Trends

Inspection

NDT

Size, Safety and Software: Driving Innovation in Nondestructive Testing of Electronics

There’s no doubt that technology is rapidly advancing in the automotive industry.

By Alex Geiger and Brandon Miller

The future of the automotive industry depends on sustainability and rapidly changing innovation. The availability and adoption of advanced technology solutions is driving the majority of the underlying trends in the marketplace. The demand for electric vehicles, connected cars, mobility fleet sharing, onboard sensors for safety, and always-on connectedness requires new production techniques as well as a reliable method of inspection.

Today’s vehicles could be equipped with anywhere from 60 to 150 sensors to keep everything running the way it should. While automakers continue to adopt smart and autonomous driving technology for the vehicles they manufacture, the total number of sensors as well as their sophistication increases. These sensors, including the electronic and electromechanical components within them, control everything from performance characteristics, temperature inside the vehicle, driver alerts for forward collision warnings to automatic braking, self-parking and so much more.

Due to this rapid sophistication, the numbers of electronic and electromechanical components are not only increasing in number but also in variation. Differing size, complexity of design and weight make each sensor a unique inspection challenge. Each one must pass a failure analysis to ensure the safety and reliability of the part, critical in an industry like automotive where it can be the difference between life and death.

That’s why it’s so important to identify the best inspection technique for the highest quality and reliability. One of the best methods is nondestructive testing (NDT) with computed tomography (CT). In 2020, the automotive industry ushered in a new decade of innovation, and although the year was fraught with challenges due to the pandemic, the industry managed to persevere. The setbacks of 2020 also gave automakers the opportunity to slow down and reposition themselves as they emerge from the crisis on a new path towards electrification and connectivity. Some major areas of focus include safety, energy efficiency, buyers’ expectations and adherence to legislative regulations. This article addresses meeting and exceeding the levels of quality to enable growth in all these areas with a focus on utilizing new X-ray and CT tools for faster and more accurate results; NDT inspection is the key to success.

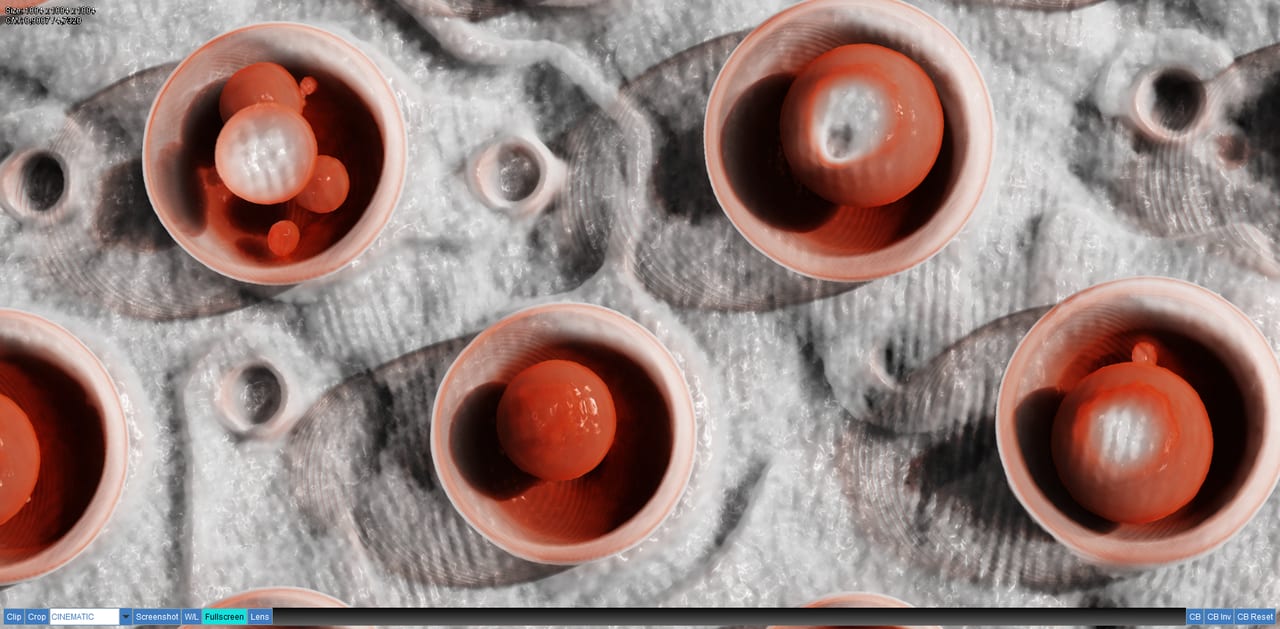

CT imaging of an LED headlight assembly with segmentation of components for ease of visualization. Source: Yxlon FF85 CT

Some of the most common electromechanical and electronic parts that nondestructive industrial computed tomography can provide solutions for are:

- Printed Circuit Boards (PCBs)

- Bare Boards

- BGAs / LGAs

- QFNs / QFPs

- Plated Through Holes

- Insulated-Gate Bipolar Transistors (IGBTs)

- Micro-bumps

- Sensors

- Micro-electromechanical systems (MEMS)

- Micro-opto-electromechanical systems (MOEMS)

- Through-silicon vias (TSVs)

- Batteries

- Connectors

Size

Increased complexity is not the only issue. There are also size, weight, and throughput extremes pushing the limits for manufacturers. Miniaturization of components to increase functionality, use of heavy and dense materials in EV batteries, and the sheer volume of sensors are all demanding new and improved methods of quality assurance.

Miniaturization

Electronic components are becoming smaller and smaller to be integrated into mechanical and other devices on the vehicle to increase functionality and connectedness. 3D imaging via laminography or CT can be used to identify cracks, open solder joints, or voids to reduce the risk of failure. With new, larger detectors (see next image) sub-micron detail detectability in 3D imaging is now possible in a fraction of the time. This enables the manufacturer to optimize their process workflow before beginning production while the manufacturing runs are still agile and able to be corrected relatively easily. Optimizing at the smallest level possible ensures long-term functionality and minimal recalls.

Battery Inspection

There are many challenges to consider when inspecting a battery, including their size and density of material. Each battery contains many different layers that, depending on the composition of the materials, deteriorate over time. When batteries deteriorate, it can lead to fires that are not easily controllable, which greatly increases the risks and consequences of failure. With industrial X-ray, quality managers can see through the various layers of the battery to identify any potential issues that may lead to a cycle/fatigue failure in the field. Utilizing a scanner set for maximum signal and a heavy-capacity load tray to increase weight capability, battery production can be designed with the highest safety and performance standards possible. Catching battery defects during R&D and in production can greatly reduce the risk of a total failure after several months of operation.

Throughput Requirements

A side effect of increasing the usefulness of each individual device means more electronics are required in total. The number of electronic sensors and boards required for each vehicle has increased to over 100 in many cases. To achieve adequate quality assurance on these components, X-ray inspection must be able to keep up. Luckily, the latest generation of detectors have been optimized for high sensitivity, resulting in throughputs more than double what used to be possible. Coupling these detectors with algorithms to aid inspection, total effectiveness of each inspection system can be multiplied for maximum cost-effectiveness.

3D imaging of BGA solder balls with voiding. Source: YXLON Cheetah EVO with ORYX 1616 detector

Safety

In order to demonstrate compliance with legislative requirements of all electronics and electromechanical parts used to create the newest offerings of the automotive industry, extensive data collection and testing is required. A single non-compliant part represents a very real risk, not only from a legal perspective, but also from a market recall that could cripple an organization. Of course, the greatest risk of part failure is the possibility of injury or even death. Proper inspection can greatly reduce or even eliminate unnecessary risks.

Accuracy

It is important to be able to define the accuracy and measurement error associated with inspection processes to quantitatively define risk. With the latest technology available in CT systems, it is now possible to define accuracy in the single-digit-micron range even for completely enclosed surfaces. Many times, there is no other way to nondestructively measure production components for field use.

Reliability & Traceability

It is one thing to be able to inspect and measure components, but without reliable and traceable processes, this data could become useless as soon as the components move to the next process. Utilizing repeatable fixturing and programmable inspection plans, automated reports can be generated on a serial number level to allow for traceability when the inevitable failure does occur. While the damage may be done, going back to analyze the images and reports can ensure manufacturers are continuously improving their products and thus, continuously making our roads safer.

Software

Once you’ve identified the right method of inspection and data acquisition, the next step is the software analysis. The secret to successful analysis lies in the software you choose. It is key to visualize the data in the most effective way to ensure all indications are clearly identified and stand out from the background. Software can not only enable the operator to view the data but the computer itself can use algorithms to pick up subtle details that the human eye may have missed. Not to mention, these software tools make it faster and more repeatable across different operators, shifts, and even different regions.

Automatic Defect Recognition

Artificial intelligence and machine learning have become buzzwords in every industry, and inspection software is no different. Utilizing new algorithms from software (see next image), laminography data can be analyzed for voiding, BGA size, or die tilt in as few as three clicks. By making it easier (and faster!) to quantify data reliably, quality standards and procedures can be built around data, and trends can be analyzed over time for patterns. The automotive market often doesn’t have time for 100% inspection of every component, every time. Using trustworthy software to help guide decision making will guarantee the best outcome.

Laminography data of voiding in various leads. Source: YXLON Cheetah EVO

Automation

Another major trend sweeping across the auto industry is automation. Whether that be assembly, welding, or even wiring, any chance to increase throughput and factory safety is thoroughly explored. Now it is becoming even easier to automate the inspection of samples with the use of acquisition software that seamlessly feeds directly into analysis and reporting. Entire inspection plans can be automated to include operator inputs as well algorithm outputs to encompass one single report per part. These reports can then be fed back into the manufacturing execution system for easy tracking of key metrics related to factory efficiency. These capabilities ultimately lead to a more trustworthy process that can reduce scrap and increase overall quality.

Laminography showing blown wire.

Source: YXLON Cheetah EVO

Support from Silicon Valley

The booming technology advancements in the automotive industry has been building over the past decade in Silicon Valley. This area, which has been known mainly for its long-standing global leadership in software development and product innovation, is fast emerging as the hub for research and development of the newest trends in the automotive industry. For example, the California Auto Tech Testing and Development Center (CATDC) located in this area is designed to support the rapidly evolving automotive industry providing state of the art testing and development.

According to Ellen Ray, application engineer for Comet Group Lab ONE in San Jose, “This area is teeming with company names you recognize in the automotive industry and so many new companies working to bring the next generation of vehicles to life.”

Summary

There’s no doubt that technology is rapidly advancing in the automotive industry. The demand for self-driving vehicles as well as a plethora of safety and driver-assist features mean the need for more sophisticated components is on the rise. Inspection is critical but complicated. The right inspection tool can make the difference between increased safety and productivity or failed parts and product recalls. When all is said and done, it comes down to size, safety, and software. The road to success for quality engineers lies in choosing the right inspection tool, the right software, and the right partner to guarantee safety and compliance in their automotive applications.

Image source: Yxlon International / Comet Group

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Alex Geiger and Brandon Miller, sales managers electronics, YXLON. For more information, email alex.geiger@yxlon.com or brandon.miller@yxlon.com or visit www.yxlon.com.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.