cobots

Vision & Sensors

V&S

H2 Deck By Bold Name

h2 xxxxxx

H1 xxxxxx

h2 xxxxx

When you buy a cobot, you may have just one application in mind, but leading cobots are platforms for almost any number of quality applications - and not just quality applications. By Mike DeGrace

Human-centric Robots Boost Quality Professionals’ Toolkits

I’ve stood beside operators and inspection workers when a collaborative robot (or ‘cobot’) cell is unveiled for the first time and witnessed that ‘click’ of recognition when they realize that cobots are not replacements for human labor.

What people are recognizing is that cobots offer a paradigm shift from traditional automation used in quality and inspection applications. Put simply, cobots offer capabilities that traditional robots don’t, especially when it comes to flexibility, programmability, and reprogrammability.

While cobots provide all the benefits of traditional automation, they are, most of all, tools designed to help humans do their jobs better, freeing quality professionals to think more holistically about questions like ‘How do I get my quality up from my suppliers?’ and ‘How do I think about automating other applications now that I understand the cobot?’

This matters because quality and inspection tasks can be extremely labor intensive and are typically performed manually or at least validated manually. It’s a lot of work, and it usually involves at least one pair of eyeballs. If you’re inspecting a part for eight hours a day, potentially looking at hundreds of thousands of products along the way, you can easily imagine missing some due to natural human variations in focus over time. Even the best quality professionals will miss stuff now and then.

3D Infotech’s Universal Metrology Automation (UMA) line is based on its Streamline quality assurance software and a platform of flexible, intuitive, and collaborative cobots from Universal Robots. With the system, users can simply pick a part and a preset program that has the scan coverage of the entire part, and then press play and walk away. By standardizing on the family of UR cobots, all of which share the same underlying technology platform and APIs, 3D Infotech can easily deploy systems for a wide range of applications. The company’s metrology solutions are part of Universal Robots’ UR+ ecosystem that approves products for plug-and-play functionality with UR cobots. Credit: Universal Robots.

From ‘drop in’ to flexible platforms

Labor shortages across the manufacturing sector are impacting companies’ ability to hire and retain people for quality and inspection jobs. Companies that see cobots as ‘drop in’ replacements for human workers will see typical automation benefits in terms of consistency, repeatability, and 24/7 availability.

However, companies that see cobots differently - as tools to boost their human workforce and as flexible platforms that can be used across multiple application domains – enjoy greater benefits.

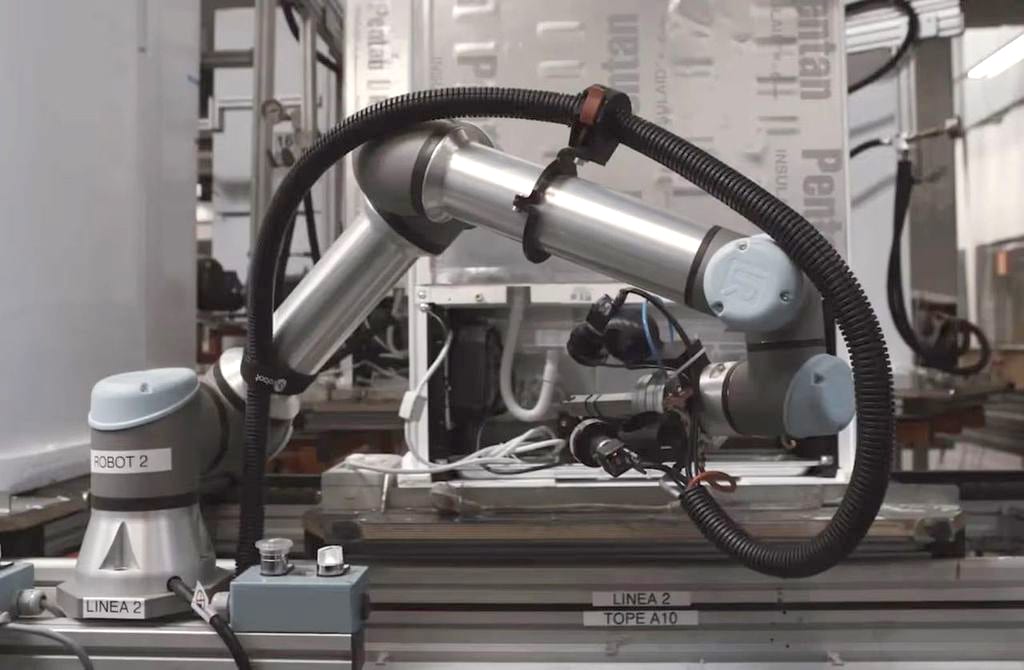

Leading cobot systems score high on both safety and usability. Cobots can be deployed and redeployed quickly with a minimum of fuss and across multiple applications. For example, a single cobot could be used to place parts in a CNC machine and to inspect the finished product when it is finished.

Safety first

Unlike traditional automation, which requires fencing, cobot-powered inspection applications can be set up unguarded - following a risk assessment - because the speed of the robot is not very high and the cobot is usually not swinging a dangerous part around. This creates great opportunities for close-proximity human-robot collaboration.

This type of human-robot collaboration - which also saves floorspace - often happens at final, end-of-line inspection. Common setups include cobots performing a machining process then passing a product to humans for inspection or a cobot with vision performing inspection as items move along a conveyor to a packaging or palletizing station.

Nondestructive testing (NDT) is an inspection methods used to identify cracks or defects in materials, or determine the elemental composition of materials without damaging it. Olympus, a Singapore-based leading manufacturer of test and measurement solutions, has a wide range of NDT devices widely used in scenarios such as inspecting aircrafts. This type of inspection is an essential part of ongoing maintenance programs to ensure the integrity of the aircraft for crew and passenger safety. Credit: Universal Robots.

Automated inspection doubles production output at Zippertubing

Arizona-based Zippertubing Company originally deployed a cobot to help in the assembly of wrap-around cable jacketing used in the automotive industry. The family owned firm, which was completely new to automation at the time, quickly grew so comfortable with the cobot that they confidently added vision guidance to the cell, enabling fast and automated inspections and rapid transfer of product to ‘reject’ and ‘good’ bins as appropriate. With cobots able to run all night, Zippertubing doubled its production output and freed workers to focus on more skilled and satisfying tasks.

AI-powered inspection detects refrigerator leaks at Bosch Siemens

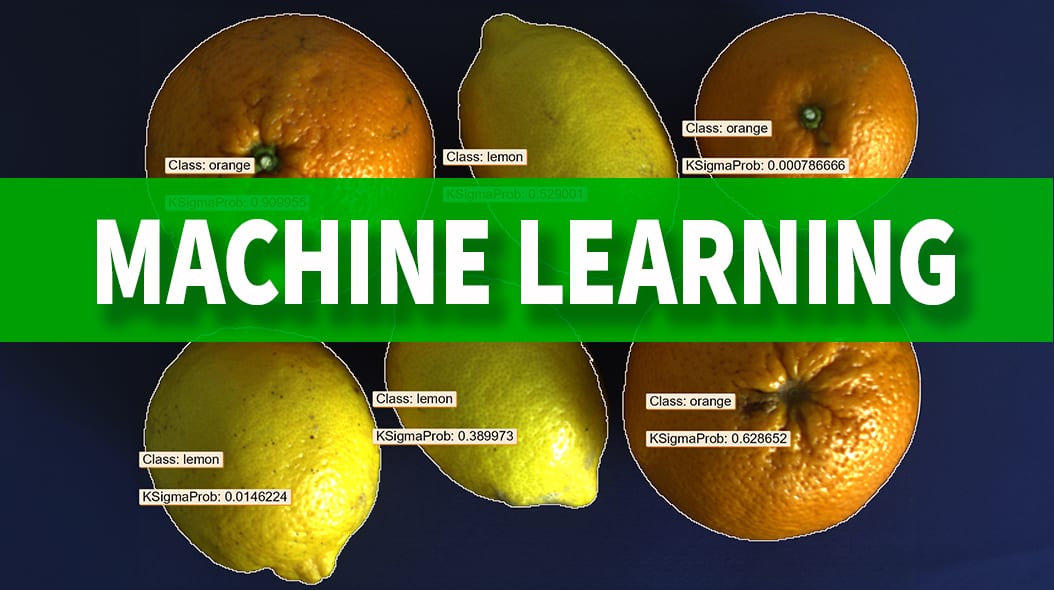

Simple inspection checks like the one Zippertubing deployed don’t require much in the way of AI or machine learning, but many cobot-based applications do.

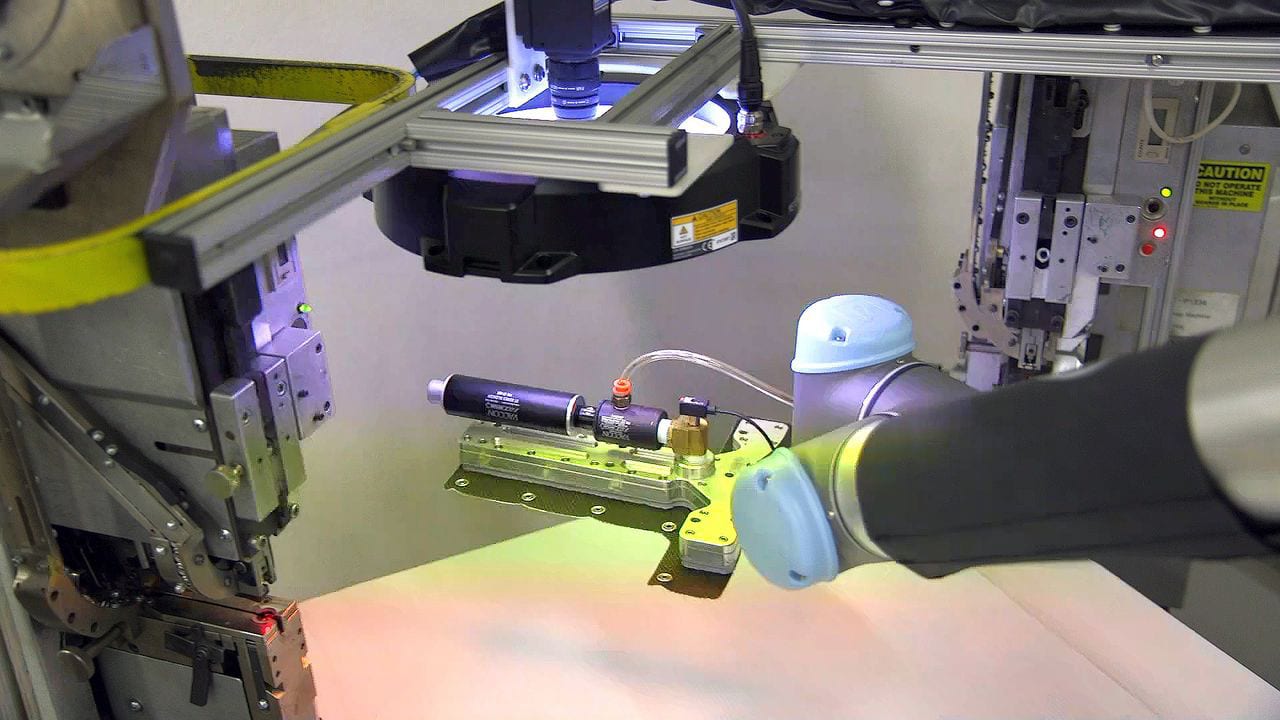

Bosch Siemens Hausgeräte (BSH) a leading European home appliance manufacturer, deployed MIRAI AI-vision software from Micropsi Industries on a cobot to automate end-of-line refrigerator leak testing.

The process involves running a sniffer probe along the solder joints of coolant pipes on the back of refrigerators, a serious challenge considering that each pipe is uniquely positioned and its solder joints vary in shape and color. It’s a task traditional automation couldn’t handle due to the variation.

Using the MIRAI vision system, the cobot can detect solder joints and guide the sniffer probe accordingly. The solution lowered BSH’s ongoing operating costs, boosted quality and reduced maintenance and troubleshooting.

Meanwhile, advanced technologies like 3D Infotech’s Aruna Vision and Aruna Motion Rotary are used in cobot-powered inspection applications that require parts to be lifted and spun around for visual inspection. This combination enables advanced inspection and metrology capabilities on a single cobot.

Bosch Siemens Hausgeräte (BSH) a leading European home appliance manufacturer, deployed MIRAI AI-vision software from Micropsi Industries on a Universal Robot to automate end-of-line refrigerator leak testing. Credit: Micropsi Industries.

Appetite for nondestructive testing

Nondestructive testing (NDT) is also possible using cobots. Singapore-based Olympus has a wide range of NDT devices that allow end-users to conduct inspections, detect defects, measure thickness or elemental compositions in a range of materials. Olympus’ NDT equipment is widely used for aircraft inspection in Singapore, a regional aviation hub. When integrated with a cobot, it is possible to automate NDT processes such as ongoing maintenance program for aircraft and verification of precious metals using the X-ray fluorescence and ultrasonic methods.

Quality ecosystems

Cobots do not exist in a vacuum. If you’re considering a cobot deployment in quality applications, be sure to pay attention to the surrounding ecosystem of hardware and software peripherals. Some cobot brands offer complete solutions specially designed for quality applications that will include all the peripherals your cobot needs to perform any number of quality and inspection tasks. To really benefit from the cobot based solutions, not only does the platform have to be trusted, but all the third-party products must be trusted too.

Not all cobots are the same. Some provide a limited ecosystem, which limits their flexibility as a platform. Make sure to choose a cobot that is extremely accessible and easy to program and is also supported by easily accessed educational resources that can guide you through deployment.

Also look for cobots that typically provide return on investment (ROI) in around 12 months. Talk to your integrator to find out more about the different cobot brands and the range of quality-specific applications each one can support.

Buying a cobot isn’t like buying a traditional, single-purpose industrial robot. When you buy a cobot, you may have just one application in mind, but leading cobots are platforms for almost any number of quality applications - and not just quality applications. This means that your investment can pay for itself many times over.