Measurement

Is your coordinate measuring machine future-ready?

By Milan Kocic

CMMs Go

Collaborative

Quality control has an important role to play in delivering a more connected, analytical and collaborative way of producing parts and products. Inspection is a crucial function that ensures customers receive the quality they paid for, and it also guarantees a manufacturer’s compliance with industry regulations, specifications and original design intent. In addition, spotting errors quickly through quality control procedures reduces waste and the need for rework, resulting in lower costs and increased throughput. All of these activities can be — and today often are — performed within manufacturing data silos without cross-collaboration.

One of the essential goals of digital transformation is to achieve real-time collaboration and information exchange between systems and people across an organization so operations become more flexible, faster and smarter. Manufacturers seeking these benefits must be able to feed real-time quality data into design, engineering and production systems. This data-driven approach removes functional silos and introduces timely, intelligent improvements to product development and manufacturing based on physical realities and virtual designs.

Digital transformation is placing urgent demands on coordinate measuring machines (CMMs) to be interconnected and communicative. Without the ability to collaborate with other systems and workers on the shop floor, CMMs risk becoming an informational black hole that prevents the flow of data required for smarter manufacturing.

Agility On-Demand

When the unexpected happens, manufacturers need agility to change production on a dime. Unforeseen events such as the current pandemic produced staggering shifts in production for many parts and products across the globe. The need for cross functional teams and safety precautions must be considered for future operations and equipment.

The Covid-19 pandemic has accelerated automation exploration in manufacturing. Large or small, production processes should be agile enough to perform certain tasks with limited-to-no human intervention. Quality professionals need tools to maintain business continuity remotely from home or in the field. This transition should also include offline metrology software and remote asset management and monitoring systems that observe CMM activity and alert users of any issues that might occur during 24/7 operations. This interconnectivity allows manufacturers of all sizes to handle the unexpected without greatly impacting the process.

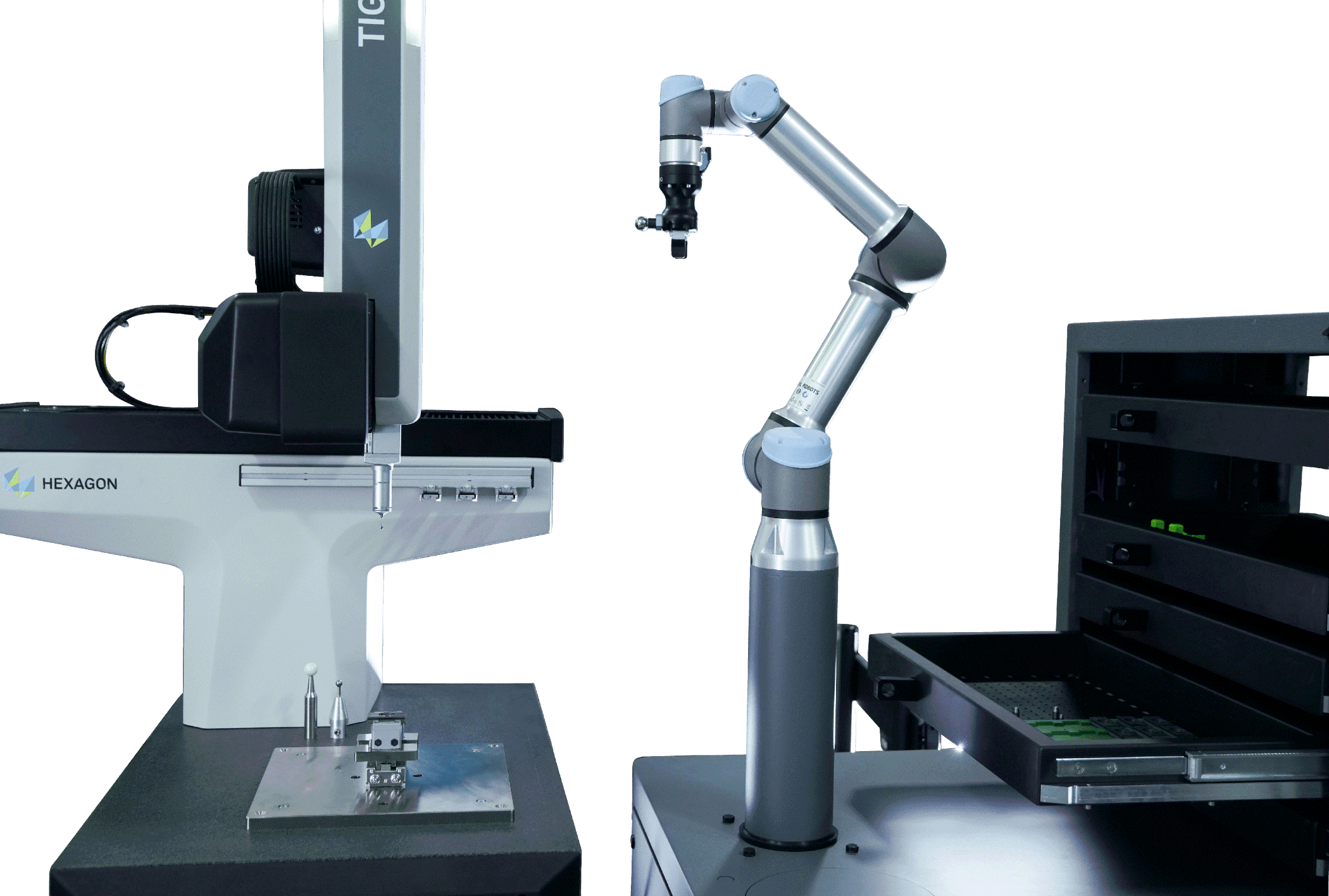

TEMPO enhances CMM workflow with off-the-shelf automatic part loading for autonomous measurement free from interruption day or night.

Smart Manufacturing is Not Just for the Big Guys

The beauty of the smart manufacturing initiative is that small to mid-size manufacturers can move toward these goals at their own pace. The current challenge is to interconnect their metrology systems to the rest of their business so that quality information is provided in real-time, without compromising security, accuracy, precision or performance.

Ease of use is an enormous factor in the success of digital transformation projects. If it’s not easy for people to adjust to a new way of working, then employees will ignore or resist change. It is also important to remember the latest generation of CMM operators has grown up with consumer technology. They expect interactions between people and machines to be simple, intuitive and real-time, with information provided in formats that are easy to understand and share.

Digitally transforming inspection technology also enables manufacturers to readily adapt to the new-gen workforce. New recruits to the manufacturing world have grown up with open, collaborative IT systems that support agile working. Forcing them to work within closed proprietary industrial technology systems limits their capacity to take on new responsibilities and adapt swiftly to changing business requirements.

Collaborative CMMs Tailor-made for Automation

Today’s CMMs provide sophisticated technologies to efficiently automate dimensional measurement workflows throughout the manufacturing process starting at the entry level. At the high end, ultra-high-accuracy multisensor and optical CMMs deliver sub-micron accuracy for measuring precision components that are manufactured to the tightest tolerances. This current generation of CMMs enables manufacturers to “think automation preparedness.”

In most cases, a single technology upgrade can help make your manufacturing smarter. For example, improper part placement or alignment has been known to cause unnecessary measurement errors, rework and time lost. Automating this process through the use of camera technology and an operator friendly software interface allows CMM operators to easily run measurement routines without being an expert in quality.

Alternatively, manufacturers can eliminate user interaction with a CMM entirely by opting for an automated CMM part loading and unloading system that runs entire inspection shifts unmanned, driven by data. At the same time, the solution can be monitored digitally. Operators will be alerted remotely of any changes surrounding the CMM such as vibrations, humidity, air pressure, crash notifications and measurement routine status. Users can work away from the CMM, and gain greater insights into root cause analysis and preventative maintenance.

Even minor pain points can be simply automated and drive a massive impact on KPIs. For example, a CMM operator is constantly moving between their desktop and the CMM to switch between controlling the system to using software applications. To some, it sounds like a mild inconvenience or a ‘usability’ issue. Besides making your operator’s life easier, addressing this issue can deliver significant cut costs via reduced cycle times. The time spent moving between the desktop and the CMM accumulates day by day, week by week, year by year. A simple upgrade to a wireless system interface, such as a Digital Control Center (dCC), allows the operator to access a full-range of metrology applications from any location around the CMM. Over time, this translates into sizeable time savings and improved throughput.

Through a highly-configurable technology platform, this CMM ensures that quality engineers creating measurement routines, operators executing the inspection, and quality managers analyzing the data all have a solution to ensure continuous improvement in production workflow.

Small Steps, Big Gains

Rather than thinking of the journey towards smart manufacturing as one big transformation project, many manufacturers will benefit from a step-by-step approach. This course of action will involve making small-scale changes to current metrology systems such as CMMs for incremental productivity gains. These strategic technology upgrades not only support business objectives and a range of key performance indicators or KPIs, they also prime internal quality processes for greater autonomy, which is another important step in the “smarter manufacturing” journey.

Many manufacturers are considering automation to stay competitive, but they also foresee several barriers for entry. From seemingly large investments to months of integration work, from implementation planning to building a skilled labor force to manage continuous process improvements, the journey might seem a bit overwhelming.

To begin, automation does not have to start as a large investment, but rather small steps that offer a better return on investment. The key to this transition is focusing on smaller areas of the business and automate them. The measurement process is a great place to start as it is independent from production as it is not actually involved in making the product. The measurement task can be easily augmented with manual support while in transition and represents every phase of producing the product.

There are also defined multiple task related areas that can be automated to not only improve the production process, but to free up resources to handle more complex tasks. Some of these measures include improving labor efficiency, CMM utilization, scrap reduction and preparing the shop floor for a connected future.

Tasks like part setup and CMM measurement routine selection can become a major production bottleneck if not executed correctly. These tasks are ideal candidates for automation, ensuring correct measurement every time while enabling operators to handle the more formidable tasks with a major impact on business. By replacing common workflows that can produce data inaccuracies with proven automated processes – such as part-inspection setup – manufacturers can avoid unnecessary rework and shipment delays.

Furthermore, production delays induced by machine maintenance, repair or correction can be avoided by connecting systems together to communicate with one another. The data communicated from a CMM to a system-wide monitoring system which provides a comprehensive picture of inspection activities, suggests optimal measurement efficiencies and provides actionable information for the quality environment. These actionable insights prepare production for incoming challenges such as machine maintenance early on to help support a smoother production rate.

Is Your Measurement Plan Future-Ready?

Traditionally, there was only one characteristic that mattered when it comes to quality inspection − measurement accuracy. Is the CMM accurate enough to measure the parts you are producing? Is the data you are receiving reproducible? Today, the requirements for the ideal quality inspection solution have changed. While measurement accuracy remains an important factor, what sets quality inspection solutions apart is their ability to hold their own as businesses start to grow, change and develop into new markets.

Enterprising manufacturers may have their sights set on improving production efficiency or implementing design changes with the use of new technologies or materials. Moving their business into the next phase will depend upon their ability to take on new projects or even strengthen their reputation with existing clients.

Before taking the jump towards production-wide autonomy, it is imperative that your current CMMs can support your long-term objectives. Review your existing equipment and determine if you need to invest in an integrator friendly I/O kit or buy a new system that includes this technology. As your company starts its autonomous journey toward the smart manufacturing, be prepared and continue to ask yourself, “Can I measure tomorrow?”