Case Studies

V&S

Vision & Sensors

This Case Studies Special Advertising Section features manufacturing companies with real-world challenges using quality equipment, software and services to solve their problems and improve their processes. These problem-solving stories describe myriad manufacturing challenges and how the correct application of a supplier’s product or service made the difference, providing quantitative benefits to quality and manufacturing issues.

The suppliers in this special section present these real-world problems and solutions to help Vision & Sensors subscribers who may have similar experiences.

Case Studies

— Special Advertising Section —

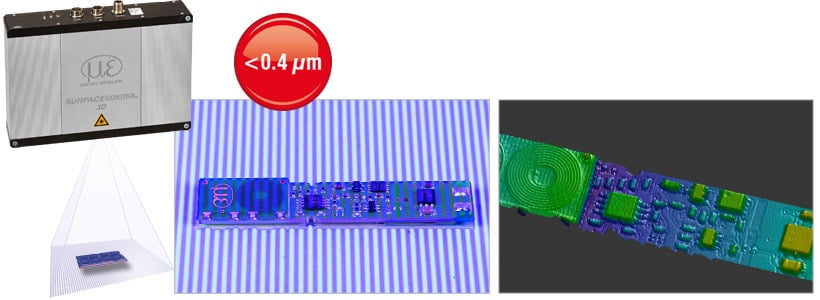

High-precision Automated Inline 3D Measurement

The high-precision surfaceCONTROL 3D 3500 is an innovative 3D snapshot sensor that is ideal for automated inline inspection of geometries, shapes and surfaces on diffuse reflective surfaces.

The surfaceCONTROL 3D 3500 features a compact design and high measurement accuracy combined with high data processing speed. With a z repeatability of up to 0.4 µm, the sensor sets new standards in high-precision 3D metrology. This means that even the smallest planarity deviations and height differences can be reliably detected.

In addition to fast data output via Gigabit Ethernet, the sensor offers an additional digital I/O interface. The 2D/3D gateway offers EtherNet/ IP, PROFINET and EtherCAT connections. Powerful software tools enable precise 3D measurements and surface inspections. GigE Vision compatibility also allows easy integration with third-party image processing software. The comprehensive SDK for integrating customer software rounds out the software package.

Application examples:

3D geometry inspection and shape detection

Inspection of electronic components

Defect detection

3D text recognition and detection of finest structures

Special features:

Complete 3D images in 0.2 s

Micrometer-accurate snapshots with large measuring fields

Highest precision up to < 0.4 μm

Up to 2.2 million 3D points / second

Digital interfaces (integrated): GigE Vision / GenICam

Digital interfaces (via 2D/3D Gateway): PROFINET / EtherCAT / EtherNet/IP

Digital in-/outputs: 4 digital I/Os for which parameters can be set (for external trigger, sensor control, output of sensor states)