Back 2 Basics

Inspection

AEROSPACE

(AQMS) Certification

Aerospace Quality Management System

If you really want a QMS to work, you need to work at it.

By Brendon Hill

Quality management systems have been around for many years now, but you might ask yourself, why set out to comply with a written standard, and why be certified? There are often discussions on this topic and whether it realizes benefits or is just a badge. The truth is that it is like anything else, you get out what you put in.

You could write a QMS, you could document it and keep it on the shelf and roll it out once a year to show a less-than-robust auditor and get an ISO9001 certificate. Indeed, there are non-IAF-accredited certification bodies out there that will write the QMS for you, then rubber stamp it. The result is you have no change in what you do or how you do it, so no benefits in efficiency, cost reduction, OTD, and critically, culture and leadership. Frankly, pointless. You know it, and your customers (if they understand the accreditation system) also know it.

If you really want a QMS to work, to realize the benefits that it undoubtedly can, you need to work at it. The start is leadership. This is often touted, but also is often paid only lip service. There are many examples where leadership has led to poor performance, and indeed critical failure. In aerospace, this can lead to loss of life, so flight safety lies at the heart of an AQMS.

So properly implemented and maintained, with continuous improvement through training, optimization, monitoring and measuring and acting (the familiar PDCA), it will pay you back at the bottom line. But only if the leadership is really engaged and the required culture is embedded. Companies often do surveys of their workforce to measure engagement; that works both ways.

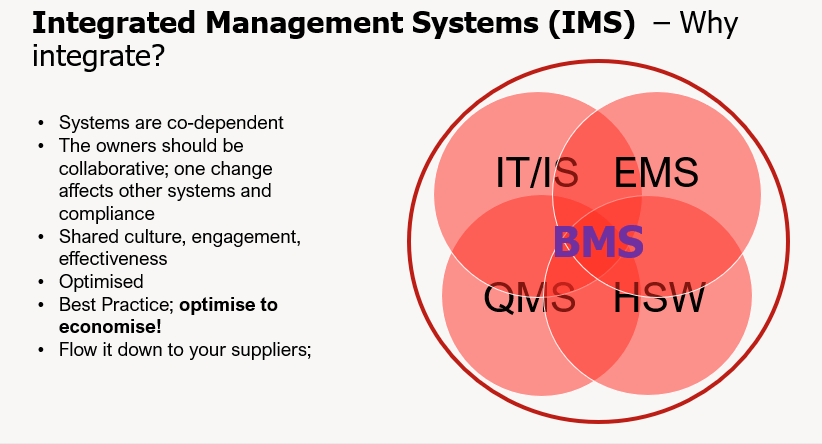

Integrated Management Systems

The business also must meet many other requirements, including health, safety and wellbeing (HSW, critical for human factors, and we are all aware of the fallout from the pandemic), cyber security and digital trust (to protect your own and customers’ intellectual property - we all know about those actively seeking to steal IP, personnel details, business plans), and all aspects of sustainability (environment, energy management, greenhouse gas emissions). These all have inter-dependencies, as you can see in this Venn diagram. Integration done right leads to optimization, shared culture, engagement; all the things to make a system really work. A business management system (BMS).

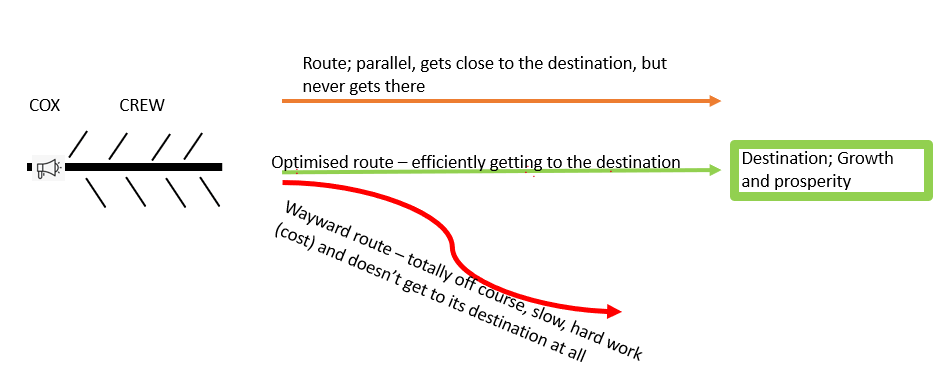

You might compare it to a rowing club 8.

The cox is the leadership. They can see what is ahead, set the direction, call the stroke to harmonize and optimize, steer the boat to avoid choppy waters and optimize the route.

The crew are the systems. They are not looking forward; they are doing the hard work. If they all pull together, harmonized and working collaboratively, they maximize efficiency and the boat is fast.

If the leadership is poor, the boat gets into choppy water and is hard going, or it has the wrong course so never gets to its destination. The crew are very unhappy, your customers start leaving.

If the crew are not harmonized, or an oar (system) fails, it goes off course, wastes effort; the team is frustrated.

For example, the cyber security oar (system) gets hacked, the quality system oar (system) is not meeting its requirements, as it depends on the cyber oar. The oars are inefficient or may even clash. You lose IP, personnel data, and credibility in the market.

If the HSW oar has problems, these lead to personnel being mentally compromised; not engaged, making errors, distracted. These human factors lead to production errors and escapes. The QMS oar is compromised by the HSW oar.

Your boat is slow, wandering off course, the crew are (maybe) working very hard to try to correct it, but are fighting the asymmetry of effort and the poor steering. Costs go up due to reworks, scrap rates, escapes. You lose customers.

Which boat is yours? This one? https://www.youtube.com/watch?v=mIxEJHAQDcw

Or this? https://www.youtube.com/watch?v=9sJU5MALkgg ?

(For a fuller understanding of the benefits of an IMS, have a look at this BSI webinar BSI IMS Webinar.)

So why certify?

Having third part certification by a credible IAF-accredited Certification Body (CB) means that firstly, your business gets a good wire-brushing to find the good, the bad and the problematic. A standard is just best practice captured and consolidated. The CB reviews your practices against these best practices.

By meeting the requirements, you and your customers can be assured that you are doing the right thing. If you are not, you will be notified, and this visibility enables action to be taken to get you back on course, to aim for your destination.

Having this business assurance helps you not only confirm to yourself (the leadership) that you are running an effective and efficient business, but to provide that assurance to your customers, and to retain them and to win new customers.

With an IMS, you can really get to see the big picture in the information that your CB gives you, and to use it to further optimize, to set your course and avoid the choppy waters.

Changes in the International Aerospace Quality Group (IAQG) AQMS Scheme

While the certifiable standards have not changed, the rules for the scheme have. The rules are in the trinity of standards: 9104-1, 9104-2 and 9104-3. The main one is the first, 9104-1, which is the “Requirements for Certification of Aviation, Space and defense QMS”, the rulebook. It brings in many changes, so if you are already certified or working towards it, this is for you.

The revised AS9104-1 permits integrated audits of your IMS. So not only do you get the benefits of integration and collaboration internally in all your systems (and if you are clever, in your supply chain too), your integrated audits can really look at your whole business in an efficient, cost-effective manner, with reductions in some audit durations due to the shared elements.

The biggest changes to the scheme are:

Only two structures: single site and multisite. Campus, Several and Complex are gone.

The planning process incorporates risk, and is called Organization Certification Analysis Process (OCAP)

Performance Based Surveillance/Recertification Process (PBS/RP). This is similar in concept to the old Advanced Surveillance and recertification Program (ASRP) but is scheme-specific. It allows very high-performing organizations to enjoy significant reductions in audit durations, but the entry bar is set very high.

For a full explanation of the revisions to the scheme, please refer to this BSI Webinar AS-EN-91XX-scheme updates

Summary

Implementing a management system that meets a published standard means you are adopting and implementing accepted and recognized best practice. You can show your clients and potential clients that you provide conforming products, meet expectations for HSW, keep their IP secure and work sustainably: all critical in today’s market.

Doing it badly means you won’t reap the benefits; doing it well means you can really improve the bottom line, grow your business through being credible in the marketplace. This requires committed and effective leadership setting the values and culture.

Adopting an IMS including HSW, data security, sustainability etc. means that you can optimize and integrate systems, so that you have harmony in the management team as they work collaboratively with all oars pulling together, following the clear path set by the team cox/top management.

The workforce will be better engaged, similarly collaborative, less susceptible to human factors. You get less waste, less absenteeism, more efficiency. Costs go down.

The now very informed public will know that you are meeting their expectations for the planet and people; you can prove it as you have independently verified by a certification body; Esse Quam Videri.

Ian R. Lazarus is president and CEO of Creato Performance Solutions, providing leadership development, training, and solutions to support operational excellence.

Brendon Hill is the global head of aerospace at BSI. For more information, call +44 20 8996 9000, email brendon.hill@bsigroup.com or visit www.bsigroup.com.

Jim L. Smith has more than 45 years of industry experience in operations, engineering, research & development and quality management.