Products

the latest products to help you improve your manufacturing process

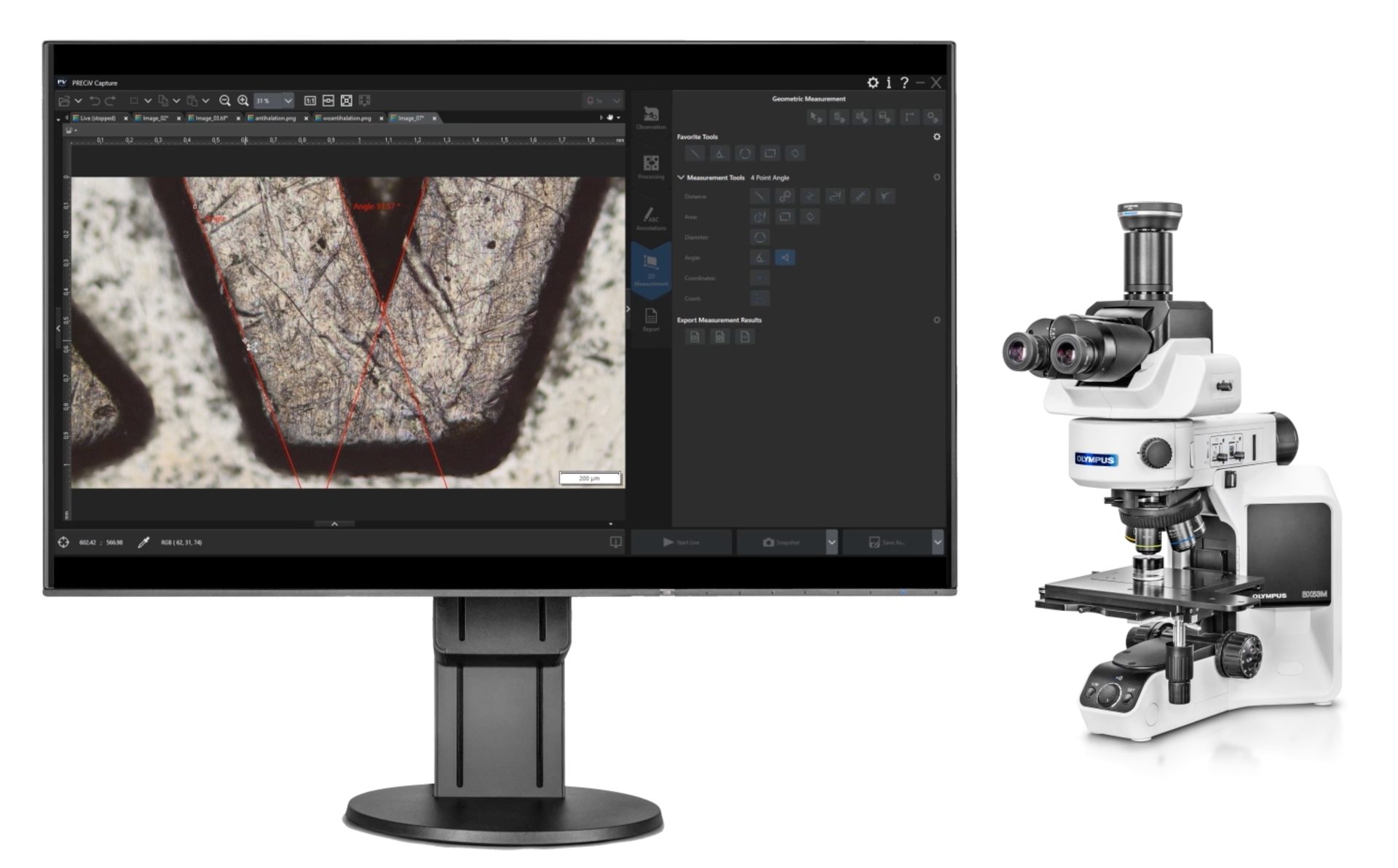

PRECiV Microscope Software

PRECiV™ software enables users in production, quality control and inspection to make precise, repetitive 2D measurements and obtain results that comply with the latest industrial standards. With robust data sharing and security features, PRECiV software makes microscopy workflows faster and more efficient.

PRECiV software turns any manual microscope into a comprehensive imaging and measurement platform. The software can control all Olympus conventional industrial microscopes, their coded functions, Olympus motorized nosepieces and Olympus digital microscope cameras. It supports brightfield, darkfield, MIX (directional darkfield), polarization and differential interference contrast (DIC) imaging for flexibility and offers robust color rendering and high resolution to provide high-clarity images.

The software’s interface is simple to use with a navigation tab that clearly groups the software’s functions—such as observation, acquisition and measurement—using large, clearly labeled buttons. For newer users, advanced settings remain hidden while experienced users can easily access all the available features and functions. The home screen can be customized so that the features and functions used most often can be readily accessed.

PRECiV software enables precise, repetitive two-dimensional measurements on a live or recorded image. Powerful functions like auto edge detection* to reliably measure the distance between two points, auxiliary lines* to make complex geometric measurements and a magic wand for automatic area detection enable inspectors to be confident in their data.

Acquiring all-in-focus images that extend beyond the microscope’s field of view is also easy. The extended focal imaging (EFI) function serially acquires multiple images in different focal planes while the panorama function enables users to move the stage across the sample and then stitch those images together into one large image. Using PRECiV software, you can now combine instant EFI and panorama images while keeping both hands on the microscope.

For advanced applications like grain sizing or non-metallic inclusions, optional Materials Solutions guide users through the steps required to acquire measurements that comply with the latest standards, including ISO, ASTM and JIS.

PRECiV software has robust data sharing and security features.** With a connected workstation, users can easily save images and configuration files to the cloud or a network drive, receive automatic software updates and security patches, use a floating license and upgrade to new versions. Images can be saved and loaded in multiple formats or saved as a JPEG with the accompanying calibration information for traceability. Sharing methods and configuration files—including measurements, image processing settings and materials solutions settings—between connected workstations makes it possible to get the right information in front of the right person quickly and easily.

PRECiV

www.olympus-ims.com

Olympus 72DL PLUS Ultrasonic Thickness Gage

The 72DL PLUS™ ultrasonic thickness gage delivers precision thickness measurements at high speed in a portable, easy-to-use device. With fast scanning, advanced algorithms and Olympus’ lowest-ever minimum thickness capability, the gage can measure the thickness of very thin layers for challenging applications across industries.

Whether used as a paint thickness gage, coating thickness gage or material thickness gage, the 72DL PLUS instrument delivers reliable, lab-quality measurements to maximize productivity and throughput on the production floor.

Capable of displaying up to six layers at once for multilayer coatings, paint, plastics and other materials, the gage includes a full-color touch screen and five measurement layouts so thickness changes can be accurately tracked and visualized.

Guided workflow makes it easier to create and save an application setup. For routine applications, inspectors can store and recall settings to simplify device setup before each inspection.

Built-in data logging and onboard file management provide streamlined thickness data collection and processing, while the PC Interface Application includes intuitive tools to review and manage data for multiple devices and parts. Connected and cloud capable for Industry 4.0 practices, the gage supports wireless LAN, Bluetooth®, and USB connectivity and integrates into the Olympus Scientific Cloud™ (OSC).

Built for industrial environments, the gage can be used indoors and outdoors, on a work surface, or using a four-point chest harness or shoulder strap. The gage meets military drop test standards (MIL-STD-810G) to protect against accidental drops or impacts, is designed to meet IP65 requirements to protect against dust and moisture, and takes reliable measurements in hot and cold climates with an impressive operating temperature range of –10 °C to 50 °C (14 °F to 122 °F).

72DL PLUS thickness gages are available in Standard and High-Frequency models. The High-Frequency model can drive transducer frequencies up to 125 MHz to measure ultra-thin materials—including multilayer paint, plastics, metals and coatings—and simultaneously display the thickness of up to six layers. The 72DL PLUS gage provides up to 2 kHz measurement speeds, a 60 Hz display update, and clean signals for fast, accurate measurements.

InnovMetric PolyWorks 2022

InnovMetric launched PolyWorks® 2022, the latest release of its smart 3D metrology digital ecosystem. PolyWorks 2022 offers new key functionalities that significantly expand the capabilities of its three ecosystem foundations:

- The universal 3D metrology platform now facilitates multipiece inspection when CAD data is not available as well as introduces a universal data hub

- Digital connectivity between data and people is improved by enabling the deployment of global metadata management strategies and the programming of alerts that automatically detect failing dimensions and notify the right people in real time

- The collaboration between probing operators and their measurement hardware is raised to a new level by mixed reality display technology that enhances the operators’ perception of 3D metrology

Manufacturing organizations often need to measure and inspect multiple pieces even though they do not have access to a reliable 3D CAD representation of those pieces. For example, in the early stages of a product engineering cycle or after having physically adjusted the design on the shop floor. To address these measurement scenarios, the PolyWorks universal platform offers a new feature measurement guide technology to guide probing, scanning, and feature extraction when measuring and inspecting multiple pieces in the absence of CAD data and nominal feature components. Users can inject a CAD model and nominal feature components at any point later in the process and propagate these changes to already-measured pieces.

The PolyWorks universal platform also features a new universal data hub that brings all relevant data under one roof:

- Inspection projects can be created automatically from third-party software measurement results and shared digitally enterprisewide

- Native CAD and QIF MBD file readers import all GD&T control types to ensure digital interoperability with the product definition processes

- Users can also use a more accurate device to measure a dimensional control and inject the measured value within a scanned or probed object for reporting purposes

In a 3D metrology context, metadata consists of important attributes describing the part design, piece fabrication, and 3D measurement processes. PolyWorks 2022 ensures metadata is meaningful and usable by managing shared properties common to multiple inspection projects and piece templates. Unified and synchronized shared properties empower searches, filtering, and analysis across the broad centralized 3D metrology data archive.

PolyWorks 2022 also enables production teams to program alerts that monitor incoming measurements and notify the right people by email when a dimension is out of tolerance or out of control. Notifications enable real-time reactivity as they include a hyperlink that instantaneously opens the problematic piece within a Web-based 3D viewer. From there, users can quickly assemble an investigation team using the PolyWorks modern digital communication technologies.

Manufacturing organizations need open solutions to interconnect their multiple enterprise solutions digitally and optimize their efficiency. InnovMetric also announced the availability of an API for its data management solution. Based on the OData open protocol, the PolyWorks 2022 secure REST API allows third-party software applications to access the hierarchy of workspaces, projects, and pieces, and the measurement objects and controls of individual pieces. The PolyWorks REST API is compatible with data analysis solutions, such as Tableau, PowerBI, and Excel, and allows users to inject parametric URLs referring to measured pieces into other enterprise solutions, such as PLM, ERP, or MES solutions, and to transfer information to other digital systems using programming languages, such as Python and C#.

InnovMetric

www.innovmetric.com

Teledyne FLIR Boson+ Longwave Infrared Thermal Camera Module

Teledyne FLIR, part of Teledyne Technologies Incorporated, announced the Boson+ with thermal sensitivity of 20 millikelvin (mK) or less. It shares the SWaP of the widely deployed and real-world-proven Boson thermal camera module. With identical mechanical, electrical, and optical interfaces, the Boson+ is a drop-in upgrade that also includes updated image processing to deliver enhanced sharpness and contrast for defense and commercial applications.

Made in the USA, the Boson+ includes a redesigned 640 x 512 resolution, 12-micron pixel pitch detector with a noise equivalent differential temperature (NEDT) of 20 mK or less which offers significantly enhanced detection, recognition, and identification (DRI) performance. Improved video latency enhances tracking, seeker performance, and decision support.

The shared Boson series interface and access to the US-based Teledyne FLIR Technical Services team reduce development risk and shorten time to market. Truly designed for integrators, the Boson+ is available with a variety of lens options, comprehensive product documentation, an easy-to-use SDK, and a user-friendly GUI. Boson+ is dual use and classified under US Department of Commerce jurisdiction as EAR 6A003.b.4.a.

The Teledyne FLIR Boson+ is available for purchase globally from Teledyne FLIR and its authorized dealers.

Teledyne FLIR

https://www.flir.com/bosonplus