Products

the latest products to help you improve your manufacturing process

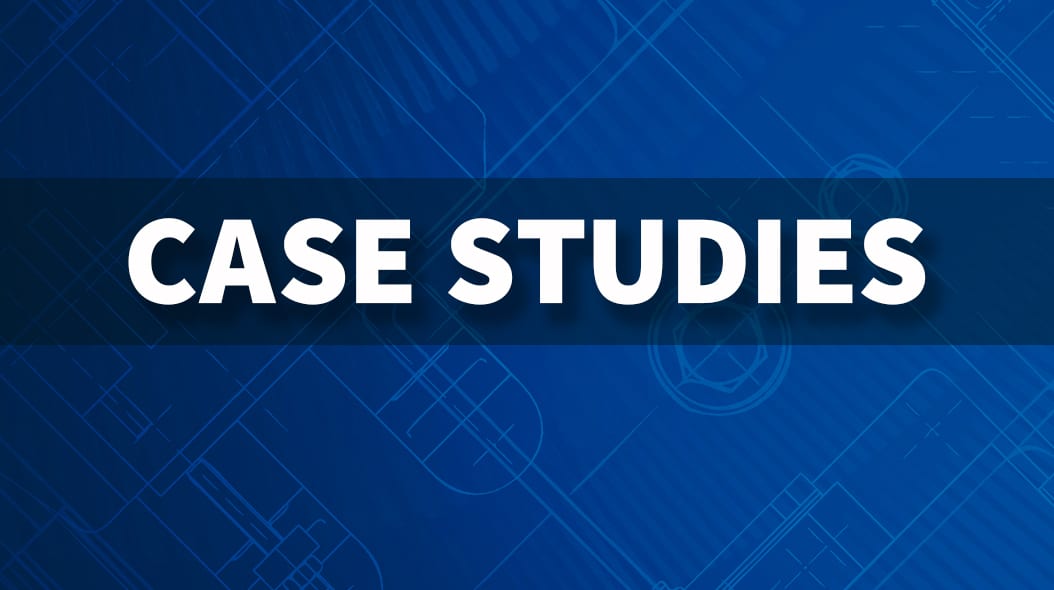

Mitutoyo America SJ-220 Portable Surface Roughness Tester

Mitutoyo America Corporation announced the release of the new Surface Roughness Tester SJ-220 Series to its line of Form Measuring Instruments, providing compatibility and versatility to meet the diverse needs of manufacturing sites.

The SJ-220 series of surface roughness measuring instruments offers excellent portability and easier use with touch screen functionality for more intuitive operability. It is equipped with a built-in battery that can be used approximately 1,000 times on a full charge, enabling operators to perform measurements in environments where power is not available.

Key Features and Benefits of the SJ-220 Surftest:

- Expanded Color Touch Screen: The SJ-220 features a larger 2.8-inch color touch screen for better visibility while maintaining a compact size to operate with one hand.

- New Interface: The SJ-220’s new user interface is more intuitive with easier operations such as changing the display screen and adjusting settings with your fingertip.

- Advanced Functions: The SJ-220 includes new functions such as being able to disable the touch screen for better security along with setting shortcuts using the HOME key for most-used functions.

- Increased Efficiency: The SJ-220 can now display results and set measurement conditions via wireless communication when used with the optional accessory U-WAVE-TIB.

- Compatible with New Standard ISO 21920

Advanced Illumination Launches New AL325 Modular Bar Light Series

Advanced Illumination, part of the Exaktera group, announced the launch of its AL325 Series Modular Bar Lights. This new series sets a higher standard for performance and adaptability, directly addressing the limitations encountered with traditional, fixed-configuration machine vision lights.

Machine vision integrators frequently face challenges adapting lighting to diverse or evolving inspection needs. Conventional bar lights often require purchasing entirely new units when beam angles or light conditioning needs change, leading to increased costs and project delays. Furthermore, during the crucial application testing phase, evaluating multiple fixed-optic loaner units can be cumbersome and inefficient. The AL325 Series overcomes these constraints with a modular system built around field-swappable lenses and light conditioning materials. This core feature allows users to easily experiment and optimize configurations directly in the field – eliminating guesswork, reducing setup time, and minimizing the need for extensive inventory.

Engineered for demanding applications, the AL325 Series leverages high-performance LEDs, efficient TIR (Total Internal Reflection) lenses, and superior thermal management to deliver best-in-class intensity, achieving nearly twice the brightness of leading competing modular bar lights. This significant advantage enables higher throughput speeds and improved image quality, even in challenging conditions.

Further enhancing its versatility, the AL325 series includes embedded control capabilities for simple, hassle-free continuous or overdrive strobe operation without external controllers. The scalability of the extrusion-based design ensures the AL325 can adapt to multiple size requirements, ranging from 150 mm to 2.1 m in length, providing optimal illumination for applications ranging from detailed component gaging to lighting for logistics scan tunnels.

To cater to a wide array of specific application requirements, the AL325 Series offers extensive customization. Customers can select from 16 different wavelengths. A variety of light conditioning options are available, including homogenizers, diffusers, polarizers, and specialized direction-turning films ideal for creating oblique lighting effects. Furthermore, the series features five distinct lens options, providing beam spreads ranging from a narrow 10° to an extra wide 56°, complemented by an elliptical lens choice for targeted 10° x 25° projections. Underscoring Ai’s commitment to rapid deployment, the AL325 features industry-leading build-to-order (BTO) lead times of just one to two weeks.

Advanced Illumination

https://www.advancedillumination.com/products/al325-series/

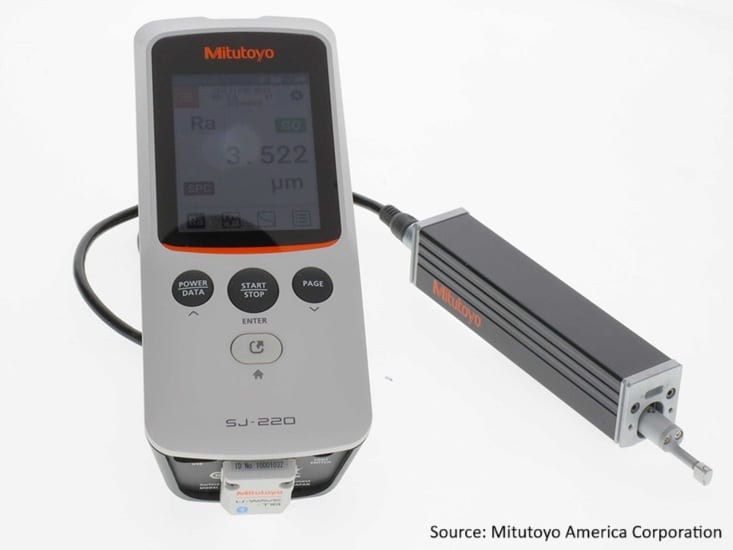

Zonetec Synergy 2000 v14.0 with Smart SPC Intelligence

Zontec Inc. introduced its AI-enabled statistical process control software, Synergy™️ 2000 v14.0 with Smart SPC Intelligence, featuring generative AI analysis and recommendations for process improvement.

Now, quality control professionals can instantly access powerful insights into their production processes. The new Smart SPC Intelligence reviews the charts produced by the software and analyzes them, providing a clear understanding of what is happening in manufacturing processes and how to improve them. The analysis provided helps companies reduce waste (which saves them money) and improve customer satisfaction by delivering higher-quality products.

When running Synergy 2000, teams currently generate reports and charts. Now, with version 14.0, they will be able to request an AI report of specific charts. That report will review the data and deliver insights immediately.

“Using Synergy™️ 2000 v14.0 with Smart SPC Intelligence is just like having one of our Zontec consultants on the floor with you, reviewing reports and making recommendations, only even faster,” said Benjamin Ha, vice president of operations at Zontec.

Zonetec Inc.

https://zontec-spc.com/

Teledyne FLIR OEM Radiometric Thermal Boson+, Hadron 640R+ Dual Thermal-Visible Camera Modules

Teledyne FLIR OEM, part of Teledyne Technologies Incorporated, announced the availability of radiometric models of its high-performance Boson®+ thermal and Hadron™ 640R+ dual thermal-visible camera modules. Built for defense and industrial applications with size, weight, and power (SWaP) optimization, the NDAA compliant and ITAR-free radiometric Boson+ and Hadron models provide real-time temperature measurement of every pixel within a scene.

“The radiometric Boson+ and Hadron 640R+ models, which already provide industry leading thermal sensitivity of 20 millikelvin (mK), or better, expand the mission set for infrared product developers and integrators,” said Dan Walker, vice president product management, Teledyne FLIR OEM. “They are optimized for unmanned ground vehicles (UGV), unmanned aircraft systems (UAS), security applications, handhelds, thermal sights, and emerging AI applications using Teledyne FLIR Prism™ embedded software.”

The eight new radiometric Boson+ models include 640 x 512 and 320 x 256 longwave infrared (LWIR) resolution options, multiple lens options, and shared mechanical and electrical interfaces with the existing non-radiometric Boson+. Automatic gain control (AGC) and direct data entry plus (DDE+) deliver dramatically enhanced scene contrast and sharpness, including lower video latency that enhances tracking, seeker performance, and decision support, day or night. The Boson+ also features multiple video output interfaces, including USB, CMOS, and MIPI for maximum integration flexibility.

In addition to an integrated radiometric 640x512 resolution Boson+, the new Hadron 640R+ is also equipped with a 64MP visible camera, featuring dual 60 Hz video output via USP or MIPI. At 56 grams and with an IP54-rating for dust and water protection in the elements, the dual-sensor payload offers longer flight time and extended battery life for unmanned aerial applications.

All Boson+ and Hadron 640+ models are compatible with Teledyne FLIR OEM’s Prism AI detection, tracking, and classification models along with Prism ISP libraries for super-resolution, turbulence mitigation, contrast enhancement, and more. With drivers available for market leading processors from NVIDIA®, Qualcomm®, and more, plus industry-leading integration support from Teledyne FLIR OEM, they minimize development cost and time to market. Furthermore, Prism can be quickly evaluated with the Hadron 640R+ using the Prism Development Kit for Qualcomm RB5.

The Hadron 640R+ and Boson+ radiometric camera module products are all dual use and classified under U.S. Department of Commerce as ECCN 6A003.b.4. They are available for purchase globally from Teledyne FLIR OEM and its authorized dealers.

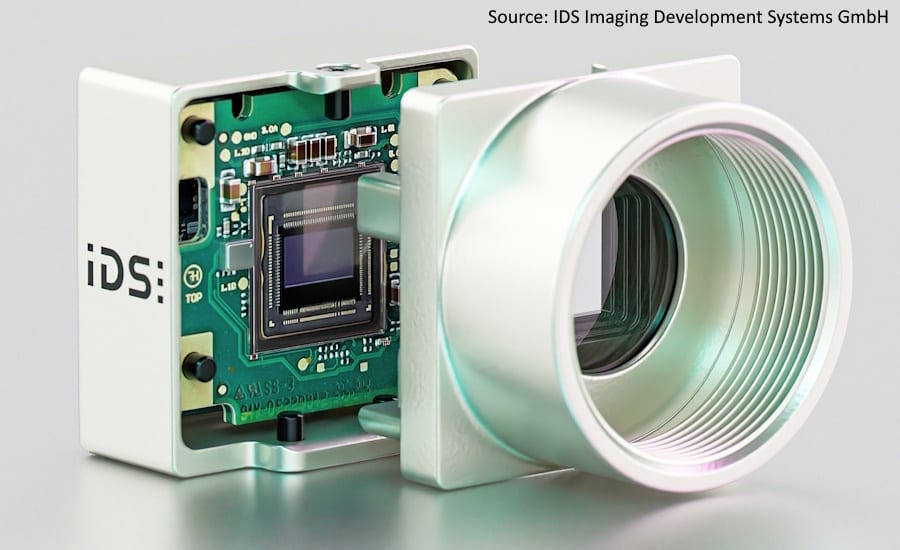

IDS uEye EVS Camera

How do you capture small, fast-moving objects as efficiently as possible and without motion blur? How do you analyze movements in general without generating large amounts of data? With the new uEye EVS, IDS Imaging Development Systems GmbH is launching an industrial camera with an event-based vision sensor that has been specially developed to meet these challenges. Instead of a continuous stream of data, it only captures relevant events. Compared to classic image-based systems, the volume of data generated is significantly reduced. The uEye EVS is therefore the ideal solution for applications that require efficiency and precision at high speed, such as optical monitoring of vibrations or high-speed motion analyses.

The ultra-compact USB3 camera visualizes the smallest movements in real time and completely loss-free. Thanks to its extremely high dynamic range, it even works in almost complete darkness. This is made possible by the SONY/Prophesee IMX636 event-based vision sensor. In contrast to conventional image sensors, it does not capture every image completely at regular intervals (frames), but only reacts to changes within a scene. It transmits events depending on when and where the brightness in its field of view changes - for each individual sensor pixel. The temporal resolution, i.e. the minimum measurable time difference between two successive changes in brightness, can be less than 100 microseconds. "Event-based cameras achieve a remarkable temporal resolution, making them optimized for highly dynamic scenes. The best conditions for capturing fast object movements without loss of information - comparable to an image-based frame rate of more than 10,000 images per second," explains Patrick Schick - Product Owner 3D & Vision Software. At the same time, the sensor ignores all motionless areas of its field of view and thus generates 10 to 1000 times less data than image-based variants. This saves memory and computing time.

With the "uEye EVS" camera line and the first uEye XCP-E product family, IDS offers event-based sensor technology in an ultra-compact industrial format of just 29 x 29 x 17 millimeters.

The fully enclosed die-cast zinc housing with C-mount adapter, the compact size and the screw-on USB 1/2 Micro-B connector make the camera ideal for a wide range of applications in both industrial and nonindustrial areas. Further variants will be added to the product line.

IDS Imaging Development Systems GmbH

https://en.ids-imaging.com/ueye-evs-cameras.html

www.ids-imaging.us

Vision Engineering EVO Cam HALO 4K Digital Microscope

Vision Engineering unveiled the EVO Cam HALO, a new 4K digital microscope for precision and clarity in inspection and measurement tasks.

Suitable for a wide range of inspection applications, EVO Cam HALO combines stunning 4K image quality with advanced, adaptive illumination, and new intelligent software, empowering users to capture the most challenging details with unparalleled accuracy.

HALO’s key features include 4K resolution which reveals previously obscured details with remarkable clarity, ensuring nothing escapes the user’s view. A Super-Wide Dynamic Range ensures the user captures images with exceptional brightness and contrast, even in challenging lighting conditions. Additionally available with HALO comes a new enhanced Illumination package, including a quadrant light, panel light, and white/UV light, to optimize illumination for a variety of inspection needs.

New Intelligent Hardware and Software automatically detects lenses and adjusts magnification settings, ensuring seamless workflow and accurate results. Real-time insights are available providing intuitive image capture, measurement, and analysis tools, enabling faster and more informed decision-making. Vision Engineering’s popular 360 Direct/Oblique Viewer also works with HALO, enabling users to inspect details from different angles, revealing hidden features that would otherwise be inaccessible.

HALO is suitable for a wide range of applications, including Medical Device manufacturing and testing, especially when inspecting translucent tubes, electro-polished devices, and other medical components with enhanced clarity and accuracy.

It is also effective at capturing fine details on small, reflective metal parts for precise inspection and quality control – perfect for Micro-Mechanics and in Industrial Manufacturing, where intricate assemblies, solder joints, and other components can be inspected with improved precision and efficiency.

Commenting on the launch, Richard Nagel, Vice President Sales and Marketing, says, “We are delighted to bring EVO Cam HALO to market. It’s introduction completes our family of digital microscopes and sits well with the EVO Cam ICON and the popular EVO Cam ll systems. The 4K image quality, intelligent hardware and easy to use software makes the EVO Cam HALO an accurate and consistent digital system for inspection requirements.”

Vision Engineering Limited

www.visioneng.us

Creaform.OS, Metrology Suite

Creaform, a business of AMETEK, Inc., is making a significant step forward in its software offering, reflecting a strategic evolution by introducing Creaform.OS™ and the Creaform Metrology Suite™, which leverage the hardware-software synergy to deliver a complete 360° 3D scanning solution.

Through its new intuitive user interface (UI), user-friendly tools, embedded content, and streamlined onboarding tools for new users, these newly reinvented software solutions were carefully designed to adapt to its users’ journey and workflow. Representing the culmination of over 20 years of experience, these additions complete Creaform’s comprehensive 3D measurement solution: metrology-grade scanners and optical CMM, intuitive software, world-class support, online training, and technical content.

The Creaform.OS platform provides all standard acquisition modules designed to provide the best 3D measurement experience across all Creaform systems, with the Scan, Probe and Photogrammetry modules. It also includes a multitude of significant improvements and features:

- New innovative interface: Completely redesigned UI to be workflow-oriented, it structures the core functionality with segmentation based on the major steps of each application.

- Customizable: New homepage, new menu structure, toolbars placement, preconfigured files for specific applications and many more options enable users to modulate the platforms to fit their unique tasks and applications.

- The new Insight channel: An integrated communication channel that enables Creaform to share complementary training tools, success stories from other clients, and new products with all users.

- On-boarding tools: The platform integrates several training tools and loading tips to empower users to learn the software on their own, simplifying new employees’ integration.

- New maximized 3D viewer: A new multiple sources lightning engine as well as additional space to view the data ensure optimal data visualization.

The Creaform Metrology Suite, on the other hand, provides a comprehensive portfolio of application software modules designed for any metrology task:

- Scan-to-CAD module: Intuitive reverse engineering toolkit for transferring data extracted from 3D scans to any CAD platform.

- Inspection module: Comprehensive and powerful software designed for efficient and accurate dimensional inspections.

- Automation module: User-friendly and integrated programming platform for deploying automated quality control solutions.

- Dynamic tracking module: Dynamic tracking module enabling simultaneous position and orientation of multiple objects in space and time.

“Engineered with optimal UX in mind, these platforms provide a versatile suite of tools designed to simplify operations, solve industry-specific challenges, and promote long-term growth,” explains Jérôme-Alexandre Lavoie, Director of Product Management at Creaform, before adding, “Innovation Takes Form in every aspect of Creaform’s hardware and software solutions, establishing partnerships founded on trust, adaptability, and technologies that not only meet today’s needs but shape the future.”

Creaform

creaform3d.com

FARO Leap ST Handheld Scanner

FARO® Technologies, Inc., has entered a new category of handheld scanning with the launch of FARO Leap ST®. The new handheld solution expands the company’s product portfolio, making FARO one of the few companies offering customers a complete range of portable 3D metrology devices. It strengthens FARO’s presence across the manufacturing sector, where speed, accuracy, and throughput are key. FARO paired this launch with an update to its FARO CAM2® Software, for a simple and effective way to scan parts.

Leap ST features five powerful operating modes: ultra-fast scanning, hyperfine scanning, deep hole scanning, large area scanning, and photogrammetry. As a metrology-grade tool, it excels in measuring and verifying a variety of surfaces and parts. The design is compact, portable, and suitable for multiple industries and applications.

Additionally, FARO enhanced its 3D metrology software offerings with the update of CAM2. The software now includes five tailored versions that address specific manufacturing measurement requirements. CAM2 now offers options for scanning devices and probing devices, as well as a hybrid approach that integrates probing and scanning for solutions such as the FaroArm with laser line probes.

RFK Racing, an existing FARO customer and eight-time NASCAR champion, praised Leap ST. “The new handheld scanner will seamlessly integrate into our processes, further boosting our manufacturing efficiency,” said Kevin Kidd, Director of Software and Analytics. “The unification of FARO data in CAM2, a software we’ve already adopted, will allow us to streamline information into one cohesive and connected system."

FARO

www.faro.com