Navigating Supply Chain Challenges with

Force Testing

Test & INspection

Recent advancements in force measurement equipment allow quality professionals to better handle unpredictable testing demands.

By Mark Fridman

The pandemic has turned the global supply chain on its head. Manufacturers of materials and finished items are under unprecedented pressure to manage a disrupted workforce, while responding to ever-changing customer demands, in many cases with profound urgency. It’s enough to make one’s head spin.

As if merely satisfying orders isn’t enough of a challenge in 2021, quality standards must be maintained throughout it all. Performing tensile and compression testing on materials, components, and assemblies requires test equipment that is flexible and quick to set up, for minimal changeover time and maximum efficiency.

Force Measurement or Materials Testing – Which Is It?

Tensile and compression testing, depending on the application’s complexity, can be categorized either as materials testing or force measurement.

Materials testing is the scientific analysis of materials such as metals, elastomers, and textiles, requiring the measurement of stress, strain, modulus of elasticity, elongation, and other calculations. Common applications include the tensile testing of aluminum, bending force of plastics, and the compression force of foams.

Force measurement is a simpler testing method, usually requiring only the measurement of force and distance. It is more often prescribed for testing components and assemblies than materials. Recently, this term is used more interchangeably with materials testing and tensile testing as advancements in force measurement equipment blur previously well-defined boundaries.

Before selecting equipment, identify the test objective, determine the expected force range, assess sample dimensions, and estimate the sample extension or deformation.

Why Measure Force Anyway?

Quality Validation

The role of the quality department is to make sure that a product is manufactured in conformance to agreed-upon standards. Measurement data help isolate problematic individual products, lots, or batches. Armed with this data, quality control and engineering professionals can determine the source of the problem, whether it’s a design issue, material defect, production problem, or other cause.

Compliance

Compliance is an ever-increasing burden on industry, made even more daunting against the backdrop of supply chain turmoil. Standards and regulations are ever expanding and changing. Some industries are affected more than others, such as medical device and aerospace. Failure to conform to norms can result in penalties or restricted access to certain markets.

While ensuring compliance can be burdensome, much of the work has already been done via the multitude of standards and methods prescribing how to accomplish particular objectives. Depending on the manufacturer’s particular product, industry, and customer base, they may follow ISO, ASTM, DIN, or other industry-specific standards. Test methods define test equipment, sample preparation, and how to interpret results.

When established standards don’t meet a manufacturer’s particular needs, companies also develop their own internal test methods to ensure baseline quality metrics.

Product Design & Improvement

The data obtained through force measurement and materials testing can help inform design engineers, giving them a quantifiable basis on which to proceed with new projects.

Adapted To The Times

Newer testing systems integrate the test frame and force sensor into one system, governed by a single software application. Such applications display the basics – force, distance, and time – while also providing an interface to design the test, analyze results, export data, and generate a report.

Faster Setup and Changeovers

Newer integrated systems allow for high levels of test configuration, with restricted user access to prevent accidental changes. For a busy testing lab encountering different kinds of samples with different requirements, switching between test types is quicker than in the past.

Multi-step Testing

Key to manufacturing and testing flexibility is multi-step testing. Combinations of push and pull sequences, hold steps, and data collection steps can be set up as needed, all through the application.

Operator Prompting

Ask prompts require an operator to input information, such as a serial number or lot number. These values are saved with the results, thereby providing traceability. Barcode scanners can be useful in inputting data quickly and accurately. Tell prompts can be used to relay information to operators, such as sample loading instructions.

Data Processing

Today’s force measurement and materials testing software packages have integrated data collection options, statistical calculations, and customizable result and report formatting. For more specialized data processing needs, data can still be exported in .csv format for external analysis.

Previous Test Graph Comparisons

Data are plotted on a graph as force vs. distance or force vs. time, depending on the application, to visualize sample behavior and identify anomalies. Previous runs may be overlaid on the graph, allowing for visual comparisons against an established standard.

How To Test

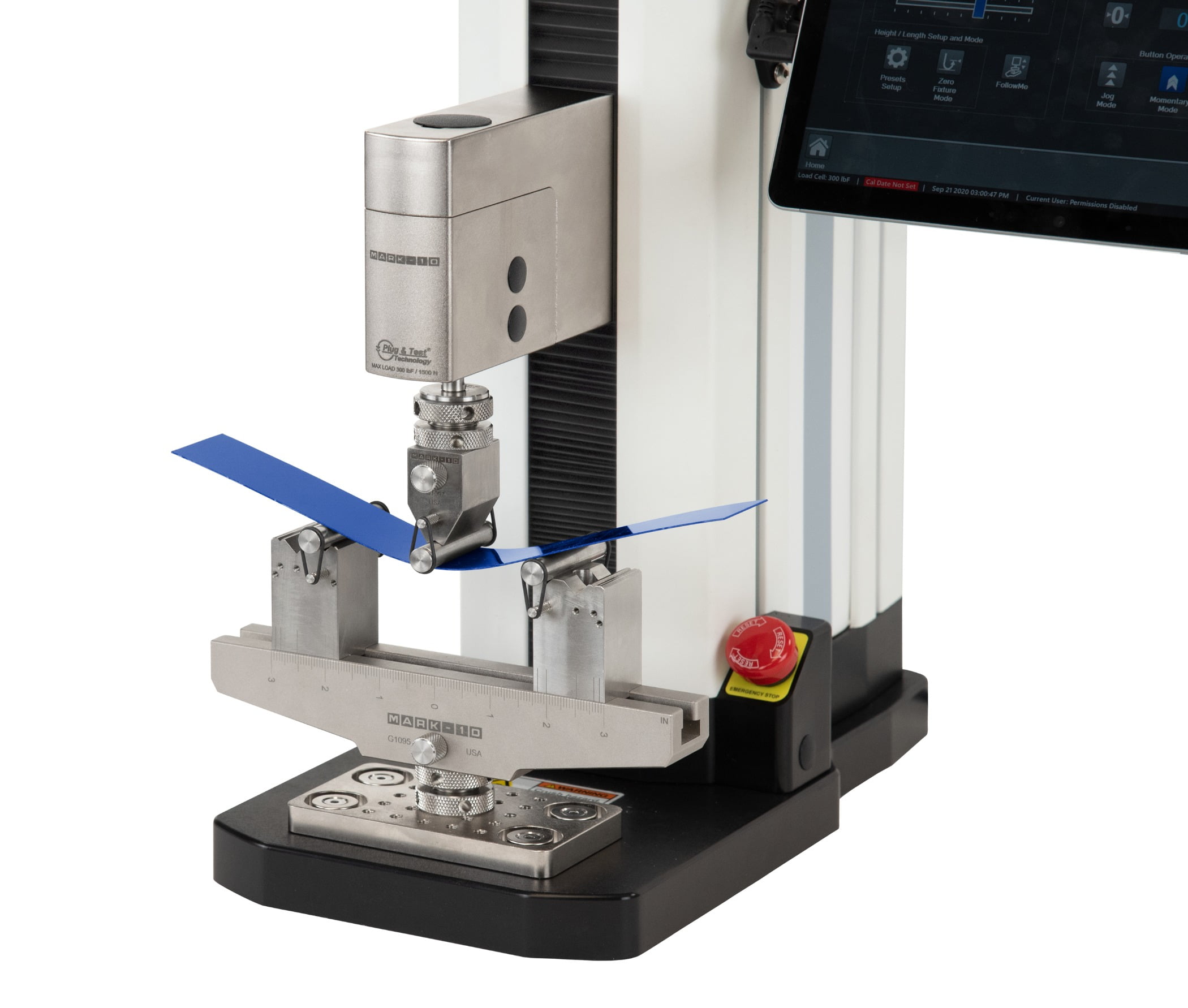

A materials tester or force measurement system consists of the following main components:

Test frame of suitable force capacity

Force sensor of suitable force capacity

Grips and fixtures

Data collection software

Before selecting equipment, identify the test objective, determine the expected force range, assess sample dimensions, and estimate the sample extension or deformation.

Test frame

A test frame produces compression and tension forces. Testing speed is regulated to ensure that samples are tested in a consistent manner, for apples-to-apples comparisons.

Test frames are offered in several force capacities, typically from as low as 100 lbF (500 N) up to several tons. For odd-shaped or large samples, column extensions increase the working height and depth. Dual-column test frames offer unlimited depth clearance, though they are typically manufactured for higher force capacities.

Performing tensile and compression testing requires test equipment that is flexible and quick to set up, for minimal changeover time and maximum efficiency.

Performing tensile and compression testing requires test equipment that is flexible and quick to set up, for minimal changeover time and maximum efficiency.

Before selecting equipment, identify the test objective, determine the expected force range, assess sample dimensions, and estimate the sample extension or deformation.

Force sensor

Force sensors (commonly known as load cells) measure tension and compression forces, and are available in many force capacities, from as low as 50 gF (gram-force) full scale to several tons.

Choosing the correct capacity is of paramount importance. A sensor should be used at no less than approximately 5-10% of its range for best accuracy. For example, an application requiring 16 lbF is best served by a 20 lbF capacity model. A 500 lbF sensor would produce lower accuracy and resolution.

Grips and fixtures

An extensive library of generalized and application-specific grips and fixtures is available by testing machine manufacturers, as well as other manufacturers specializing in fixture design. When a standard solution is not suitable, companies may opt to customize a solution. 3D printing has made fixture design fast and inexpensive in many cases.

Ready For What’s Next

Nobody knows how the pandemic will play out, but with recent advancements in force and materials testing systems, manufacturers are well equipped to meet the testing challenges of today and tomorrow.