Test & INspection

Creating a Standard

The scope of inspection is so vast that no one wanted to exclude a topic but we also did not want a standard so detailed that it was not user friendly. By John Vandenbemden

The journey to create a standard is very interesting and requires attention to detail. Before a standard can be created one must develop the need and benefits for its development. The need for an inspection standard was presented to the ASQ Inspection Division by numerous organizations and members for several years. The ASQ Inspection Division management team decided to create a National Standard for inspection in 2017.

2017 Inspection Division Leadership Team

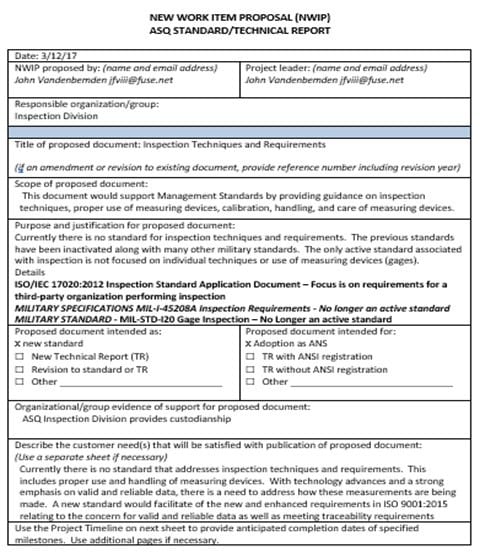

The development began by completing and submitting a “New Work Item Proposal (NWIP), ASQ Standard/Technical Report.” The proposal and associated timeline were approved by the Standards Committee. The approval triggered the creation of a development (writing) team, which was composed of Inspection Division members and non-inspection division members to ensure a robust standard was created that addressed inspection holistically.

At this point of development the easiest step was obtaining approval to move forward. The next step was to decide what topics should be included. You would think that this would be an easy step, but it was challenging. The scope of inspection is so vast that no one wanted to exclude a topic but we also did not want to compose a standard that was too detailed it was not user friendly. Once these decisions were finally made the writing process could begin.

To begin the writing process a outline was created to document the agreed upon content of the inspection standard. The outline was then utilized to assign team members various sections for them to address. Reference material used was collected in order to document it in the standard.

ASQ/ANSI Inspection Standard

- General Requirements

- Impartiality, independence

- Confidentiality

- Structural Requirements

- Administrative,

- organizational and management

- Resources requirements

- Competence

- Equipment and facilities

- Subcontracting

- Process requirements

- Inspection methods

- Gage Inspection Methods

- Precision Measuring Equipment

- In-Precise Measuring Equipment

- Preservation of Measuring Equipment

- Handling inspection samples and items

- Evidence

- Reports and certificates

- Complaints and appeals

- Quality Management System Requirements

- Quality Policy

- Manual and procedures

- Control of records and documents

- Management Review

- Corrective and Preventive Action

- Management Review

- Internal Auditing

During the development process, the original outline was modified numerous times. This was based on the writer’s experience as well as input from inspection division members and reviews. Thus, several drafts were created with the team self-critiquing and revising text. This process continued until the team felt that they had a product that met the needs of our members. Thus, the standard was at a development point where feedback was required externally. The outline changes and revisions changed to structure to nine clauses covering 43 pages. The revised format included:

1.0 Scope

2.0 Definitions

3.0 Administrative requirement

4.0 Inspection Organization

5.0 Structure

6.0 Process Requirements

7.0 Types of Inspection and Test Methods

8.0 Measurement and Test Equipment

9.0 Management System Requirements

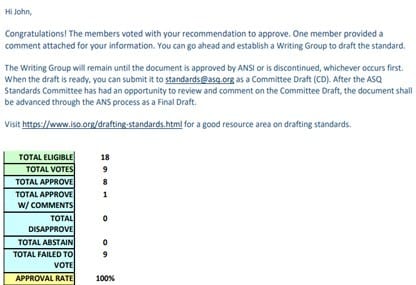

The final draft was submitted to Standards during March 2019. The next step of the process requires an ANSI public announcement and an ANSI posting for public review. The public review feedback was reviewed and incorporated into the draft standard as appropriate. These changes took the work into 2020 and into the pandemic. The pandemic did affect the team’s availability and ability to progress to meet the original timeline. Thus, the timeline was updated and extended into 2021. During this time, the standard was also sent out to members of the ASQ Standards Committee, which were requested for them, and technical committee members as applicable to provide feedback.

ASQ and ANSI (American National Standards Institute) have an agreement for managing the National Standards. The Standards Committee of ASQ was accredited on February 9, 1977. ANSI defines the scope of the ASQ Standards Committee to be:

“The responsibility of the Standards Committee of the American Society for Quality is consensus development and approval of generic standards and other documents in the technical disciplines of quality, environment, dependability and statistics. The requirements contained in these documents are not measurement sensitive, and the use of the metric measurement is not relevant. Product and sector specific documents are not included in the scope of responsibilities and activities of this Committee.”

The Secretariat of this committee is the Standards Manager at ASQ Jennifer Admussen. Julie Sharp (retired) was the primary ASQ Standards member who provided guidance and expertise to make the inspection standard a reality. In recognition of criticality of standards, the Standard Manager reports within ASQ to the CEO.

The comments were compiled and submitted to the development team to review, disposition, and act. This was a challenging task for the team with members dealing with the pandemic and changes in work responsibilities. The standard was revised and reviewed by the team prior to its submittal for approval. The “ANS Inspection Techniques and Requirements – Guidelines” was approved on August 23, 2021.

The final standard consists of 36 pages and can be purchased from the ASQ website for ASQ members ($40) as well as non-members ($50). The introduction of the inspection standard expresses the team’s approach during the development process.

“Introduction

This document defines the principles to help ensure good inspection processes. The intent of the document is to provide a holistic approach to inspection. Thus, not all sections of this document may be relevant to an industry sector or inspection process.

There are many types of inspection processes that are utilized depending on the industry and size of an organization. These include but are not limited to design verification/validation, fabrication inspection, home inspection, bridge inspection, product inspection, installation inspection, commissioning inspection, service inspection, expediting, witnessing, consignment verification, arms inspection, vehicle inspection, modelling and inspection for the purpose of grading. Inspection processes have numerous factors that not only create an interrelationship but also an interdependence for the inspection processes to be effective and efficient. These factors include personnel, environment, equipment, facilities, applicable test standards, regulations and corporate policies, government policies, technology, and methodology.

Personnel use professional judgement for decision-making that is supported by a defined methodology and objective evidence. Identification of what is inspected and where in the process professional judgement is exercised, enables inspection activities to provide reliable and valid results.”

All standards are required to have a documented scope. The introduction provided the foundation for the development of the scope for the inspection standard. Which is defined as:

“1.0 Scope

This standard provides processes and techniques that correspond with requirements that pertain to the inspection and testing necessary to substantiate conformity and compliance to drawings, specifications, and contractual requirements as well as all inspection and tests required by regulatory / statutory requirements. It is applicable to all organizations that conduct inspection and/or testing.”

Population

Sampling

Inference

Sample

The following is a section of the Inspection Techniques and Requirements – Guidelines to provide you with an example of its content.

“6.2 Sampling

Inspection activities often require sampling to make inference of the conformity level of a lot or batch of product. Such samples may be retained for reference purposes or have further testing performed after initial inspection is performed.

There are several methods for sampling that may be defined in the inspection procedure. Acceptance Sampling plans recommended for destructive testing. There are several plans both for variable and attribute that include:

- Single sampling – Inspect or measure randomly sampled items (n). Accept or reject lot based on that one sample.

- Double / multiple – Inspect or measure randomly sampled items (n). Accept or reject the lot based on the first sample if the results are very good or very bad. Otherwise take additional sample. Accept or reject the lot based on the combined samples (or take a third sample).

- Continuous sampling – Inspect or measure items continuously sampled from the lot. The sample results affect the frequency of sampling.

- Sequential sampling – Inspect or measure randomly selected items one at a time. After each item, accept lot, reject it, or select another item.”

I hope you have gained an appreciation for the time and attention to detail there is to create a standard. The hours spent in development and review is conducted by volunteers who are dedicated professionals. Even though I cannot recognize all the volunteers who provided input and review, I would like to recognize the core team since without their support this standard would not have been developed. Thus, in the Forward the following is documented.

“This standard was prepared by the ANSI/ASQ Project Team sponsored by the Inspection Division of ASQ. The project team members are as follows:

- John Vandenbemden, Project Manager & Technical Content

- Ben Tomic, Technical Content & Review

- Anthony Roark, Technical Content & Review

- Jenny Elkins, Technical Content & Review

- Marie Lawton, Technical Content & Review

- James Spichiger, Technical Content & Editor

- ASQ Standards Committee, Technical Content & Review”

I would like to highlight that one of our project team members passed away during the development process. Thus, I would like to recognize Anthony Roark for his contribution who was a good friend, colleague, and dedicated quality professional.