How to Reach Unmatched Precision in Distance and Thickness Measurements with Confocal Sensors

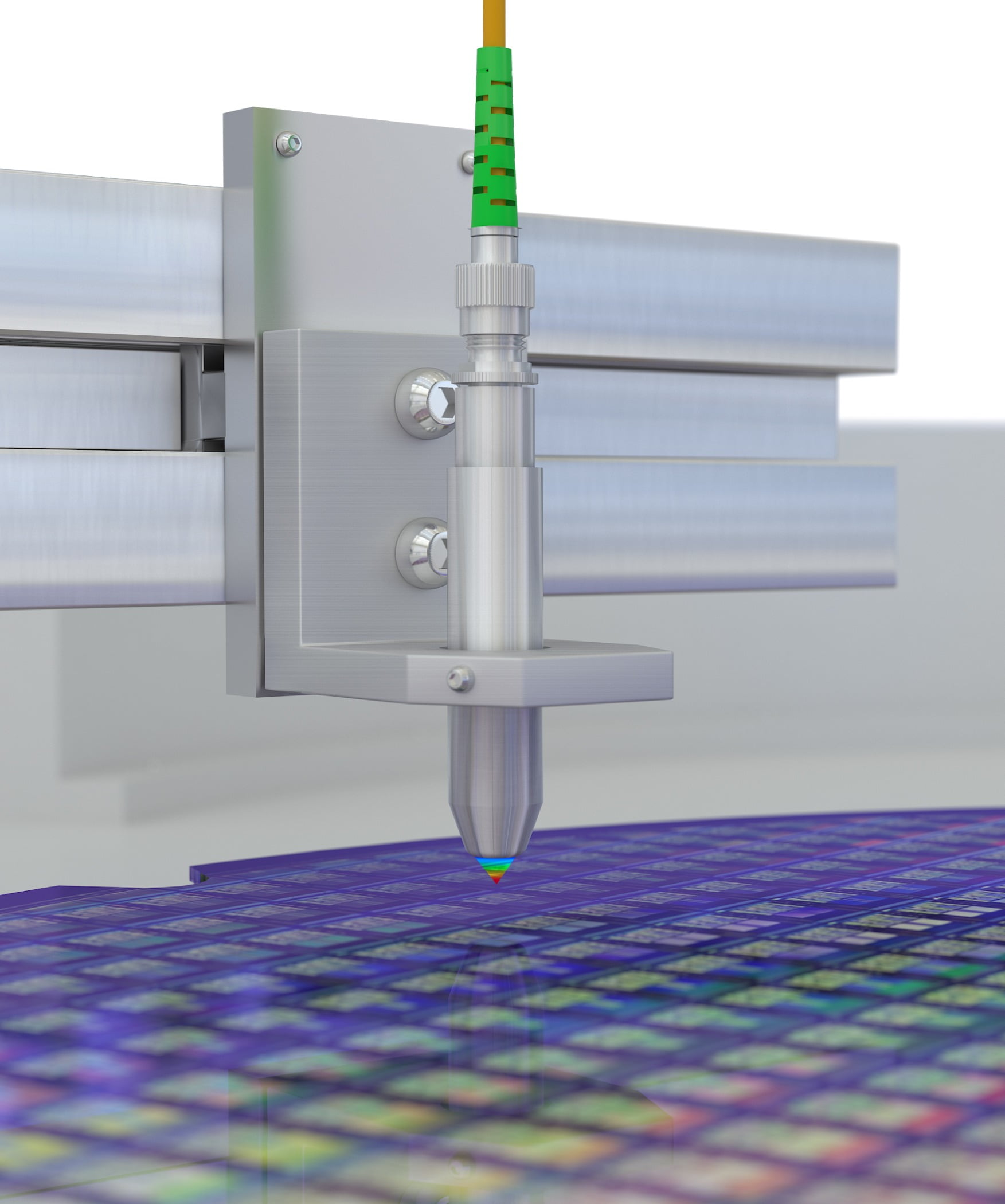

Confocal chromatic sensors from Micro-Epsilon provide state-of-the-art technology for displacement, distance, position and thickness measurements combined with maximum precision and high speed. A wide range of sensors and different controller interfaces open up a variety of application areas, e.g. in the semiconductor industry, glass industry, medical engineering and plastics production. Confocal sensors provide high accuracy, especially when measuring on reflecting and shiny targets, and are ideal for inline production processes where tactile measurement technology reaches its limits.

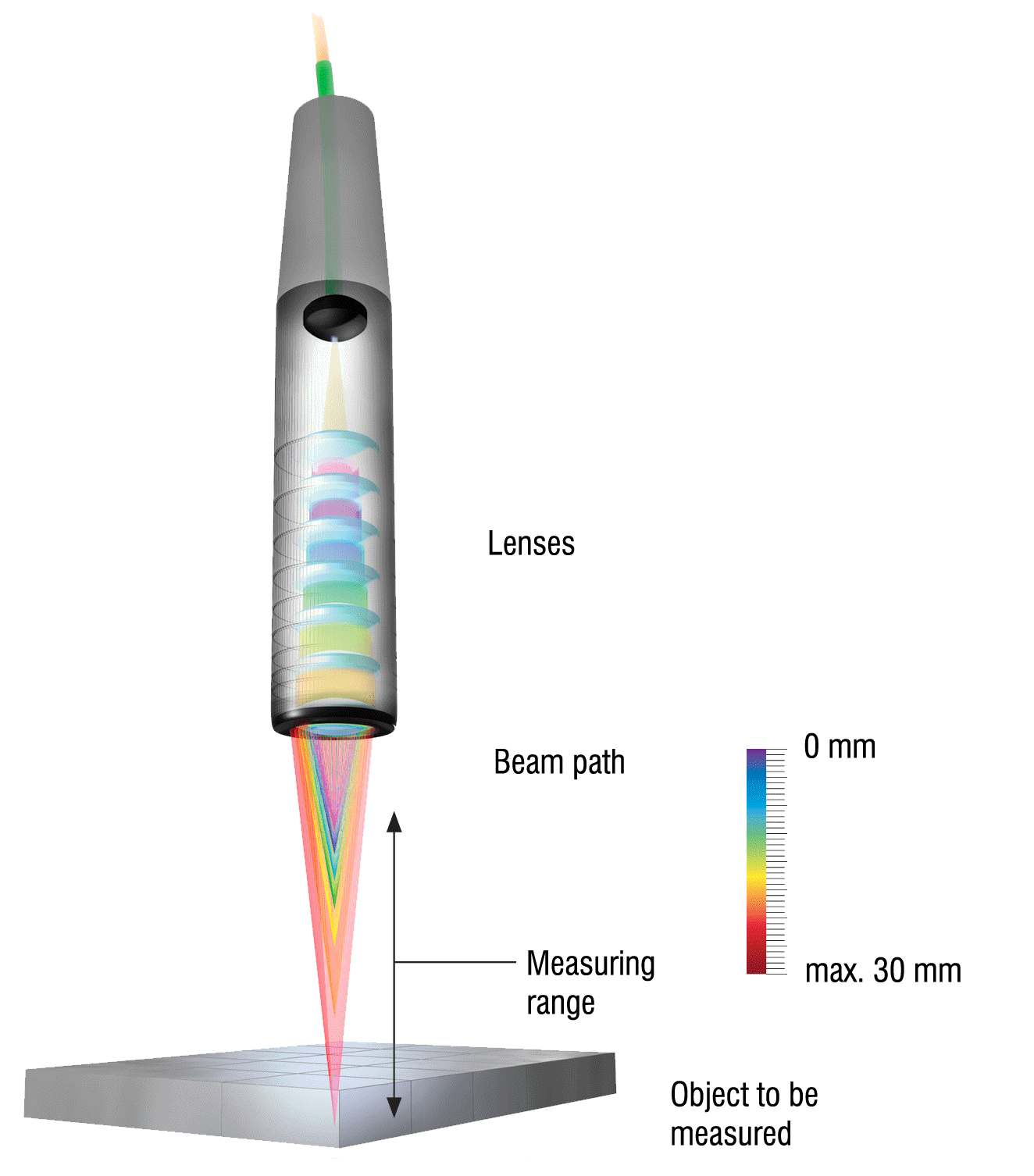

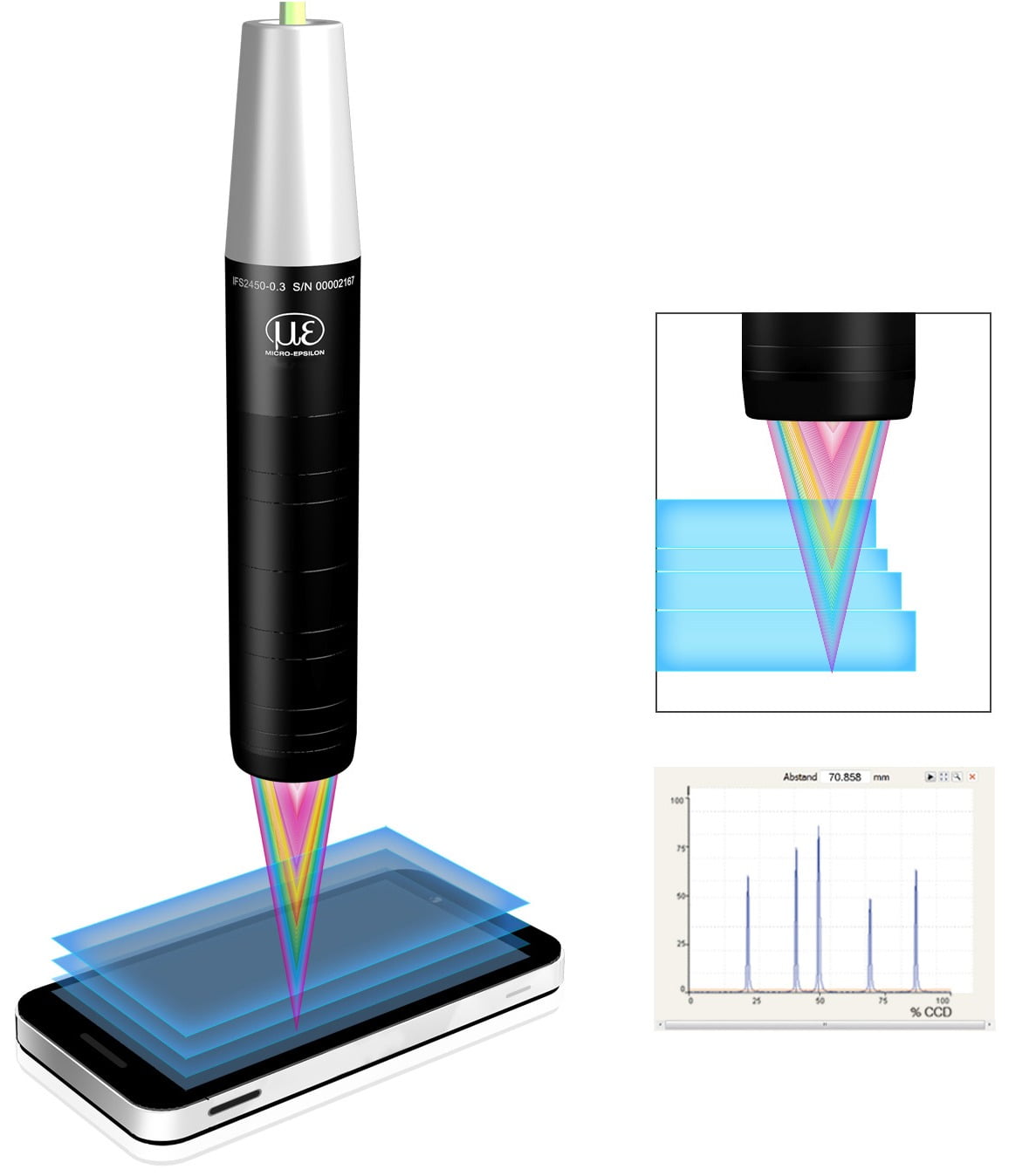

Polychromatic white light is focused onto the target surface by a multi-lens optical system. The lenses are arranged so that the white light is dispersed into monochromatic wavelengths by controlled chromatic aberration. To each wavelength, a specific distance is assigned by factory calibration. Only the wavelength which is exactly focused on the target is used for the measurement. An optical arrangement images the light reflected onto a light sensitive sensor element, on which the corresponding spectral color is detected and evaluated. In the case of multi-peak measurements, several distance points are evaluated accordingly.

Decisive Advantages of confocal chromatic sensors

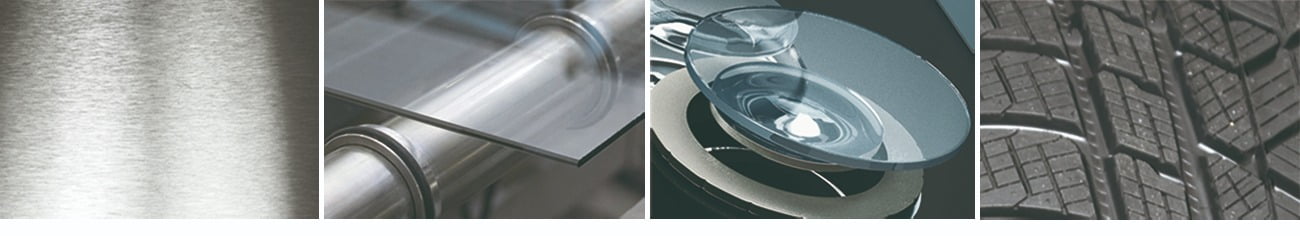

Compared with laser triangulation sensors, confocal chromatic sensors from Micro-Epsilon offer numerous advantages. Especially when measuring on reflecting and shiny targets, confocal chromatic sensors provide high accuracy whereas laser sensors are overdriven due to the high light intensity. The sensors are inherently immune to EMI and even suitable for EX-proof environments and vacuum.

Decisive Advantages of confocal chromatic sensors

In contrast to laser-optical sensors, confocal chromatic sensors are almost independent of the light reflected by the surface. Therefore, the distance can be measured from dark and mat surfaces as well as from shiny and reflecting surfaces.

One-sided thickness measurement of transparent materials

The confocal chromatic measuring sensors enable thickness measurements of transparent materials such as glass. The thickness is detected to micrometer accuracy using just one single sensor which uses the reflections of the front and rear side of the material. These reflections generate peaks on the CCD array based on which the corresponding distance and thickness are calculated.

High Performance with confocal Sensors

- Distance and thickness measurement with high resolution and measuring rate

- Extremely small and constant spot size

- Nanometer resolution

- Almost surface-independent, also valid for mirrored and glass surfaces

Highest precision with nanometer resolution and 70 kHz measuring rates

Confocal chromatic sensors provide an extremely high resolution. As individual spectral colors are used for the measurement, nanometer resolution is possible. Using a high-powered light source and a high-speed spectrometer, measurement rates up to 70,000 Hz can be reached. Additionally, confocal sensors from Micro-Epsilon generate the smallest of light spots <3 µm due to their high numerical aperture. Therefore, the finest details and structures can be detected reliably.