Software & Analysis

Test & INspection

Management

Measurement

Quality 101

Software & Analysis

Management

Measurement

Test & INspection

Quality 101

Software & Analysis

Management

Measurement

Test & INspection

Quality 101

Building a Sustainable Future

What executives are saying.

By Willem Sundblad

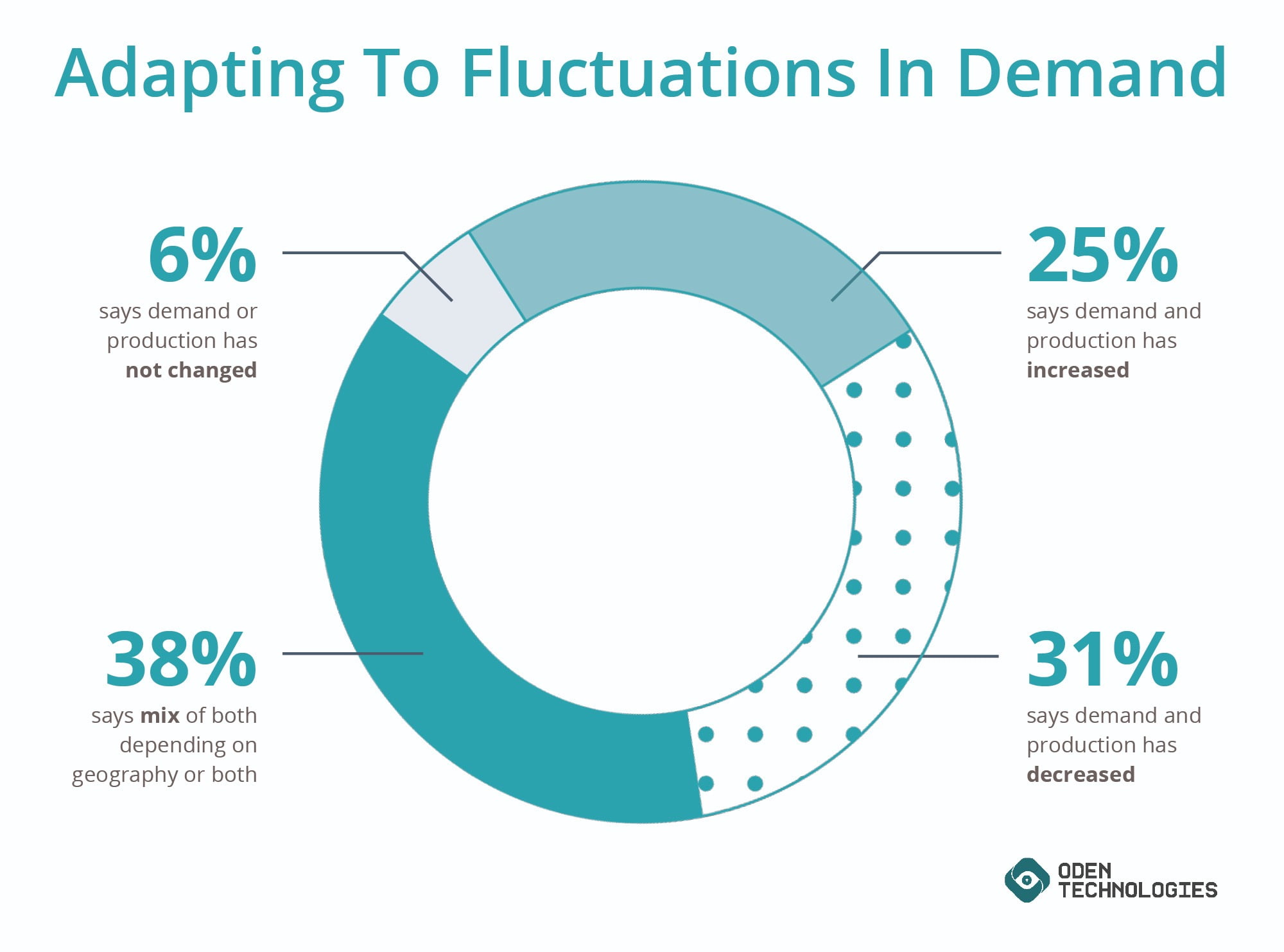

This past year has been ripe with massive disruptions. In fact, 94% of manufacturers surveyed say demand has significantly changed as a result of COVID-19. Manufacturers must work toward the future, with historical levels of supply chain disruption and new workforce agility norms in place.

Oden Technologies surveyed more than 75 manufacturing executives in a State of Manufacturing Report that not only highlights some of the key issues facing the industry but also how executives are preparing for the uncertainty manufacturers will continue to face in 2021.

While it’s difficult to predict the future, one thing is for certain: preparedness is key.

Maintaining Contribution Margins

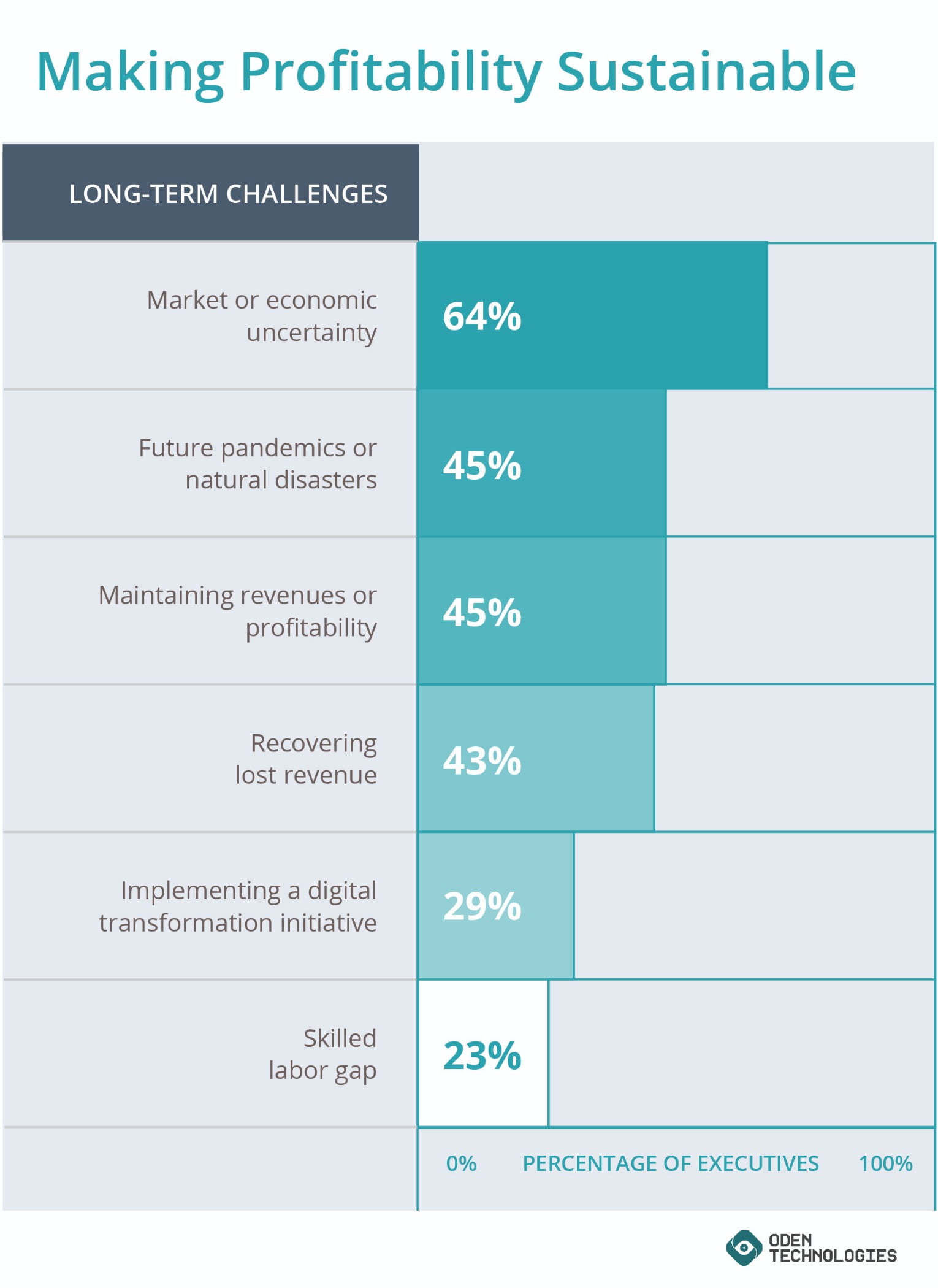

It’s no surprise that over 50% of executives cited minimizing costs to maintain profitability as a top challenge. Executives are identifying new priorities as a means to ensure financial resilience.

“Lean startup mentality and incremental growth with a return to fundamentals are crucial in battling through a changing marketplace as well as tsunami-like risks,” said David Rosen, CEO and Founder of Kira Labs. “Reducing fixed costs is essential to weathering the ongoing and unplanned market. Innovation, R&D, and regular partner communication is also key to staying ahead of potential demand and supply issues.”

Graphic 1. Adapting to fluctuations in demand. Source: Oden Technologies

A key area of growth for manufacturers is leveraging data and analytics to help control operational costs. Better, more accessible data helps reduce process variance in addition to allowing manufacturing teams to react quickly and fix potential problems before they have a significant impact on margins. Organizations that are leveraging this strategy say they have improved production performance along with reduced quality failures, further improving margins.

“Manufacturing businesses have long looked to technology as a means for cost reduction in operations,” said Drew Caylor, Managing Director of WILsquare Capital. “What I think many manufacturers will discover through this crisis are the sales opportunities that can be created through digital marketing and e-commerce. The opportunity to reduce the distance between manufacturers and end-users through digital technology may be more transformative than the newfound ability to occasionally work from home.”

In times of uncertainty, it is crucial to focus efforts on production aspects that can be controlled rather than aspects, like the economy, that manufacturers have no control over. Forward-looking organizations are working to identify opportunities to improve operational resilience and put processes in place that enable adaptability.

Preparing For the Skilled Labor Shortage

In 2019, the predicted labor shortage was a major concern for manufacturers. However, only 23% of executives say that the skilled labor gap is a long-term challenge. As the working population ages and the number of retirees continues to increase, there will still be a lack of skilled workers to replace them.

“I think in the next few years there will be a skill mapping shortage,” said Manju Parkhe, a senior leader in manufacturing. “In the new world of post-COVID-19, a line operator may need to end up doing quality testing, and that operator may not have the skills or be used to IT testing on a circuit board. Skills need to be upgraded or enhanced.”

As technical challenges continue to grow, manufacturers need employees who can grow in tandem. This is about providing interesting and fulfilling jobs that are not weighed down by the historical constraints of one person or one skill.

Graphic 2. Making profitability sustainable graphic. Source: Oden Technologies

Think Differently About Labor and Upskilling

The loss of domain knowledge as workers retire presents a significant risk for manufacturers. The first step to mitigating the risk is to translate that domain knowledge into intellectual property. This compilation of intellectual property or tribal knowledge can be achieved by systemizing it and putting it into business workflows and processes that can be used to train new employees.

Machine learning technologies can play a significant role in capturing domain knowledge by analyzing data from past production runs to identify the process settings that contributed to your most, and least, profitable and efficient runs. These technologies can then offer recommended settings that enable any employees to replicate profitable production runs consistently.

“There needs to be a shift to have employees better use their time so that people are valued for their decision making and their ability to leverage technology to increase their productivity,” said Christopher Lind, Head Of Global Digital Learning, GE Healthcare. “People are tapped out in their current roles with too much to do, so prioritizing [digital transformation] can also help drive employee engagement because they are spending more time on things they care about.”

Investing in technology can also create awareness and interest in opportunities available in the manufacturing industry. The next generation doesn’t want to be performing repetitive tasks. They value the opportunity to learn data analysis tools and how to manage or maintain automation equipment.

Accelerating Digital Transformation, Again

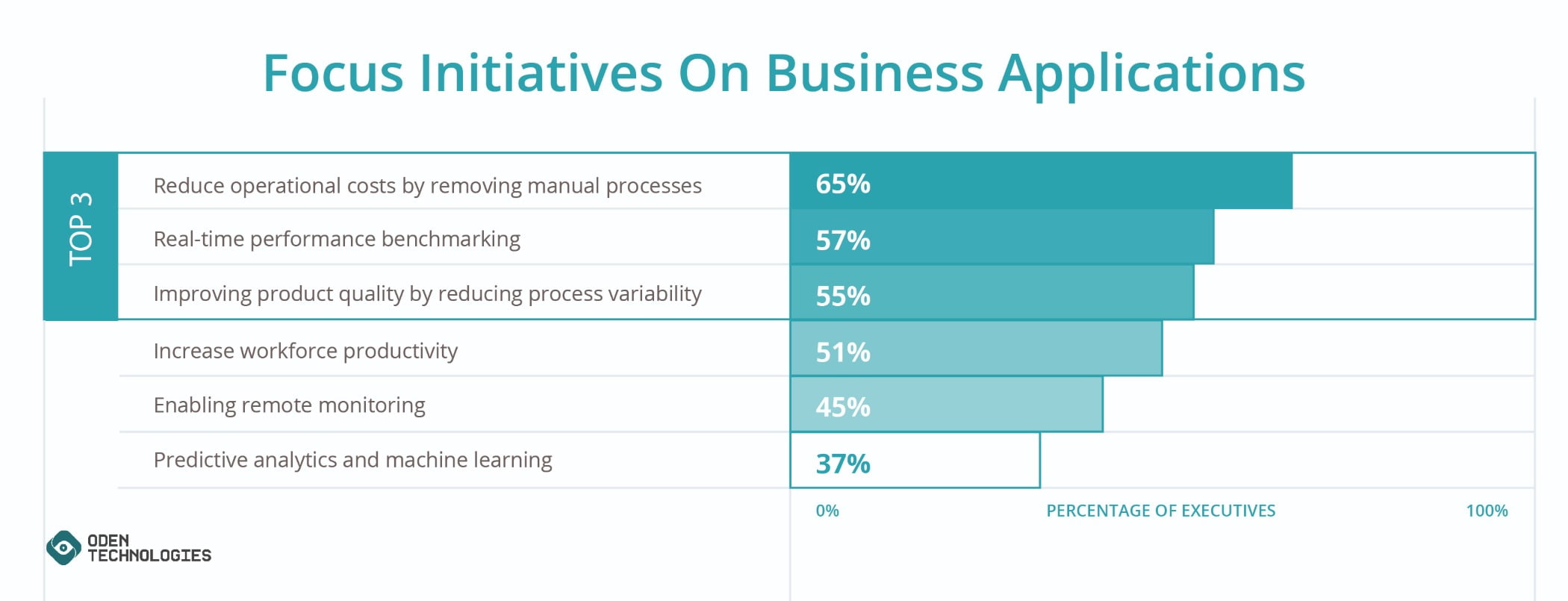

Executives have consistently stated that digital transformation is a top priority, so it’s no surprise that 71% of manufacturers said that digital transformation has increased in importance as a result of COVID-19.

In the past, implementation has been slow. The success rate has been extremely low, with less than 30 percent of organizations succeeding in implementing an effective digital solution, according to McKinsey & Company.

Starting with a business problem, such as high scrap rates that increase operational costs, can help provide the focus needed to map out a successful application. Other areas that are top-of-mind for manufacturers are enabling real-time performance benchmarking along with reducing process variance to improve product quality.

Graphic 3. Top digital transformation initiatives. Source: Oden Technologies

Building Alignment Around Digital Transformation

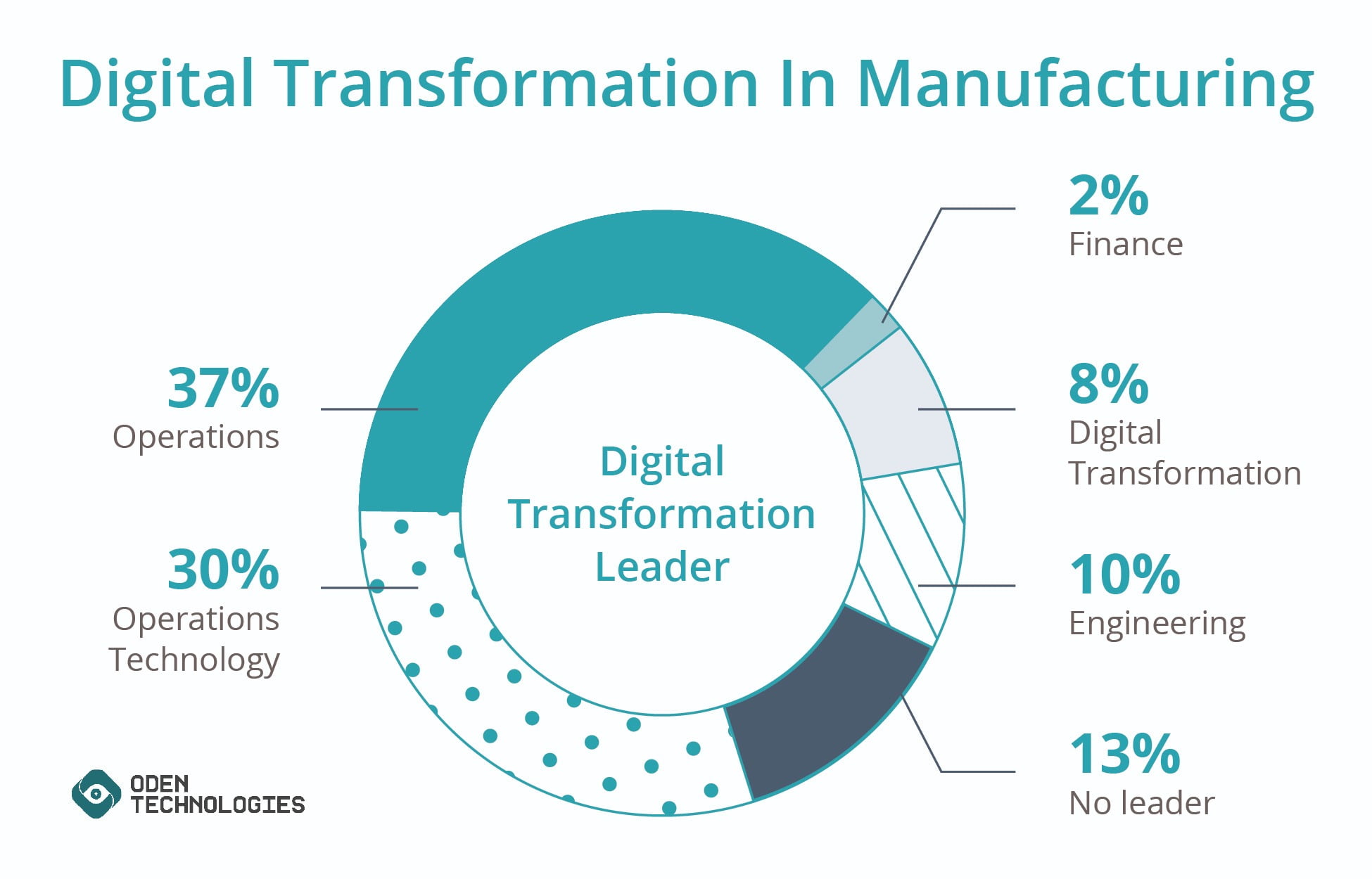

Having strong leadership at the top is a key to success in digital transformation, and 76% of manufacturers have appointed leaders. While digital transformation is heavily technology-centric, it’s a mistake to focus only on the roles that are tech-intensive when building out your leadership team.

“There’s a myth that digital transformation is more tech-focused. In reality, it’s the people that make it happen,” said Christopher Lind, Head of Global Digital Learning at GE Healthcare. “If you're viewing it through a single lens, digital transformation can look overly simplistic. But when the implications for all affected employees, business units, functions, and geographical groups are considered, it becomes exponentially more complicated.”

Digital transformations are a cultural shift, which means preparing your workforce is a must. To be successful, you need leaders who understand the culture and will help pave the way for new ideas. It’s essential to consider and set expectations for how workers’ lives and jobs will change when implementing new technologies.

Overcoming Data Silos

Another major stepping stone in digital transformation is data connectivity, which includes collecting and storing data. It’s not uncommon for manufacturers to house live and historical data in different formats and locations that are either incompatible or not easily accessible.

Graphic 4. Digital transformation leaders. Source: Oden Technologies

“Right now, we are rebuilding our data architecture, and there are so many IT and OT systems within the enterprise to integrate like ERP, CMMS, and financials, said Justin Swenson, Head of Data Governance, Sub-Zero Group. “Security silos and layers make it difficult, but an easier way to approach this is by creating centralized security and access and identifying a few people who can understand the full data ecosystem. Overall, the best approach is to put tools in place that allow business access to what is really needed while still being compliant with data security regulations.”

Instead of focusing data efforts on creating large centralized data warehouses, manufacturers should focus on creating centralized security and access. Technologies that act as a data conduit, such as OPC UA, simplify the protocols that integrate data and allow manufacturers to leverage both on-premise and cloud storage solutions while avoiding silos.

Making Digital Transformation Stick

Challenges and uncertainty will always be present, so the future of manufacturing demands creativity and resourceful leadership. We could easily fall back into old habits and leave ourselves vulnerable to further disruptions. Or we could think of better long-term solutions that support adaptability and resilience.

“I am a firm believer that digital transformation will stick because new technologies are becoming a mindset and lifestyle,” said Don McCartney, Global VP of Enterprise Digital Manufacturing, Oshkosh Corporation. “We are accelerating our use of digital technologies to determine where we have opportunities for our employees to deliver operational and innovative excellence. We are also utilizing technologies to determine how we can change and improve business processes.”

COVID-19 has brought about an unprecedented period of disruption. For adaptable manufacturers, this presents a significant opportunity to innovate and build a sustainable organization.