H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

Automotive

Each component must withstand mechanical, thermal, and environmental stresses throughout its lifecycle. By Carl Bramley

EV Batteries:

Materials Quality Testing to Avoid Bumps in the Road

Automotive

H2 Deck Info By Paragraph Style Bold

Headline

As the demand for electric vehicles (EVs) and hybrid cars continues to rise, the automotive industry is being required to shift emphasis to the quality and integrity of these battery components. The step change in moving from the internal combustion engine (ICE) to battery power introduces very different challenges as the industry is driven in this new direction.

Automotive batteries must meet stringent performance, safety, and durability standards to ensure long-term reliability and efficiency. Increasingly, this requirement has a knock-on effect on the second life of batteries as sustainability in the sector is improved.

This article explores the critical role of how materials used in automotive battery manufacturing—which includes metals, polymers, and adhesives—undergo rigorous mechanical testing to verify their quality and to maintain industry standards.

The importance of testing materials for automotive batteries

Automotive battery final assemblies are surprisingly complex, comprising multiple components from cell internal electrodes, separators, casings and terminals to interconnects and current collectors up to modules and packs and their physical containment structures.

Each component must withstand mechanical, thermal, and environmental stresses throughout its lifecycle.

Key mechanical tests for automotive battery raw materials and components and assemblies

Quality testing of components in the ‘tank-to-wheels’ phase helps manufacturers assess the strength, durability, and consistency of materials, ensuring compliance with international regulations such as ISO 12405 and SAE J2929. Safety is the cornerstone of many regulations, with tests to mitigate against the potential dangers of the electro-chemical nature of battery power—thermal runaway and the potential escalation to fire or explosion being a prime concern.

Mechanical testing adds impact, vibration and shock considerations (in-service or abuse) augmented by variations in environmental conditions.

Tensile testing of electrodes to current collector interconnects

Electrodes and current collectors play a crucial role in battery efficiency by facilitating electron flow. These components are often made from materials such as aluminum (for cathode) and copper (for anode) foils, which require precise mechanical properties to maintain electrical conductivity while withstanding mechanical stress. The bonding between the electrode plate and the terminal tab or [bond] wire interconnect is also checked in this procedure, which highlights the weakest link in either raw material or joint.

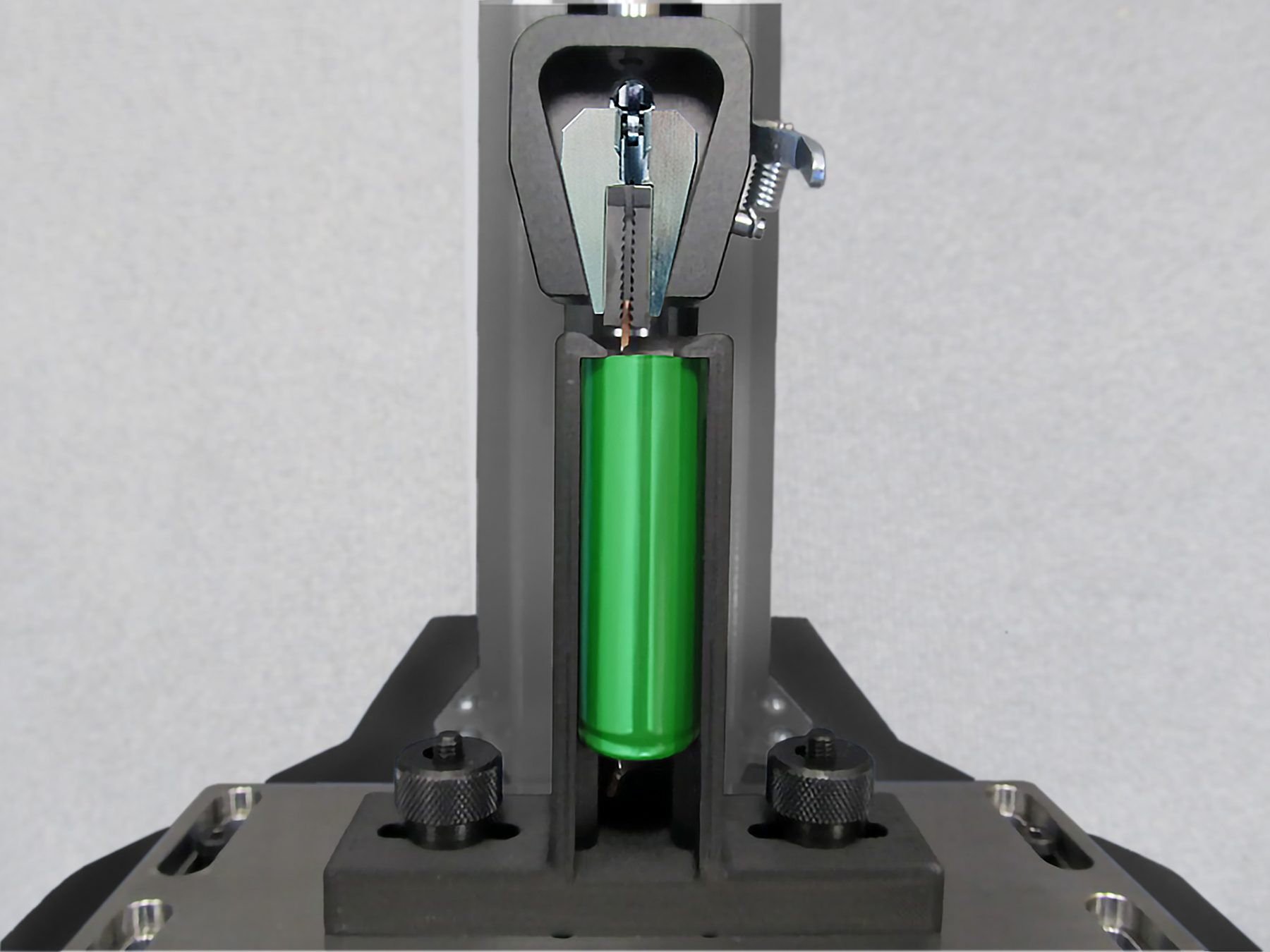

A pull-off tensile test on the terminal interconnect tab at the cathode (positive) end of a cylindrical cell battery. The axial force is consistently increased until failure, which may be the tab material itself or its welded joint to the casing, and the peak load is recorded. Efficiency and repeatability of testing a batch of battery samples is enhanced by use of a custom-built fixture to load, secure and release the cell. A serrated-toothed jaw self-tightening wedge grip ensures the metal tab does not slip.

Torque testing of electrodes to current collector interconnects

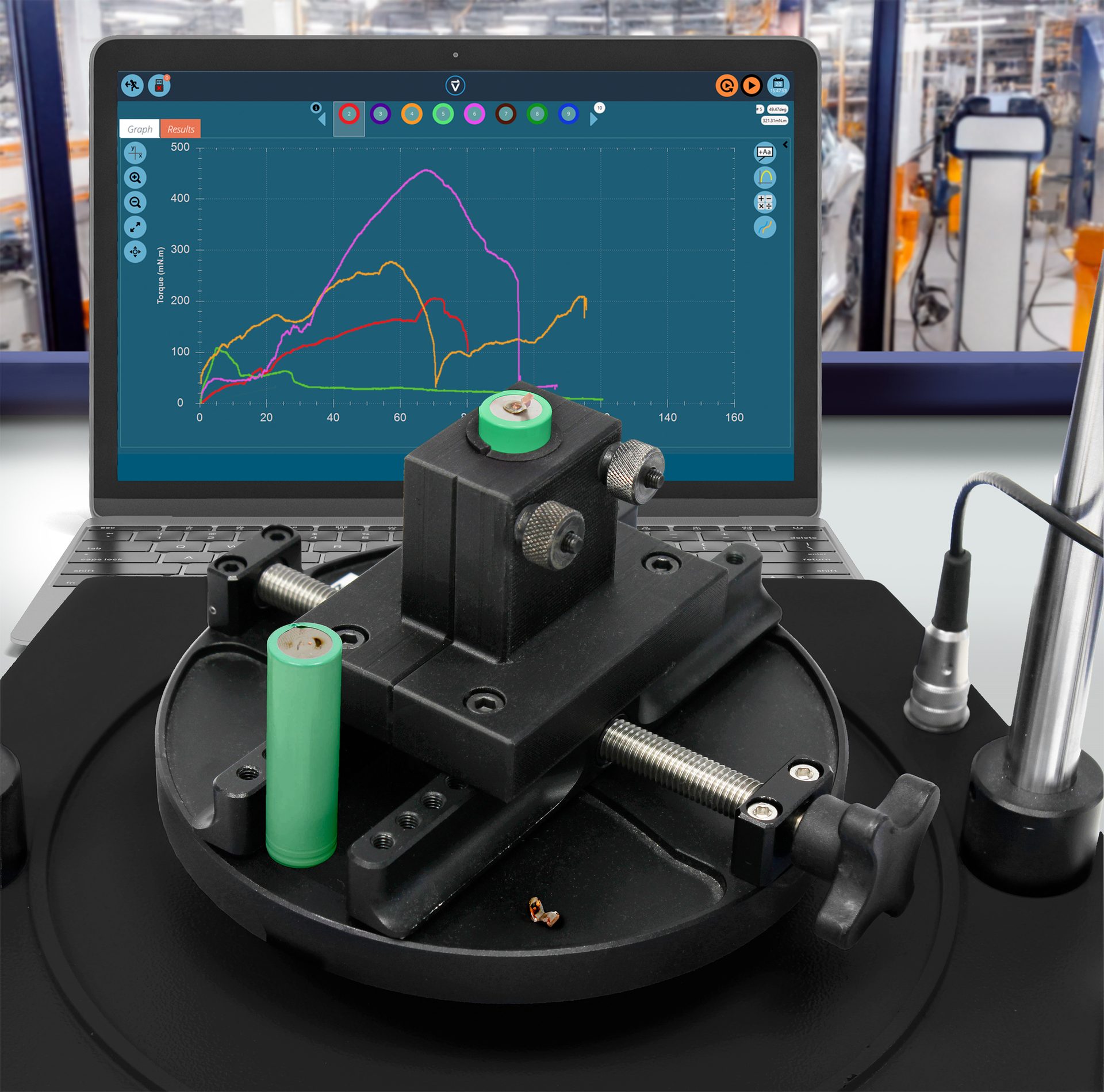

A twist on the mechanical integrity test of current collector tab manufacture is to again test to failure but by the application of a torque rather than an axial force. The vibration experienced by the battery pack in service will be random in nature and manufacturers take advantage of software-controlled systems to implement a variety of loadings in order to thoroughly test a component’s resilience.

A 180° peel test on metallic film. In this version one substrate is adhered to the vertical plate fixture and the other is peeled by the upper grip of the UTM. By gripping the edges of both films with a similar vice grip in the lower fixture another 180° peel may be performed. The 90° test places the test sample on a horizontal bed which moves in the lateral direction at the same rate as the upper fixture pulls the film vertically, thus maintaining the appropriate angle.

A twist-off test measures the torque required to make the electrode tab fail. An adjustable clamping fixture grips the cell’s exact geometry enabling meaningful comparative testing of batches.

Peel and adhesion strength testing of coated battery components

The internal components of a battery are largely comprised of thin, coated sheets densely packed within the casing—the cathode, anode and separator elements. Efficiency is heavily dependent on the effectiveness of the chemistry inside the cell and these components are coated with films to maximize these reactions and optimize charging performance. The bonding of the coatings is tested to quantify the ability of the adhesion agent (slurry) to remain in place and perform over the lifetime of the battery.

Standard peel tests are used, of which there are several, to provide a range of data to benchmark a particular formulation’s suitability. A peel test applies pull to one substrate at a controlled angle, typically 180°, 90° and the Z direction (effectively 0°).

A universal testing machine (UTM) implements specific procedures by means of fitting fixtures to hold and apply forces to a test specimen. Thus, the same machine may also perform the Z-direction test, whereby one substrate specimen (cut to certain dimensions) is subjected to a pulling force evenly over its cross-section, pulling apart—not a ‘peel’ motion in the conventional sense but a universally implemented and valuable measure of bond strength.

Universal testers for puncture and compression

Test standards for automotive EV batteries often focus on the deterioration in electrical or thermal states as a result of the test. A comprehensive and relevant standard is SAE J2464 which deals with procedures replicating ‘abuse.’ In addition to testing methods which subject the DUT (Device Under Test, which may be at cell, module or pack level) to certain environmental conditions, there are mechanical tests which are used to determine the effect on electrical performance, or some physical failure which raises the significant likelihood of hazards—electrical, chemical or thermal.

UTMs can aid the mechanical ‘penetration’ and ‘crush’ abuse, with the use of appropriate fixtures. These cell-level and above procedures ultimately apply to final product assemblies; however, the physical strength of the materials used in the cell, module or pack enclosure is pivotal to the overall performance against these standards.

Dedicated dynamic testers for shock, drop and vibration

Further mechanical testing of these products and assemblies considers the added safety risks afforded by transportation conditions. Vibration, shock, impact and drop conditions form a comprehensive range of real-world external factors that must be guarded against with hazardous products. Dedicated machines—often of very large capacity, for complete battery packs—are required to subject the test specimen to these dynamic loads and record the desired data. These same conditions are also representative of the inputs that an assembled EV battery pack will experience under its intended driving conditions and OEMs can leverage the testing equipment to implement their own in-house quality assurance regime.

Raw materials characterization

Chemistry is key for improving the efficiency of EV batteries. Developing compounds and alloys to retain core properties that meet fundamental objectives whilst endeavoring to add charge-to-charge distance to counter range anxiety is the desired roadmap for manufacturers in this industry.

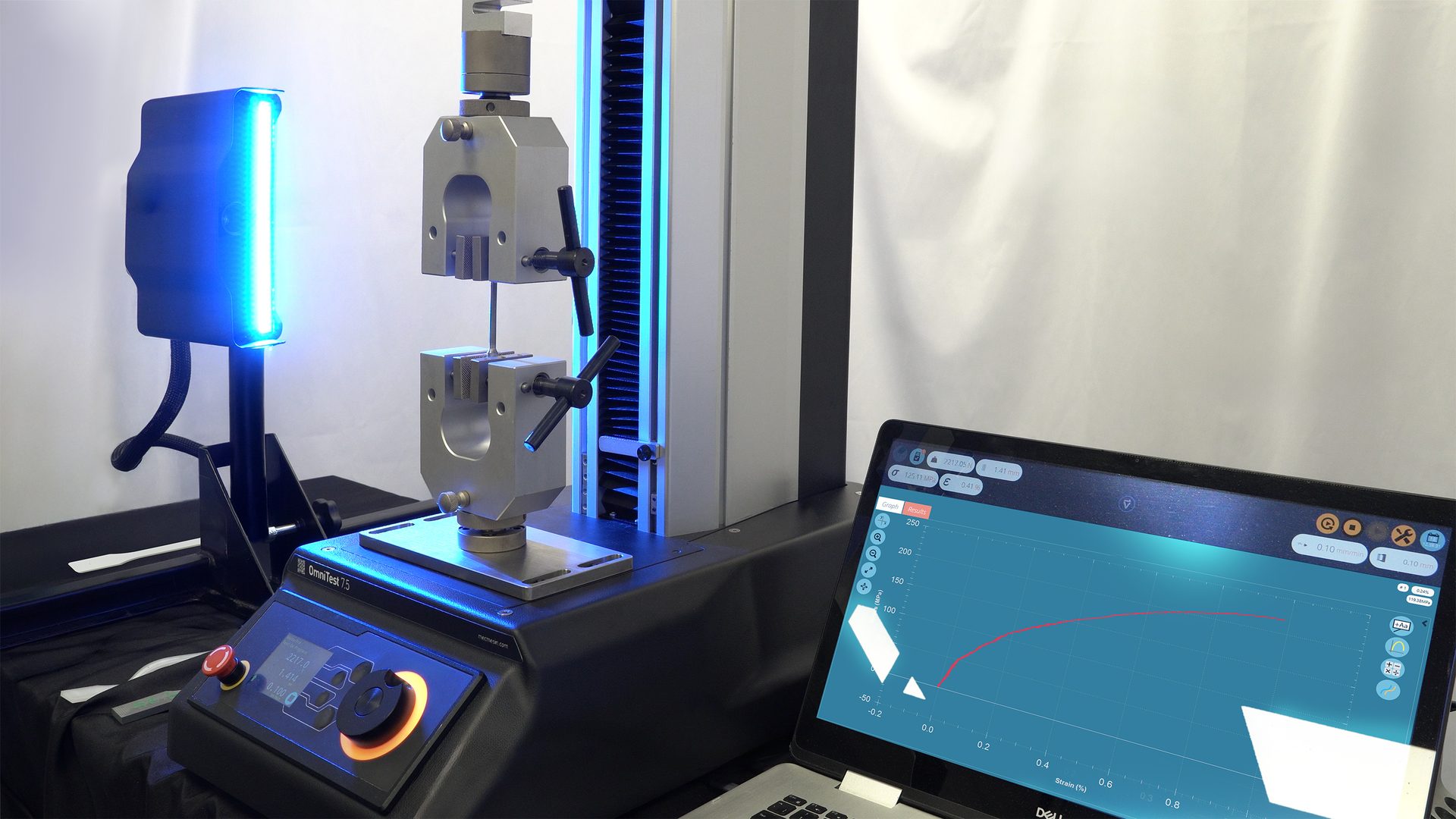

Measuring the stress-strain behavior to the point of failure of a standard dumbbell-shaped material test piece is the fundamental method of determining a raw material’s physical strength. The specimen is put under tension and calculations based on the load-elongation curve is used to quantify benchmark properties. Understanding how a new material with improved electrical efficiency might be impacted in terms of mechanical strength is a vital insight. Changes to the structure to elicit gains in conductivity, ductility, ease-of-bonding or thermal behavior must be evaluated against any significant loss in robustness.

An established tensile load-displacement test on a metallic raw material test piece. Accuracy of calculated physical properties is important where fabricated components are part of an EV system, as efficiency improvements are at the forefront of current research and development objectives. This system employs a video extensometer which measures the true strain (elongation) of the test piece without contact, optimizing the accuracy of the measured value.

As seen earlier, battery terminal tabs and current collectors are also checked in their final form by tensile testing. Their performance is greatly influenced by the inherent strength of the metal from which they are made and as a result, the weakest link may be within the joint rather than the tab itself.

A software-controlled UTM easily facilitates similar tests on other EV battery components such as the electrode separator, which is usually a polymeric material, providing useful economies of scale.

Driving the point home

In an industry sector where safety, performance, and longevity are paramount, rigorous mechanical testing of materials used in EV battery systems is not optional—it’s essential. From raw materials to assembled packs, understanding and verifying the mechanical properties of every component ensures batteries can withstand real-world stresses while delivering the reliability and efficiency consumers expect if they are to adopt this form of propulsion in the numbers that are needed to meet fossil fuel reduction ideals. As electric vehicles continue to evolve, so too must the quality standards and testing practices that support them—paving the way for safer, longer-lasting, and more sustainable battery-powered transport.