This Case Studies Special Advertising Section features manufacturing companies with real-world challenges using quality equipment, software and services to solve their problems and improve their processes. These problem-solving stories describe myriad manufacturing challenges and how the correct application of a supplier’s product or service made the difference, providing quantitative benefits to quality and manufacturing issues.

The suppliers in this special section present these real-world problems and solutions to help Quality Magazine subscribers who may have similar experiences.

Case Studies

— Special Advertising Section —

GAGEtrak® Helps Halliburton Improve Measurement Quality in Energy Technologies

Founded in 1919, and with more than 60,000 employees worldwide, Halliburton serves the upstream oil and gas industry throughout the life cycle of the reservoir – from locating hydrocarbons and managing geological data, to drilling and formation evaluation, well construction and completion, and optimizing production through the life of the field.

Challenge: Responsible for ensuring that the company’s several thousand gages are properly managed, tracked and calibrated, Halliburton’s Kathy Paredes needed to save time, reduce costly errors and inconsistencies associated with storing and tracking data via spreadsheets and implement company-wide standardization of gage and calibration data.

Solution: GAGEtrak® Calibration Management Software by CyberMetrics. Halliburton initially installed one license of GAGEtrak at a single location in early 2005 because it is “easier to use and has a place for all the required information to maintain our gages,” Paredes says. She also notes that her favorite GAGEtrak features are “the calibration due list and the ability to develop custom reports.” Paredes has also had great success with CyberMetrics’ support team, commenting that “the support team is very helpful and they teach me something new every time I call.”

Impact: Halliburton found GAGEtrak to be such a valuable asset that since 2005, they’ve installed GAGEtrak at an additional 60 locations worldwide. Halliburton continues to use GAGEtrak “because it is the best fit for all locations whether they calibrate their own gages or have them outsourced.”

GAGEtrak is used at thousands of facilities worldwide to improve measurement quality, assure compliance and increase efficiency. Contact the GAGEtrak experts today to learn how it will do the same for your company.

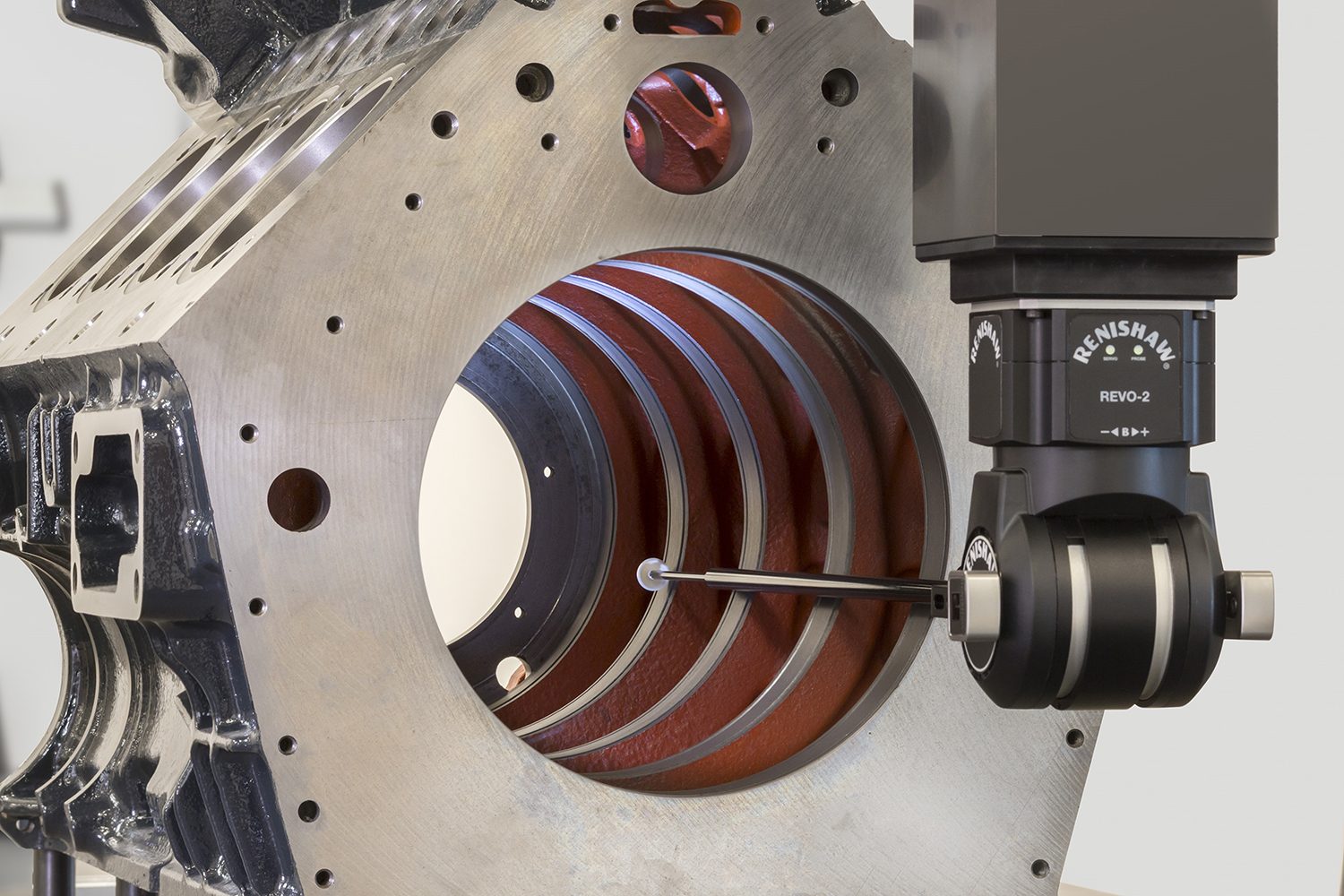

Aerospace sub-contractor eliminates bottleneck with REVO® system

ANT Industries carried out a study on its production processes with the aim to make improvements, it was clear that inspection was a major bottleneck. However, following the purchase of a new co-ordinate measuring machine (CMM) equipped with a Renishaw REVO five-axis scanning system, the situation has changed markedly.

“Now we have the new machine we are playing a different game – there is no other option to REVO, nothing else comes close”, adds Mr. Rowley. “The closest alternative was a system costing five times as much, but it wouldn't have achieved the same levels of throughput.”

With a sophisticated, highly efficient machining operation, ANT Industries also use Renishaw's spindle-mounted touch probes and tool monitoring systems for process control on their multi-axis machining centers and CNC lathes. However, post-process inspection had to be improved to keep pace.

The system uses Renishaw's MODUS™ metrology software, which has particularly impressed Mr. Naylor. “Support from Renishaw has been excellent, not just in training operators in using the MODUS software but also introducing a new way of thinking to inspection methods. It could have been intimidating but it turned out to be a very straightforward transition.”