xxxxxx xx

xxxxxxxxxx

Additive

NDT

NDT

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

It’s tempting to think of AM quality as a wholly unique challenge. In truth, many of the issues are identical to those in traditional manufacturing. By Colin Spellacy

Why Additive Manufacturing Must Mature to Deliver on Its Promise

For decades, additive manufacturing (AM) has captivated engineers and innovators alike. Its promise of limitless design freedom, rapid prototyping, and on-demand production has spurred widespread excitement. Yet as AM transitions from prototyping into full-scale production, a new reality is emerging, one that exposes a critical bottleneck threatening its credibility as a serious manufacturing method.

That bottleneck is quality.

For too long, AM has been seen as disruptive because of what happens inside the build chamber. But in real-world production environments, where end-use parts must be consistent, functional, and cost-effective at scale, the technology is facing the same expectations that have underpinned conventional manufacturing for decades. In this arena, it’s not the ability to print that determines success. It’s the ability to finish.

WHY QUALITY IS AM’S MAKE-OR-BREAK ISSUE

In the context of AM for production, quality is non-negotiable. It extends far beyond simple material strength or dimensional accuracy. It means achieving repeatability across batches, ensuring surface finishes meet stringent application standards, and building traceability into workflows to satisfy regulators and end-users alike.

This shift has caught many in the AM world off guard. For years, speed and design freedom were the metrics by which additive technologies were measured. But in sectors like aerospace, medical, and automotive, the conversation has changed. A part isn’t “manufactured” unless it can be produced reliably, finished to specification, and validated for end-use performance.

Here lies the challenge. AM parts often leave the build chamber in a state that is far from production-ready. Powder residues, support structures, and rough as-built surfaces mean post-processing is not an optional extra, it’s an integral part of the manufacturing workflow. Unfortunately, too many in the AM space still treat post-processing as a nuisance rather than a strategic discipline. That mindset must change.

POST-PROCESSING

The most overlooked fact in AM is that post-processing determines whether a printed component will succeed in the field. Whether it’s cleaning, smoothing, or refining geometries, these steps bridge the gap between “printed” and “production-ready.”

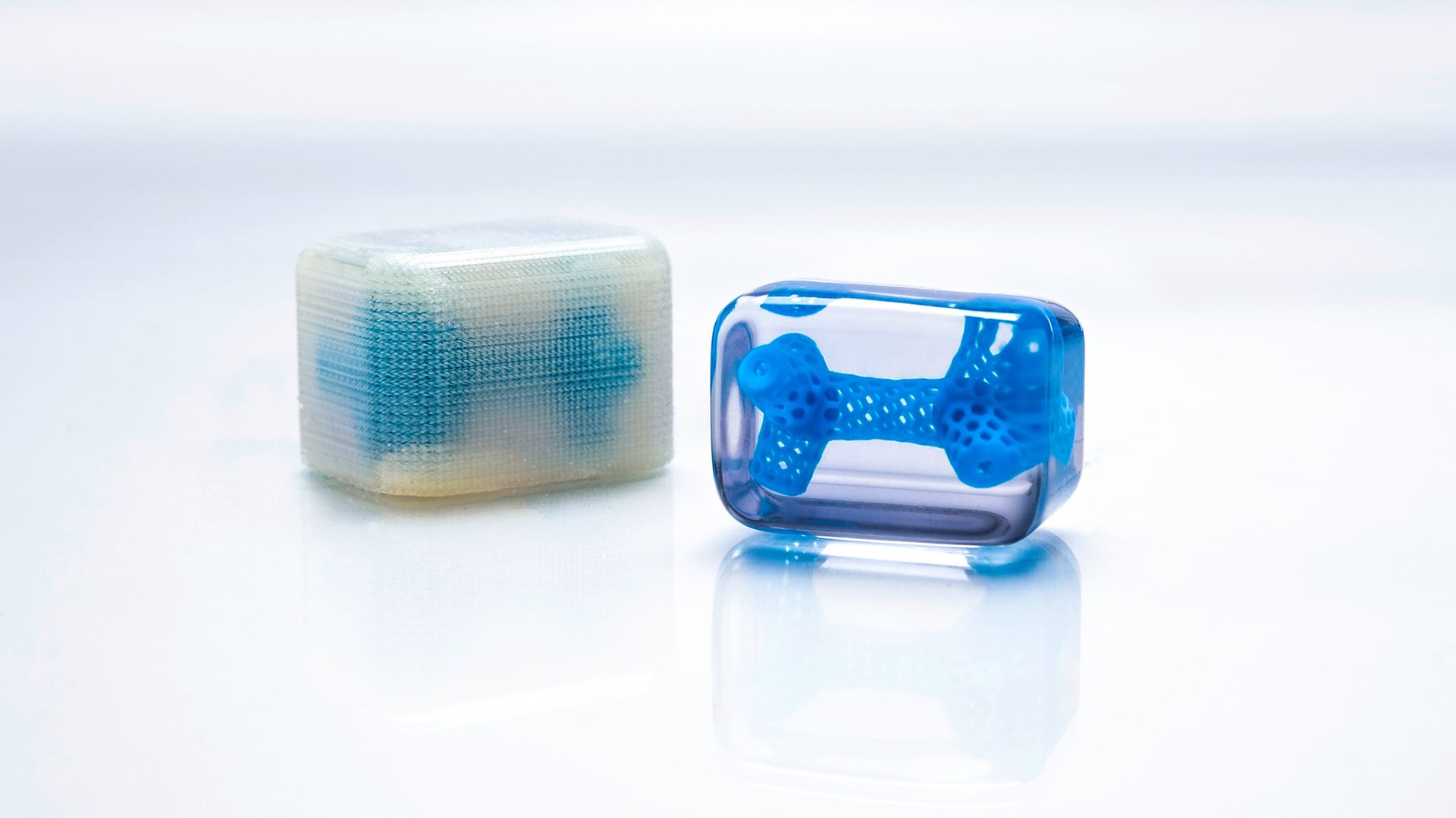

Yet the reality on the ground can be sobering. Manual depowdering, sanding, or ad hoc cleaning are still commonplace. These methods are not only labor-intensive and inconsistent, but they also fail to scale as AM moves into higher-volume production. Automated, repeatable post-processing isn’t therefore a luxury, it’s essential for achieving the levels of consistency and efficiency demanded by modern manufacturing. Systems that combine multiple steps (such as depowdering and surface finishing) into a single workflow are proving critical in helping manufacturers reduce handling times, cut costs, and ensure quality across every batch.

QUALITY IN AM

It’s tempting to think of AM quality as a wholly unique challenge. In truth, many of the issues are identical to those in traditional manufacturing, parts must be finished and validated to ensure they function as intended.

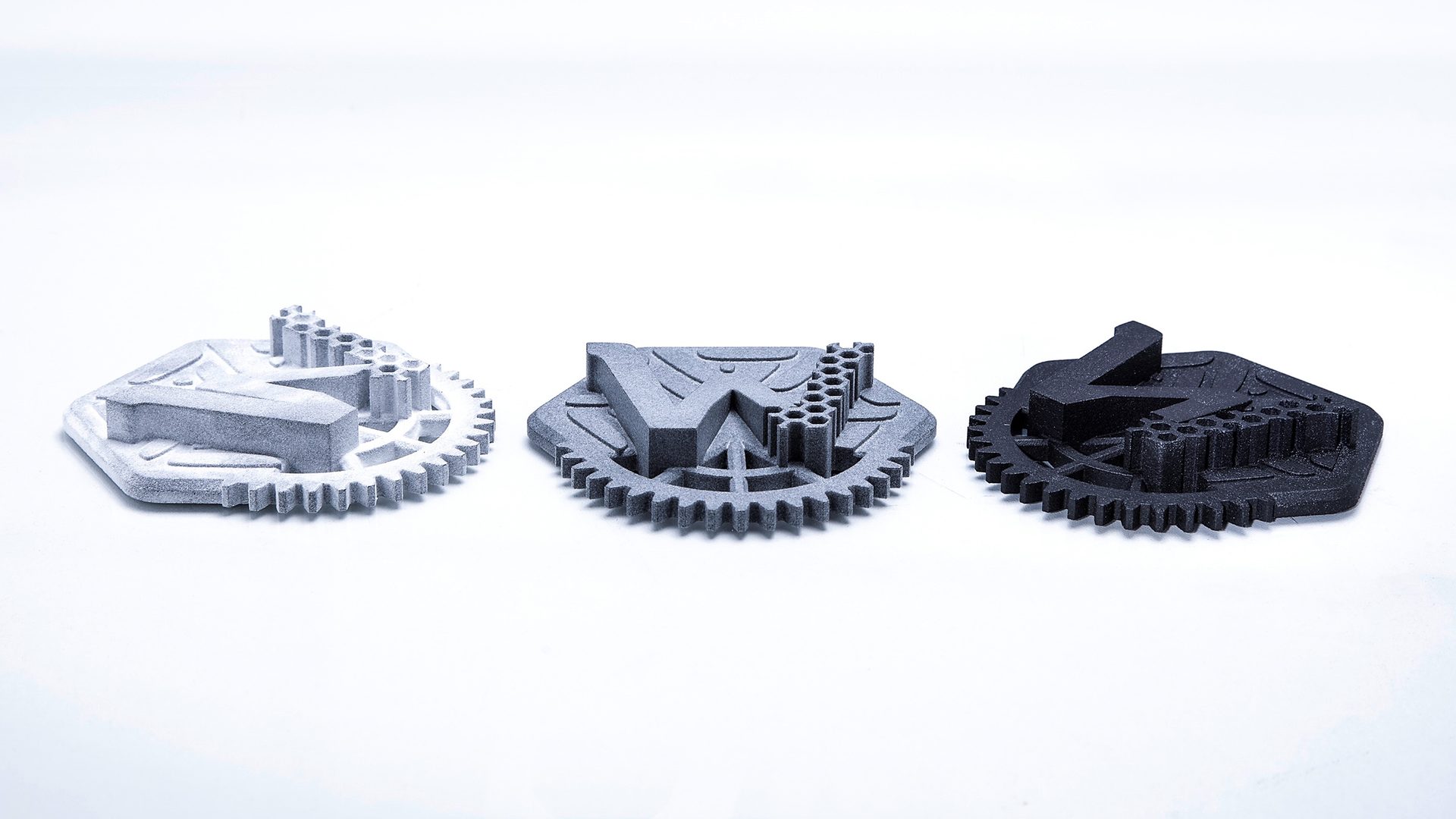

However, additive processes introduce “added layers” of complexity that require careful management. Powder removal, for instance, isn’t just about improving appearance. Trapped particles can compromise functionality or even create safety hazards in critical applications. Surface finish, too, plays a central role in determining mechanical properties like fatigue resistance, corrosion protection, and aerodynamic or fluid dynamic performance.

Then there’s the geometric complexity of AM parts, which often include intricate lattice structures or delicate features that traditional finishing techniques struggle to accommodate. And finally, repeatability is paramount. Achieving consistent, validated results at scale requires finely tuned, automated processes that eliminate variability and deliver the same result every time.

In short, AM parts need to be finished, and shown to be finished, to standards that meet or exceed those of conventionally produced parts.

EFFICIENCY AND COST-EFFECTIVENESS IN FOCUS

As AM is increasingly adopted for production, cost-per-part becomes a defining metric. Post-processing cannot be the weak link that erodes the efficiency gains achieved elsewhere in the workflow. This is why the shift towards automated, multi-step solutions is so significant.

Integrated systems that depowder and finish parts in a single process are helping manufacturers streamline operations and reduce labor costs, while ensuring consistent outcomes. These solutions don’t just save time, they minimize the risk of damage from excessive handling, lower contamination risks, and support cleanroom-compatible processes for industries like medical and aerospace. Ultimately, efficiency and quality go hand in hand. If post-processing cannot scale economically, neither can AM.

THE NEW ROLE OF SURFACE FINISHING IN AM

Surface finishing in AM is often misunderstood as a purely aesthetic concern, yet it directly influences part performance. A poor surface finish can create stress risers that lead to premature failure, compromise wear resistance and sealing surfaces, undermine biocompatibility in medical applications, and negatively impact aerodynamic or fluid dynamic performance in aerospace and automotive parts.

Advanced finishing techniques, whether mechanical, chemical, or hybrid systems, are vital in bringing AM parts up to specification. The key is developing processes that are robust, validated, and compatible with high-throughput production environments.

THE CALL FOR BETTER CONVERSATIONS ABOUT QUALITY

If AM is to fulfil its promise as a production technology, the conversation around quality needs to shift. It’s no longer enough to ask, “How fast can you print this?” or “What’s the cost per part?” The better questions are, how do we ensure these parts meet functional and aesthetic requirements every time? What processes are in place to validate surface integrity and cleanliness? And can this workflow scale economically without sacrificing quality?

Forward-thinking manufacturers are already asking these questions. Those that aren’t risk being left behind as AM matures into a truly industrialized process.

Our mission has been to bring the same level of innovation to post-processing that additive has brought to design and manufacturing. By developing intelligent systems that automate critical post-processing steps and deliver repeatable results, we’re helping manufacturers close the gap between potential and performance.

THE FUTURE OF QUALITY IN AM

The future of AM belongs to those who treat quality as a strategic priority. As the technology matures, the winners will be the companies that integrate automated, efficient post-processing workflows and embrace surface finishing as a core competency, not an afterthought.

Because in the end, quality isn’t just about making parts that look good, it’s about making parts that work in the real world, every time.

It’s time for AM to mature and meet the same standards that have defined excellence in conventional production for decades. And it starts with rethinking how we finish.