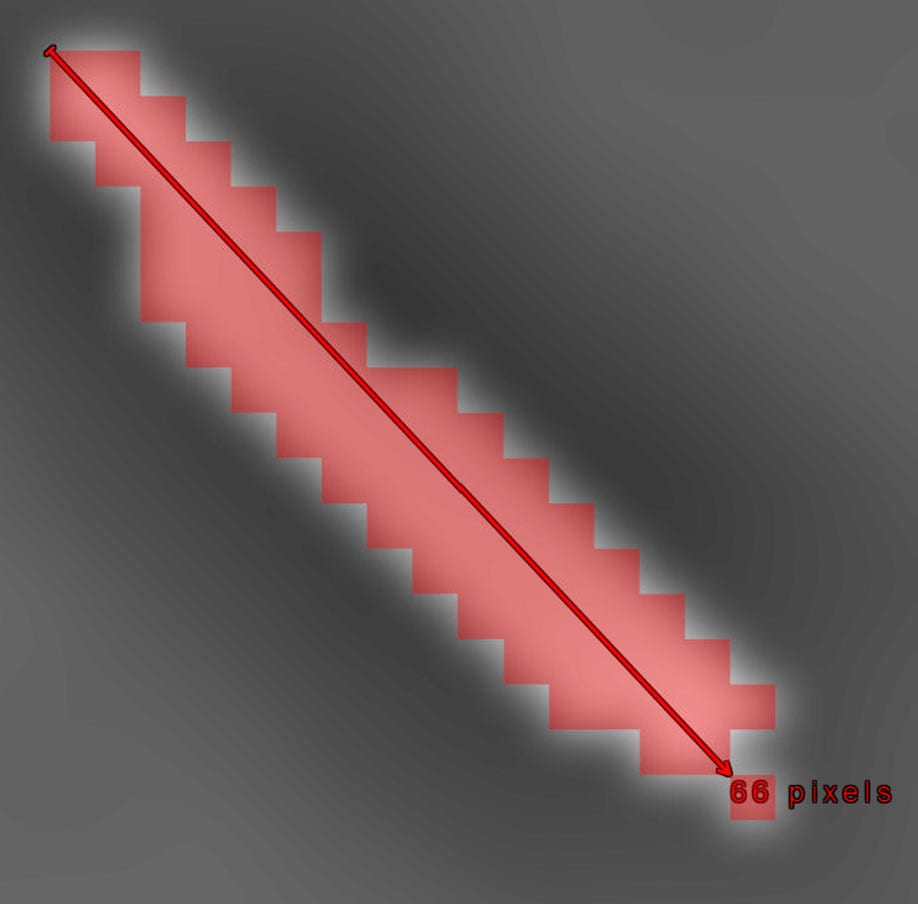

Shrinkage (Size filter: min 100, max 120 pixels)

Inclusions (Size filter: min 20 pixels)

Gas Porosity

ADR threshold

ADR annotation

Simulated Cracks (Size filter: min 50 pixels)

Simulated Cracks (Size filter: min 50 pixels)

Fig. 2: Indications which were part of the ADR study

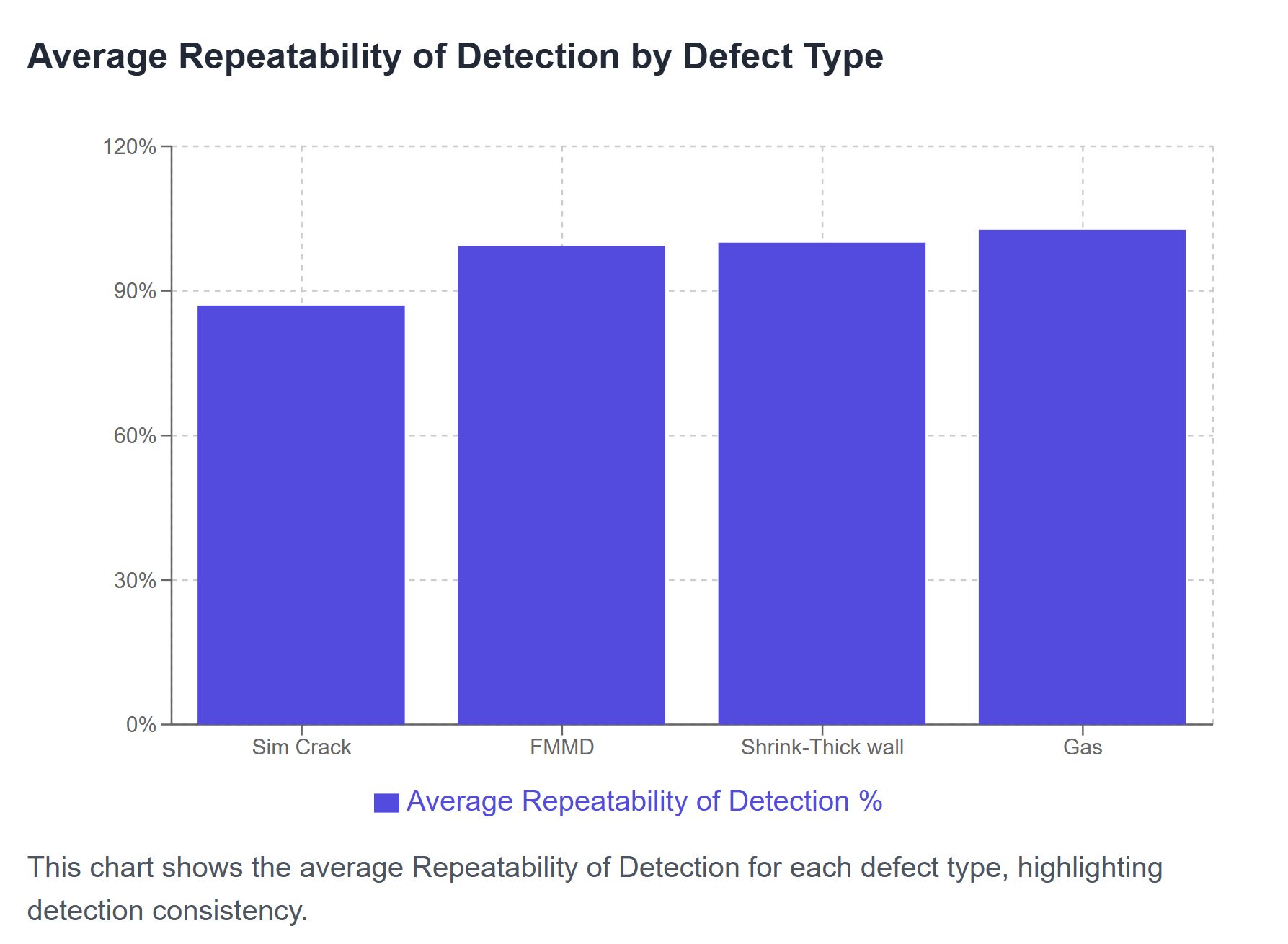

Summary of Study

This study analyzed the performance of an Assisted Defect Recognition (ADR) using an automated processing system across 360 trials, focusing on repeatability of detection in radiographic testing. Key metrics include Repeatability of Detection and Pixel Coverage. The ADR processing time is consistently 1.5 seconds per image.

- Overall Average Repeatability of Detection: 97.25%

- Defect Types Analyzed: 4

- The defect type “Simulated Crack” has the lowest average Repeatability of Detection at 86.97%, indicating potential challenges in detection.

Fig. 3: Chart showing average repeatability of detection by defect type for the ADR used in the study

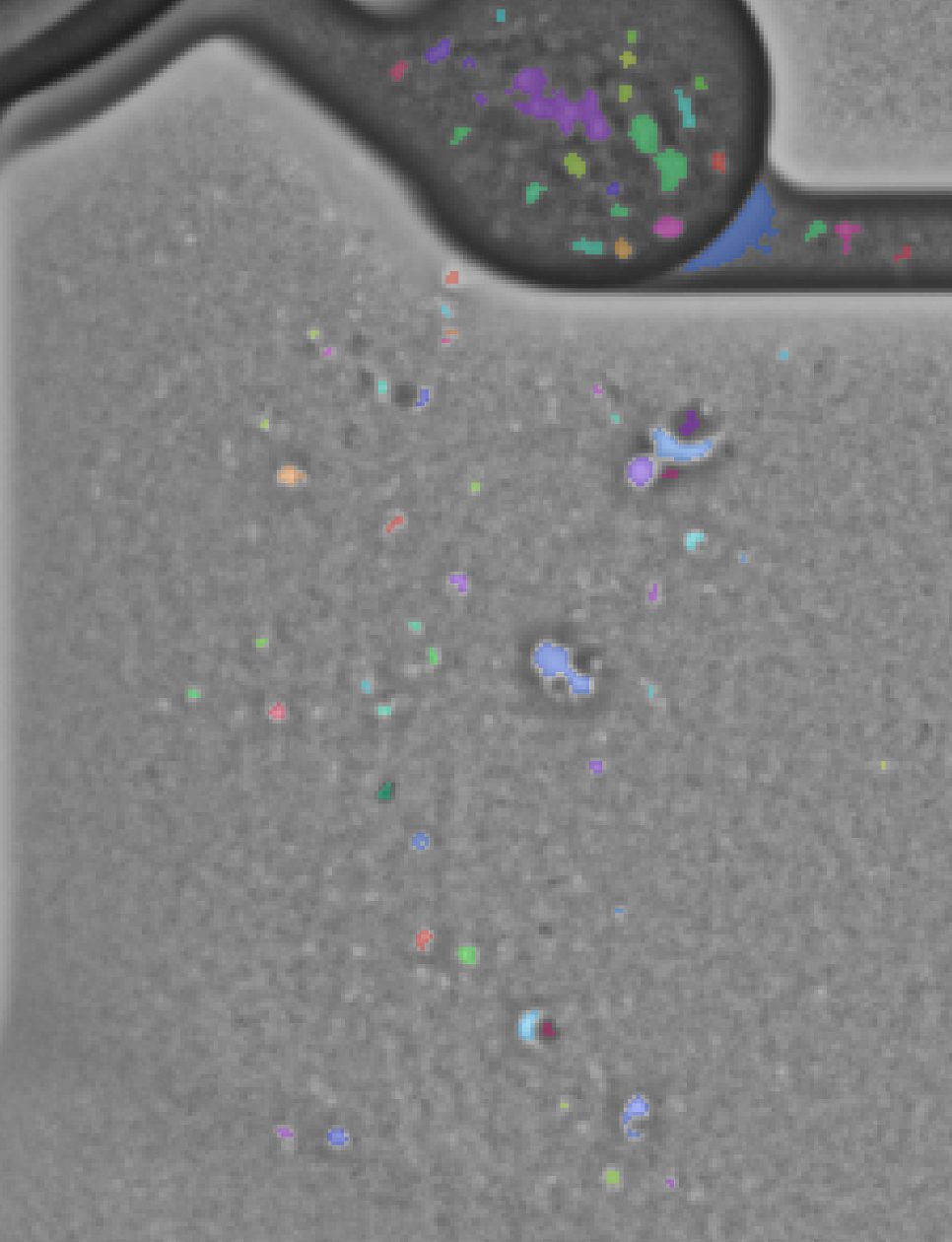

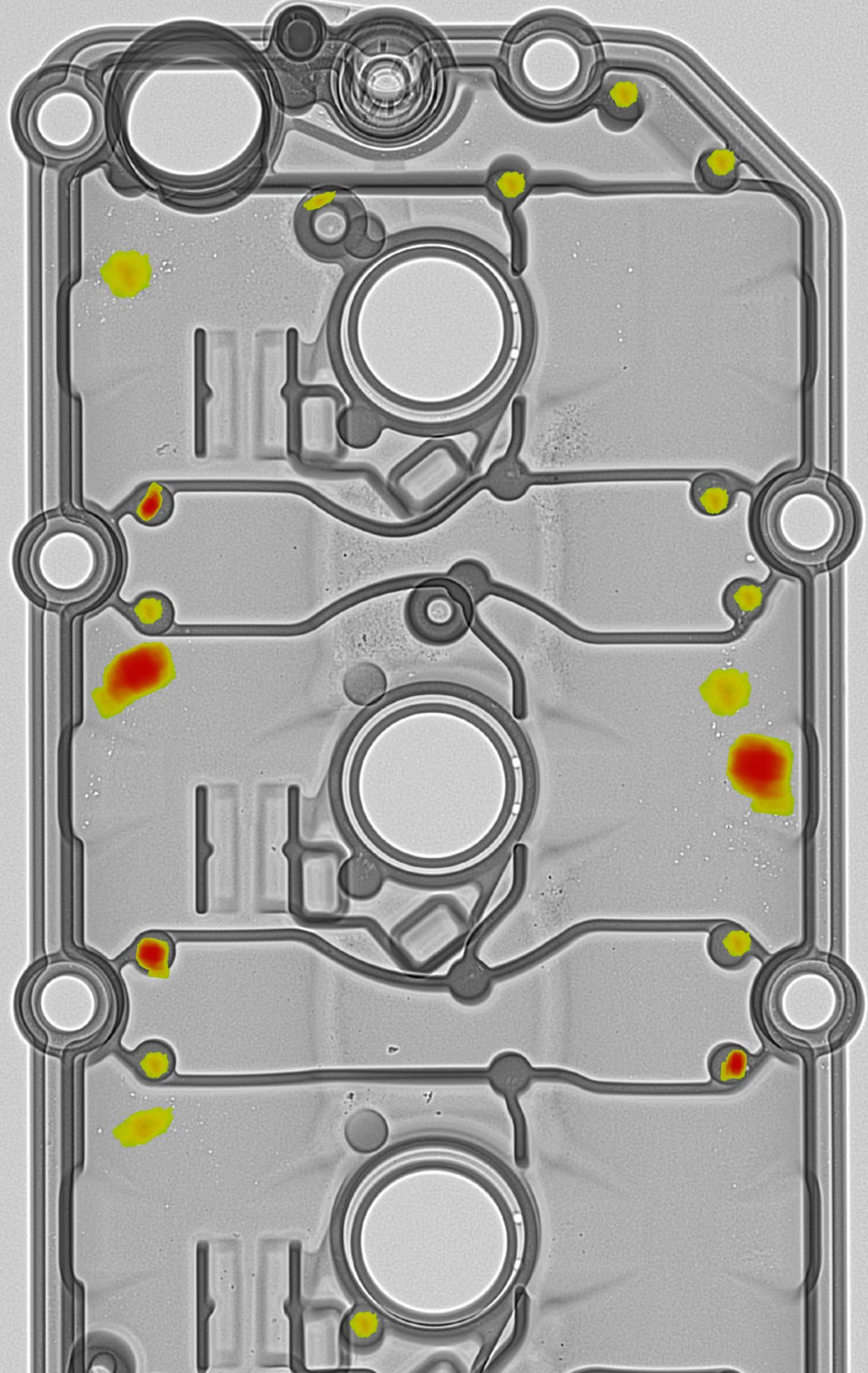

Heat Map in ADR

In engineering, comparing actual product output to designed input is crucial. The ADR system used provided a valuable feature that helped pinpoint problem areas in parts. It analyzed a large set of ADR images, identified indication locations and displayed them as shaded, color-coded spatial mappings based on severity.

Fig.4: Heat map showing technician areas of interest for further interpretation

POD and TPR per ASTM E3327

It is important to note that ASTM E3327 provides a detailed framework for calculating Probability of Detection (POD) and True Positive Rate (TPR), offering a standardized method for validating ADR performance.

Output, Reporting and Human Oversight

Effective reporting and data output are critical for Level II and Level III technicians to communicate effectively to engineers, allowing them to monitor and optimize their processes. Clear, actionable data provides insights into performance, bottlenecks, and trends, enabling engineers to make informed decisions. By tracking key metrics, engineers can identify areas for improvement, streamline workflows, and enhance efficiency. Well-structured reports transform raw data into meaningful information, empowering engineers to refine their processes and achieve better outcomes.

While ADR offers a lot of advantages in NDT in general, it is imperative for systems to be monitored by experienced professionals and for those individuals to have override capabilities within the software, helping to implement “engineering judgment” based on experience and knowledge of the inspected components.

Archival: Long Term Storage, DCM, and Servers

Proper long-term storage of radiographs, particularly in the DICONDE format, ensures their preservation, traceability, and accessibility for future reference. DICONDE, a standardized digital format, enhances interoperability across systems, maintaining image quality and metadata integrity over time. Traceability allows engineers to track the history, origin, and context of each radiograph, supporting quality control, audits, and compliance with industry standards. This organized approach facilitates efficient retrieval, reduces data loss risks, and enables analysis for process improvements, ultimately enhancing reliability and decision-making in engineering workflows.

DR software programs eliminate the challenges of film-based processes. Key benefits include:

- Elimination of Film Storage: Replaces bulky film warehouses with digital storage, freeing up space.

- Streamlined Access: Removes the need to search for job-specific film crates, simplifying retrieval.

- Cost Savings: Cuts warehouse-related expenses, reducing operational overhead.

- Enhanced Traceability and Searchability: Leverages image metadata for improved organization and quick access to images.

- Durable Long-Term Storage: Ensures digital images remain high-quality over time, without degradation concerns.

These advancements make radiography more efficient, cost-effective, and reliable.

This case study highlighted a 2D digital radiography (DR) system and software as transformers for quality control in automotive and aerospace foundry casting. By integrating advanced automation, ADR software, and DICONDE-based archival, a user can achieve remarkable efficiency gains, reducing image evaluation time by up to 30% and boosting annual radiograph assessments significantly. The system’s high repeatability (97.25% overall) and robust traceability ensure reliable defect detection. Comprehensive reporting empowers engineers with actionable insights, while long-term DICONDE storage enhances data accessibility and process optimization. This solution defines precision and productivity in high-throughput manufacturing, such as found in the aerospace and automotive sectors.

Further development in ADR, AI, and digital integration will continue to expand the role of 2D DR in industry. Careful attention to system validation and best practices ensures these technologies contribute meaningfully to the safety and performance of critical components.

References:

- ASTM E2597/E2597M-14(2020), Standard Practice for Manufacturing Characterization of Digital Detector Arrays

- Liu, S. et al. (2022). “Nondestructive Evaluation of Battery Packs for EVs Using Digital Radiography.” Journal of NDT Technology, 48(2), pp. 112–120.

- “Assisted Defect Recognition (ADR): Digital Tools for Consistent Image Evaluation.” ASNT Materials Evaluation, Vol. 79, No. 3, 2021.

- 4nsi.com. (2023). How to Apply Industrial Automation Solutions in Industrial X-ray and CT Scanning, https://4nsi.com/how-automate-industrial-ct-and-x-ray-scanning

- ASTM E2737-10(2019), Standard Practice for Digital Detector Array Performance Evaluation and Long-Term Stability

- 4nsi.com. (2025). How 2D Digital Radiography Enhances Automotive and Aerospace Quality Control, https://4nsi.com/case-study/how-2d-dr-enhances-automotive-and-aerospace-quality-control/?utm_source=quality