Robotics

Robotics

Vision & Sensors

V&S

The Rise of Smarter Robots

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot.

By Jim Anderson

Using a system-solution approach provides you the answer to running a more efficient, cost-effective, and accurate production line. With multiple robot guidance systems, there are solutions available now to fit your business needs that can help you gain flexible material handling operations.

Manufacturers across multiple industries face a number of current challenges, including shorter production series (lot size one), lower costs, and a need for increased flexibility. But perhaps the greatest challenge is effectively implementing automated material handling solutions.

Manual part picking is an expensive, labor-intensive process. As a result, robots are increasingly replacing repetitive manual handling. The challenge with robots, however, is that they are blind, and many are not flexible enough to accommodate ever-changing automated production processes. This is changing at an incredibly fast rate though. The number of technologies including camera-based vision systems is on the rise along with the ongoing integration of robots, sensors and cameras and software taking advantage of the improvements in deep learning and artificial intelligence.

With robot vision guidance systems, both 2D and 3D, flexible material handling is made possible for industrial production and warehousing. These customizable vision systems provide the competitive advantage many manufacturers are looking for in part localization applications.

“With the creation of many new technologies for the industrial automation industry, this is a very exciting time,” says Nick Longworth, SICK market product manager robot guidance systems. “Simple and repetitive tasks of lifting heavy parts from deep bins, conveyors, and racks has always been a primary source of long-term back injuries, accidents, and inefficiencies.”

There are several different robot guidance systems that use different types of machine vision technology to provide flexibility in the production process. These automation solutions can also give you the improvement your business needs to gain flexibility in the material handling operations as well.

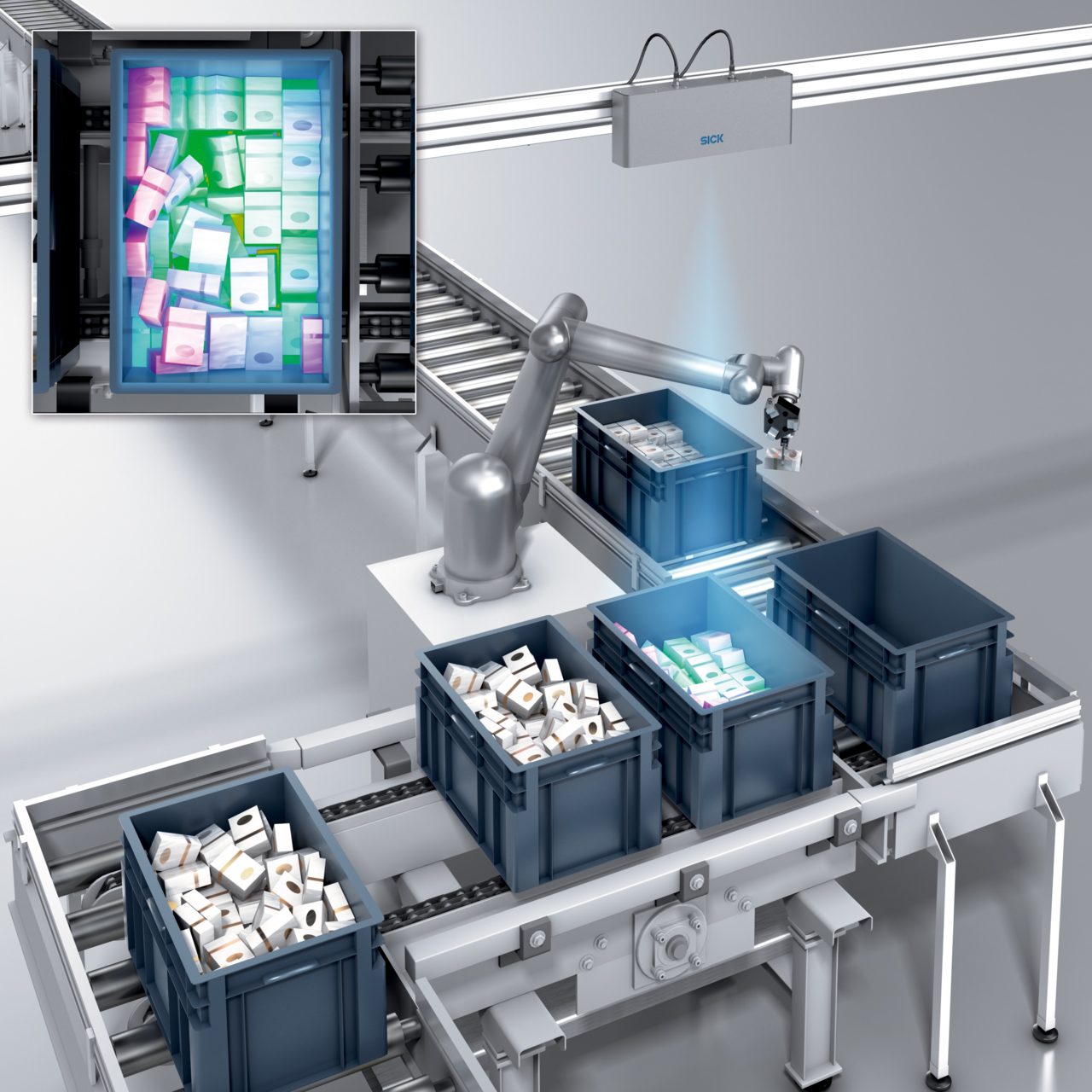

Robot-automated part picking eliminates the need for precise part placement in the bin or the pallet, thereby maximizing part-handling uptime. With the PLB vision system, you’ll get a complete solution that comprises of hardware and preconfigured and tailored software. With this system, you can identify and pick objects nearly regardless of size.

Using a high-quality 3D camera, the robot can locate the part, regardless of orientation, and provide pick coordinates to the robot. The robot then verifies that a collision-free space is available for the gripper in reported pick positions. The system provides a localization time typically within just a few seconds, usually less. In many cases the cameras are calibrated and aligned with the robot’s coordinate systems, so the data is delivered in the robot’s preferred data structure, taking that calculation away from the robot and allowing for more speed. Many systems can deliver multiple pickable objects per scan as another way to increase the throughput.

PLB 3D Randomized Bin Picking System

There are multiple technologies used in the scanning and image creation for these types of systems. There are 3D laser triangulation scanners used when the total field of view and depth of field are the driving factors for the application. When the overall resolution of the image is more important than size of the FoV, imaging techniques like structured light stereo are often used. When longer range is needed, and lower costs are driving the solution the use of Time-of-Flight-3D cameras is an option. All of these technologies provide data in different formats and when the format is the same the data density and overall amount of computing required to handle the 3D data can be tricky or require specific software interfaces for each type.

The part localization software implemented in the PLB system is unique in that it offers multiple ways to teach new objects for picking. It is also unique in the fact that the software can handle 3D and 2D from many different camera types and technologies. The software is teaching the camera what to target based on a CAD drawing. A visual graphical user interface (GUI) works with the CAD software to provide a visual dashboard for the user to see everything the system is locating. There are other options that are based on standard stereo vision techniques, and still others that add additional cameras for adding color or snapshot images to the 3D point cloud data.

The PLB is an easy-to-use solution that makes it possible to configure new applications quickly and efficiently with its CAD-based, 3D-shape matching part localization software, edge algorithm, and available plugins. It noticeably reduces the effort of analyzing and designing solutions for new applications. The software simply matches the CAD model of a part to the 3D image it takes, and the robot then picks the part. In addition, advanced users gain additional versatility with the ability to develop plugins for localization, letting the PLB do the rest of the work.

These machine vison guided robot picking systems are ideal for the automotive production industry, primarily for powertrain manufacturing, part suppliers, and machine loading operations in component production. In addition, the system has intralogistics applications in de-palletizing and de-stacking tasks and parcel singulation. There are also some process automation applications for the handling of foundry and forging parts.

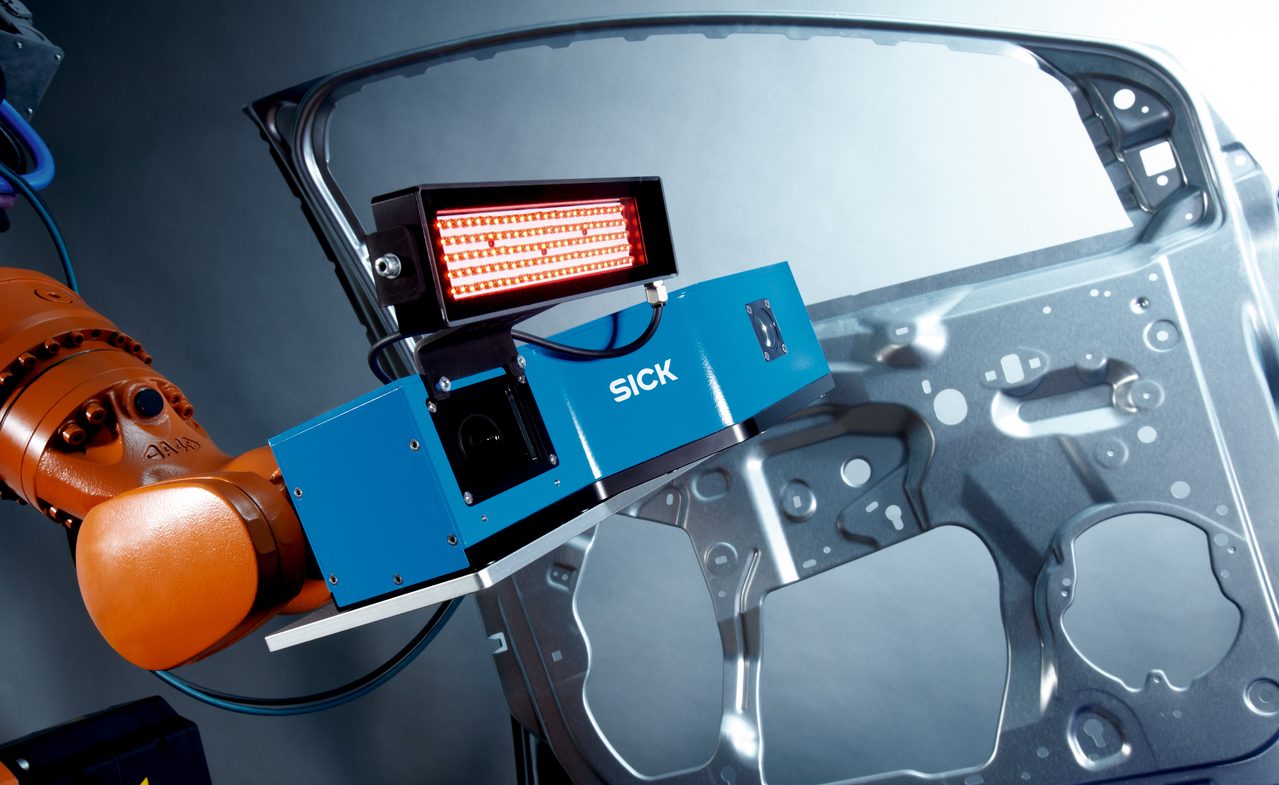

PLR 3D De-Racking System for Automotive

Part Localization In Racks

With part handling directly from racks, a vision-based robot guidance system provides flexibility to adjust around inaccurately placed or damaged part racks, titled stacks on a pallet, part positions shifting during transport, or natural part manufacturing tolerances. There are multiple systems that have a large range in features and price. The main goal of these systems is to provide reliable robot guidance to shorten cycle times and reduce costs.

It is best at helping to overcome challenges around handling large, bulky stamped sheet metal parts. The parts that are to be manipulated or transported might move or shift during transport or the racks themselves can be damaged. As a result, the PLR, one of these pre-configured systems, can overcome these challenges and keep your production running smoothly.

These systems are ideal for the automotive production industry, primarily in automotive body production. It can also be used for localization of parts stored in containers in spot welding and gluing stations. It could also be used to align a robot mounted to an AGV with an attached work surface or one that it drives up to.

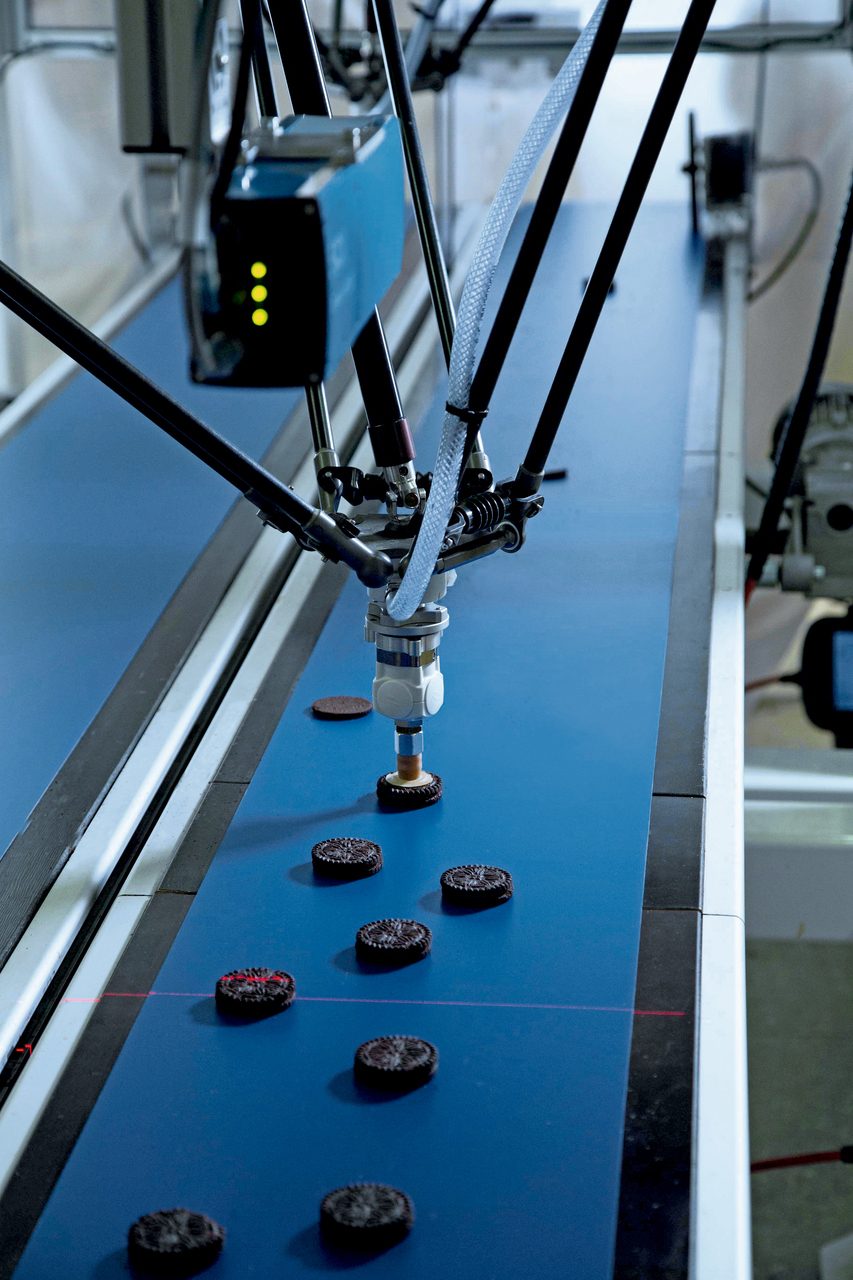

Belt Pick 3D Vision System

Part Localization On Conveyors

Robot guidance systems can also be used for conveyor-picking applications. These vision systems are often 2D and use contrast for part localization. They consist of high-quality image processing hardware and are equipped with extremely high-performance localization algorithms for reliable and fast part location.

Many systems have tools or functions for synchronizing the data with the speed of the conveyor. For example, there is a system that accounts for rapid movement on the conveyor system allowing for a collaborative effort between the conveyor and the robot arm to work at a rapid pace. This all enables the effective localization of multiple simultaneous parts and rapid transfer of localization data to the robot.

Working with 3D vision in your conveyor picking projects increases both the reliability of your picking process and the quality of the handled products. The 3D data is especially good for locating products on a conveyor belt in packaging applications in consumer goods. For each detected product, the camera reports location, height and orientation to the robot controller.

These systems are ideal for automotive production, and the consumer goods industries. The 3D solutions are great for products in consumer goods where color may give 2D systems difficulty. In addition, the system has retail and warehousing applications for depalletizing.

Autonomous Vehicles

Often times the robots used in the production of items are given more visibility, especially when it comes to quality, but the use of AGVs and now AMRs have just as much impact on the customer’s quality of experience and overall perception of the company. Robots help move product through the warehouse and to the location it is needed whether that is delivering raw materials to the production line or loading pallets on to the trailer for shipment.

The consumer expectation of same-day delivery or next-day delivery is increasingly becoming the norm. Therefore, e-commerce and retail organizations are increasingly looking at building efficient, flexible, and automated supply chain processes to satisfy customer expectations. Adoption of warehouse automation technologies to enable faster, efficient, and dynamic order fulfilment is amongst the primary targets for automating supply chain operations and updating production capabilities.

This trend has been on a rapid increase and has only been exaggerated with the onset of the pandemic. The need for safe, consistent quality products getting produced and shipped became difficult when people could not do the jobs during the global shutdowns. Working with reduced human labor has allowed some factories to stay afloat during these times.

Advancements in robotics technology have led to the emergence of affordable robotics and automation systems, such as automated guided vehicle (AGV), autonomous mobile robots (AMR), drones, automated storage and retrieval systems (AS/RS) and other flexible automation systems, thereby increasing the number of companies that are deploying robotics and automation technologies to improve warehouse operations and address workforce challenges and in the production side of the factory.

AMRs are equipped with numerous sensors and software application to interpret and understand its surrounding environment, navigate through various obstructions, automatically determine an optimum route to accomplish tasks and work collaboratively with operators for performing a range of operations, including order picking, sorting, and other material movements within the warehouse.

AMRs may include sensors for mapping, navigation, localization, computer vision, 3D cameras, and other environmental sensors. Most AMR uses LiDAR sensors for dynamic navigation, avoiding various fixed and moving obstructions.

Growing global competition for customers and skilled employees are further adding to the challenges with substantially higher customer churn rate because of bad customer experience.

Organizations are increasingly adopting/upgrading various supply chain technologies to optimize end-to-end supply chain and warehouse operations and boost their capabilities to improve overall customer experience and overall quality.

One trend in the implementation of robots and AMRs in smaller companies is Robots-as-a-Service. Just as it sounds, the service or subscription model is allowing many organizations regardless of size to pursue robot-based automation projects without the traditional barriers such as capital. The robot’s fundamental value proposition of improving warehouse efficiencies and productivity by automating various non-value-adding material movement activities and freeing up human workforce for value-adding activities, helping organizations iaddress labor shortage challenges, and providing quick ROI are driving market growth and providing companies with advantages and improvements in overall quality.