1H 2023 Reshoring + foreign direct investment (FDI) job announcements continued their record-breaking run. 1H2023 announcements were in line with 2022’s record rate. We expect to see upwards of 300,000 jobs announced by year-end. EV battery and chip investments along with other essential product industries supported by Bidenomics account for the bulk of the announcements.

Reshoring Initiative 1H 2023 Report

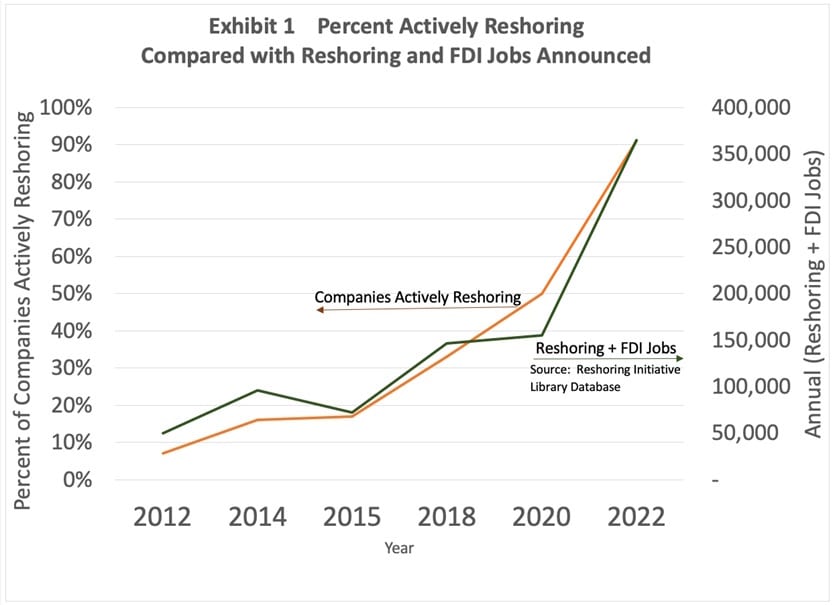

Several factors have come to light that substantiate the strength of U.S. reshoring and FDI trends. In the first quarter of 2023, average spending on U.S. factory construction was more than double the average from the past 17 years. Reshoring Initiative data parallels the magnitude and focus of the construction investments. Independently conducted surveys on reshoring actions by U.S. companies also correlate very closely with Reshoring Initiative data on jobs announced over the past 12 years (Exhibit 1) adding validity to both data sets.

Reshoring and FDI job numbers demonstrate exceptional progress for U.S. manufacturing after decades of offshoring. If this progress can be combined with an industrial policy that supports greater cost competitiveness, we will continue our rapid strengthening of U.S. supply chains.

The Reshoring Initiative’s 1H 2023 Report contains data on U.S. reshoring and FDI by companies that have shifted production or sourcing from offshore to the United States.

“We publish this data to show companies that their peers are successfully reshoring and that they should reevaluate their sourcing and siting decisions,” said Harry Moser, founder and president of the Reshoring Initiative. “With 5 million manufacturing jobs still offshore, as measured by our $1.2 trillion/year goods trade deficit, there is potential for much more growth. We also call on the administration and Congress to enact policy changes to make the United States competitive again.”

For more information, visit www.reshorenow.org.

JAI A/S Celebrates 60 Years in Machine Vision

JAI A/S marked its 60-year corporate anniversary. Founded in Denmark in 1963 by Jørgen Andersen, the company designs, manufactures and sells industrial area scan and line scan cameras used in factory automation systems, food sorting, semiconductor inspection, life sciences, intelligent traffic systems, and other industry segments around the world.

JAI engineered its first industrial camera 50 years ago. Since then, the company has expanded its operations both organically and through acquisitions of a Japanese industrial camera manufacturer, and the Japanese California-based camera manufacturer Pulnix. This latter acquisition not only strengthened JAI's position as a global provider of area scan and line scan cameras for the machine vision industry, but also launched JAI into the field of specialized traffic cameras and subsystems.

Today, JAI offers a robust product portfolio comprising more than 100 feature-rich standard industrial camera models, complemented by a range of high-resolution cameras and special multi-sensor cameras designed to support advanced vision requirements in the machine vision industry.

JAI’s multi-sensor cameras feature innovative prism-based technology not available from most other camera manufacturers. These cameras include 3-sensor prism-based area scan and line scan cameras, which are prized for their high degree of color accuracy in food sorting, pharmaceuticals, printing, and life sciences applications. Prism technology is also used to create cameras for multispectral imaging, combining the visible spectrum with near-infrared (NIR) or short-wave infrared (SWIR) imaging to reveal defects and other data that can’t be detected under visible wavelengths alone.

According to Jørgen Andersen, JAI’s longevity in the industry is not only due to innovations such as these multi-sensor cameras, but also to the company’s longstanding focus on quality and strong customer relationships. "We develop new cameras and functionality in close cooperation with customers aiming at improving the efficiency of their vision systems. And customers want cameras that not only work exceptionally well, but offer exceptional reliability,” says Jørgen Andersen. “We’ve always made quality a top priority for our customers. With high-quality components, low-noise camera designs, innovative prism technologies, and meticulous quality assurance procedures, JAI builds cameras that deliver outstanding image quality across all our models, and that’s what keeps us in business."

Jørgen Andersen remains active in the company, serving as chairman of the board and contributing to shaping the company's future strategic direction. He sees the 60-year anniversary as both a time to reflect and to look ahead.

"Looking back, JAI has achieved many fantastic milestones and all-in-all, it has been six decades of success, with more than 1 million cameras sold. I would like to thank JAI's loyal customers, business partners, and employees. It would not have been possible without the hard work, dedication, and commitment of them all,” says Jørgen Andersen. “Looking forward, I can see a future of possibilities filled with great opportunities for JAI in the vision industry."

For more information, visit www.jai.com.

AEM Welcomes 2024 Officers, New Directors at Annual Conference

The Association of Equipment Manufacturers (AEM) announced its 2024 officers and directors elected to the AEM Board of Directors and Agriculture and Construction Equipment Sector Boards during its annual business meeting in Ft. Lauderdale, FL.

The 2024 AEM Officers:

- Chair: Todd Stucke, President of Kubota Tractor Corporation and Executive Officer of Kubota Corporation

- Vice Chair: Linda Hasenfratz, Executive Chair and CEO, Linamar

- Ag Chair: Bill Hurley, VP of Global Government Affairs, AGCO

- CE Chair: Eric Sauvage, President and CEO, LBX Company

- Treasurer: Melvin Porter, President and CEO, Link-Belt Cranes

- Secretary: Megan Tanel, President, AEM

“We extend a warm welcome our 2024 officers and new and returning directors and wish to publicly thank them and their companies for steadfastly supporting the Association and its goals,” said AEM President Megan Tanel. “AEM’s success and growth hinges on the unwavering dedication of its volunteer leadership and the active involvement of its members. Their commitment and contributions are instrumental in propelling the industry forward. Through their engagement we strive to deliver excellence and provide the most valuable service and programs for our members.”

AEM’s Officers and Directors provide strategic direction and guidance for Association initiatives that help members and the industry succeed. Key action areas include advocacy and public affairs, market information, exhibitions and events, and safety, regulatory and technical issues. For 2024, AEM’s boards include:

2024 AEM Board of Directors:

- Jason Andringa, President and CEO, Vermeer

- Kris Flitcroft, Vice Chairwoman, AC Business Media

- Richard Fox-Marrs, President, JCB North America

- Dave Gilmore, Senior VP, Deere & Company

- Grant Godbersen, VP of Manufacturing, GOMACO

- Mike Haberman, Executive VP, Industrial Equipment Division, Alamo Group

- Scott Harris, Brand President of Case IH and STEYR, CNH Industrial

- Linda Hasenfratz, Executive Chair and CEO, Linamar

- Bill Hurley, VP of Global Government Affairs, AGCO

- Keith Johnson, President, Kondex

- Phil Kelliher, Senior VP Americas Distribution, Service & Marketing, Caterpillar

- Laura Ness Owens, VP, Global Brand and NA Marketing, Doosan Bobcat North America

- Greg Petras, President, Kuhn North America

- Melvin Porter, President and CEO, Link-Belt Cranes

- Austin Ramirez, CEO, Husco

- Jeff Reed, Chairman, Reed International

- Eric Sauvage, President and CEO, LBX Company

- Rod Schrader, Chairman and CEO, Komatsu America

- Todd Stucke, President of Kubota Tractor Corporation and Executive Officer of Kubota Corporation

- Pat Weiler, President and CEO, Weiler

2024 AEM Ag Sector Board:

- Chair: Bill Hurley, VP of Global Government Affairs, AGCO

- Vice Chair: Greg Petras, President, Kuhn North America

- Grant Adolph, Chairman of the Board and COO, Buhler Industries

- Kurt Buehler, Group President, MacDon Industries

- Shane Coates, VP, Agriculture, JCB

- Kurt Coffey, VP, Case IH, North America, CNH Industrial

- Mark Core, Executive VP, Forage and Lifecycle, CMO, Vermeer

- Fernando Cuccioli, Executive VP, Cluster Americas, DeLaval

- Charlene Finck, President, Farm Journal

- Dave Gilmore, Senior VP, Deere & Company

- Mike Gomes, VP, Sustainability and Global CSR, Topcon Positioning Systems

- Doug Griffin, Partner, Context Network

- Bill Hurley, VP of Global Government Affairs, AGCO

- Keith Johnson, President, Kondex

- Todd Kniffen, Senior VP, Engineering & Global Product Management, Kinze Manufacturing

- Dietz Lankhorst, President and CEO, Krone NA

- Brian Nelson, CEO and Chairman, HCC

- Gustavo Oberto, President, Global Irrigation, Lindsay

- Greg Petras, President, Kuhn North America

- Viren Popli, President and CEO, Mahindra USA

- Eric Raby, SVP, Americas, CLAAS of America

- Todd Stucke, President of Kubota Tractor Corporation and Executive Officer of Kubota Corporation

2024 Construction Equipment Sector Board:

- Chair: Eric Sauvage, President and CEO, LBX Company

- Vice Chair: Erica Baird, Executive Director, Global Sales and Service, Cummins

- Jay Allen, President and CEO, Allen Engineering

- Erica Baird, Executive Director, Cummins

- Brian Bieller, President, BOMAG Americas

- Otto Breitschwerdt, Senior VP, Building Construction Products of Caterpillar, Caterpillar

- Glen Calder, VP, Operations, Calder Brothers

- Susanne Cobey, CEO, Eagle Crusher Company

- Jason Daly, VP Sales, Marketing, Aftermarket & Customer Success, John Deere Construction and Forestry Division

- Mike Gidaspow, VP, Products, Service and Solutions, Komatsu America

- Jim Glazer, President and CEO, Elliott Equipment

- John Grote, COO, Grote Industries

- Willie Harbert, VP, Danfoss Power Solutions

- Dave Hughes, VP, Global Sales, McElroy Manufacturing

- Pete Large, Senior VP, Construction, Trimble

- Leandro Lecheta, President, NA Construction Segment, CNH Industrial

- Brian Metcalf, President and CEO, Ring-O-Matic

- Pete Moeller, Group VP, Construction Businesses, The Toro Company

- Melvin Porter, President and CEO, Link-Belt Cranes

- Bryan Rich, Executive Strategic Advisor, SmartEquip

- Eric Sauvage, President and CEO, LBX Company

- Magnus Thibblin, VP, Heavy Construction, Hexagon

For more information, visit www.aem.org.

U.S. Department of Energy Awards Eight Projects to Strengthen Microbattery Designs, Manufacturing Practices

The U.S. Department of Energy (DOE) announced awards for eight new designs for microbatteries, through its Microbattery Design Prize. This prize aims to accelerate the commercialization of these innovative microbattery designs, along with their integration into the existing technologies needed for clean energy manufacturing. In addition to automatically advancing to phase two of this prize, each selected project will receive an award consisting of $75,000 in a cash prize along with performance and safety testing services with DOE National Laboratories.

Currently, the microbattery market is unable to leverage many of the existing manufacturing processes of the larger battery supply chain ecosystem, due to the requirements associated with their small size. This presents a major barrier to the development and commercialization of new microbattery chemistries and designs, along with an opportunity to increase domestic production and secure supply chains.

“From powering sensor systems for improved smart manufacturing processes to running sensors for grid monitoring, microbatteries are becoming more and more crucial for clean energy manufacturing scale-up and smart technology innovation,” said Jeff Marootian, Principal Deputy Assistant Secretary for Energy Efficiency and Renewable Energy. “As our nation rapidly transitions to a clean energy future, the ability for us to domestically produce a wide range of microbatteries is going to be hugely important for achieving the Biden-Harris Administration’s clean energy goals of achieving 100% clean electricity by 2035 and net-zero carbon emissions by 2050.”

The eight selected projects were chosen as winners of the first phase of this two-phase Microbattery Design Prize. In this first ‘Ideas’ phase, competitors developed and submitted technical designs and schematics for microbatteries that serve a specific application (like a grid monitoring devices) and meet certain performance goals (like a specific storage capacity, cycle lifetime, safety, or recyclability) that go beyond what is commercially available today.

For more information, visit https://www.energy.gov/eere/ammto/microbattery-design-prize-phase-i-selections?utm_medium=email&utm_source=govdelivery.

NAM Bolsters Government Relations Leadership

The National Association of Manufacturers named Stef Webb as its new Managing Vice President of Government Relations. Webb joins the NAM from Gopuff, the fast-growing $15 billion global consumer goods and food delivery company, where she served as director of corporate affairs, helping to establish its federal affairs program and spearhead public and government affairs during key market entries globally.

“Whether she’s bringing together lawmakers and line workers in Midwest manufacturing facilities or building relationships on Capitol Hill or in world capitals, Stef has built a sterling reputation as an effective and collaborative advocate who does not relent until the policies or priorities she’s fighting for are across the finish line,” said NAM President and CEO Jay Timmons.

Reporting to NAM Executive Vice President Erin Streeter and working alongside the organization’s broader advocacy leaders, Managing Vice Presidents Jamie Hennigan (Communications and Public Affairs), Chris Netram (Policy) and Chrys Kefalas (Brand Strategy), Webb will lead the association’s government relations strategy to advance the competitiveness of manufacturers in the United States.

“In this unpredictable and fast-changing political environment, it’s never been more important to have a government relations team that is steps ahead of where the policy opportunities and challenges could go,” said Streeter. “With Stef helping to lead our team, we’ll build on our track record of preparing for tomorrow, anticipating future needs and being a credible and trusted go-to voice and resource for manufacturers and our nation’s leaders.”

Webb brings proven experience in many areas critical to continuing to drive unapparelled results for the industry. She has held leadership roles in government relations, policy, political fundraising, political affairs, communications, membership, finance and operations. Prior to Gopuff, Webb served as director of federal government affairs at NAM member company Anheuser-Busch, showcasing her ability to bridge divides, winning support for key manufacturing priorities in the United States and creating initiatives—like Brew Across America—that brought policymakers together. During this part of her career, Webb's successful and effective advocacy work first came to the attention of Timmons and Streeter.

“Manufacturing is the backbone of the American economy and the foundation of business in America, impacting nearly every industry and person,” said Webb. “The NAM has built a reputation as the most trusted voice and resource for manufacturers in the United States, and I’m excited to join this team to create an even better environment for manufacturers to compete, to create more jobs and to improve lives.”

Webb also serves her country as an officer in the United States Navy Reserve.

For more information, visit www.nam.org.

US DoE Announces $121M to Reduce Emissions Across US Industrial Sector

The U.S. Department of Energy (DOE) Industrial Efficiency and Decarbonization Office (IEDO) announced a $38 million funding opportunity that will accelerate the innovative, cross-sector technologies required to create a clean energy economy. Additionally, DOE announced a notice of intent (NOI) to issue a $83 million funding opportunity that will decrease emissions in the hardest to decarbonize industrial subsectors. Decarbonizing the U.S. industrial sector is an essential component of President Biden’s Investing in America agenda and is key to achieving the nation’s clean energy goals. By accelerating the development and adoption of sustainable technologies that increase efficiency and eliminate industrial greenhouse gas (GHG) emissions, this funding will help tackle the climate crisis, boost the competitiveness of domestic manufacturing, and create good-paying jobs for American workers.

The U.S. industrial sector is central to our nation’s economy, creating the products society relies on —from the chemicals used to create consumer products, to the cement and concrete in our roads, and the steel and iron in our buildings and cars. Yet, this vital sector accounts for one-third of all energy-related domestic GHG emissions. Achieving a net-zero industrial sector requires an aggressive, multidimensional approach. This NOI and FOA focus on a two-pronged research, development, and demonstration (RD&D) strategy to drive industrial decarbonization: tackling the complex systems at the heart of the most energy- and emissions-intensive industries and pursuing cross-sectoral enabling technologies for challenges that are common across many industries.

The Cross-Sector Technologies (CST) FOA focuses on high-impact, applied research, development, and pilot demonstration projects to advance the transformational cross-sector technologies and innovations required to reduce energy use and GHG emissions across the industrial sector. FOA topics include electrification of industrial heat, efficient energy use in industrial systems, and decarbonizing organic wastewater and wet waste treatment.

Full applications are due March 20, 2024, at 5:00pm ET. EERE envisions awarding multiple financial assistance awards in the form of cooperative agreements. The estimated period of performance for each award will be approximately 24 to 36 months.

The Energy- and Emissions-Intensive Industries (EEII) funding opportunity will focus on applied RD&D for the highest GHG-emitting industrial subsectors, specifically: chemicals and fuels; iron and steel; food and beverage; building and infrastructure materials (including cement and concrete, asphalt pavements, and glass); and forest products. Together, these industries account for more than 65% of U.S. industrial manufacturing emissions that have global impacts. Decarbonizing these subsectors will have immediate impacts on overall manufacturing and far-reaching impacts on domestic supply chains across the U.S. economy.

This funding opportunity will also include a joint topic with the Hydrogen and Fuel Cell Technologies Office (HFTO) and the Office of Fossil Energy and Carbon Management (FECM) focused on pre-front-end engineering and design (pre-FEED) studies that support the development of decarbonized industrial processes using approaches that include innovative, pre-commercial technologies. Potential pre-FEED areas of interest include: (a) integration of green hydrogen as a feedstock in clean fuels, chemicals, and iron and steel production; (b) carbon capture for select industrial sectors; and (c) integration of multiple decarbonization technologies for chemical production, mineral processing, and iron and steel.

For more information, visit https://www.energy.gov/eere/?utm_medium=email&utm_source=govdelivery.

September 2023 Manufacturing Technology Orders Down, Still Above Historical Averages

New orders of manufacturing technology totaled $398.9 million in September 2023, according to the latest U.S. Manufacturing Technology Orders Report published by AMT – The Association For Manufacturing Technology. September orders declined 2.8% from August 2023 and 23.4% from September 2022. Year-to-date orders reached $3.64 billion, 13.8% lower than the first three quarters of 2022.

“Though 2023 orders are down, activity is still above long-term historical averages, indicating relative health overall,” said Douglas K. Woods, president of AMT. “We are still seeing strength in key industries, with contract machine shops, medical, and automotive continuing to invest heavily in manufacturing technology.”

Contract machine shops increased order value by nearly a third while units ordered grew by a much smaller degree. Similarly, manufacturers of medical supplies dramatically increased their overall spending. The automotive sector also continued to increase orders. Because of the longer production horizon as well as a sustained increase in demand for new vehicles, automotive manufacturers made capital spending investments despite labor challenges.

“The disparity in manufacturing technology investment across industries indicates that not all are paring back capital spending at once,” said Woods. “Industries that are spending healthily on manufacturing tech appear to be shifting expenditures toward highly automated machinery as evidenced by rising per-unit values.”

Though year-to-date orders have declined compared to a strong 2022, order levels are above historical averages, and there are pockets of strength in several industries.

“Industries supported by high consumer demand and benefiting from long production timelines continued to be reliable customers of manufacturing technology,” said Woods. “We are detecting a shift in capital goods investment toward improving productivity through adoption of manufacturing technology automation.”

For more information, visit www.amtonline.org.

Verisurf Software, CAD/CAM Consulting Services Inc. Announce Reseller Agreement

Verisurf Software, Inc. and CAD/CAM Consulting Services Inc. (CCCS) announced the signing of a reseller agreement at the opening of Westec 2023 at the Long Beach Convention Center. Under the agreement, CCCS will help introduce and sell Verisurf metrology solutions in Southern California and Nevada.

The reseller relationship between Verisurf and CCCS is unique. CCCS is an authorized Mastercam reseller. Verisurf metrology software is built on the Mastercam platform, providing an integrated CAD/CAM/CAI (Computer Aided Inspection) and RE (Reverse Engineering) solution. When Verisurf software is enabled, its complete functionality and toolset are accessible from the Mastercam menu bar.

Verisurf also works as a stand-alone metrology solution and is the only metrology software offering full-featured 3D CAD/CAM with intelligent Model-Based Definition (MBD). This ensures data integrity and lets users perform metrology workflows in a seamless CAD environment while maintaining model-based digital continuity. Verisurf software supports all CAD file formats (or drawings), and the Verisurf Device Interface (VDI), with virtual CMM display, communicates with and operates all programmable and portable CMMs for universal compatibility.

The software’s modular design, ease of CMM programming, and built-in productivity tools let users quickly create measurement routines using efficient and repeatable workflows for quality process control. With Verisurf’s open platform compatibility, a single measurement routine can be run across virtually any CMM, including portable arms, fixed CNC CMMs, scanners, trackers, and more. The software’s modular applications allow users to quickly shift from inspection to reverse engineering to tool building, efficiently capturing and processing measurement data.

“Today’s shops are looking for increased compatibility and integration of systems and data throughout the design-build process. Our mutual commitment to Mastercam as an open and proven platform catalyzes Verisurf and CCCS. Together, we provide practical solutions to help customers design, build, and verify products more efficiently,” said Nick Merrell, executive vice president of Verisurf Software, Inc.

For 30 years, CCCS has provided sales and support of CAD/CAM software and other solutions for the efficient programming of CNC machines. The Company partners with leading providers of CAD, CAM, DNC, shop management systems, machine tool manufacturers and distributors, and now Verisurf Software to offer integration and support services throughout the region.

“We have been a close partner with Verisurf for many years, and we’re honored and excited to be able to enter the next level of our relationship as a Reseller. We strive to offer our customers sales, service, and support in their entire manufacturing process. The addition of Verisurf allows CCCS to be one step closer to realizing that goal. We only provide the best-in-class products, and Verisurf is just that,” said Patrick Shelar, president of CCCS.

In addition to the products and services CCCS offers, Verisurf software allows CCCS to close the loop in the manufacturing process by including Inspection, Reverse Engineering, and real-time metrology-based assembly, all on the same Mastercam platform. The complete shop floor inspection solution includes everything needed to begin in-process and first article inspections and reporting right out of the box.

For more information, visit www.verisurf.com.

America Makes Announces Winners of IMPACT Project Call Totaling $11.7M

The National Center for Defense Manufacturing and Machining (NCDMM) and America Makes are proud to announce the winners of the “Improvements in Manufacturing Productivity via Additive Capabilities and Techno-Economic Analysis (IMPACT)” directed project call funded by the Office of the Under Secretary of Defense, Research and Engineering Manufacturing Technology Office (OSD(R&E)) and the Air Force Research Laboratory (AFRL), worth a total of $11.7M.

The objective of the IMPACT project call is to demonstrate productivity and yield benefits for casting and forging manufacturing via additive manufacturing (AM) technologies, execute techno-economic analysis for metal powder AM, and to bridge component sourcing gaps with AM parts for casting and forging applications. Additionally, the project call was seeking innovative solutions in robotic AM process planning for continuous fiber-reinforced composite structures.

AM is of significant interest to the U.S. manufacturing base as the technology enables shorter lead times, mass customization, energy reduction, complex shapes, and production of parts on demand providing benefits to both new acquisitions and legacy systems. “This project call addresses the needs of a broad cross-section of our nation’s supply chain including the casting and forging industry,” stated Brandon Ribic, Ph.D., America Makes Technology Director. “The U.S. government considers metal casting and forgings to be one of the most critical supply chain items to our national defense and economic health. Thus, we see the need for casting and forging operations to seek advanced manufacturing capabilities that can upgrade production capacity, improve throughput, reduce cost, and take risks out of the supply chain equation. The awardees of this project call will work to shed light on the critical need for long-term strategic investments in AM to strengthen the U.S. supply chain.”

Additionally, the techno-economic analysis study on metal powder AM seeks to prioritize investment areas to improve the business case of one of the most mature AM processes. The research in robotic planning strategies for continuous fiber-reinforced printing aims at reducing the producibility barriers of autonomous unmanned aerial vehicles. “Applying the full 3-dimensional power of advanced manufacturing technologies, such as industrial robotic arms to use for AM applications can unlock many unseen potentials,” stated John Martin, America Makes Additive Manufacturing Research Director.

Below is the list of award winners and related topics/projects:

- Topic 1: Develop/disseminate leading practices and accelerate the adoption of 3D printed molds/cores for sand castings

- Project 1: Implementing Best Practices and Technology Improvements for 3D Printed Molds/Cores for Sand Castings

- Team Lead: Honeywell International, Inc.

- Project Team: American Foundry Society; Chicago Magnesium Casting Co.; ExOne; Hoosier Pattern, Inc.; Ohio Aluminum Industries, Inc.

- Topic 2: Mature AM ceramic technology and promote adoption for rapid, low-volume production of investment castings for defense applications

- Project 1: AM Ceramic Shell Technology for Investment Casting

- Team Lead: Investment Casting Institute

- Project Team: Alfred University – Center for Advanced Ceramic Technology; Barron Industries, Inc.; Bescast, Inc.; Concurrent Resources, LLC; Intrepid Automation; Kovatch Castings, Inc.; Lithoz America, LLC; Metaltek International – Wisconsin Investcast Division; Missouri University of Science and Technology; O’Fallon Casting; Pennsylvania State University; Product Development & Analysis, LLC; Rangeview, Inc.; SeaCast, Inc., Shell Cast, Inc.; Signicast, LLC; Tethon 3D; University of Arizona; University of Texas El Paso

- Project 2: 3D CREATE – 3D Ceramic Research & Extensive Application of Tools for Engineered Molds

- Team Lead: Renaissance Services, Inc.

- Project Team: Aspen Technology, LLC; Product Development & Analysis, LLC; The Ohio State University, Center for Design and Manufacturing Excellence; University of Northern Iowa Metal Casting Center

- Project 3: Maturation of Ceramic 3D Printed Shell-based Investment Casting Foundry Capabilities of the 76th CMXG at Tinker Air Force Base

- Team Lead: DDM Systems, Inc.

- Project Team: Air Force Sustainment Center 76 CMXG, Mueller Additive Manufacturing Solutions

- Topic 5: Optimizing Forging Preforms Production Using Different Additive Manufacturing Routes: Process Selection, Testing, and Performance Evaluation

- Project 1: Pilot the Industrialization of AM preforms to Expedite the Forging Process for Low-Volume Forged Components

- Team Lead: Cleveland State University

- Project Team: Canton Drop Forge; FasTech, LLC; Forging Industry Association; Georgia Southern University; SIFCO Industries, Inc.; and Wright State University

- Topic 6: Develop and disseminate leading DED and cold spray practices to promote adoption of die repair for forging applications

- Project 1: DED Additive Manufacturing for Forging Die Repair

- Team Lead: Cleveland State University

- Project Team: Absolute Welding and Machining; Canton Drop Forge; FasTech, LLC; Forging Industry Association

- Topic 8: Techno-economic analysis and manufacturing readiness assessments to address bridging component sourcing gaps with AM parts for critical casting and forging production

- Project 1: Casting & Forging Techno-Economic Framework

- Team Lead: Deloitte Consulting, LLP

- Project Team: N/A

- Project 2: Techno-Economic Analysis and Assessment to Bridge Sourcing Gaps between Casting and Forging to Additive Manufacturing

- Team Lead: Wichita State University – National Institute for Aviation Research

- Project Team: N/A

- Topic 9: Powder AM techno-economic analysis

- Project 1: Techno-Economic Analysis of Metal Powder Bed Fusion for the Air Force

- Team Lead: Wohlers Associates, Powered by ASTM International

- Project Team: NA

- Topic 10: Innovations in robotic additive manufacturing process planning

- Project 1: 3D Toolpathing Software Advancements for Steered Continuous Fiber Robot Process Planning

- Team Lead: Continuous Composites, Inc.

- Project Team: N/A

Project teams will report on their progress with these projects at the America Makes Technical Review and Exchange and other industry events during the execution phase of the program.

Basler, Siemens Join Forces to Enhance Machine Vision, Factory Automation Capabilities

At right: Basler’s CEO Dr. Dietmar Ley and Rainer Brehm, CEO Factory Automation at Siemens, agree on their companies’ partnership: combining Basler’s machine vision and Siemens’ automation expertise.

Basler AG announced its new partnership with the technology company Siemens. This strategic partnership will make it much easier for automation customers in all industries to integrate machine vision solutions directly into their automation systems.

The cooperation between Basler and Siemens will bring significant benefits to customers. System integrators, machine builders, and professional end users looking to use computer vision will have easy access to innovative, automated, and easy-to-integrate solutions through this partnership. This will allow them to streamline their production process, increase efficiency, lower costs, as well as improving transparency and quality control—all aimed at maximizing overall productivity.

The first result of this alliance is the Basler Vision Connector—a powerful, easy-to-use app that allows Basler's vision components to be easily integrated into Siemens' Industrial Edge ecosystem. "The Vision Connector is a game changer for our customers," explains Dr. Dietmar Ley, CEO of Basler AG. "By being an integral part of the ecosystem, it significantly lowers the bar for our customers to integrate computer vision into an existing automation system." In addition, the Basler Vision Connector will also be integrated into Siemens’ SIMATIC TIA ecosystem, enabling customers to freely choose the best-fitting solution for their applications.

This connectivity represents a significant improvement in the use of machine vision. "We are very excited about our new partnership with Siemens," said Ley. "By combining our expertise in machine vision with Siemens' strong background in the automation and digitalization market, our collaboration will allow us to offer pre-tested application scenarios and aligned product portfolio options for customers to choose from. We are able to develop solutions that can help them significantly reduce their time-to-market."

This is only the initial phase of the partnership; plans are in place to broaden its scope to encompass a wider array of computer vision applications by offering Basler's pylon SDK on Siemens’ automation devices. This will allow customers to easily and seamlessly integrate vision applications into their automation processes, including conventional computer vision functionality as well as performing evaluations based on machine learning. The partnership also includes aligning customer support between the two companies to ensure that customers have a single point of contact for information and advice.

“Together we’re integrating machine vision into automation. This helps with many tasks, for example when it comes to difficult quality control or to reduce errors and thus defects in industrial production, or to react to the shortage of skilled workers. In doing so, we are taking an important step towards an adaptable, sustainable production and increasingly autonomous production processes,” says Rainer Brehm, CEO Factory Automation at Siemens.

For more information, visit www.baslerweb.com.

Carestream Announces Upcoming Retirement of Chairman, President and CEO Westgate; Names Clegg Interim President, CEO

Carestream announced the retirement of David C. Westgate, the company’s Chairman, President, and Chief Executive Officer, which occurred on December 1, 2023. Carestream’s Board has appointed Todd Clegg to be interim President and CEO, effective December 1, 2023.

“On behalf of the entire Board, I want to express our sincere thanks to Dave for his leadership of Carestream. Dave oversaw and directed significant accomplishments that contributed to the success of the company during his tenure including the 2019 divestiture of the Health Care Information Systems business, navigating through the global pandemic and executing a successful restructuring that resulted in fundamental changes to the company’s financial position and global footprint,” said Robert Rasmus, Director on the Carestream Board.

Mr. Clegg is an experienced executive, investor and board member. From 2005 to 2022, he was a Managing Director of Onex Corporation, a Canadian investment management firm that owned Carestream from 2007 until 2022. He was involved in the formation of Carestream when it was carved out of Kodak in 2007, spent a year working at Carestream in 2010 and partnered closely with Carestream’s leadership team as a member of its Board from 2019 to 2022. Mr. Clegg is a current board member of Lannett Company, QualTek Services and The Goddard Center. He is a prior board member of over 10 large corporations and graduated from the University of Pennsylvania’s Wharton School of Business.

For more information, visit www.carestream.com.

Generational Equity Advises Q-PLUS Labs in Sale to Industrial Inspection & Analysis

Generational Equity, a mergers and acquisitions advisor for privately held businesses, announced the sale of its client Q-PLUS Labs to Industrial Inspection & Analysis, Inc. (a portfolio company of SRM Equity Partners). The transaction closed November 1, 2023.

Since its founding in 1987, Q-PLUS Labs (located in Irvine, California) has built a reputation as a leader providing a wide range of quality dimensional measurement, inspection, reverse engineering, 3D scanning, CT scanning, modeling, part sorting and quality-related services and products. Q-PLUS Labs is ISO 9001:2015 registered, ISO 13485:2016 and AS9100D certified, and ISO 17025:2017 accredited.

Based in Atlanta, Georgia, Industrial Inspection & Analysis (IIA) has an extensive footprint across North America and an ever-expanding global presence in the industrial sector. With the addition of Q-PLUS Labs, Industrial Inspection & Analysis has 15 locations, including nine laboratories, across North America and China.

“We are excited to bring Q-PLUS Labs on board, and we look forward to growing together. As we leverage our combined lab expertise, technology and geographic footprint, this acquisition represents a win for both of our companies, as well as current and future customers,” says Christopher Niebuhr, Chief Executive Officer of Industrial Inspection & Analysis.

Niebuhr added, “Q-PLUS Labs will enhance Industrial Inspection & Analysis’s premier Laboratory Services division and allow us to better serve customers on the West Coast. We are excited to welcome Q-PLUS Labs’ talented team to the IIA family.”

“The team at Q-PLUS Labs has decades of experience helping manufacturers perfect their products. We are excited to bring our expertise and culture of excellence to Industrial Inspection & Analysis,” says Mike Knicker, CEO of Q-PLUS Labs.

Knicker added, "As part of the Industrial Inspection & Analysis family, we will be able to provide our customers access to additional laboratory, inspection and engineering services that complement what we do, while still providing the great customer service and extreme attention to detail we are known for.”

Generational Equity Executive Managing Director of M&A – Western Region, Stephen Crisham and his team, led by Sr. Managing Director Mergers & Acquisitions, Fred Zweifel, with support from Sr. Managing Director - Western Region, Lori Galloway closed the deal. Executive Managing Director Bill Kushnir established the initial relationship with Q-PLUS Labs.

For more information, visit https://www.genequityco.com/.

Scholarship Memorializing Metrology Legend, DMSC Co-founder, Bailey Squier, Created for UNC Charlotte Students

With the passing of Bailey Squier, co-founder of Digital Metrology Standards Consortium (DMSC), its Board of Directors contemplated ways to ensure his accomplishments and legacy are not forgotten.

As a symbol of gratitude and admiration for the life and legacy of Mr. Squier, the DMSC Board established the Bailey H. Squier DMSC Metrology Memorial Scholarship.

Curtis Brown, DMSC President, L, and Bailey H. Squier at a recent DMSC meeting.

Serving as the DMSC executive director from 2005 to 2019, Squier’s leadership efforts helped make Quality Information Framework (QIF) into the leading digital metrology standard for Model-Based Enterprise. Prior to DMSC, Squire was well-known throughout the ANSI and ISO standards organizations, with substantial influence over Manufacturing and Quality standards during his 40-year career with the CAM-I organization.

Additionally, Squire was the primary technology architect of the DMIS (Dimensional Measuring Interface Standard) metrology standard which enabled traceability of measurement processes and interoperability between coordinate measuring systems. Curtis Brown, active DMSC President, remembers; “… Bailey had a warm personality that one could never forget. He would draw people to him and leave them smiling when he left. He was just as comfortable discussing nuclear fission as he was talking about weather. We are honored to provide a lasting remembrance with this scholarship.”

The scholarship, established in partnership with the University of North Carolina at Charlotte’s William States Lee College of Engineering, will provide up to two awards annually to students studying Mechanical Engineering with a concentration in Precision Metrology.

Dr. Ed Morse, Director of UNC Charlotte’s Center for Precision Metrology, is a long-standing contributor to the DMSC, in particular with QIF standardization activity. Dr. Morse stated, “In my early years, Bailey Squier was always there with gentle guidance regarding participation, and he was instrumental in arranging UNC Charlotte's membership in the DMSC beginning in 2014. I am thrilled that the DMSC has chosen to create a scholarship at our University to memorialize Bailey. This is a meaningful way for us to remember him and his contributions.”

UNC Charlotte’s Center for Precision Metrology has been producing master’s and Ph.D. graduates for over 30 years, often receiving requests from companies for engineering talent trained in metrology. To meet this need, W.S. Lee College of Engineering has worked with the department of Mechanical Engineering and Engineering Science to develop an undergraduate concentration in precision engineering and metrology that launched Fall 2023. The concentration includes hands-on studies in a newly-outfitted undergraduate metrology lab, four related, technical elective courses, and a two-semester senior design capstone course involving precision engineering. The new Bailey H. Squier DMSC Metrology Memorial Scholarship is designed specifically to support students in this concentration, offered only at UNC Charlotte.

The required high academic standards and attributes will ensure this scholarship reflects Squier’s affinity for leadership, engineering and metrology. The inaugural award for this newly announced memorial scholarship will be for the Fall 2024 semester.

For more information, visit www.qifstandards.org.