Guest Column | Ian R. Lazarus

Speaking of Quality | Jim Spichiger

Face of Quality | Jim L. Smith

Other Dimensions | Hill Cox

From the editor | Darryl Seland

Zeiss Donates Powerful Primo Star Digital Classroom Microscope to White Plains High School

Zeiss announces it recently donated a Primo Star Digital Classroom Microscope to the White Plains School Department, in White Plains, NY. The Primo Star features an integrated HD streaming camera and Labscope imaging software, an easy-to-use imaging app that enables teachers to connect several classrooms to a network. Also donated was an Axiocam 208 8 megapixel color microscope camera, ideal for helping science teachers presenting and sharing laboratory activities. Several White Plains High School science teachers are using the equipment in biology, environment, and other classes to enhance lab activities for both students in the classroom and those working remotely. The donation was made as part of Zeiss’s Science Classroom Outreach Program for Educators (SCOPEs) Grant, established to help teachers face the new challenge of educating students through remote learning.

“It is difficult to offer authentic science learning experiences when you do not have kids in front of the microscope, and they cannot touch things,” said Dr. Margaret Hawthorne Doty, Coordinator of Science and Engineering for White Plains Public Schools. “The Zeiss equipment provides an incredibly valuable resource that helps students feel like they’re getting authentic science at a time when its challenge to do so.”

Integrating Zeiss network-compatible microscopes with imaging systems lets teachers easily create digital classrooms or digital labs and share images with the touch of a finger. The equipment also enables teachers to record high resolution images and videos and share images, reports, and videos.

“With the Zeiss equipment, whether participating in virtual labs or using microscopes in school, all students will be seeing and observing the same thing,” said Jorge Gonzalez, a White Plains High School teacher. Two students can be in the laboratory using microscopes, while the rest can see what the other students are doing on the same day.”

Despite the challenges associated with the COVID-19 pandemic, the SCOPEs Grant helps to ensure science students can stay connected and learn from home. The SCOPEs Grant is open to K-12 science teachers in Putnam, Rockland, and Westchester Counties, New York; Bergen County, New Jersey; and Fairfield County, Connecticut.

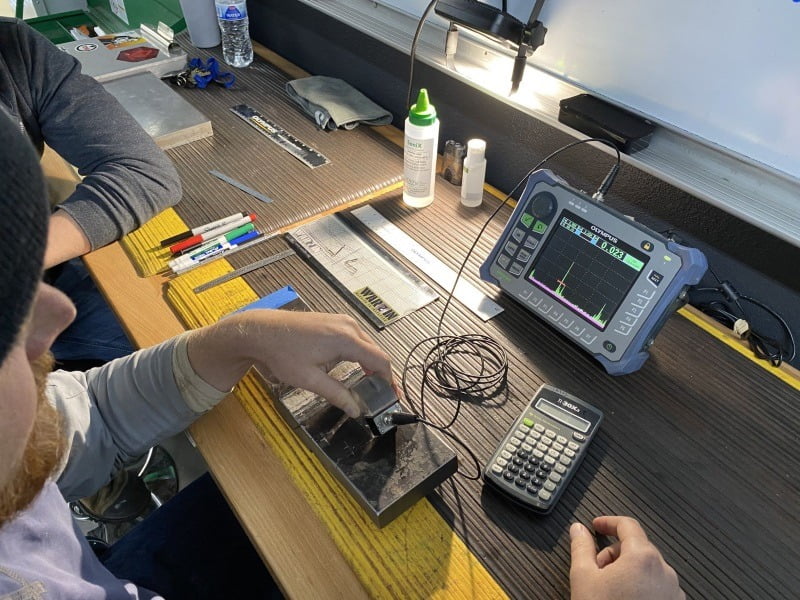

Collaboration Helps Military Veterans Transition into NDT Careers

Olympus is supporting training school Warrior To Inspector’s mission to help transition retiring military veterans into a new NDT career by providing advanced inspection instruments for their ultrasonic testing (UT) courses.

Transitioning into an NDT career can be challenging without the right training, certifications and hands-on experience. Warrior To Inspector helps veterans find job success through their 3-semester, full-time NDT program that offers classroom and field training on real-world job sites. This ASNT CP-189 compliant program includes certifications in magnetic particle testing, ultrasonic thickness testing, ultrasonic shear-wave testing, phased array ultrasonic testing and Creaform laser profilometry.

This collaboration will enable veterans to train with Olympus’ cutting-edge UT equipment used in the NDT field today.

“We’re very excited to contribute to the Warrior To Inspector mission,” said Dave Menne, VP of Sales and Marketing at Olympus. “Kenny Greene and his team are exceptional trainers with a unique educational approach. The veterans and other civilians in the class are clearly energized to be in such an impressive program.”

Kenny Greene, President and Lead Instructor of Warrior To Inspector, explained how Olympus has remained a vital resource for their programs. “During a significant project in 2004, Olympus showed how committed they were to customer service. Olympus brought in as much demo equipment as we had purchased to help ease the burden of outfitting a team of shear-wave technicians. Again in 2011, I was part of another quickly growing NDT department in need of phased array equipment. This led to a very large purchase of OmniScan™ MX2 flaw detectors, and the Olympus team exceeded all expectations again,” said Greene.

Greene continued, “As I am tasked to create an NDT and Pipeline Integrity Trade School that the industry has been demanding for decades, Olympus is once again there for us as we help meet the needs of military veterans and civilians and join their commitment to training tomorrow’s inspectors.”

Smart Vision Lights Awarded ISO 9001:2015 Certification for QMS

Smart Vision Lights (SVL) announced that it has earned ISO 9001:2015 certification for its quality management systems (QMS).

ISO 9001:2015 is an international QMS standard developed and published by the International Organization for Standardization. The standard is based on several quality management principles, including an outlined process-based method, strong customer focus, and involvement of upper-level company leadership. Organizations worldwide use the standard to demonstrate the ability to consistently provide products and services that meet customer and regulatory requirements.

Smart Vision Lights’ ISO 9001:2015 certificate was issued by American Systems Registrar, an international ANAB-accredited and IATF-approved registrar. The scope of SVL’s certification includes design and build of LED light assemblies for machine vision lighting systems.

“It is the purpose of Smart Vision Lights to provide our customers with the highest quality product at the lowest cost and deliver that product on time. A promise made is a promise kept,” said SVL president and CEO Dave Spaulding. “Our ISO 9001:2015 certification exemplifies our commitment to quality assurance and safety.”

The path to certification requires time and commitment. SVL began the process in May 2020 and was officially notified of its approval at the end of October. Annual audits are required for a company to retain its certification.

Report: Reshoring Up Despite COVID

In 2020 reshoring is exceeding foreign direct investment (FDI) in job creation. Reshoring will continue to be key to manufacturing growth and to U.S. economic recovery in 2021 and beyond. From 2010 through 2019 over 900,000 reshoring and FDI manufacturing jobs have been announced. Allowing for a conservative two-year lag, over 600,000 will have been hired. This figure accounts for 44% of the 1.41 million increase in U.S. manufacturing jobs since the manufacturing employment low in 2010, and 5% of total 12/31/19 manufacturing employment of 12.9 million.

The 2019 combined reshoring and FDI announcements totaled more than 117,000 manufacturing jobs, the third highest pre-revision annual rate on record. Additionally, the number of companies reporting new reshoring and FDI in 2019 was at the second highest annual level in history, 1,100 companies. The numbers demonstrate that reshoring and FDI are major contributing factors to the country’s rebounding manufacturing sector.

The Reshoring Initiative’s 1H2020 Data Report contains data on U.S. reshoring and FDI by companies that have shifted production or sourcing from offshore to the United States. The report includes cumulative data from 2010 through 2019, as well as projections from 2020 1st half data and provides data and analysis in 10 categories, ranging from the number of manufacturing jobs gained, to reasons cited for reshoring, to a breakdown of data by industry, country, region and state.

Top Takeaways from the Report:

- Due to the pandemic, in 2020 we are seeing U.S. reshoring outpacing FDI for the first time since 2014. COVID uncertainty is causing companies to emphasize operations in their home countries.

- The national demand to shorten and close supply chain gaps for essential products to make the U.S. less vulnerable is most likely to benefit the following industries: PPE, medical, tech, and defense. Already, 60% of cases after March 2020 mention the pandemic as a factor in reshoring decisions.

- Going forward, we believe President Biden will prioritize reshoring highly but apply different methods than President Trump.

- There is continued growth in efforts by MEPs, EDOs and states to enable reshoring. The Reshoring Initiative is deeply involved in these efforts. By year’s end we will be working with 50 or more companies to reshore about 100 products. As a measure of corporate interest, the demand for this service is more than 20X the rate of 2019. Companies are doing their best to reshore, and we are here to help.

“We publish this data annually to show companies that their peers are successfully reshoring and that they should reevaluate their sourcing and siting decisions,” said Harry Moser, founder and president of the Reshoring Initiative. “With 5 million manufacturing jobs still offshore, as measured by our $800 billion/year goods trade deficit, there is potential for much more growth. We call on the administration and Congress to enact policy changes to make the United States competitive again. Our Competitiveness Toolkit is available to help quantify the impact of policy alternatives, including a stronger skilled workforce, competitive corporate tax and regulatory structures and a lower U.S. dollar.”

OGP Celebrates the Big 7-5

Optical Gaging Products (OGP), a division of Quality Vision International Inc (QVI®), is celebrating its milestone 75-year anniversary as a world-leading manufacturer of precision multisensor metrology systems for industrial Quality Control.

Chairman and CEO Edward T. Polidor, remarked, “In my time with the company, I have witnessed a dramatic change in how optical instruments perform measurement. When OGP was founded 75 years ago, users typically relied on microscopes and optical comparators, depending entirely on their own judgement to ascertain the measurement. Today, the modern automatic video measuring system is completely computer controlled, using video cameras that depend little on the operator’s visual skills to produce accurate measurements. How these systems became more accurate, automated, faster, and ever more capable is OGP’s contribution to this remarkable transformation.”

OGP has enjoyed a long history of innovation. The company started from humble beginnings in post-war 1945 producing optical comparators. Automatic edge detection for the optical comparator was developed in 1956 in the form of Projectron, an early electro-optical image sensing system. OGP introduced the first truly revolutionary computer controlled automatic video measuring system in 1980 – the Vidicom Qualifier. Then, OGP pioneered multisensor measurement by adding lasers and touch probes to video systems starting in 1986 with the IQ-2000, and the technology advancements continue today with a wide range of powerful multi-sensing systems.

OGP systems have played a vital role in ensuring the quality of component parts used in a wide variety of industrial success stories: From personal computers and smartphones, to digital video and electric cars – even the space program. Consumer products produced around the world contain parts measured on OGP systems.

OGP is spending 2020 – 2021 reflecting on the accomplishments that have allowed it to achieve international recognition for optical measurement in the highest echelons of industry. Looking ahead, OGP will continue to forge the future. Every day, the employees of OGP innovate and execute, producing practical solutions for the most challenging measurement tasks demanded by its toughest customers. OGP celebrates these innovations in its 75th year.

R. Stephen Flynn, president of OGP, added, “We have been an international company for over half of our 75 years, having established subsidiary offices in multiple countries, and channel partners covering every industrialized corner of the globe to support our growing list of customers on a local basis. During our anniversary celebration, we recognize and celebrate our channel partners and employees for being such an integral part of our success over these 75 years.”

U.S. Manufacturing Technology Orders Up 26.4% in September

U.S. Manufacturing Technology Orders totaled $373.7 million in September 2020, an increase of 26.4% from August 2020, and the highest monthly total of the year, according to the latest U.S. Manufacturing Technology Orders report published by AMT – The Association For Manufacturing Technology. The September total decreased 3.2% from September 2019, and orders to date reached $2.32 billion, nearly a quarter lower than the 2019 YTD total.

“In addition to the positive numbers this month, we are now seeing the economic recovery reach a broader spectrum of the overall capital equipment market,” said Douglas K. Woods, president of AMT. “Manufacturing is ramping back up as production, shipments, and order levels continue to improve throughout most sectors. The high demand for mold-and-die products during the height of the pandemic led to reshoring portions of the industry’s output. Additionally, a strong housing market continues to expand demand for household appliances, creating backlogs that will keep production lines busy into the winter.”

“Unfortunately, there are still a few soft spots. The aerospace and oil & gas sectors, representing almost a third of our industry’s orders, will likely need several years to return to pre-COVID levels of shipments and capital spending. Still, opportunities exist, even in the hardest-hit sectors, such as growth in space and defense sectors in the aerospace industry.”

“Unlike the recovery from the great recession, this recovery will not impact manufacturing sectors equally. Material handling, mold and die, and firearms will have a better year in 2020 than 2019. Manufacturing technology, cutting tools, and industrial machinery will return to 2019 levels sometime next year, but some key sectors will not see growth until after 2021.”