Software

Management

Measurement

Test & INspection

Quality 101

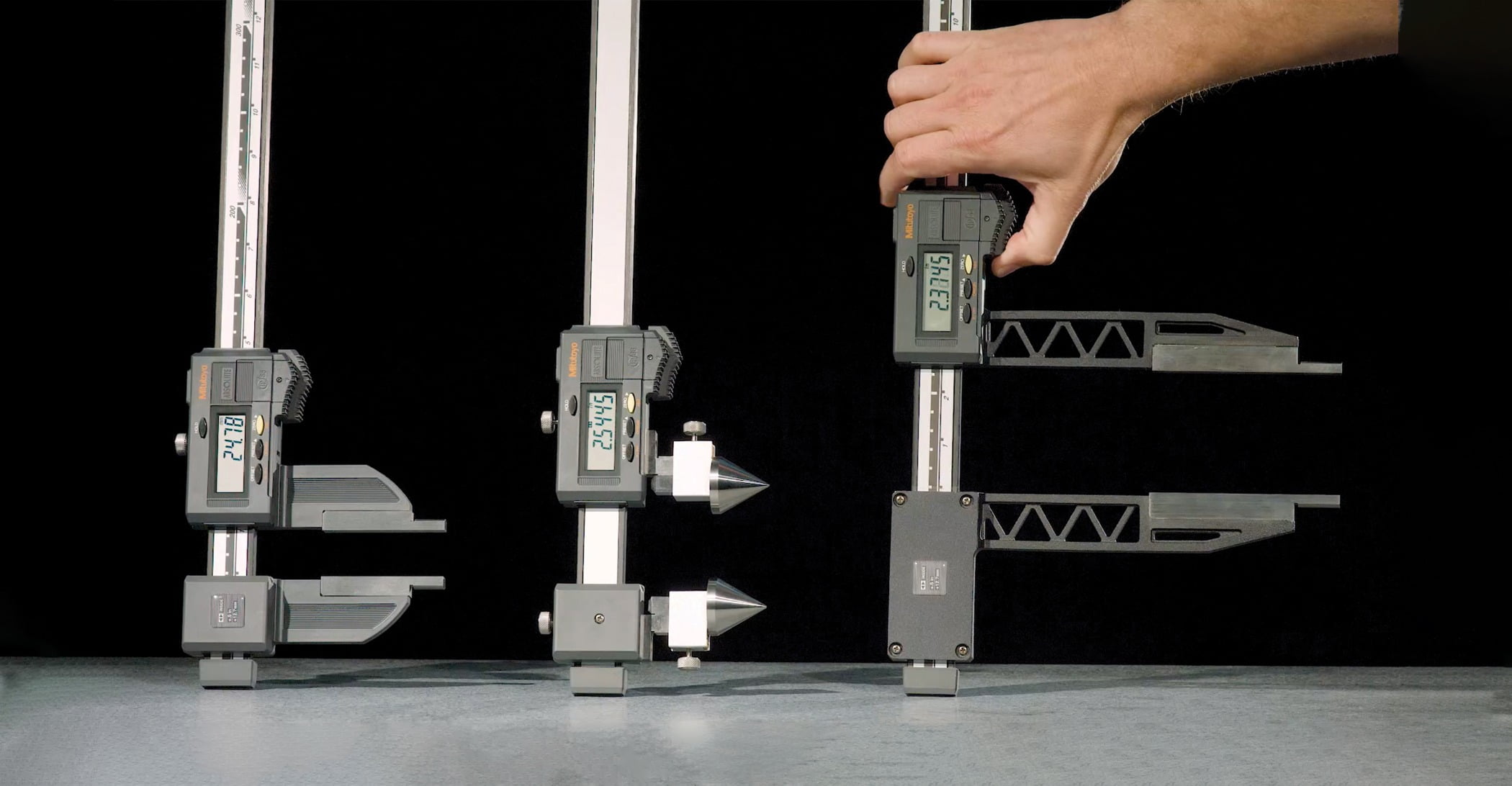

Example of Carbon Fiber Calipers. Carbon Fiber calipers are a lightweight alternative ideal for large, long-range calipers. Source: Mitutoyo America Corporation

The basics and beyond.

By Michal Grosenbach

Calipers 102

Calipers are an integral tool for many applications, yet they’re a tool that likely doesn’t garner much reflection. Whether you’ve been using them for years or are investing in them for the first time, here are the ins and outs of caliper design and use that you’ll want to keep in mind.

Caliper Types: A Rundown

There are essentially four different types of calipers:

- Standard calipers, which are typically a type of stainless steel.

- Coolant Proof calipers, which are also stainless steel, but with other materials in the detector that are specially formulated to come into contact with coolants, harsh fluids and liquids used in the industry. And in some cases, because they are IP67 rated, they are used in the presence of fine dust that can easily get into standard electronics.

- Carbon Fiber calipers, which are a lightweight alternative ideal for large, long-range calipers.

- Plastic calipers, which are usually used for do-it-yourself type projects, come in both digital, dial and Vernier types. Due to their construction, they’re less accurate and less rigid.

Caliper Materials: What’s New?

Zirconia ceramic is a newer caliper material. It’s used for contacts on some models of carbon fiber calipers, as well as for some test gages and anvils for higher accuracy gages. Zirconia ceramic has an extremely high wear resistance—ten times greater than steel, three times greater than carbide—while also being non-magnetic. That means, if someone were to measure magnets, these types of calipers would not stick. This makes them ideal for electric motor manufacturing, where magnets are incorporated, especially within electric and hybrid vehicles.

Choosing the Right Caliper

While stainless steel remains the industry standard, there are some instances where other materials could be a better fit. For instance, if you’re in need of a larger caliper but also one that is lightweight, ergonomic, and easier to handle, a carbon fiber caliper is an ideal choice.

It’s important to keep in mind that there are also different types of jaws for the different types of calipers. For example, there are extended jaws for stainless steel and carbon fiber calipers, which give you more reach to measure larger diameters or components in general. There is also a nib-style jaw, which is less likely to get bent, dented, or dinged at the tips compared to a standard style jaw. Nib-style jaws are also thicker and wider, and a better fit for measuring inside diameters due to their rounded nature.

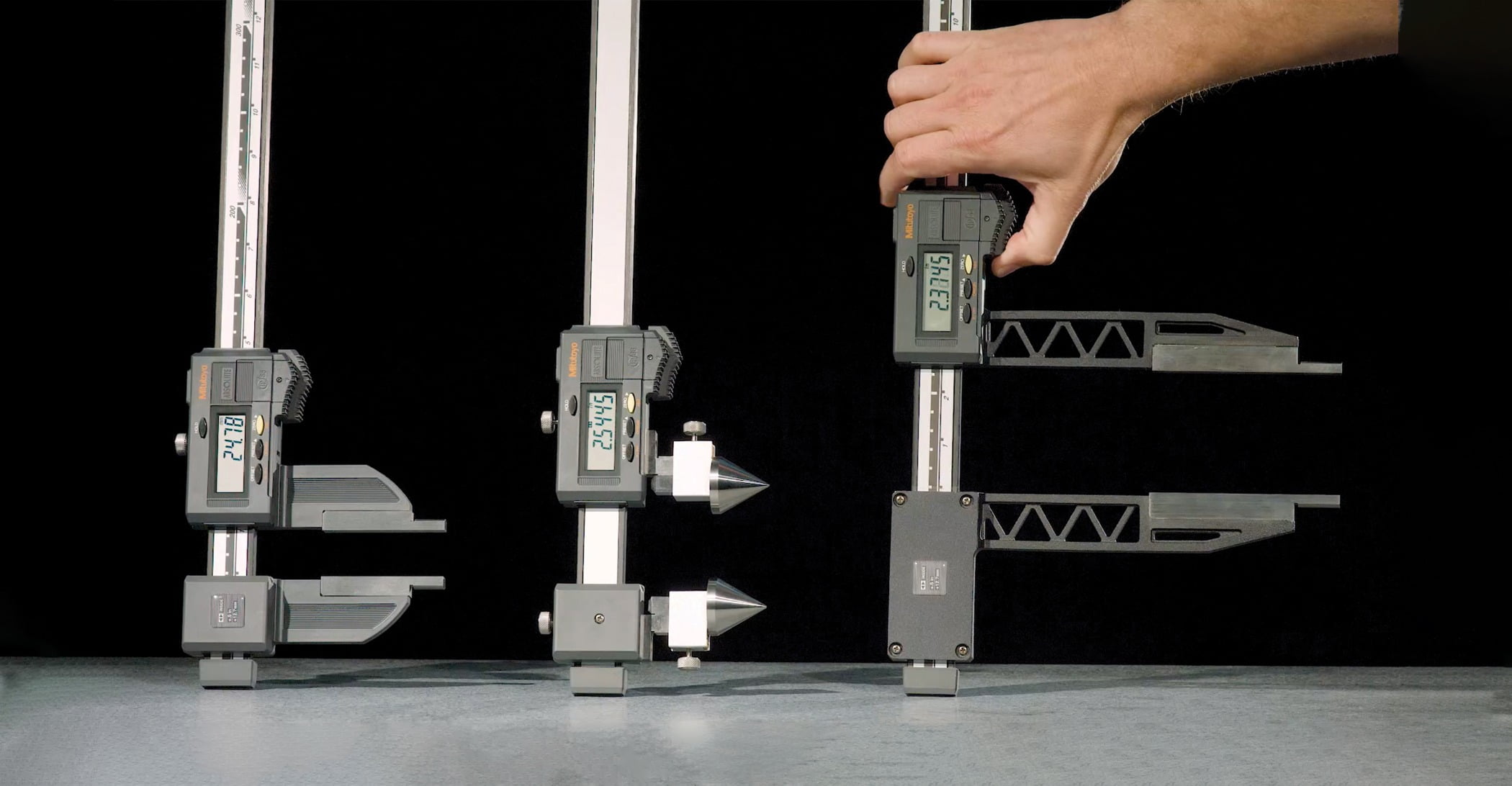

Example of a Leakage Detection System. It’s important to test calipers as it helps to ensure products work as intended right out of the box. For example, the air leakage test is used to verify the international protection rating of a caliper. This signifies whether the caliper will be resistant to dust or coolants, and to what degree. Source: Mitutoyo America Corporation

It’s also good to keep inserts in mind. While the standard for carbon fiber inserts is generally stainless steel, ceramic inserts are also available. Ceramic inserts tend to have better wear resistance, so if operators are rough with the calipers, they won’t be damaged versus using stainless steel that can be dinged. That’s because a ding on a stainless-steel caliper tends to flow the material up, resulting in an irregular surface that can impact accuracy. Ceramic, on the other hand, merely chips out when dinged, preventing material flow that could result in a false surface reading.

The Importance of Caliper Testing

Caliper testing helps ensure products work as intended right out of the box. For example, the air leakage test is used to verify the international protection rating of a caliper. This signifies whether the caliper will be resistant to dust or coolants, and to what degree. This rating is especially important given that modern parts are manufactured in machine tools, where you are not able to take the part out of the machine tool to recheck it for accuracy. There are also robotics tests that calipers undergo to verify accuracy, resulting in inspection or calibration certificates that are included with calipers as another form of quality verification.

Not All Caliper Outputs are Created Equal

Calipers provide a measurement number, which not only confirms or denies the quality of the product, but can also be used for liability purposes, to produce process capability or simply to create a customer report. Manufacturers have created many different types of calipers to help you ultimately get to that essential measurement number. Options include standard calipers with output ports that can support wired or wireless accessories, calipers with built-in wireless output and those with no output at all.

The caliper chosen is typically based on several factors, including convenience and cost. Calipers with no output are the least expensive initially, but costs can accumulate with the time, labor and errors attributed to manually recording measurements. Wired calipers can be a simple and cost-effective solution to quickly and easily get data into a remote display, PC or printer for a fast report, but the cables can be cumbersome. Wireless output can eliminate those issues while still saving time with the push of a button, in addition to maintaining a 6s workplace free of cables.

Caliper Maintenance and Preservation Tips

- To clean and disinfect these tools, it’s recommended to use pure ethanol.

- It’s also recommended to apply a thin layer of micrometer oil and then wipe off the excess. This extends the life of the tool, especially if you’ll be storing it for some time.

- Be sure to keep pressure consistent/use the same force every time.

- Regularly check for damage when you close the calipers, looking for gaps in large jaws that would indicate they’re not parallel and measuring in the same plane. Also, ID jaws should be tilted at a slight angle and you should see a slight light in the straight line.

Calipers with built-in wireless, specifically, can be an attractive option due to their low profile and simplicity. However, if they’re accidentally dropped or damaged, and either the wireless or measuring component is damaged, the entire tool is no longer useful. This results in higher costs due to the need to replace. However, if the caliper has a modular design where the wireless transmitter is an accessory, either can be replaced or repaired independently. And, when the caliper is due for calibration, the transmitter can remain on the shop floor or in the QC lab to continue to share critical measurements.

While Bluetooth is a popular wireless option, some customers question its data security. One alternative is a Zigbee-based transmitter, which is a low-power radio signal that offers better security, transmission distance, and longer battery life. Unlike typical Bluetooth setups, a Zigbee-based system does require a dedicated receiver but it will allow connection to many more transmitters than Bluetooth’s typical 7-device limit.

Example of Coolant Proof Calipers. Coolant Proof Calipers are also stainless steel, but with other materials in the detector that are specially formulated to come into contact with coolants, harsh fluids and liquids used in the industry. And in some cases, because they are IP67 rated, they are used in the presence of fine dust that can easily get into standard electronics. Source: Mitutoyo America Corporation

What to Keep in Mind When Looking for a Caliper Manufacturer

First and foremost, look for a reputable manufacturer that uses quality materials and will be able to repair or replace components down the line, if needed. Keep in mind that calipers produced by less reliable manufacturers can have pitting, might not be parallel or might not even be perpendicular to the surface being measured. In addition, a reputable manufacturer will have a gage you know is going to last, and either have battery indicator warnings when the battery needs to be replaced or have a longer battery life in the first place. Also, be careful when purchasing calipers from third-party sources where there could be a risk of counterfeit products.

Lastly, be vigilant of resolution versus accuracy. Physical or mechanical causes of error, such as Abbe’s Error, create limitations regarding what a gage is capable of when it comes to accuracy. For this reason, simply increasing the resolution of a gage may not have any impact on the accuracy of the gage.