H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Case study

How one company turned the skilled labor shortage into an opportunity. By Emily Starinieri

Communicating Complex Data Simply

Case study

H2 Deck Info By Paragraph Style Bold

Headline

Founded in 1988, Trace Die Cast (Trace) produces aluminum high-pressure die castings, primarily supplying tier-one and tier-two automotive OEMs. Its campus in Bowling Green, KY, houses machining and assembly operations and 44 diecast machines, making it one of the largest die casters in North America.

To grow throughout the years, the company had to withstand a challenging and changing economic environment.

“The availability of skilled labor in the manufacturing industry started to go down after the big market crash in 2009, and that affected us. So, in recent years, we’ve had to adapt. We realized we don’t need highly skilled engineers to make decisions on the shop floor; we just need people who come to work every day with a passion for what we do. We base our success on being able to train people from the bottom, teach them to understand the business, and make them successful,” said Rodrigo Luis, VP of Quality at Trace Die Cast.

Prior to 2018, Trace Die Cast communicated quality data and information using reporting and SPC software. While these reports were sufficient for engineers, they were difficult for entry-level shop floor workers to understand. Luis and his team tried simplifying the reports themselves, but the process was lengthy, involving copying and pasting CMM data from hundreds of dimensions into Excel to produce a report. On average, this process would take three to five days, depending on the number of dimensions required for the part number.

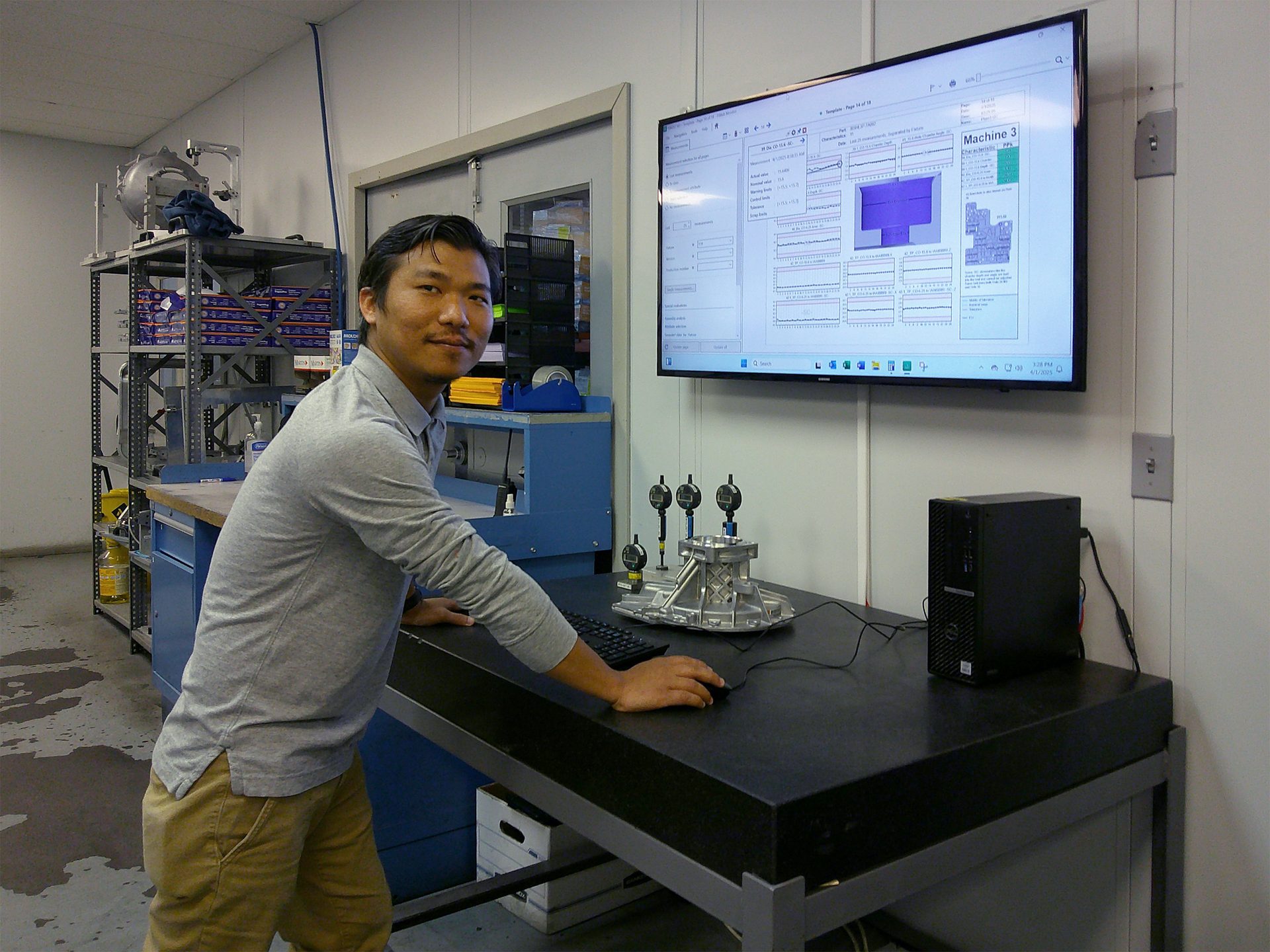

ZEISS PiWeb enables Trace Die Cast to make reliable decisions faster by analyzing data quickly and easily.

Quality Auditor Kam Khai monitors measurements from various machines using ZEISS PiWeb.

A faster and more efficient way of communicating and reporting information was needed to empower workers on the shop floor to make decisions with confidence. As a solution, Trace Die Cast purchased ZEISS PiWeb from ZEISS in 2018.

ZEISS PiWeb is a data management software for monitoring, sharing, and analyzing data from CMMs, manual gages, and other measurement devices. With the ability to customize reports, ZEISS PiWeb enhances operational efficiency and quality management by enabling users to visualize and communicate data with the right level of complexity or simplicity to make time-sensitive decisions on the manufacturing floor.

“The ability to customize charts is what attracted me to ZEISS PiWeb because one of the problems we had was figuring out how to explain information to anyone who needs to understand what the data is showing, regardless of skills or training,” said Luis.

Implementing ZEISS PiWeb was easy. Using ZEISS PiWeb Designer, Trace started creating customized charts, menus, and dashboards for the casting and machining plants, along with a few part numbers and cavities. Then, some team members were given ZEISS PiWeb Monitor licenses.

“Immediately, they said, ‘I can finally see the information in the way you were talking about.’ It was an ‘a-ha’ moment. That was the feedback we were looking for before we started growing and making things more complex by expanding ZEISS PiWeb’s capabilities throughout our facilities,” said Luis.

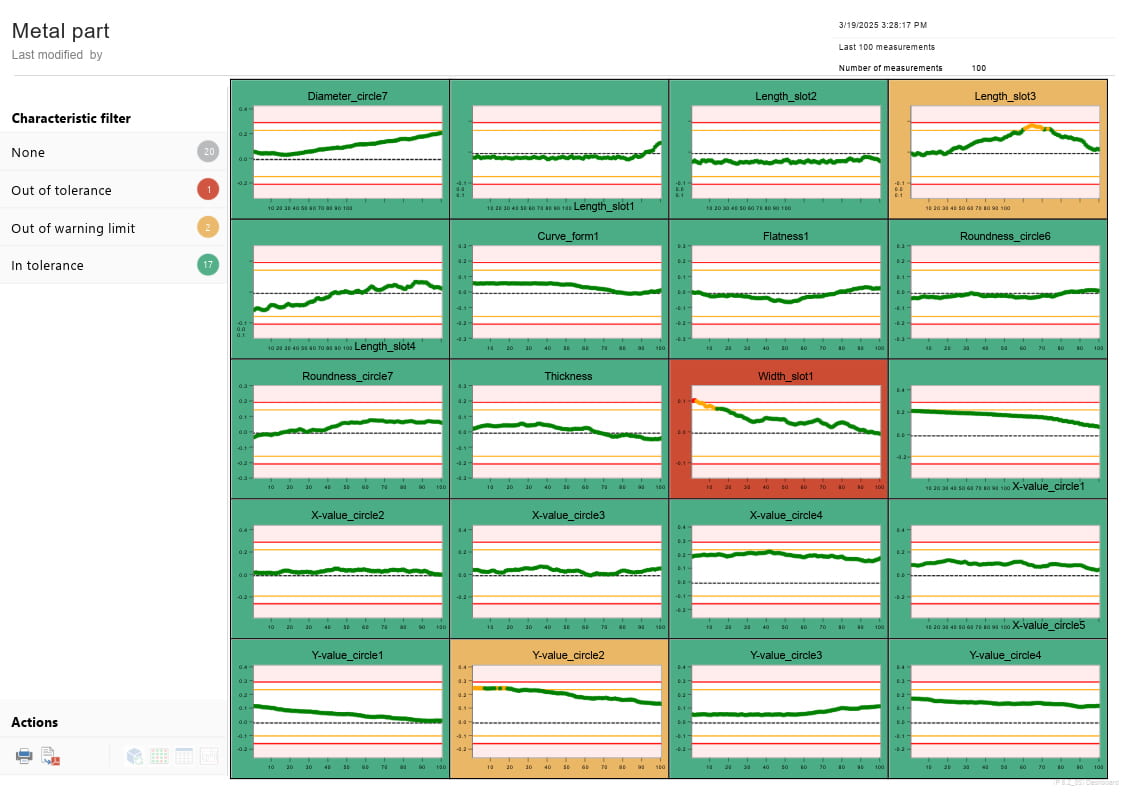

An example of a report in ZEISS PiWeb.

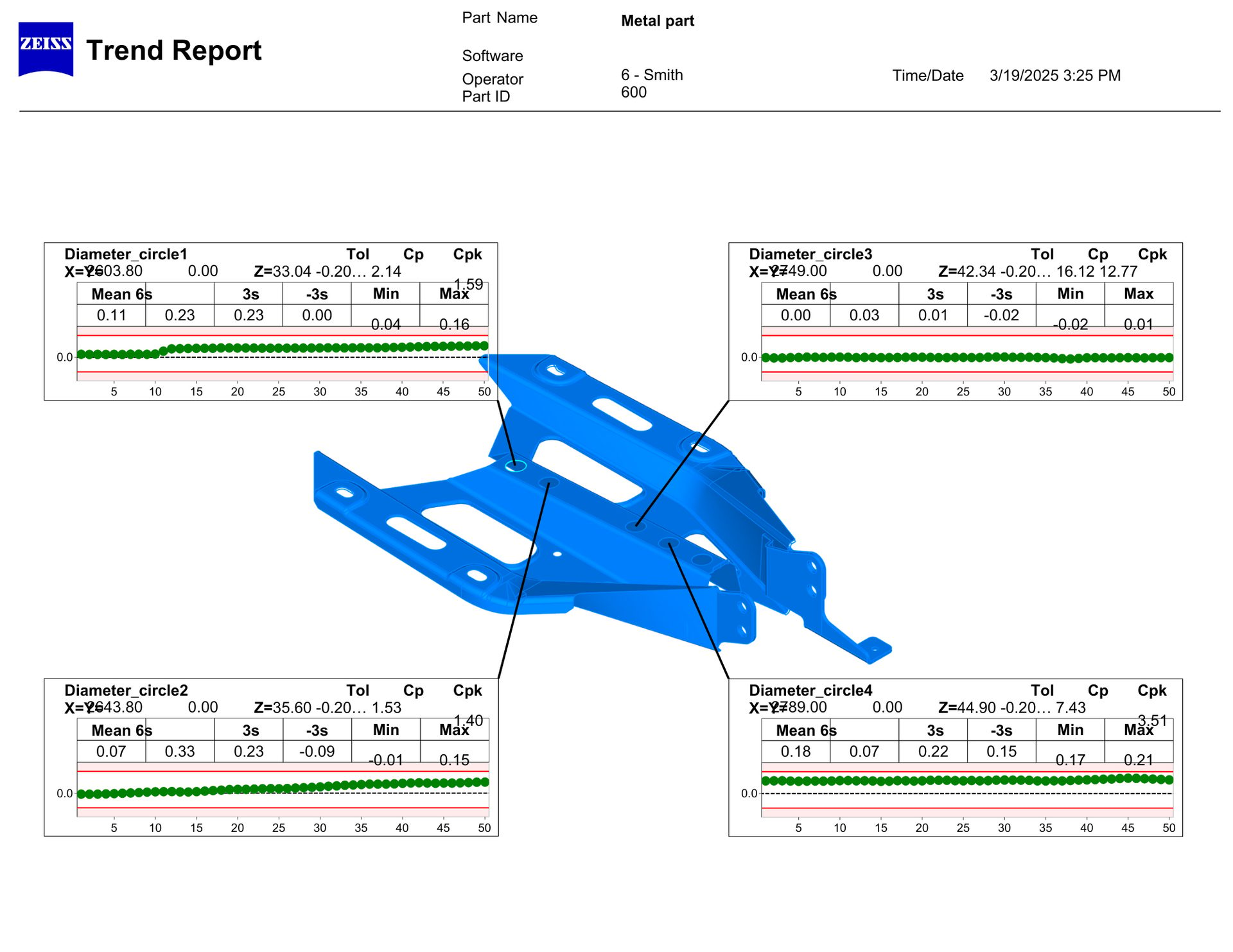

An example of a trend report in ZEISS PiWeb.

Next, more customized menus were created to correlate each part number with the different tools, dies, fixtures, jigs, machines, and other equipment making it. These menus allow the data from a specific piece of equipment to be monitored in a simple way so that the workers on the floor can make decisions when needed. Since variation is common in the die casting process, the ability to easily assign someone to monitor issues also helps Trace Die Cast become more reactive and agile.

“With simple training, anyone off the street will understand, ‘If you see this line trending out,’ or whatever it might be, just let me know, and we’ll send the appropriate team member to respond,” said Luis.

Now, Trace Die Cast also uses ZEISS PiWeb Designer to create custom charts that are easy for technicians to read. Within ZEISS PiWeb, all products are broken down by cavity and fixture. Inside the charts, they are broken down by specific critical dimensions. A typical CMM report contains 600 to 700 dimensions. With tools like customizing, grouping, and labeling, ZEISS PiWeb simplifies these reports to support internal communication of the information. For example, a technician may use a CMM to measure flatness, and there may be 14 different points where the CMM probe touches the surface, and the technician only needs to know if the casted part is flexing and where. With ZEISS PiWeb Designer, Trace can make a chart showing exactly what die section needs correction. This clear, actionable insight shows the technician exactly what to do. In addition, if the main chart shows a trend, they can retrieve a detailed chart to understand the affected parameters and troubleshoot. Compared to the previous method of simplifying reports by manipulating data with Excel, Trace Die Cast saves four days of work on average using ZEISS PiWeb, according to Luis.

“ZEISS PiWeb is a very flexible tool for communicating complex information and putting it into a simple means of communication. With ZEISS PiWeb’s ability to customize charts, we can simplify complex measuring information into a language anyone can understand,” said Luis. “We used to have a smaller footprint of people using ZEISS PiWeb, and as we saw its benefits, we started growing the number of people using the tool to make decisions. The team asks for a specific type of chart that shows something they need to see to help guide a decision because the team knows the power of customizing these reports in a way that allows them to see what they need to see.”

Trace Die Cast also uses ZEISS PiWeb’s customization features to communicate with other levels within the organization. ZEISS PiWeb generates reports that help engineers and management visualize the health and efficacy of processes and product lines from a statistical standpoint. They use ZEISS PiWeb to produce a sophisticated Ppk or Cpk process capability report to easily identify which CNC machine and fixtures are not running capable in a specific period. Complex information is communicated in a customized four-page report using a red and green stoplight system to quickly indicate pass/fail instead of producing numbers.

“In that one document, I can see how that automated line, which is probably using 30% or more space in our machine operation building, is running. If we are not running well, we know on which dimensions and how many— and I’m very happy about that. These management reports give me the status quo of the system, for a specific period. We produce a report for every part number, and with ZEISS PiWeb, you get to see the whole picture in one page,” said Luis.

Specific dimensions used at the casting plant also affect the machining plant. ZEISS PiWeb enables information between plants to be tracked and monitored to ensure everything is running smoothly. “We can seamlessly use ZEISS PiWeb as an enterprise—from our machining plant to our casting plant,” said Luis.

The inserts within the dies are moving parts, making it challenging to explain why one specific dimension is moving. Trace Die Cast creates ZEISS PiWeb charts to monitor a dimension for every piece of steel on a given die to determine why a specific dimension is moving, how it’s been affected by other moving pieces, and what pieces may be affecting it by default. When trying to troubleshoot a problem, ZEISS PiWeb allows temporary solutions to be put in place to understand how the various moving parts are performing day after day.

“That saves us a ton of time invested in trying to understand how all the moving pieces are working together. The savings also come from understanding where the problem is. One piece of steel may cost $10-20 thousand dollars. If that piece of steel was not the reason a dimension was moving, you just wasted that much money because once you take it off the shelf and put it on the die, there's no going back. ZEISS PiWeb guides us to make smarter decisions about what pieces of steel we need to replace based on the data and how we are looking at it— and that’s where the real savings are,” said Luis.

Temperature can also affect measurement results and the products in production, so Luis uses historical data to monitor changes in the winter or summer. A customized report enables the comparison and monitoring of the data against the current and historical charts.

“Our solutions today are more precise than they were six years ago. We produce a lot of data, and with ZEISS PiWeb, we are able to make decisions faster and more effectively because now we know how to show how a product behaves in a report and in trends – and we can see the whole picture at once,” said Luis.

With the help of ZEISS PiWeb, Trace Die Cast turned a skilled labor shortage into an opportunity to improve communication, processes, and quality throughout the organization.