Products

the latest products to help you improve your manufacturing process

Siemens Mcenter Platform

A centralized, open interface, on-premises platform, Mcenter will enable manufacturers with CNC machine tools to achieve optimum efficiency in the management of all manufacturing resources on the shopfloor.

Siemens presents its hardware automation and software technology portfolio, including the introduction of Mcenter, a new manufacturing and resource management platform, designed to enhance the preparation of tool scheduling, workflow supervision and NC program management — plus Mcenter will smartly and seamlessly network the machine tools with the company’s IT / OT landscape.

Part manufacturing companies across several industrial sectors are facing ongoing and increasing pressures to make their production more cost-efficient, more flexible and more sustainable. Looking at the shopfloor today, as companies of all sizes wrestle with the issues of digitalization and improved asset management, the challenges of preparing production orders, materials and tooling acquisitions plus devising the best use of machines on the floor for optimum workflow and output can be daunting.

In response, Siemens offers Mcenter as a solution to these challenges.

Machine tools traditionally communicate with the central server of a machine shop or factory network via clients that are directly integrated into the control. Web applications are used that can easily be accessed via a PC or tablet web browser. In contrast, user dialogs embedded in the CNC’s HMI are also provided for tasks performed directly at the machine. Connection to existing IT systems in the production environment can usually be established via application programming interfaces (APIs). Mcenter balances these conditions to achieve the desired outcomes.

Mcenter further helps part manufacturers of all sizes reduce their IT administration complexity through centralized platform functionalities such as connectivity, security roles, rights, application management, etc. and thus forms the backbone of the Siemens Smart Shopfloor protocol.

Siemens offers Mcenter for the optimum management of a machine shop’s manufacturing resources, including the following elements:

- Tool Management — The application Manage MyResources /Tools provides full transparency about the available tools and their current locations. This feature enhances productivity by minimizing the time needed to pair the right tool with the right machine at the right time.

- Program Management — Manage MyResources /Programs provides an immediate overview of all the available NC programs and their status for easier programming and setup.

- Overall Equipment Effectiveness (OEE) — Analyze MyPerformance /OEE allows the important indicators to be identified for the improvement of machine or work cell utilization and the elimination of bottlenecks in production.

Mcenter further offers the following advantages to shops as they accelerate on the path towards digitalization:

- Encompasses all machine tools — With Mcenter, it is possible to manage all types of machines, regardless of their age or controller brand, across the shopfloor. Deeper onboard integration with SINUMERIK CNC machines provides additional value and Siemens continues to improve the CNC integration with other brands in the global market today.

- Increase overall productivity with minimal effort — Mcenter enables companies of all sizes to increase productivity by providing the user detailed insights on tooling, NC programs and machine utilization. Enhanced integration of higher-level systems with the CNC on the machines makes it possible to manage the entire workflow on the shopfloor with reduced effort. This feature significantly lowers set-up times, the chief impediment to productivity, plus it optimizes resource utilization, thereby lowering overall cost to the manufacturer.

- Integrate with existing IT infrastructure — Mcenter provides open interfaces that allow flexible integration into existing IT infrastructure and processes such as connecting to pre-setters for automated data transfer. Mcenter also offers additional opportunities for the manufacturer to utilize the Siemens Teamcenter digitalization portfolio.

Mcenter is a centralized, open interface, on-premises platform from Siemens, designed to optimize machine utilization and overall production efficiencies in shops of all sizes and which utilize a variety of machine and controller types.

Siemens

www.siemens.com

Bristol Instruments Dinel DLS-35 Series Universal Level Sensors

Bristol Instruments introduces the Dinel DLS-35 Series of capacitive level sensors. These sensors are designed for use with liquids and bulk solids. Limits are set easily with a magnetic pen. A quick-set mode lets users perform set up without the presence of medium.

DLS-35 level sensors can be directly mounted to tanks, vessels, sumps, tubes, silos and hoppers. Bar, rod and rope electrode options collectively cover electrode lengths from 2 in (50 mm) to 19.7 ft (6 m) over five range options.

Two LED indicators show operation status and provide visual confirmation of settings. Signal output options are NPN, PNP or NAMUR (change in supply current).

DLS-35 Series models for operation in standard, high temperature, mining and explosive environments are available. Housing and electrodes are available in either 304 or 316L stainless steel. G3/4, G1, M27 and M30 threaded and C134 and C150 Tri-clamp process connections are available.

Bristol Instruments

https://www.bristolinstruments.com/level-meters/

Starrett to Highlight Range of Advanced, Automated Metrology Products at Quality Show South 2024

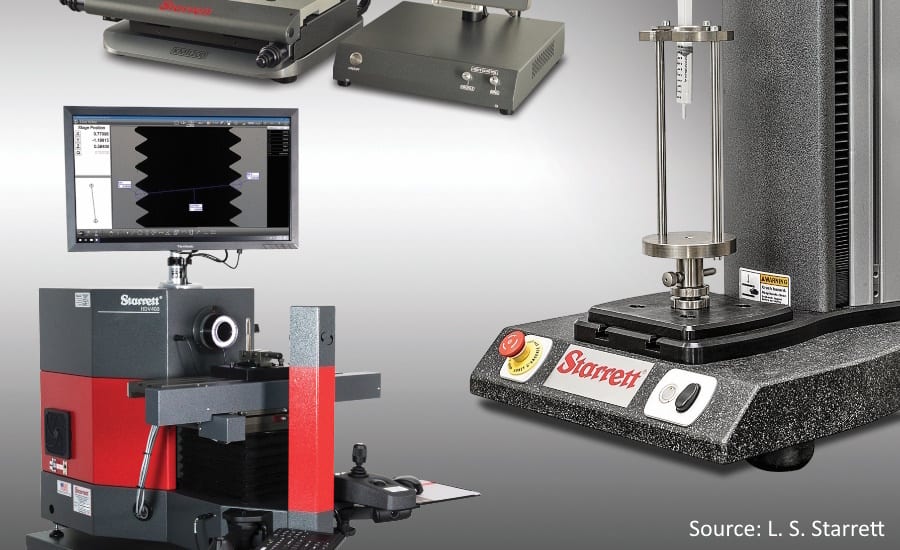

The L.S. Starrett Co. announced it will be highlighting its latest Vision Systems, Digital Video Comparators and Force Measurement Systems at Quality Show South Booth #422 at the Music City Center, Nashville, TN, on May 1st and 2nd, 2024.

Starrett Optical and Video-based measurement systems combine high-resolution images, powerful intuitive software, and precision mechanical platforms to deliver superb accuracy and repeatable measurement results.

Starrett will demonstrate pattern recognition and automated inspection on several metrology systems at Quality Show South including:

The NEW Starrett KMR-MX 200 Manual Vision System offers a unique platform, filling the gap for companies that want the speed and accuracy of a video-based platform, but do not need a PC-based system. The KMR-MX has a manually driven X-Y stage motion paired with a 6.5:1 zoom lens and MetLogix™ Mx200 digital readout in a stacked display format. Ideal for a range of industries such as medical, aerospace and defense that require traceable and secure measurement data, operators can perform measurements without Windows® - based software or a PC.

Also featured at Quality Show South, the Starrett HDV Horizontal Digital Video Comparator combines the best features of Vision and Optical Comparator technology. Starrett HDV systems feature MetLogix M3 touch screen software with the powerful M3 DXF/ FOV option pack. With this software, the HDV can import DXF/CAD files over a network and make automatic 2D “go/no-go” comparisons to an engineering design by using Video Edge Detection, with no need for Mylar overlays required with conventional optical comparators. This dramatically increases measurement throughput while eliminating operator subjectivity.

Starrett will also demonstrate the AVR200 Multi-Sensor Vision System, a full CNC benchtop Vision System, ideal for repetitive measurements and automatic comparison to CAD files. In addition, the Starrett HD400 Horizontal Dual Lens Optical Comparator offering a two-lens mount, enabling instant switching between two magnification lenses or video camera adapter will be featured at Quality Show South.

Starrett will also demonstrate its Force Testing Systems, highlighting the flexible architecture that enables the range of Starrett force and material testing software programs to be compatible with its different test frames. At Quality Show South, Starrett will demonstrate its FMS Series test frame measuring the force to draw fluid in and out of a syringe. This application uses Starrett L2Plus software to capture peak and average load data.

In addition, Special Precision Gage Solutions will be demonstrated at the show. When a unique precision gage is needed for QC, Starrett designs and manufactures custom gaging for the application at hand. For over 50 years, Starrett has provided special gaging solutions to industries including medical, energy, aerospace, automotive, food packaging, high-technology plastics, NASA, defense and more.

The L.S. Starrett Company

https://www.starrett.com/

https://www.starrettmetrology.com/qualityshowsouth

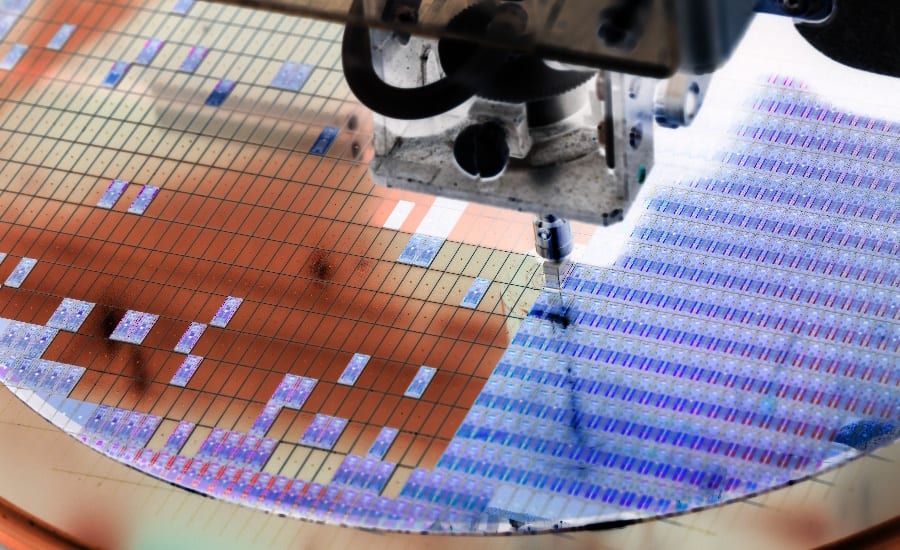

Teledyne e2v 5D Image Sensor

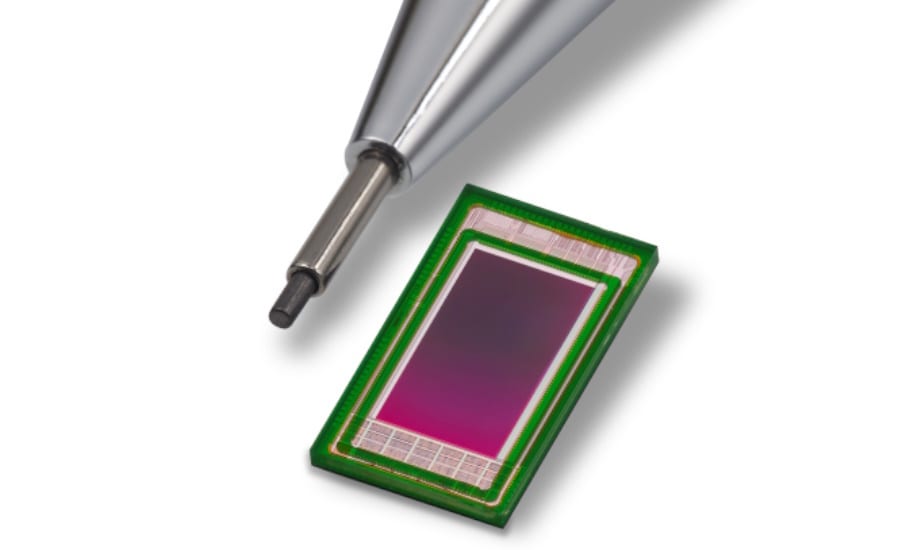

Teledyne e2v, a Teledyne Technologies company, announces Topaz5D™, a full-HD CMOS image sensor designed to combine 2D vision with the generation of 3D depth maps. A single Topaz5D sensor used in challenging lighting conditions delivers 3D object visualization based on the contrast detected, ideal for various logistics applications, AR/VR headsets, access control devices, household vacuum robots, and Autonomous Mobile Robots (AMR).

Topaz5D combines a small 2.5 µm global shutter pixel with a post-processing diffraction layer to create angular sensitive pixels. This enables 3D angular signal raw data to be generated and then processed by a 5D compatible SDK. Topaz5D is a 3D-enabled variant of Teledyne e2v’s popular Topaz 2M, which is widely used in logistics/retail markets and smart factories.

Topaz5D has a 2 megapixel (1,920 x 1,080) resolution and is currently available in both monochrome and color. Its tiny form factor (7.65 mm x 4.45 mm) makes it easy to integrate into space-constrained optical engines or modules and it consumes only 200 mW of power to run at full frame rate. It generates 3D depth maps and displays the contrast details of any kind of object, even black or very shiny ones, or those seen through sheets of glass or transparent organic material (e.g., plexiglass or plastic bottles).

Unlike other 3D technologies, which rely on illumination of the scene, Topaz5D can be used in very diverse operating conditions, including indoor lighting or direct sunlight. Compared to a stereoscopy solution, only a single sensor plus a lens is required, without the need for complex dual-lens system alignment and there is no risk of optical occlusion. In addition, Topaz5D delivers an unmatched cost of ownership compared to other competitive 3D vision technologies.

Documentation, samples, and kits for evaluation or development are available upon request.

Teledyne e2v

imaging.teledyne-e2v.com

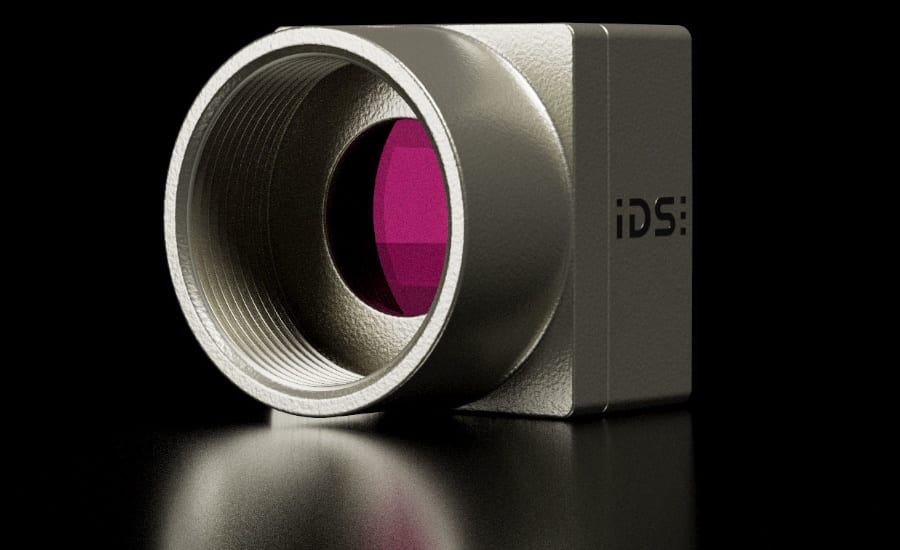

IDS Industrial Camera Offer Sony Sensor IMX662 in Both Color and Mono

Compact, cost-effective and with exceptional image quality in low ambient light, the IDS industrial camera offers the 2 MP sensor IMX662 in both color and monochrome versions. The sensors belonging to Sony's Starvis 2 series are designed for maximum light sensitivity. They are now available either as compact uEye+ XCP models or as board-level versions in the uEye+ XLS series.

Both camera families are characterized by their compact design and are therefore suitable for embedded applications, for example. While uEye+ XCP models have a completely closed housing measuring 29 x 29 x 17 mm with a C-mount lens holder, the uEye+ XLS models measuring just 29 x 29 x 7 mm are available as board-level cameras with or without a C/CS- or S-mount lens holder. The new USB3 industrial cameras deliver particularly impressive results when used in low-light conditions.

In addition to the special, highly sensitive pixel technology, customers benefit from another distinctive characteristic, as Jürgen Hejna, Product Manager uEye at IDS, explains: "We offer this rolling shutter sensor with anti-reflection coating, which further improves the image quality." Thanks to this feature, disruptive reflections – known as lens flare – are reduced or completely avoided within the camera.

The company plans to make the entire range of Sony Starvis 2 sensors available in different camera families in the future. This will provide customers with the greatest possible flexibility when selecting these light-sensitive sensors.

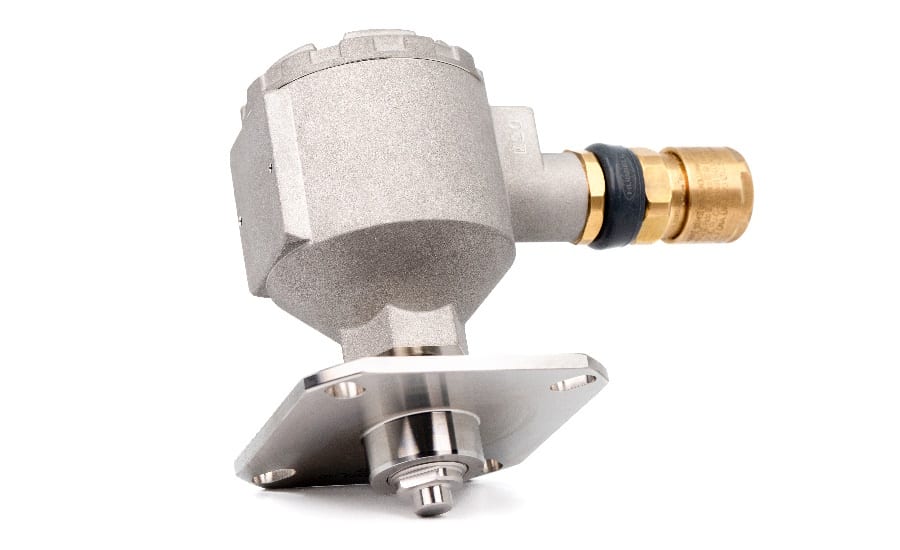

Emerson Acoustic Particle Monitor

Emerson announced the release of the Rosemount™ SAM42 Acoustic Particle Monitor for measuring the amount of entrained sand in the output from oil and gas wells. The monitor can detect extremely low concentrations of entrained sand in challenging conditions with a high level of measurement repeatability and sensitivity. Accurate real-time data helps minimize erosion risk, allowing producers to maximize throughput without compromising asset safety. An all-in-one design features onboard data processing, explosion-proof protection, and simple installation with no pipe penetration needed.

The output from oil and gas wells often contains varying amounts of entrained sand that can pose a serious erosion risk and lead to equipment damage, loss of containment, environmental risk, costly repairs, curtailed production, and reduced profits. Effective sand management depends on knowing the amount of entrained sand flowing through the topside piping infrastructure in real time.

Many facilities rely on “grab-samples” to characterize and quantify the entrained sand, which only measures the entrained sand for that one moment in time. This method is ineffective as sand production can fluctuate significantly, posing safety risks to personnel and equipment through delayed decision making. Failure to act quickly exposes assets to excessive erosion, increasing maintenance expenses and the risk of unexpected shutdowns.

The Rosemount SAM42 Acoustic Particle Monitor addresses these issues by sending critical data instantly to staff onsite and to asset management systems via a Modbus® RTU RS485 digital wired connection, where it is used to adjust production flows as needed. A compact and non-intrusive design makes the device easy to install without pipe modifications, simplifying field deployment and reducing maintenance costs.

The Rosemount SAM42 is available in two versions that are designed to accommodate pipe surface temperatures between -40 degrees Fahrenheit (-40 Celsius) and 554 F (290 C), making it suitable for oil and gas applications and geothermal energy production. It can be mounted on pipes with diameters between 2-48 inches and is rated for use in hazardous areas with Ex d (Flameproof) approvals, including ATEX, IECEx, USA, and Canada; and Ex i (Intrinsic Safety) approvals, including ATEX, IECEx.

Kassow Robots KR Pulse Ecosystem

Kassow Robots launched its KR Pulse ecosystem. The aim of KR Pulse is to enable systems integrators and industrial end customers to seamlessly combine Kassow Robots cobots with end-of-arm tools and software solutions. Copenhagen-based Kassow Robots, majority owned by Bosch Rexroth, has added a new ecosystem section to its website.

The approach to which Kassow refers is the core idea of his 7-axis lightweight cobots: to enable industrial end customers to automate more flexibly than is possible with conventional cobots.

KR Pulse is made up of three segments: components such as grippers or vision systems, application kits such as hardware for applications like welding or dispensing, and engineering tools to foster processes such as simulation.

In 2024, Kassow Robots will continue to drive its systematic expansion of the KR Pulse ecosystem with strong partner companies ready to join in the coming months.

Kassow Robots C-Buns (compatibility bundles) are one of the most important building blocks of the KR Pulse ecosystem. They enable the seamless functional integration of other products with Kassow Robots cobots (plug and play), a capability that is in high demand for end customers today. Everybody knows how convenient it is, when you’re installing a printer at home to be able to simply plug in the cord and activate the printer in the system settings. C-Buns allow plug and play functionality for partner solutions.

Kassow Robots

www.kassowrobots.com

Kistler All-Purpose Industrial Charge Amplifier

The new multi-purpose charge amplifier ICAM-B from Kistler is a versatile device thanks to its unique combination of proven analog signal routing and integrated digital data transmission. These advantages make it ideal for use with piezoelectric sensors in almost any application. Users benefit from intuitive web interface control, a wide range of signal conditioning features, and various IIoT connectivity options.

Sensor-based production control and monitoring play a crucial role in modern manufacturing environments. Integrated piezoelectric (PE) sensors deliver multiple benefits for industrial manufacturers in many sectors. They maintain and ensure the quality of the end products, they reduce downtimes and boost efficiency by reducing waste; they also support process optimization and data-driven decision making. Manufacturers who want to take advantage of PE sensors in industrial environments require robust measuring chains with suitable charge amplifiers that convert the sensor’s charge signal into a low-impedance voltage signal for further processing.

The new ICAM-B charge amplifier from Kistler not only meets these requirements, but also offers far more thanks to its unique combination of analog and digital signal processing. The ICAM-B (or 5073B) is a multi-channel, high-bandwidth, universal charge amplifier with a wide and adjustable measuring range (±20 to ±1,000,000 pC), integrated IIoT protocols (OPC UA and MQTT), and a web user interface for configuration and commissioning. The ICAM-B can be used wherever mechanical quantities need to be measured with piezoelectric sensors in quasi-static or dynamic processes. Areas of application include micromechanics, medical technology, semiconductor manufacturing, and many more.

Depending on the selected version, the ICAM-B’s robust metal housing one to four input channels, depending on the version. Compared to its predecessor (5073A), the new 5073B comes with improved power management, an extended measuring range starting from ±20 pC, and improved usability and connectivity.

The ICAM-B features six analog outputs, and each input channel can be flexibly routed to any of these outputs. Users can choose between different output signal modes such as instant value, peak, RMS (root mean square), or integral value. For advanced signal processing, the ICAM-B offers programmable offsets as well as selectable low-pass filters and switchable high-pass filters. The new web user interface enables not only individual channel configuration, but also direct display of measurement values and visualization of the live signal versus time. The new 5073B device includes two virtual channels for real-time calculations (e.g. sum, weighted sum and subtraction) of different input signals.

Condition monitoring involves the use of various parameters to assess and analyze the health of machinery or systems. Key parameters for such assessments include RMS and integral. The 5073B’s D-sub connector offers pins that can be configured as digital outputs which send a signal to control systems if the user-defined threshold value for a process is exceeded. Machine monitoring based on defined process thresholds in the ICAM-B can help prevent unexpected breakdowns, reduce downtime, and extend machinery lifespans.

The ICAM-B’s new Ethernet interface enables remote access, remote configuration and monitoring, firmware updates, integration with control systems, data streaming, and a web-based user interface. Kistler’s latest charge amplifier features two integrated IIoT protocols – OPC UA and MQTT – so multiple devices can be interconnected and remotely controlled. Moreover, data can be easily streamed from field level to higher-level systems and the cloud. The integrated REST API makes machine integration simple and enables connections to other systems.

The new 5073B industrial charge amplifier comes with voltage (±10 V) and current output (4 to 20 mA) variants. To guarantee compatibility with the 5073A predecessor model, an optional RS232 interface is available on the side of the housing. This makes it easy to replace existing devices directly with the new model whenever necessary. As compared to the 5073A, the new 5073B offers the advantage of variants with three different sensor connector types to deliver protection classes IP50, IP65 and IP67, as appropriate to each customer’s testing environment.

Kistler

www.kistler.com

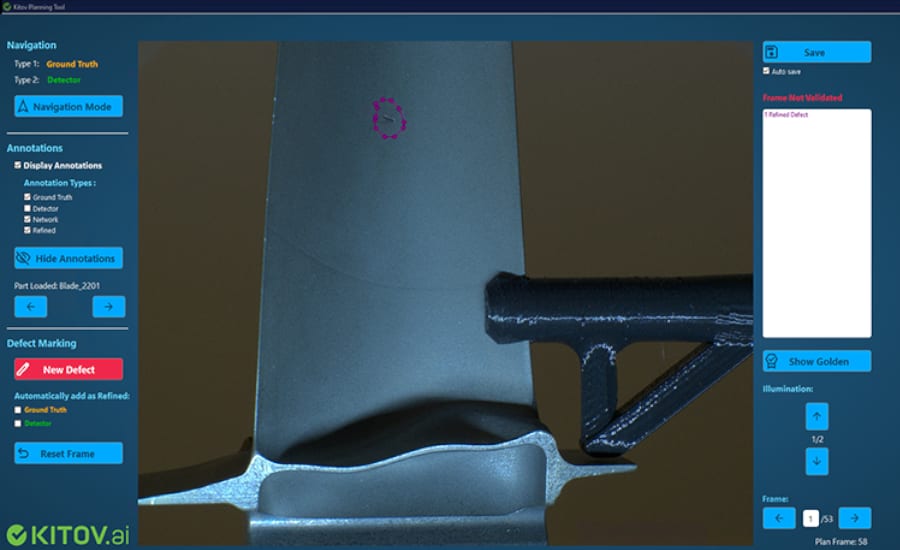

Kitov.ai Software Platform for Improved Automated Visual Inspections

Kitov.ai announces significant improvements to its flagship software platform with the introduction of version 2.7. The latest version brings about enhanced user experience and expanded functionality, offering a more efficient and user-friendly workflow along with increased control options.

The software suite by Kitov.ai features multiple components designed to enable smart inspection processes. Its improved AI Trainer permits operators without specialized expertise to rapidly gather and label defect data, thus providing a solid foundation for the software’s neural network learning.

Enhancements in version 2.7 mainly shine in the Planner Tool, which integrates seamlessly with various robotic systems. It uses AI to create optimized inspection strategies and simplifies the process of transferring these plans to the inspection equipment. Improvements include a more accessible interface, equipped with intuitive icons, tool tips, contextual menus, and versatile features like an undo function for reversing unintended actions.

CAD2SCAN functionality, a vital part of the Smart Planner, benefits from refined workflows and additional improvements in the 2.7 update. It allows quality inspectors to define test parameters directly on a CAD model of the part being inspected, making it much easier and faster to handle components with complex shapes. The tool now supports an expanded range of quality tests that can be applied to a CAD model, enhancing its ability to detect missing components; mark part edges, patterns, and surfaces; and more.

Furthermore, the Workcell Configurator has been updated to allow for 70% quicker configuration and validation of robotic workcell hardware through a straightforward and intuitive user interface.

Kitov.ai

www.kitov.ai

Emerson Rosemount 9195 Wedge Flow Meter

The Rosemount™ 9195 Wedge Flow Meter optimizes performance in applications with high-temperature, high-viscosity, or abrasive liquids, while reducing lifecycle costs.

Emerson released the Rosemount™ 9195 Wedge Flow Meter, a fully integrated solution consisting of a wedge primary sensor element, supporting components, and a selectable Rosemount pressure transmitter. The new meter’s unique flexible design is ideal for measuring process fluids with a wide range of demanding characteristics in various heavy industry applications, including metals and mining, oil and gas, renewable fuels, chemicals and petrochemicals, pulp and paper, and others.

It can be very difficult to measure volumetric flow accurately and reliably in applications where the process liquid is highly viscous, extremely abrasive, prone to plugging, at high temperature, or a combination of these conditions. In applications with low ambient temperatures, hot process media, or a combination of both, heat tracing is often required, necessitating supply of electrical power, and creating a maintenance-intensive single point of failure.

The Rosemount 9195 Wedge Flow Meter addresses these and other common measurement challenges with its unique design. The wedge element itself has no small passages that could plug due to entrained particles, and it is abrasion-resistant due to the shallow approach angle of the process liquid and the lack of critical sharp edges. Highly viscous liquids are measured accurately due to the linear response of the meter, even at low Reynolds numbers.

The sensor’s operating temperature range is -40 to 1,000 degrees Fahrenheit (-40 to 538 degrees Celsius), and the meter is available with Emerson’s Rosemount 3051S Thermal Range Expander for measuring hot or viscous liquids, without the need for heat tracing.

Two-way digital connections from the selected pressure transmitter to a host, such as a distributed control or an asset management system, can be made via 4-20 mA HART®, WirelessHART®, FOUNDATION™ Fieldbus, Modbus®, or BSAP/MVS. Depending on the selected transmitter, a wide range of process variables can be sent to host systems for process control and monitoring, diagnostics, and other purposes.

Application flexibility is provided with three sensor/transmitter connection styles:

- Compact: Reduces pipe standoff to address plugging and cleaning concerns. Saddle-style remote seal connection reduces the weight of the meter by 50%.

- Flanged: Incorporates a 2-inch NPS/DN50 connection. This traditional style is used if flushing rings and valve assemblies are required.

- Threaded: Incorporates a ½ inch NPT connection with tubing, ideal for applications where plugging is less of a concern than erosion or wear.

To simplify ordering and ensure the correct remote seal system is specified, five optional application packages—including standard, abrasive, ultra-high process temperature, cold environment, and remote mount—are available for the sensor element.

Available line sizes for the sensor are 2-inch to 8-inch (50 to 200 millimeters). All wetted materials are 316L stainless steel, and the meter complies with ASME B31.3 and CRN safety standards. Additional materials and sizes can be accommodated upon request.

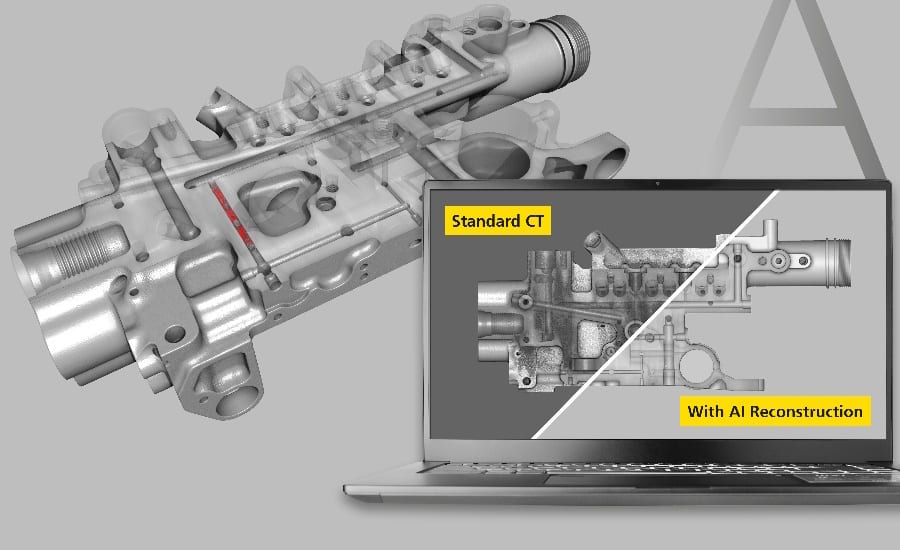

Nikon AI Reconstruction 3D CT Software

Nikon IMBU has released AI Reconstruction, a 3D computed tomography (CT) reconstruction software solution powered by artificial intelligence that lifts the traditional trade-off between scan speed and image quality.

By applying Deep Learning techniques to enhance image quality, Nikon’s breakthrough technology enables rapid results and superior analysis. Traditionally, CT users have had to pick between fast, lower-quality scans or slow, higher-quality scans. If scans are quick, important details can be missed. If scans are slow, fewer items can be scanned.

AI Reconstruction lifts these limits through AI enhancement tailored to individual customer needs by Nikon’s Applications Engineering team. The Deep Learning modeling underpinning AI Reconstruction is trained to distinguish relevant information from the scan artifacts to effectively filter noise and improve clarity.

Examples of where this technology will demonstrate a profound impact include the automotive, aerospace and manufacturing sectors, as well as the medical device industry. In these sectors and others, meticulous quality control via precise metrology is essential for product safety.

Through rigorous trials, Nikon’s breakthrough technology has been validated to provide dependable performance. It offers flexible integration with leading analysis packages for reliable inspection of the most challenging component geometries.

AI Reconstruction has been designed to comply with the European Union’s Ethics Guidelines for Trustworthy Artificial Intelligence. These guidelines propose seven key requirements for trustworthy AI systems: human agency and oversight, technical robustness and safety, privacy and data governance, transparency, diversity, non-discrimination and fairness, societal and environmental well-being, and accountability.

Nikon’s new AI solution is built on the same technology as Nikon’s LiB.Overhang Analysis, released in 2023. Although they both use Deep Learning AI, their goals are different. LiB.Overhang Analysis is a dedicated analysis solution that enables fast, precise, and consistent CT inspection and analysis of anode overhang in lithium-ion batteries (LiBs) during mass production.

By automatically analyzing the 3D CT scan data using AI, LiB.Overhang Analysis can accurately measure the critical dimensions of anode overhang regions in LiB cells to ensure they are within the required tolerances for optimal battery performance and safety.

Nikon’s AI Reconstruction is provided as a tailored service drawing on the company’s expertise in meeting specific customer needs. An experienced Nikon Applications Engineer partners directly with each client to train an accurate model using samples from a target workflow.

AI Reconstruction’s launch will see Nikon focus on LiB cell production, where the company is already a leading partner for many manufacturers.

Nikon is already proactively contacting existing customers to explain AI Reconstruction’s benefits. New customers should contact their local Nikon Metrology representative to arrange an introductory call and in-person demo.

Nikon Metrology, Inc.

https://industry.nikon.com