Automotive

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Test & INspection

the role of connected workers will continue to evolve. By Eric Whitley

5 Important Ways Connected Worker Tech Benefits the

Automotive Industry

As our world becomes increasingly influenced by digital innovation, the rise of connected worker technology marks a significant turning point in our approach to industrial operations.

Connected worker technology is essentially a suite of tools and platforms that provide real-time communication, collaboration, and data accessibility to workers, maximizing operational efficiency and productivity.

These tools range from wearable devices and mobile apps to augmented reality (AR) and Internet of Things (IoT) devices, all designed to deliver information directly to workers when and where they need it.

These technologies dramatically redefine the automotive manufacturing process. Examples include smart glasses used for minimizing errors, IoT devices that ensure seamless supply chain management, and connected safety gear triggering alerts in potentially hazardous situations. This symbiotic relationship between the worker and technology underpins the modern automotive manufacturing facility.

Connected Worker Technology in the Automotive Industry

The automotive industry has undergone radical changes with the advent of digital technology, and the adoption of connected worker technology has set a new standard in the industry by enabling operations to be more efficient, precise, and adaptable to changing market demands.

Several key industry trends underscore the growing necessity of connected worker technology:

Increasing demand for customization: As consumers increasingly seek personalized vehicles, connected worker technology allows for more flexible production systems that can efficiently handle customized orders.

Sustainability and resource optimization: With a growing emphasis on reducing carbon footprint and waste, connected technologies provide data-driven insights for efficient resource utilization.

Rapid technological advancement: As vehicles become more technologically complex, connected worker tech supports workers with real-time information and guidance to assemble, test, and maintain these advanced machines.

xxxxxxx

xxxxxx

xxxxx xxxxxx.

Introduction to the Benefits of Connected Worker Tech

The impact of connected worker technology on the automotive industry is multifaceted, with significant benefits across a wide array of operations. In the following sections, we delve into five key areas where this tech is having a transformative impact.

Increasing Operational Efficiency

Connected worker technology can significantly enhance productivity by reducing manual labor and automating processes.

For instance, IoT-enabled smart tools can automate repetitive tasks such as tightening bolts to the correct torque or applying precise amounts of adhesive. Additionally, smart glasses can provide workers with real-time visual instructions, reducing the time taken to refer to paper manuals or computer screens.

Enhancing Quality Assurance and Control

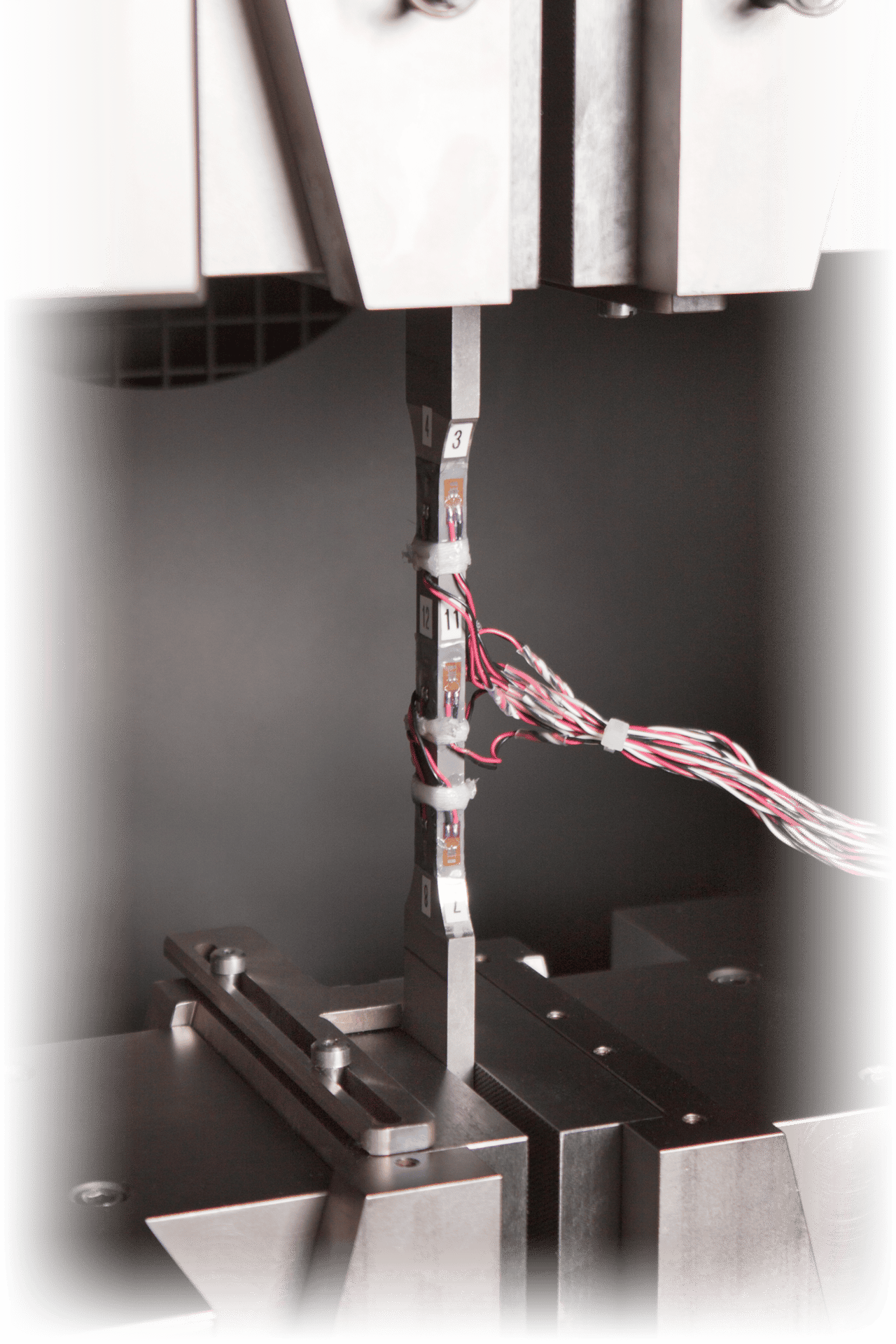

Connected devices play a crucial role in maintaining consistent product quality, especially by integrating sensors and software into the assembly process.

Workers can use handheld scanners or wearables to scan barcodes or QR codes on parts, ensuring the correct components are used at each step. Connected systems can also detect deviations from the standard process in real time, enabling immediate correction and reducing the likelihood of producing defective vehicles.

Promoting Worker Safety

The technology also promotes worker safety. Wearables equipped with biometric sensors can monitor workers’ heart rate, body temperature, and other vital signs, alerting them and their supervisors of potential health risks.

Smart helmets and vests are another great example. These can detect unsafe environmental conditions, such as high noise levels or hazardous gases, providing immediate alerts to the wearer. Companies like Toyota have reported a decrease in workplace injuries following the implementation of these technologies, which we’ll expand on later.

Encouraging Collaborative Work Environments

Another important facet of modern manufacturing is a collaborative work environment, and connected technology helps build one by facilitating seamless communication among workers.

AR headsets can enable remote assistance, where an expert can guide a worker through a complex task from a different location, and improve problem-solving. Collaborative platforms can foster a culture of knowledge-sharing and innovation, where workers can easily share insights and best practices.

BMW, for example, reported improved problem-solving efficiency after introducing collaborative tech in its factories.

Improving Training and Skill Development

Companies are revolutionizing their training programs as well. With AR-based training, workers can learn complex tasks in a safe and controlled environment. But it doesn’t stop here; connected tech can facilitate on-the-job learning, where workers receive real-time guidance as they perform tasks.

This not only enhances their skills but also accelerates the learning process. Volvo, after introducing AR-based training, reported a reduction in training time and an improvement in skill levels — another example we’ll explore in more detail below.

Examples of Connected Worker Technology in Action

Real-life applications of connected worker technology are the place to get valuable insights into its practical benefits. The following examples explore how leading automotive manufacturers have used this technology to improve quality assurance, training, and worker safety.

The BMW Group's Use of Smart Watches for Quality Assurance

The BMW Group set a compelling example of adopting smart watch technology in their assembly lines for quality assurance. The smart watches were integrated with their quality control systems, providing real-time notifications and instructions to the workers.

The watches would vibrate to signal the successful completion of a task or to alert about any discrepancy during the assembly process. As a result of implementing this innovation, BMW reported a significant decrease in assembly line errors and increased the overall efficiency of their operations.

This feedback mechanism also improved worker engagement and job satisfaction rates.

Volvo Cars' Adoption of Augmented Reality for Training

Volvo Cars took an innovative leap by introducing augmented reality (AR) technology for training its workers.

Using AR headsets, trainees could experience the entire assembly process in an immersive 3D format, providing them with a deeper understanding of their tasks. The training simulations included real-world scenarios that they might encounter, helping them troubleshoot and make decisions.

Volvo reported that this approach resulted in a 60% reduction in training time and a notable improvement in skill retention among trainees. The company also reported an increase in the overall productivity of the newly trained workforce, underscoring the long-term benefits of this AR-based training method.

Toyota's Approach to Connected Worker Safety

Toyota focused on the safety aspect of its workers by investing in wearable safety tech.

Workers were equipped with exoskeletons and wearable sensors to monitor their physical conditions and detect potential hazards in their environment along with helping workers to perform their tasks more easily.

For example, their Strongarm FUSE Platform uses machine learning to capture and analyze trunk movements, develop a safety score, and improve their workers’ lifting technique. Reportedly, 83% of team members improved their lifting technique, resulting in a 15% injury risk reduction by the end of the trial.

Implementation of these different solutions resulted in a significant reduction in the incidence of accidents and health-related issues on the factory floor. For example, Toyota reported it reduced its injury compensation costs to zero on processes where shoulder exoskeletons were successfully deployed.

The Future of the Connected Worker in the Automotive Industry

At the precipice of a technological revolution, connected worker technology will likely play a pivotal role in shaping the future of the automotive industry. As technological innovations become more deeply embedded in industrial processes, the interaction between humans and machines will continue to evolve.

We can anticipate several trends in the near future:

1.Greater reliance on data analytics

With increased adoption of IoT devices in the manufacturing landscape, the volume of data generated is expected to grow exponentially.

This massive influx of data, often termed “big data,” can provide invaluable insights into various aspects of operations. Real-time analytics can enable quick decision-making, predictive analytics can foresee potential issues and prevent downtime, and prescriptive analytics can provide optimized solutions based on historical data.

This heightened reliance on data analytics could streamline manufacturing processes, cut down waste, improve efficiency, and ultimately lead to better-designed and manufactured vehicles.

2. Advancements in wearable tech

Wearable technology is expected to evolve significantly, offering a wider range of functionalities. Innovations in wearables could extend beyond merely providing instructions or monitoring workers’ health.

They could become more integrated into the workers’ tasks, serving as a tool to manipulate digital information or providing more comprehensive and real-time overviews of production metrics.

Future wearable devices could also harness biometric data to a greater extent, tracking fatigue levels, stress, and even cognitive load, all to better manage workload and ensure worker well-being. These advancements could lead to more proactive and preventative measures for worker safety.

3. Increased use of AR and VR

Both AR and VR technologies are anticipated to become even more integral parts of the automotive manufacturing process. They’re expected to play larger roles not just in training, but also in real-time problem-solving, quality control, and maintenance tasks.

For instance, a worker could use AR to visualize the internal components of a machine without disassembling it or use VR to simulate and test an assembly process before it’s implemented on the production line.

As AR and VR become more refined and accessible, their use cases in the automotive industry are likely to expand, offering more immersive, interactive, and efficient ways to work.

4. Integration with AI

As AI capabilities continue to advance, AI is expected to become more deeply integrated with connected worker technology.

AI can process vast amounts of data and crunch the information into predictive analytics, potentially foreseeing issues before they occur and suggesting preemptive solutions. Furthermore, AI can automate repetitive or dangerous tasks, freeing up human workers for more complex and creative tasks.

It can also provide personalized assistance to workers, understanding their unique work patterns and tailoring the information it provides accordingly. The integration of AI can result in not just more efficient and safer operations, but also a more adaptable and resilient workforce.

The confluence of these advancements in connected worker technology will likely lead to a manufacturing environment that is more flexible, efficient, and responsive to rapidly changing market demands. This allows the automotive industry to innovate, drive productivity, and improve worker safety and satisfaction, setting a benchmark for other industries to follow.

Conclusion

Connected worker technology and its revolutionary potential have become an indispensable part of the automotive industry. As we navigate towards the future, the role of connected workers will continue to evolve, driven by continual advances in technology. It’s therefore crucial for the automotive industry to embrace this technological revolution and work on shaping a future that is as much about the people as it is about the cars they produce.