America Makes and the American National Standards Institute (ANSI) announced the availability of a Gaps Progress Report tracking efforts by standards developing organizations (SDOs) and others to address the gaps identified in the Standardization Roadmap for Additive Manufacturing (version 2.0, June 2018), published by the America Makes and ANSI Additive Manufacturing Standardization Collaborative (AMSC).

The AMSC is a cross-sector coordinating body established in 2016 whose objective is to accelerate the development of industry-wide additive manufacturing standards and specifications consistent with stakeholder needs. The Standardization Roadmap for Additive Manufacturing, developed with contributions from more than 300 individuals from 175 public- and private-sector organizations, lists published standards, those being developed, and others that are needed to help grow the additive manufacturing industry. It identifies 93 gaps where no published standard or specification currently exists to respond to a particular industry need. The roadmap also flags 65 of these gaps as requiring pre-standardization research and development (R&D).

The gaps progress report was compiled by ANSI staff based on inputs from SDOs, subject matter experts, alert mechanisms, and independent research. It lists newly published standards and new standards projects, alongside suggestions for future roadmap modifications. The report is not a consensus document but rather is intended to serve as an interim “living document” that will be maintained and periodically re-published until such time as the AMSC develops a next version of the standardization roadmap. The report is provided in PDF and replaces an earlier HTML gaps tracker portal that was onerous to maintain given the volume and pace of additive manufacturing standardization work.

To get on the AMSC’s mailing list, or to offer suggested edits to the gaps progress report, email amsc@ansi.org.

Gaps Progress Report Available: America Makes, ANSI Standardization Roadmap for Additive Manufacturing

Silicon Software GmbH has been merged with Basler AG. Basler had acquired Silicon Software in 2018 and managed it as an independent GmbH within the group structure. Functions such as production, logistics, sales and technical support were already merged shortly after the acquisition, and other functional areas followed step by step. The integration of both companies under company law now completes this process.

CEO Dr. Dietmar Ley, who was also managing director of Silicon Software, explains, "The employees of both companies have been working so closely together since the acquisition that the step to legally unite both companies under the name Basler AG feels very natural and logical. We are very pleased to have a location in Mannheim with such experienced and qualified colleagues, to continue to grow together and to develop exciting offerings for the computer vision market under the Basler brand."

With the acquisition of Silicon Software GmbH, Basler had complementarily expanded its portfolio with the product areas frame grabbers and software (VisualApplets). The acquisition was a step to support the growth strategy of Basler AG and in particular to implement it in the direction of the performance segment of the computer vision market. With the merger, the product areas frame grabbers/interface cards and VisualApplets will be managed under the Basler brand and the portfolio will be further expanded.

For more information, visit www.baslerweb.com.

Silicon Software GmbH, Basler AG Merge

Verisurf Software announced it has appointed Jeff Long to the position of Sales Engineer in the South-Central Region. Jeff will work closely with Verisurf regional sales managers to best serve the inspection and measurement needs of customers.

Jeff comes to Verisurf with broad knowledge and an understanding of manufacturing, machining, and quality processes. With hands on experience in detail and assembly level inspection of aerospace structures, jig and fixture building, working with CAD and drawings, combined with a background of repairing and maintaining portable and fixed CMMs, Jeff provides Verisurf customers a knowledge-based perspective and added value.

“Jeff brings the experience our customers have come to rely on, and we are extremely pleased to have him on our team,” said Pat Bass, director of sales.

For more information, visit www.verisurf.com.

Long Joins Verisurf Software as Sales Engineer, South-Central Region

Zeiss plans to expand its national coverage in the U.S. for its Industrial Quality & Research segment by acquiring Capture 3D. Headquartered in Santa Ana, CA, Capture 3D is the leading U.S. partner for GOM 3D non-contact measuring solutions. With this acquisition customers will benefit from a seamless integrated experience to get the best measuring solutions for their specific tasks.

"We are pleased to bring the Capture 3D team and their know-how into the Zeiss Group," states Dr. Jochen Peter, member of the Zeiss Group Executive Board responsible for the Industrial Quality & Research segment. "After the acquisition of GOM two years ago, we will now also combine our strategic forces in the important U.S. market to provide customers with best-in-class measuring solutions from one source."

"We look forward to being a part of Zeiss to combine our efforts in serving our customers with the best in class measuring solutions and services," adds Richard White, CEO of Capture 3D. "Being part of the Zeiss Family will open up new opportunities for the Capture 3D team and our customers in the future."

"Having such a talented team with expert industry knowledge and a passion for 3D metrology is important," states Michael Kirchner, head of Zeiss Industrial Quality Solutions in the U.S. "This will expand the Zeiss support network for our customers."

Once the transaction is complete, Capture 3D will become part of the Industrial Quality Solutions strategic business unit within the Zeiss Industrial Quality & Research segment (revenue in 2019/20: 1.640 billion euros). Subject to approval by the regulatory authorities, the transaction is due to be finalized in summer 2021. Both sides have agreed not to disclose the financial details of this transaction.

For more information, visit www.capture3d.com or www.zeiss.com.

Zeiss to Acquire Capture 3D

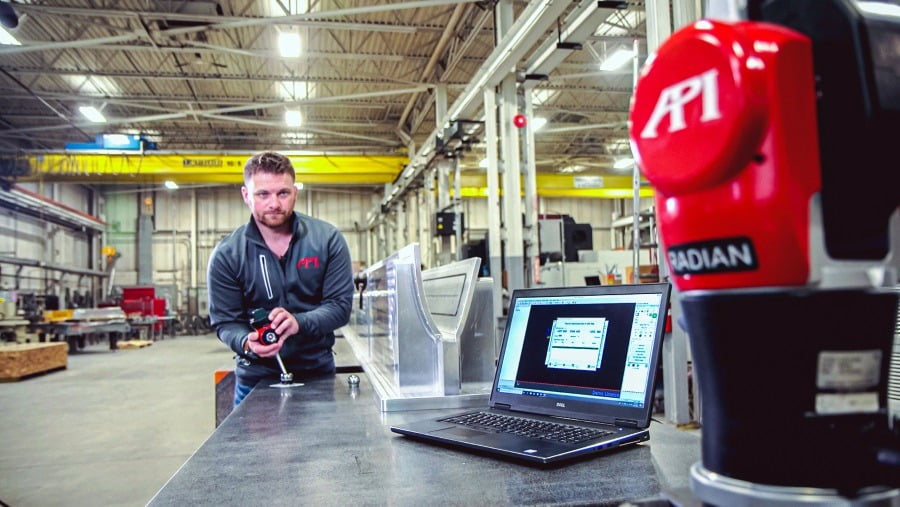

API and Mitutoyo Corporation have announced a partnership to distribute API’s portable dimensional metrology equipment throughout Mitutoyo’s worldwide network.

Production times and tolerances continue to grow tighter for manufacturers around the world, and their need for precise, portable measurement hardware and software has increased to meet this demand. Adding API’s complete portfolio of portable equipment to Mitutoyo’s already diverse portfolio to meet this demand was a natural fit for both companies.

“API really invented portable dimensional metrology, especially in the form of precise, laser measurements,” says Yoshiaki Numata, president of Mitutoyo Corporation. “So, for Mitutoyo, this was a great opportunity to add the most complete line of high-quality portable metrology equipment to what we can offer to our customers.”

“Mitutoyo has developed the most diverse, comprehensive portfolio of metrology equipment, hardware, and software, and they have built a truly impressive global distribution network,” says Joe Bioty, president of API. “By adding API’s portable equipment to that offering, Mitutoyo really becomes a one-stop shop for metrology needs in manufacturing worldwide, which provides tremendous value to the customer.”

API’s complete offering of portable equipment and Mitutoyo’s already diverse portfolio is an ideal combination that will deliver high-quality metrology products to companies at the speed they need. API products through Mitutoyo are available in regions around the world now.

For more information, visit www.apimetrology.com.

API, Mitutoyo Announce Worldwide Reseller Agreement

Verisurf Software announced it has appointed Tara Mitchell to the position of business development manager for the Americas. Tara will work closely with both customers and Verisurf regional sales managers in her new role, applying critical thinking for inspection and measurement solutions across the manufacturing enterprise.

“We are delighted to have Tara as a team leader for business development; her experience and reputation as being highly effective and customer-centric are a great fit for Verisurf,” said Pat Bass, director of sales.

Mitchell’s work history and ongoing involvement in metrology-related community organizations adds to her relevant expertise and provides a clear perspective on industry and customer challenges.

Previously, Mitchell was responsible for business development in the western region for Hexagon Metrology, where she sold inspection and measurement solutions, including fixed CNC CMMs, portable CMM arms, and more.

Notably, during her tenure with Hexagon, Mitchell also served on the Executive Committee of the CMSC for nearly ten years, where she pursued the organizations’ goal of bringing the world of metrology one step closer to its audience. While working with the CMSC, Tara helped foster an educational atmosphere through programs and the annual CMSC conference that encouraged attendees to network and learn about innovations in 3D measurement solutions from the world’s leading providers of metrology systems.

Mitchell is also a member of the Manufacturing and Fabrication Technical Advisory Committee at Renton Technical College, Renton, WA, where she will continue her role of supporting programs designed to prepare students and incumbent workers for careers in industrial production and fabrication.

For more information, visit www.verisurf.com.

Mitchell Joins Verisurf Software as Business Development Manager – Americas

Creaform announces the opening of a new office and innovation center in Texas. Strategically located in Houston, this investment strengthens Creaform’s geographic footprint within the United States and furthers its global expansion initiatives.

At the new location, customers will be able to benchmark the full portfolio of Creaform portable and automated 3D metrology solutions for a variety of applications, including quality control, NDT surface inspections and product design. The site features a fully automated CUBE-R 3D scanning CMM and a technology center for seminars, workshops and one-on-one demonstrations.

The new center complements Creaform’s existing U.S. footprint with greater geographic and multi-industry coverage, provides a centralized hub for regional operations, and anchors its U.S.-based metrology services and support teams. Initially founded and headquartered in Canada, Creaform has steadily grown U.S. operations through regional staff placements and a California office established in 2015.

“The United States continues to be a focal point for Creaform. Our technologies provide solutions for manufacturing, automotive, energy and aerospace industries from coast to coast,” explains Jarrod Schmidt, national sales manager for Creaform USA. “Texas is a growing hub for technological innovation and offers great customer outreach opportunities for our team across the United States. Creaform now will be able to more effectively provide support and expertise for each region’s unique manufacturing and quality control challenges.”