Products

the latest products to help you improve your manufacturing process

Massivit 3000 Large-Format 3D Printer

Massivit 3D Printing Technologies signed 15 new purchase orders for the sale of Massivit 3000 printers valued at $3 million. The company’s printers will be provided by the end of 2024. All new orders were received during the largest international printing exhibition, drupa, which was held in Germany on May 28 to June 7.

During the exhibition, Massivit launched the Massivit 3000, the latest large-scale 3D printer belonging to its Gel Dispensing Printing product line, designed for high-speed production of large parts, at a competitive penetration price.

Erez Zimmerman, CEO commented, “It was a pleasure to return to the drupa exhibition after the event’s 8-year hiatus. The exhibition enabled the company to reach a diverse customer base from the printing, advertising and global marketing industries. drupa was an excellent platform for our Massivit 3000 launch. At the exhibition we experienced a high level of interest as we showcased use cases and applications that can be printed on the Massivit 10000 and Massivit 3000.”

“The Massivit 3000 enables companies in the advertising and marketing industries to print large-scale objects ultra-fast. These printed items can be used as point-of-purchase displays, window displays, and billboards. Thanks to the launch of the Massivit 3000, we targeted a new audience and signed 15 new agreements during the show.

“In addition to this drupa event, the company received two recent purchase orders, the first of which is for a Massivit 1800 printer from Bombardier - a Canadian company that specializes in manufacturing executive planes and trains. Bombardier plans to use the Massivit printer tomanufacture prototypes and interior parts for its aerospace division. The second order was for a Massivit 5000 from Navistar - an American truck and bus company owned by Volkswagen.

“Lastly, I am proud to update that last week we won two prestigious awards at the TCT 3Sixty Exhibition in the UK where we presented the Massivit 3000. We were awarded as Winners of the Consumer Product category. In collaboration with our Italian customer, Woltz Nautic, we used the Massivit 5000 printer, proving our ability to manufacture bath tubs that weigh 100 kg less than standard baths, thereby providing a saving of 260 working hours. The second accolade was awarded for our recently-releasedCIM 84 material, the first 3D-printing material with certified flame retardance that allows companies in the theme park industry to produce flame-rated creative construction. As reported previously, Disney Imagineering acquired the Massivit 10000 at the end of last year to manufacture parts for theme parks.”

Massivit

https://www.massivit3d.com/

CERATIZIT Additively Manufactured Milling System

Developed specifically for heat-resistant materials such as titanium and other super alloys, CERATIZIT has launched their new, additively manufactured MaxiMill – 211-DC indexable insert milling system with advanced coolant supply.

For heat-resistant materials, conventional milling systems are limited and unpredictable. The MaxiMill – 211-DC was created through in-house additive manufacturing with 3D- printed cooling channels. Additive processes allow the patented shoulder mill to funnel the maximum amount of coolant directly on the insert flanks. In turn, it provides process reliability when machining heat-resistant super alloys.

The MaxiMill – 211-DC has 60% longer tool life compared to tools with standard cooling. Further, despite the complexity of the coolant holes inside the tool body, the MaxiMill – 211-DC is compatible with standard adapters with through-coolant supply without requiring any standard coolant on the chip breaker.

“We put additive manufacturing to work for our customers and to achieve results that are only possible when we push boundaries,” says Dan Cope, president of the Americas for CERATIZIT Group. “Titanium and other super alloys are unconventional materials that require unconventional strategies.”

CERATIZIT USA, Inc.

www.CuttingTools.CERATIZIT.com

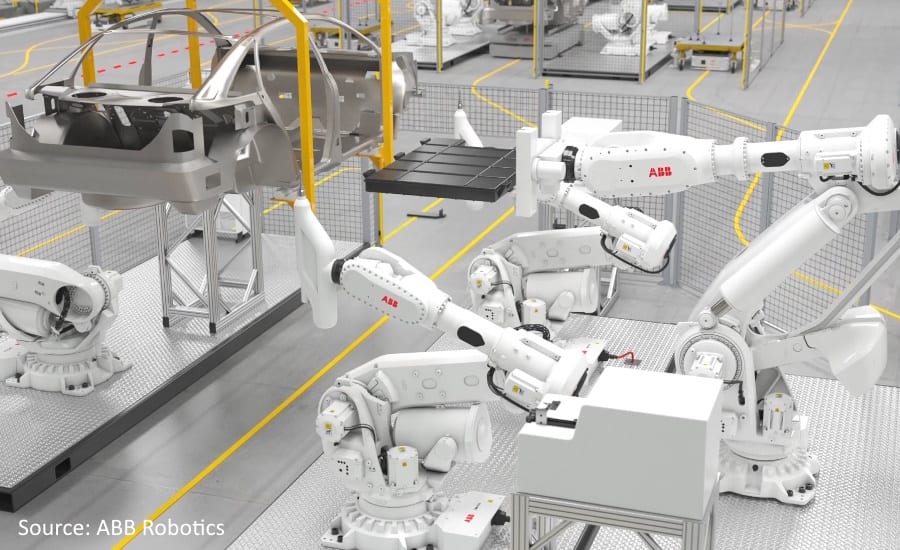

ABB Robotics OmniCore Control Platform

- Platform increases business productivity and flexibility through faster, more precise and more autonomous automation.

- Result of $170 million strategic investment in control platform for next-generation robotics to accelerate advanced, more sustainable automation

- Unique, single control architecture integrates ABB Robotics’ complete range of hardware and software

ABB Robotics launched OmniCore™, an intelligent automation platform that is faster, more precise and more sustainable, to empower, enhance and futureproof businesses.

The OmniCore platform, the result of more than $170 million of investment in next generation robotics, is a step change to a modular and futureproof control architecture that will enable the full integration of AI, sensor, cloud and edge computing systems to create the most advanced and autonomous robotic applications.

“For our customers, automation is a strategic requirement as they seek greater flexibility, simplicity and efficiency in response to the global megatrends of labor shortages, uncertainty and the need to operate more sustainably,” said Sami Atiya, President of ABB’s Robotics & Discrete Automation Business Area. “Through our development of advanced mechatronics, AI and vision systems, our robots are more accessible, more capable, more flexible and more mobile than ever. But increasingly they must also work seamlessly together, with us and each other, to take on more tasks in more places. This is why we are launching OmniCore, a new milestone in our 50-year history in robotics; a unique, single control architecture – one platform, and one language that integrates our complete range of leading hardware and software.”

OmniCore’s class-leading motion performance delivers robot path accuracy at a level of less than 0.6mm, with multiple robots running at high speeds of up to 1,600mm per second. This opens new automation opportunities in precision areas such as arc welding, mobile phone display assembly, gluing and laser cutting. Overall, OmniCore enables robots to operate up to 25 percent faster and to consume up to 20 percent less energy compared to the previous ABB controller.

OmniCore is built on a scalable, modular control architecture that offers a wide array of functions to create almost any application imaginable, making it suitable for businesses embracing automation in existing and new segments, such as biotechnology and construction, amongst many others. With over 1,000 hardware and software features, customers can design, operate, maintain, and optimize operations easily. This is enabled by software features including ABB's Absolute Accuracy, and PickMaster® Twin, as well as hardware options spanning from external axis and vision systems to fieldbuses.

“The OmniCore difference is its ability to manage motion, sensors and application equipment in a single holistic unified system,” said Marc Segura, Division President ABB Robotics. “OmniCore opens the door to the entire ABB Robotics portfolio of hardware and software, in any combination under a single control platform, offering endless possibilities and more avenues for value creation. For example, OmniCore enables automotive manufacturers to increase production speed, offering tremendous competitive advantage, increasing press tending production from 12 to 15 strokes per minute to produce 900 parts per hour. As we celebrate our 50th anniversary in Robotics, we believe that OmniCore offers the potential for many more industry breakthroughs, empowering our customers across all sectors to meet the challenges that lie ahead.”

OmniCore replaces ABB Robotics IRC5 controller which will be phased out in June 2026. ABB will continue to support its customers using IRC5 with spare parts and services through the remaining lifetime of the robot.

ABB

https://new.abb.com/products/robotics/controllers/omnicore

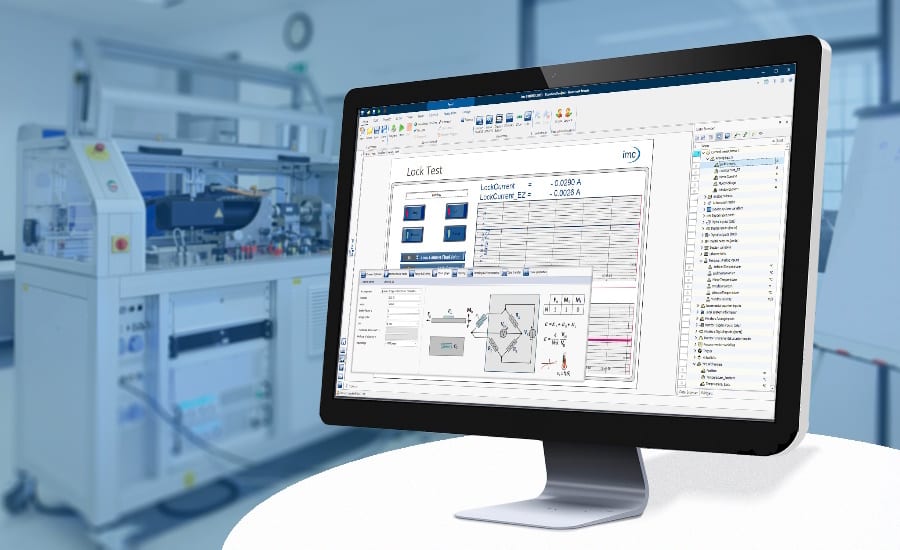

imc STUDIO 2024 Measurement Software

imc Test & Measurement, an Axiometrix Solutions brand, announces the release of imc STUDIO 2024, the new and improved version of the test and measurement software for the entire measurement process. The most important new features include more efficient input and management of metadata for documenting measurements, for example in test and boundary conditions, as well as support for convenient calibration of measurement microphones and a Python® interface for enhanced data analysis options in post-processing. Overall, functionality and usability have been improved along with faster reaction speeds when working with configurations of hundreds of active channels.

In order to enable test engineers working with IMC measurement systems and data loggers to concentrate even more on their core competence in the future, namely the reliable execution of measurements and sound interpretation of their results, imc STUDIO’s efficiency, functionality, and user-friendliness have been further enhanced. These enhancements include comprehensive measurement documentation options using metadata, new useful interfaces, and the recording of the complete calibration history of measurement microphones for the purpose of traceability and trend detection.

To draw the most accurate conclusions from the results of complex measurement series for later analysis, it is beneficial to carefully document all important additional information on test conditions and any parameters or environmental variables that changed during the process. This is the best way to gain the most valuable insights from valuable and carefully compiled measurement data. Imc STUDIO offers a convenient solution for managing metadata. It can prompt for input and then assign metadata in text or numerical form to measurement data, which is available both in FAMOS and for display and editing in display panels and reports.

The new Python® interface opens up the possibility of combining measurement data with one of industry’s most popular programming languages – for instance in the fields of machine learning (ML) and artificial intelligence (AI) – in post-processing. This opens up new, innovative ways of analysis by integrating algorithms coded in Python® and offers the opportunity to benefit from a global and collaborative open-source community. For users who already use established workflows and processes with Python®, imc STUDIO fits in seamlessly.

As standardized software, imc STUDIO 2024 supports all previous generations of imc systems, in particular the new imc ARGUSfit data logger with all current modules and functionalities.

imc Test & Measurement

https://info.imc-tm.com/whats-new-in-imc-studio-2024/

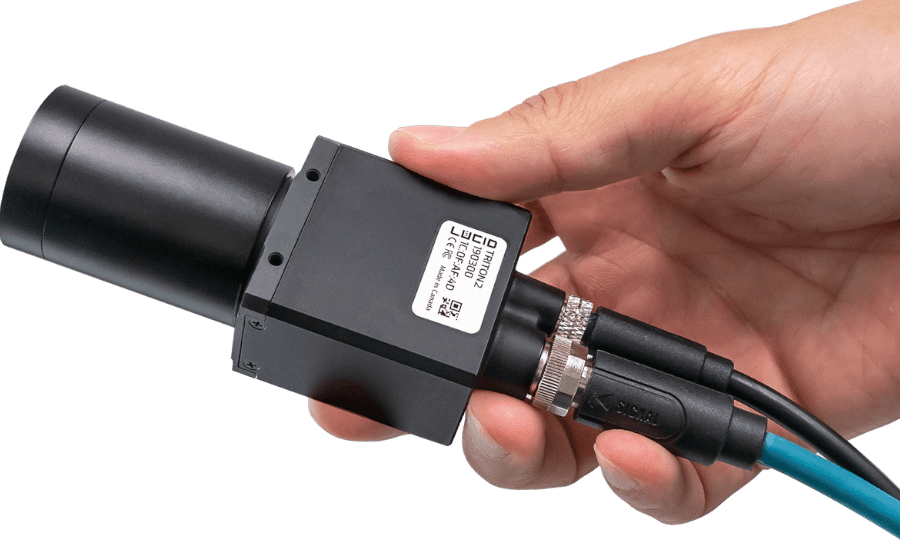

Lucid SWIR Cameras

Introducing the Triton2 – 2.5GigE SWIR cameras featuring Sony’s IMX992 and IMX993 SenSWIR sensors. These sensors deliver high-performance imaging in the short-wavelength infrared (SWIR) spectrum, boasting a resolution of 5.2 megapixels for IMX992 and 3.2 megapixels for IMX993. With a more compact pixel size of 3.45 µm (compared to 5 µm in the IMX990 and IMX991), these sensors achieve higher resolutions in a compact sensor size, enabling the use of C-mount lenses. When combined with the Triton2, these new SWIR models provide IP67 protection, active sensor alignment, robust M12 and M8 connections, Power over Ethernet, and 2.5GigE (300 MB/s) bandwidth for outstanding performance and value.

Lucid’s Atlas, Triton and Triton2 SWIR cameras are IP67, GigE Vision PoE cameras featuring wide-band and high-sensitivity Sony SenSWIR 5.2 MP IMX992, 3.2 MP IMX993, 1.3 MP IMX990, and 0.3 MP IMX991 InGaAs sensors, capable of capturing images across both visible and invisible light spectrums, and boasting miniaturized pixel sizes of 3.45µm (IMX992, IMX993) and 5µm (IMX990, IMX991). The camera’s capability of capturing on the short-wavelength infrared light spectrum opens up a world of industrial applications with greater precision in fruit inspection and sorting, packaging, IR microscopy, semiconductor inspection, material sorting and more.

Lucid provides users with 2 unique SWIR camera families. The Atlas SWIR is engineered for maximum image quality for 24/7 streaming and long exposure times. Thanks to the integrated sensor TEC, internal heatsink, and larger case size, the Atlas SWIR maintains consistent sensor temperature without the need for external heatsinks or fans. The Triton SWIR prioritizes size and weight with a lower cost to deliver an ultra compact SWIR camera. The Triton SWIR is intended for users who need flexibility to integrate it into smaller spaces and who wish to build their own heat management design for the camera.

Zarbeco Handheld Digital Microscope

Zarbeco, LLC, has released a new high resolution handheld digital microscope, the MiScope® MP4K. The USB 3.0 powered digital microscope combines observation, recording, measurement, and image comparison capabilities into a single palm-sized device that connects to a PC, macOS, or Android device. It fits easily in a small space on a lab bench or office desk. The MiScope MP4K microscope has 10x-360x magnification, switchable white light illumination, resolution to 1.1 microns, a 13 megapixel camera sensor, and up to 60 frames per second. Optional built-in UV and IR illumination allows for portable fluorescence microscopy or imaging at wavelengths beyond what is visible to the human eye. Video Toolbox Premier PC software is included with the MiScope MP4K. This software offers tools for image and video capture (including time-lapse), adding labels and drawing on the live image. The program can also make metrology-level measurements (with export to EXCEL) and features an optional upgrade to import CAD files as properly-scaled transparent overlays on the live video display. The MiScope is used for quality inspection, field sciences, forensic examinations, research, and documentation.

Zarbeco, LLC

www.zarbeco.com

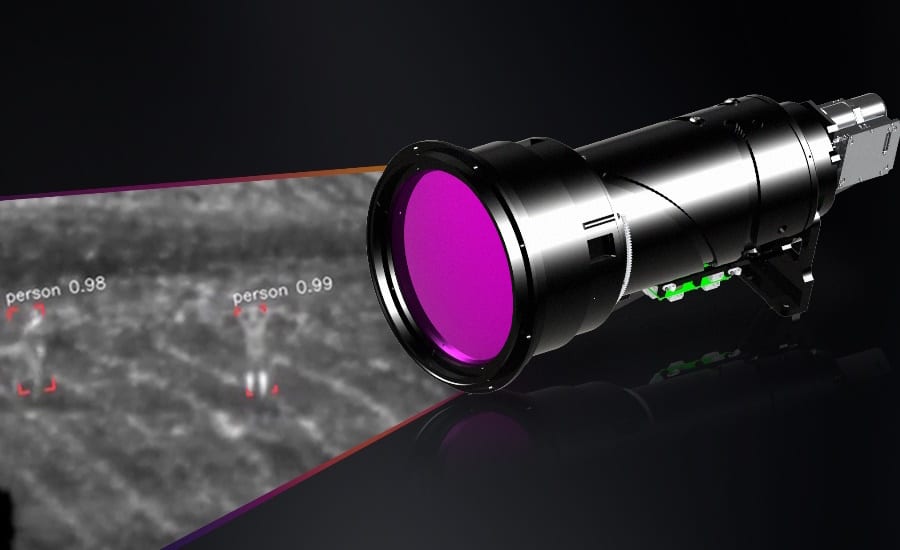

Teledyne FLIR AI-Enabled Neutrino Ground ISR Imaging Module

Teledyne FLIR, part of Teledyne Technologies Incorporated, announced the next mid-wave infrared (MWIR) Neutrino Ground ISR imaging module. The new ITAR-free Neutrino SX8-ISR 35-700 model with 1280x1024 resolution combines Teledyne FLIR’s MWIR camera module and continuous zoom (CZ) lens for integrators developing intelligence, surveillance, and reconnaissance (ISR) systems.

The industry adopted and highly configurable AgileCore™ imaging electronics interface seamlessly with the new Teledyne FLIR AVP, an advanced video processor that powersPrism™ AI and computational imaging at the edge. The AVP, built on the latest Qualcomm QCS8550, efficiently runs Teledyne FLIR Prism AI software providing detection, classification, and target tracking. It also operates Prism ISP algorithms including super resolution, image fusion, atmospheric turbulence removal, electronic stabilization, local-contrast enhancement, and noise reduction, to improve data fidelity and more accurate decision support.

The Neutrino Ground ISR series utilizes a long-life Linear Stirling cooler that provides a superior mean-time-to-failure of greater than 27,000 hours and fully integrated CZ optics. Developed and produced by Teledyne FLIR, formerly New England Optical Systems (NEOS), which joined FLIR in 2019, the CZ lenses provide a range of focal length options to maximize detection, recognition, and identification (DRI) performance.

All Neutrino Ground ISR products are manufactured in the USA, classified under US Department of Commerce jurisdiction as EAR 6A003.b.4.a, and are not subject to International Traffic in Arms Regulations (ITAR), providing greater flexibility for integration and development with foreign customers. Integrators also have access to a comprehensive software development kit (SDK), integration support, documentation from the highly qualified technical services team at Teledyne FLIR, and an industry-leading two-year warranty.

Teledyne FLIR

https://www.flir.com/products/neutrino-ground-isr-series/?vertical=mwir&segment=oem

Siemens SINAMICS G220 High-Performance Drive

With SINAMICS G220, Siemens is launching a new high-performance drive to join the SINAMICS drives family and recently introduced it to the North American market. SINAMICS G220 is an innovative multi-purpose adjustable speed drive with built-in Clean Power technology, which reduces harmonics by up to 97% without the need for an AC line reactor or DC choke. SINAMICS G220 is significantly more efficient in terms of space utilization and operation. SINAMICS G220 makes the system engineering and its integration into a production or processing machine much easier.

SINAMICS G220 is also the first drive to join the Siemens Xcelerator portfolio, the Siemens-wide business platform for digital transformation. SINAMICS G220 drives are an integral part of the TIA Portal and feature a digital twin in Startdrive, the drives commissioning tool from Siemens. This allows the behavior of the drive to be tested and optimized before the hardware is available.

SINAMICS G220 has an integrated web-server for commissioning which eliminates the need to install software or an app on a PC or mobile device. This saves time and makes drive setup very intuitive and extremely user-friendly.

These new drives are also equipped with an IIoT module. This means that SINAMICS G220 can easily be integrated into Cloud and Edge applications, which increases the transparency of the applications and makes remote monitoring and accessibility of the drive system possible. Machine availability can even be optimized and system uptimes can be further improved.

In the area of cybersecurity, SINAMICS G220 comes standard with state-of-the-art security integrated, providing highly secure communication, integrity and authenticity checks to protect against tampered firmware. Additionally, the drives offer User Management and Access Control (UMAC) within TIA Portal.

SINAMICS G220 drives come with a range of modular and flexible hardware options as well as software and Safety Integrated functions, which can be easily adapted to user-specific application requirements. For example, the SINAMICS G220 is also available in UL Type 12 (IP55) wall-mount design and a special conformal coating option is also available for the operation of a drive in the harsh environments where the presence of corrosive gases such as Hydrogen Sulfide, Sulfur Dioxide or Ammonia is unavoidable. Thanks to the superior quality of its components and robust hardware design according to UL 61800-5-1, the drive is built to ensure a long service life.

When it comes to integrated safety, SINAMICS G220 reaches the next level by meeting hardware based SIL 3 functional safety requirements. Thanks to its built-in media and S2 system redundancy, maximum system availability is guaranteed and the continuity of critical processes are maintained.

SINAMICS G220 ensures the improved sustainability of processes through robust, safe, secure and efficient design and operation. This new drive contributes to a sustainable future along its entire lifecycle from design to delivery thanks to the carbon neutral production sites and paperless delivery system. This new drive is suitable for all industries, but especially food-and-beverage, pharmaceutical, chemical, oil-and-gas, marine, automotive and tire manufacturing.

Siemens Corporation

siemens.com

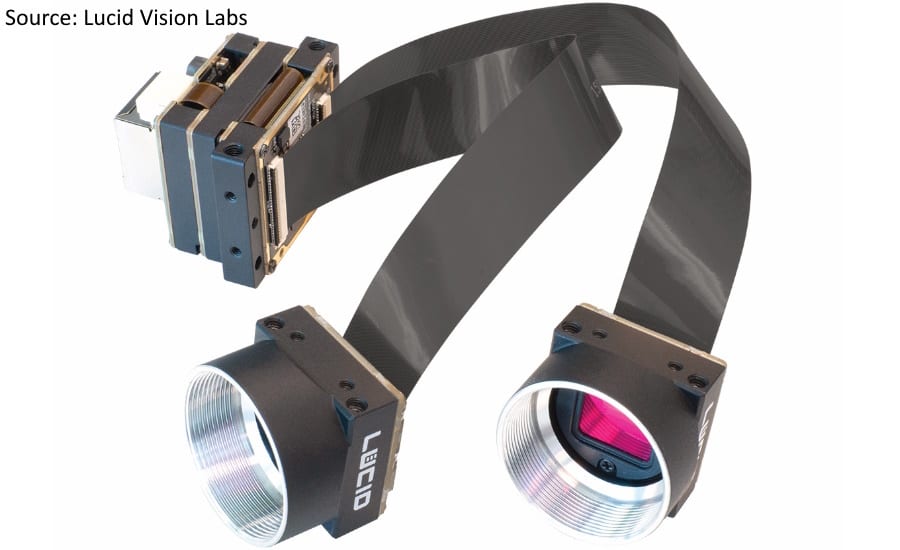

Lucid Phoenix Dual Extended-Head Camera

Lucid Vision Labs, Inc. announced the launch of the new Phoenix Dual Extended-Head camera, expanding its modular Phoenix camera family.

The Phoenix Dual Extended-Head camera seamlessly transmits synchronized images from its dual 5.0 MP sensors, catering to a diverse range of applications that require a wider Field of View (FoV). Equipped with two Sony IMX264 global shutter image sensors, each with a resolution of 2448 x 2048 pixels, this camera is tailored to provide an extended Field of View for stereo vision systems, Autonomous Mobile Robots (AMR), Unmanned Arial Vehicles (UAV) and Intelligent Transportation Systems (ITS). Its lightweight and compact 28 x 28 mm design allows for effortless integration into various space-constrained setups.

“Whether deployed for stereo vision configurations, drones with diverse viewing angles, or Intelligent Transportation Systems (ITS) applications requiring both IR-filtered and non-filtered sensors, the Phoenix camera ensures consistent and reliable performance with its dual extended-head, single-body design,” says Rod Barman, Founder and President of Lucid Vision Labs. “The camera delivers a cost-effective solution for multiple sensor setups, offering synchronized images and more flexibility to position the sensors as needed."

All Lucid cameras adhere to the GigE Vision 2.0 and GenICam3 standards and are supported by Lucid’s own Arena Software Development Kit (SDK). The Arena SDK provides customers with easy access to the latest industry standards and software technology and is compatible with the Windows, Linux 64-bit, and Linux ARM operating systems, and supports the C, C++, C#, and Python programming languages.

Lucid Vision Labs

www.thinklucid.com

Fowler High Precision, Sylvac SA SP25 Scanning Probe for Select Optical Scan Machines

Fowler High Precision and Sylvac SA announced a transformative measuring solution to its existing optical scan machines with the addition of a SP25 3D contact scanning Probe.

“Sylvac has a well-established range of optical Scan machines for shaft measurement, offering impressively fast and accurate measurements for a plethora of applications for many different market sectors, running on our renowned easy to use Reflex-Scan software. This exciting addition of a 3D contact scanning probe, opens new solutions for our customers, offering measurements not possible with only optical technology such as, blind holes, slots and form. We are excited to start this new era of 3D multi-sensor Scan machines and look forward to solving customer applications around the world,” said Duain Brisco, Global Sales Manager at Sylvac SA.

Tony Diiorio, National Sales Manager at Fowler, stated, “I am incredibly excited about the new Sylvac Scan S145 Optical Measuring System now fitted with an optional SP25 scanning probe. Its expanded measuring range and ability to measure previously unmeasurable features like blind bores, keyways, distances, runouts, and more are game changers. This innovation brings a new level of precision and functionality, ensuring our customers receive more reliable data and achieve greater throughput than ever before."

Fowler High Precision

www.FowlerPrecision.com

FLIR A6301 Cooled Automation Camera

FLIR, a Teledyne Technologies company, announced the FLIR A6301, a cooled-core longwave thermal imaging camera designed for 24/7 inspection and automation applications aimed at making production lines more efficient and improving product quality.

This advanced automation thermal camera can serve as a component in process control, monitoring, and quality assurance to improve yield, throughput time, costs, and quality for a wide range of industries: these include machine building, integration, automotive, and factory floor production of EV batteries, food, beverages, pulp, and paper. The FLIR A6301 can detect small thermal variations and accurately measure temperatures on moving products to maximize equipment uptime and minimize costs as an essential component of planned maintenance.

The FLIR A6301 includes a 27,000-hour-life linear cooler using a revolutionary hot mid-wave infrared (MWIR) detector. This is a crucial specification that allows for around-the-clock automated monitoring for more than three years so both integrators and suppliers can avoid dangerous situations brought about by automated monitoring system failures.

FLIR developed the automation camera with customers and integrators at the forefront. Camera interfaces, commands, and connectors are all purpose-built for automation-related use cases. Going further, the FLIR A6301 is the smallest commercial-cooled camera platform ever built by FLIR, so size and weight won’t get in the way of system integration. When integrated with additional smart sensors within a broader automation system, advanced machine learning, and deep learning methods, the FLIR A6301 can help provide for a smarter, more efficient process.

Smarter, more efficient automation through the FLIR A6301 includes the following benefits:

- Reduced direct labor cost in production from automated quality assurance

- Integration with a computerized 24/7 system reduces the risk of uneven quality control due to individual decisions and fatigue

- An automation system that can lead to higher overall product quality while lowering the cost of quality

- When used to alert, the camera can potentially help reduce the number of injuries during production

FLIR

https://www.flir.com/products/a6301/?vertical=rd%20science.

ABB Modular Large Robot Portfolio

ABB Robotics is continuing the expansion of its modular large robot portfolio with the introduction of the new IRB 7710 and IRB 7720. The new robots, combined with recently launched IRB 5710-IRB 5720 and IRB 6710-IRB 6740, offer a combined total of 46 different variants capable of handling payloads between 70kg-620kg, to give customers a new level of flexibility, greater choice and performance in their operations.

ABB’s new IRB 7710 and IRB 7720 robots offer 16 new variants and are ideally suited to support applications across various industries. Operators can choose from a wide range of ABB robots to ensure they have the ideal variant to handle various applications for electric vehicles (EV), hybrid, and traditional car production – spanning from press automation, body-in-white, EV battery construction, and final assembly. These robots are perfect for high payload assembly, such as giga casting, high speed press tending and palletizing, as well as high accuracy contact applications, such as machining and friction stir welding.

Powered by OmniCoreTM, the new robots achieve class-leading motion control with path accuracy down to 0.6mm, even with multiple robots running at high speeds of up to 1600mm/s and moving payloads of up to 620kg. Customers can also benefit from an up to 25% reduction in cycle times1 further enhancing productivity and quality. In the automotive industry, the all-new IRB 7710 with the latest OmniCore controller, will boost the production output of robotic press lines from 12 to 15 strokes per minute to produce 900 parts per hour. Furthermore, in the construction sector, the new robots will support the growth in modular construction, capable of constructing steel building frames and surface finishing, with improvements in speed and quality.

The IRB 7710’s energy efficient design in combination with OmniCore’s re-generation technology achieves up to a 30% energy reduction1, while the built-in power pack can relay energy back to the grid.

- New IRB 7710 and IRB 7720 alongside wider portfolio offer new levels of flexibility and greater choice with almost 50 variants

- New series delivers up to a 30% reduction in energy consumption1

- Latest robots ideally suited for use in industries such as automotive, general industry and logistics

ABB Robotics

https://new.abb.com/products/robotics/robots/articulated-robots/irb-7710

Aven Cyclops 4K Ultra HD Digital Microscope

Aven introduced the new Cyclops 4K Ultra HD Digital Microscope. This breakthrough instrument increases accuracy and productivity while easing eye strain and user fatigue – valuable benefits in high-volume applications, such as parts inspection in assembly operations.

Cyclops 4K Ultra HD Digital Microscope offers users an immersive viewing experience with 4K resolution, delivering unprecedented detail and clarity. Equipped with advanced optics and high-resolution imaging technology, the Cyclops provides magnification levels ranging from 13x to 140x, ensuring exceptional versatility for a wide range of inspection tasks.

Key Features of the Cyclops 4K Ultra HD Digital Microscope include:

- 4K Ultra HD Resolution: Experience world image clarity and detail with stunning 4K resolution, allowing for precise examination of even the smallest components.

- Versatile Magnification Range: With magnification levels ranging from 13x to 140x, the Cyclops offers unmatched versatility for various inspection tasks, from detailed electronics assembly to biological specimen examination.

- Flexible Viewing Options: Seamlessly switch between HDMI and USB output modes for flexible viewing options and easy integration with existing imaging systems.

- Intuitive Controls: The Cyclops features user-friendly controls and a simple interface, allowing for effortless operation and precise image capture.

- Enhanced Connectivity: Connect the Cyclops to a computer or monitor via HDMI or USB for real-time viewing and image capture, making it ideal for collaborative work environments.

- Compact and Portable Design: Designed for convenience and portability, the Cyclops boasts a compact and lightweight design, making it perfect for fieldwork or on-the-go inspections.