Digital twins allow manufacturers to predict outcomes and detect errors with far greater precision than trial-and-error methods. By Allen Cius

Digital Twins

Software & Analysis

H2 Deck Info By Paragraph Style Bold

Headline

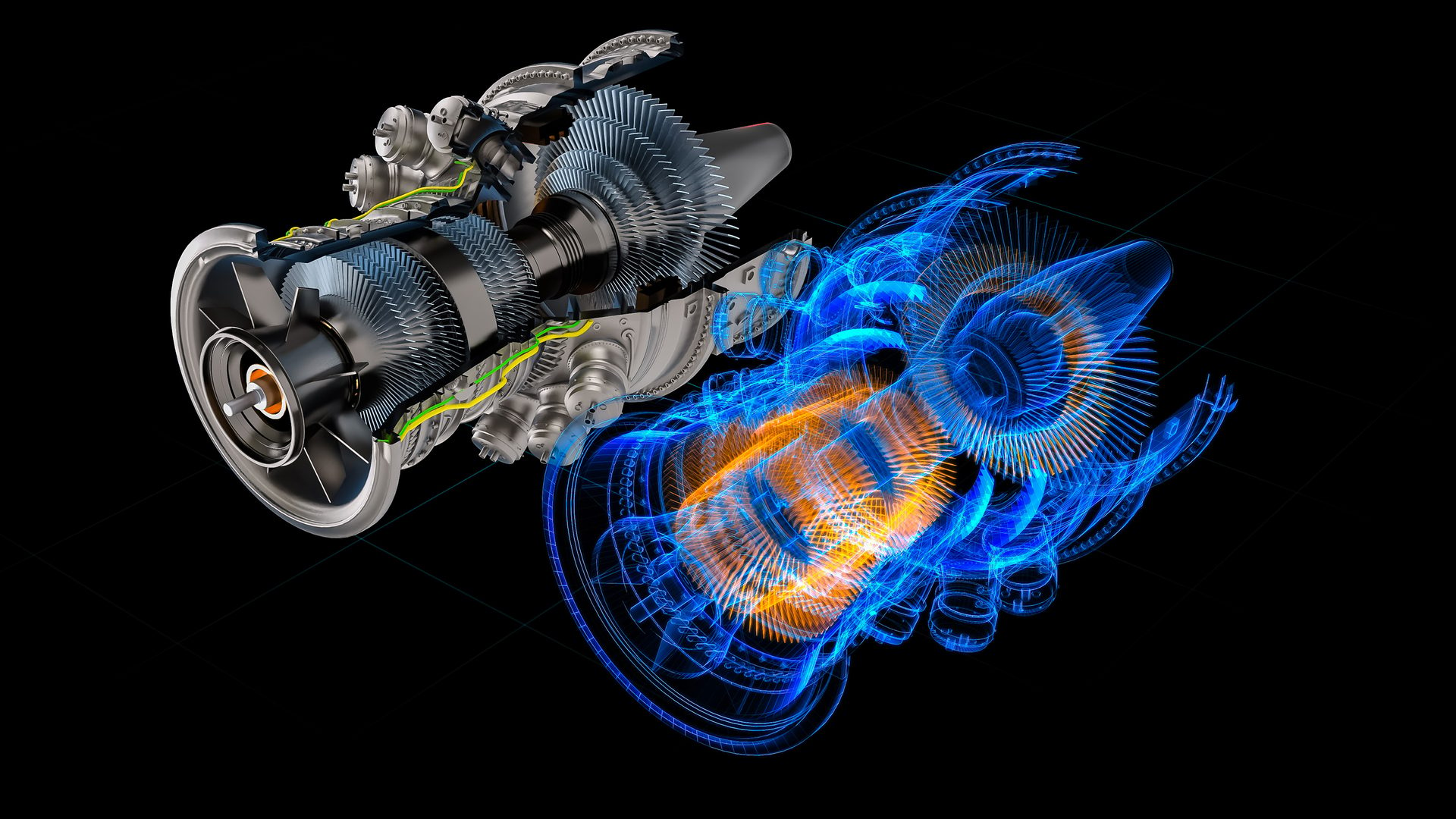

Digital twins, once a concept reserved for speculative fiction, now stand at the forefront of modern manufacturing and quality control. These virtual replicas of physical assets that range from individual machines to entire production lines, enable organizations to simulate, test, and optimize processes before making real-world changes.

By mirroring actual systems in a dynamic, data-driven model, digital twins allow manufacturers to predict outcomes and detect errors with far greater precision than trial-and-error methods.

Setting the Stage

Traditionally, rolling out new production processes has involved incremental tweaks, physical test runs, and often costly do-overs if something went awry. While some manufacturers still rely on these approaches, they do so in a rapidly evolving industrial landscape. Technological advancements have led to increased automation, tighter tolerances, and a constant push for faster production cycles. In this setting, digital twins offer a new paradigm: a continuously updated virtual space that provides near real-time insights into machine performance, environmental variables, and quality metrics.

For quality control specialists and engineers alike, this shift means having the ability to foresee collisions, monitor machine health, and refine measurement routines without halting a production line. Instead of responding to problems as they emerge, teams can make proactive, data-driven decisions based on simulated outcomes. The result is a significant competitive edge: fewer interruptions, minimized risk, and a more confident approach to innovation.

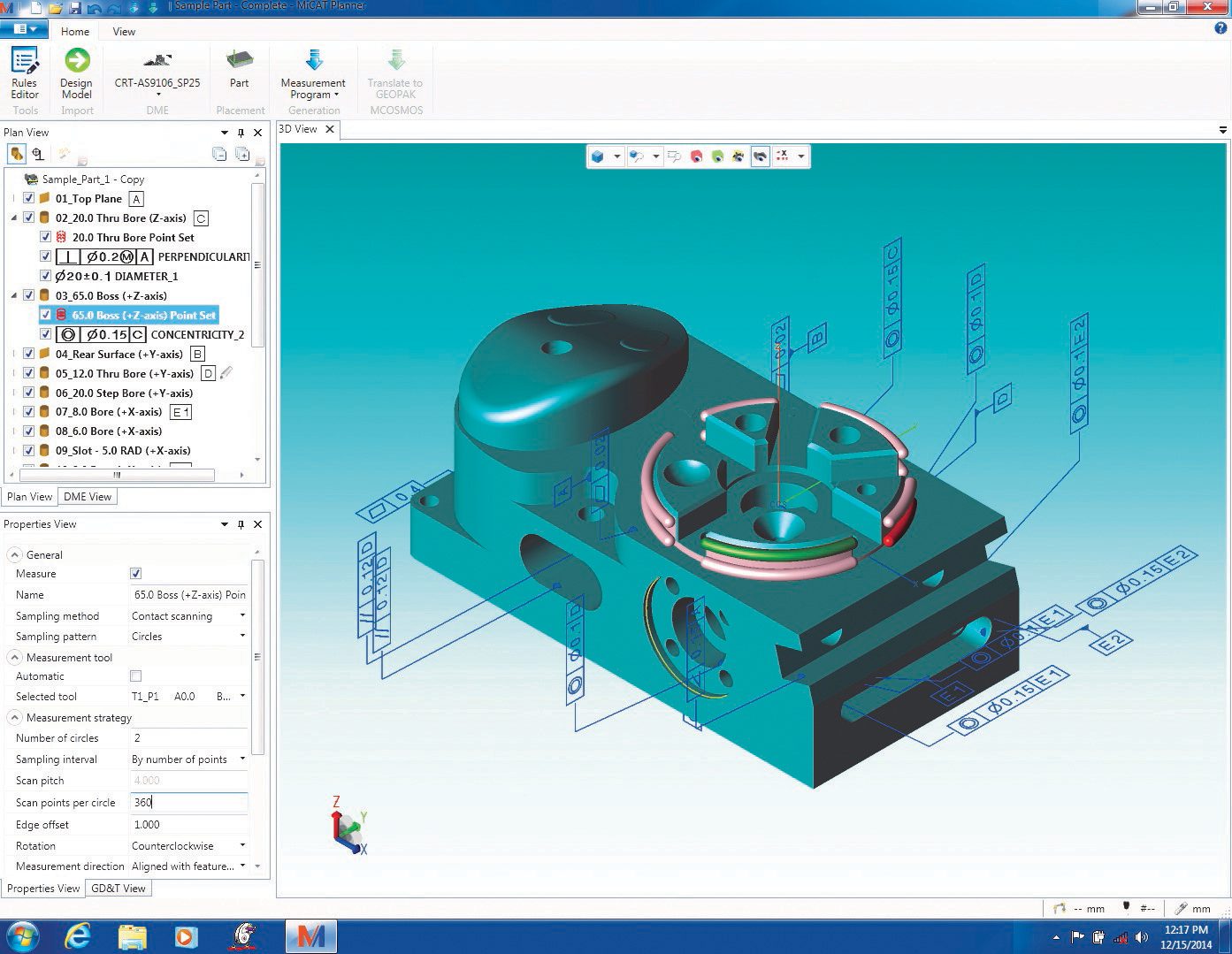

By comparing measured data against a digital CAD model like in the image, manufacturers can detect deviations in real time and adjust production processes accordingly. Digital twin technology can continuously update the virtual model based on physical measurement feedback. Source: Mitutoyo

Core Benefits

Predictive Maintenance and Uptime

One of the core advantages of digital twins is the capacity for predictive maintenance. In a conventional setup, machines are serviced according to a schedule or when obvious signs of trouble appear—often too late to prevent downtime. Digital twins take a different route.

- Proactive Repairs: By analyzing historical performance data and current sensor inputs, a digital twin can highlight when a particular component is nearing the end of its service life. This might manifest as subtle vibration patterns, temperature spikes, or changes in operational speed.

- Downtime Reduction: Because the digital model flags potential issues in advance, maintenance teams can schedule repairs or part replacements during planned downtimes, rather than scrambling to fix urgent breakdowns. This foresight keeps the production line running more consistently and helps maintain safe working conditions.

Improved Machine Utilization

In many facilities, equipment usage is imbalanced. Some machines end up overloaded, while others sit idle. This not only accelerates wear and tear on heavily used machines but also represents lost productivity on underutilized assets.

- Balanced Workload: By replicating each machine in a virtual environment, managers can view real-time usage patterns. This visibility makes it easier to distribute workloads more evenly, prolonging machine life and preventing bottlenecks.

- Avoid Overuse/Underuse: A digital twin can track factors like power consumption, cycle times, and the number of parts produced—giving decision-makers the data they need to shift tasks from one piece of equipment to another. Such balancing directly translates to cost savings and extended machine lifespan.

Enhanced Visibility

Digital twins don’t just replicate how machines run; they also visualize how machines, parts, and processes interact within a production environment.

- Collision Detection: Particularly relevant for robotics and multi-axis CNC equipment, the virtual environment can flag potential crashes before they become costly real-world incidents.

- Condition Monitoring: By integrating sensor data—from temperature readings to vibration signatures—digital twins monitor machine health in real time. Subtle shifts can indicate wear, misalignment, or the need for lubrication.

- Optimized Measurement Paths: Within quality control, digital twins are instrumental in planning part-inspection sequences. They not only suggest the most efficient paths for coordinate measuring machines (CMMs) but also help identify potential obstacles or required fixture modifications.

Data Management Bridge

While data is critical to effective decision-making, it’s only as good as the systems that harness and interpret it. That’s where digital twins excel, serving as a connection between physical operations and analytical insight.

- Real-Time Feedback Loops: By comparing real-world measurement data to the digital model on the fly, production teams can spot deviations from expected tolerances and make immediate adjustments.

- Shorter Measurement Times: The ability to reconcile measured values with a virtual model reduces back-and-forth measurement loops. This streamlined process means fewer tool changes, less idle machine time, and faster turnaround for quality checks.

Real-World Examples

Robotics

Robotic arms and automated guided vehicles (AGVs) offer some of the most compelling uses for digital twins. Any machine with moving components—and that often means rotating joints, telescoping arms, or servo-driven actuators—can benefit from having a digital mirror.

- Virtual Robot Arms: By simulating a robot’s range of motion, cycle times, and load tolerances, engineers can identify bottlenecks or inefficiencies in a production sequence well before a single physical component is engaged.

- Simulation First: This approach is not merely academic. In practice, manufacturers simulate complex pick-and-place operations to ensure that a robot arm won’t collide with conveyor belts or other robots. This reduces trial-and-error time on the shop floor, making robotic cells safer and more productive.

CMM Part Programming

Quality control often hinges on accurate measurements, especially in industries where tight tolerances are non-negotiable.

- Pre-Installation Setup: One of the standout applications of digital twins is the ability to create part programs for coordinate measuring machines before the physical equipment is installed. Metrology engineers can design probe paths, determine fixture requirements, and finalize measurement strategies virtually.

- Reduced Trial-and-Error: Once the machine arrives, the part program is already refined and ready to go. This shortens the time needed for manual adjustments, thereby reducing the cost and effort typically associated with on-site experimentation. It also minimizes the chance of damaging sensitive probes or parts due to collisions or misalignments.

Challenges & Considerations

Implementation Costs

Despite the clear advantages, implementing a digital twin strategy is not without its hurdles.

- Initial Investment: Hardware (sensors, networking equipment) and software (simulation packages, data analytics platforms) can be expensive, especially for smaller facilities with limited budgets.

- ROI Perspective: Many organizations find that the upfront costs are offset by long-term gains in uptime, quality, and productivity. Nevertheless, a thorough cost-benefit analysis is essential to ensure that the financial commitments align with strategic goals.

Data Security and Integration

Because digital twins rely on near real-time data from networked sensors and control systems, protecting that data is paramount.

- System Interoperability: The challenge of connecting digital twins to existing manufacturing execution systems (MES) or enterprise resource planning (ERP) software can be significant. Not all legacy systems integrate seamlessly with modern simulation platforms, requiring potential upgrades or custom interfaces.

- Cybersecurity Concerns: As more devices come online, the risk of unauthorized access or data breaches rises. Manufacturers must invest in secure networks, encrypted data transmission, and rigorous authentication protocols to protect both intellectual property and operational stability.

Workforce Training

Introducing digital twins also means introducing new processes, tools, and mindsets to the workforce.

- Upskilling: Machine operators, quality inspectors, and engineers need training to interpret digital twin data and make informed decisions. In some cases, this requires learning new software tools or developing a deeper understanding of data analytics.

- Change Management: Even the most advanced technology can stumble if the human element is overlooked. Gaining buy-in from staff who may be used to more traditional methodologies requires transparent communication, clear demonstrations of benefits, and a supportive transition plan. Showcasing early successes—like avoiding a costly collision—can go a long way in demonstrating value to skeptical team members.

Trends & Future Outlook

While digital twins are already making waves in manufacturing and quality control, the broader industrial ecosystem points to even more transformative changes on the horizon.

- AI-Driven Analytics: Machine learning algorithms are increasingly being integrated into digital twin platforms. This enables more sophisticated predictive modeling, where the twin can “learn” from data patterns to proactively suggest improvements or detect anomalies that might not be visible through traditional analysis.

- IoT and Cloud Services: As sensor technology evolves and cloud computing becomes more accessible, smaller and medium-sized manufacturers will find it easier to adopt digital twins without massive infrastructure investments. On-premises systems are giving way to hybrid or cloud-based solutions that can scale quickly with demand.

- Industry 4.0 Synergy: Digital twins are one facet of a larger shift toward Industry 4.0, which emphasizes interconnected systems, automation, and data exchange. As more manufacturers adopt industrial internet of things (IIoT) devices, the quality and volume of data feeding digital twins will only improve. This cyclical relationship—more data enabling better simulations, leading to more efficient physical processes—propels continuous innovation.

Beyond these immediate trends, digital twin technology has the potential to shape entire supply chains. By extending the concept across multiple facilities and linking suppliers with end users, organizations could create a seamless loop of real-time feedback that optimizes every stage of a product’s lifecycle. While such a vision may require further standardization and cross-company collaboration, it exemplifies the far-reaching potential of virtual simulation in manufacturing.

From replicating intricate movements of a robotic arm to fine-tuning part measurement routines, digital twins stand out as a powerful catalyst for modern manufacturing. Their ability to predict machine failures, balance production workloads, detect collisions, and shorten measurement times translate into tangible gains in productivity, efficiency, and safety.

For those exploring how to stay competitive in an era of ever-tightening tolerances and ever-shortening product cycles, investing in a digital twin strategy could be a game-changer. By harnessing real-time data and leveraging advanced simulations, manufacturers can identify potential pitfalls long before they become real-world problems, saving both time and money.

Moreover, as artificial intelligence and the Internet of Things continue to evolve, digital twins may become even more integral to Industry 4.0. Early adopters who refine their digital twin capabilities now will likely remain at the leading edge of technological innovation, setting themselves apart in a marketplace that rewards precision, speed, and adaptability. For quality professionals and engineers alike, the future of manufacturing may lie just as much in the virtual realm as it does on the shop floor.