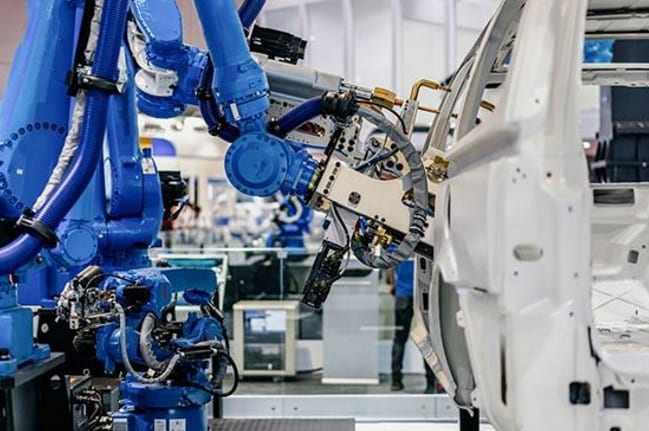

Robot orders in the second quarter of 2021 were up 67% over the same period in 2020, showing a return to pre-COVID 19 pandemic demand for automation as manufacturers and other North American companies return to business. According to the Association for Advancing Automation (A3), North American companies ordered 9,853 robots valued at $501 million in Q2 2021, up from 5,196 sold in Q2 2020, the peak of the pandemic.

Robot Orders Increase 67% in Q2 2021

The Q2 2021 increase, which marks the third-highest quarter on record for robot units sold overall, also showed more than half (5,530) came from non-automotive customers as industries such as metals, semiconductor & electronics, plastics and rubber, food and consumer goods, and life sciences recognize the benefits of automation.

“With the big increases in automation sales, and favorable economic conditions in U.S. manufacturing sector throughout much of 2021, it’s clear users have accelerated their orders for robotics and other forms of advanced technologies,” said Jeff Burnstein, president of A3. “While companies have long realized that automation increases efficiencies, expands production and empowers human employees to do more valuable tasks, the pandemic helped even more industries realize those benefits. By automating—either for the first time or expanding on how they use automation—companies will be better prepared to handle any upcoming issues that impact their business.”

According to A3, the substantial increases in robot orders in Q2 came from companies in:

- metals (up 99% over Q2 2020)

- automotive components (up 85%)

- semiconductor & electronics/photonics (up 62%)

- plastics & rubber (up 51%)

- food & consumer goods (up 51%)

- automotive OEM (up 49%)

- life sciences/pharmaceutical/biomed (up 21%)

In addition to the large increase in robotic orders, machine vision, motion control and motor markets saw record increases over Q2 2020, A3’s report shows. North American machine vision statistics reveal that the market expanded 26% to $764 million, a new record. For January through June of 2021, the North American machine vision market grew 18% to $1.5 billion, which is the best start to a year on record.

The motion control and motors sector recorded $1.065 billion in shipments, 13% greater than Q2 2020 sales and setting a new record. Motors, actuators and mechanical systems and electronic drives saw the largest increases.

“The revitalization of automation we’re seeing across myriad industries is extremely encouraging,” Burnstein added. “Not only will the increase in automation use be a win for our member companies, but it will also help the U.S. economy grow even more as customers increase productivity and fill the millions of manufacturing jobs that remain unfulfilled.”

For more information, visit https://www.automate.org/.

Hexagon's Nomination Committee Proposes Two New Directors to Board

Hexagon AB's Nomination Committee proposes the election of Erik Huggers and Brett Watson as new members of Hexagon's Board of Directors at the upcoming Extraordinary General Meeting (EGM) on November 17, 2021.

Erik Huggers brings extensive experience from the digital media and tech industry. Erik is a Supervisory Board Member at WeTransfer and ProsiebenSat.1 Media. Huggers previously served as CEO of Vevo and held key executive positions at Verizon Communications, Intel Corporation, BBC and Microsoft Corporation.

Brett Watson is the President of Koch Equity Development, the investment subsidiary of Koch Industries, where he is responsible for managing investments and corporate development activity across Koch’s diverse portfolio. Watson serves on several boards including Infor, Getty Images, Transaction Network Services, MI Windows and Doors, and the Flint Group. Prior to joining Koch in 2010, he spent nearly a decade in investment banking and private equity.

For more information, visit www.hexagon.com.

Small Manufacturers Detail Workforce Impacts of Pandemic

The Manufacturing Institute’s Center for Manufacturing Research and national CPA and advisory firm BKD released results from their fall survey of small and medium-sized manufacturers. This semiannual survey looks at workforce impacts and the “new normal” for manufacturers with 500 or fewer employees. The inaugural survey was released in February.

Key survey findings include the following:

- Nearly 79% of SMMs have enhanced workplace safety measures and requirements since the COVID-19 pandemic began.

- More than 71% of respondents said their firms had not received any resistance or hesitance to returning to work.

- Fifty-six percent noted a need for increased worker flexibility, and roughly half had reevaluated what work could be done remotely where possible. With that, 41% said that their business was working to reengineer the production process with social distancing in mind.

“Small and medium-sized manufacturers have needed to be pragmatic and flexible in the face of extraordinary challenges from the COVID-19 pandemic,” said Center for Manufacturing Research Director and National Association of Manufacturers Chief Economist Chad Moutray. “The battle for employees is intense right now, and small business leaders have stressed the importance of being flexible in a safe and healthy workplace environment. Adding to the worker challenge, the adoption of new technologies has continued to alter the worker profile and the types of training and upskilling that are required in a modern shop floor environment. This survey underscores the mission of Creators Wanted, the joint campaign of the MI and NAM to build the workforce of tomorrow—and excite, educate and empower a new generation of creators in the United States today.”

“It has been said by many that the pace of change will never be as slow as it is now, meaning future changes will continue at a more rapid rate and on a continuous basis,” said BKD, LLP Partner John Mather. “As seen in the key findings noted below and in the details of the fall survey, many companies do not have a solid handle on what is the “new normal” as it varies by company and seemingly changes every day. What is prevalent is that supply chain concerns and the ability to attract, train and retain employees continue to be the two top challenges facing manufacturers today. As already noted by Chad Moutray, the Creators Wanted campaign exemplifies and supports the need to build the next generation of manufacturing leaders.”

To view the full survey, visit https://www.themanufacturinginstitute.org/research/the-manufacturing-institute-bkd-small-and-medium-sized-manufacturers-survey-2/. For more information, visit www.themanufacturinginstitute.org.

FABTECH 2021 Makes In-Person Return to Chicago

As the first large-scale B2B and manufacturing trade show to be held at Chicago’s McCormick Place since the onset of the COVID-19 pandemic, FABTECH 2021 brought two years’ worth of groundbreaking innovations, inspiring keynote presentations, and solution-based education sessions to the global metal fabrication community. From September 13-16, North America’s largest metal forming, fabricating, welding and finishing event welcomed over 24,000 attendees from across the United States with long-awaited opportunities to experience product evaluation, in-person networking, education, and collaborative discussions on key topics impacting the industry today.

“FABTECH 2021 was a great show,” said Michael Bell, director of sales, Pemamek LLC. “The show exceeded our expectations by far and our company closed several large deals during the week. We met with the right buyers. The people who came to FABTECH were here to learn and to buy. We already have our booth for next year!”

“We have been exhibiting in FABTECH for years,” said Adam Bowden, president, Jet-Set Hydraulic Spray Systems. “Year after year, they have all been good, but this year the show has changed the trajectory of my business. We had an amazing experience at FABTECH 2021.”

Three exhibit halls hosted close to 1,000 exhibitors (including 93 new exhibitors) demonstrating over 400 new products and highlighting emerging trends and technologies. As the first event in two years for many industry professionals, energy was high, and sales activity was robust on the busy exhibit floor throughout each day. Featured technology-focused pavilions at FABTECH included the 3D/Additive Manufacturing Pavilion, one of the fastest-growing technologies of the 21st century, and the Robotics & Industrial Automation Pavilion that introduced new technologies to fill workforce gaps and increase productivity and profitability.

“FABTECH is grateful for the support of all the participating exhibitors, speakers and attendees who joined us in Chicago,” said Mark Hoper, FMA senior vice president media & expositions, FABTECH. “We would like to thank them along with all our partners, vendors and the City of Chicago who supported this endeavor throughout a challenging 18 months leading up to this important industry event.”

FABTECH featured a motivating lineup of special events, including keynote presentations, FABx Tech Talks and Leadership Exchange discussions. During the packed keynote presentations, industry luminaries discussed key learning moments and philosophies that led them to notable successes like landing a rover on Mars, creating boundary-pushing motorized builds and establishing a successful workforce development formula. Speakers included Adam Steltzner, leader and chief engineer of the NASA Mars 2020 Perseverance Rover Mission, David Ankin, CEO of ToyMakerz, Inc., and Adam Genei, owner of Mobsteel and Detroit Steel Wheel Co.

The Leadership Exchange and State of the Industry panels featured groups of subject matter experts who discussed the next phase of advanced manufacturing, the importance of mobile robot and standard robot interoperability, tactics for cultivating the next generation of manufacturing talent and how to navigate 2022 with the industry’s constant state of transformation. During the FABx Tech Talks, visionary manufacturers shared details about how they are integrating technologies like automation, AI and data analytics into all aspects of their operations—from the production floor to the supply chain.

FABTECH’s education offerings for attendees included more than 150 conference sessions and workshops led by industry thought leaders and subject matter experts. The sessions spanned 14 technology tracks with sessions focused on automation, smart manufacturing, welding, cutting, lasers, workforce development, business management strategies and more. On-demand content from the conference is now available to purchase for those who were unable to attend.

“FABTECH is family. It’s about connection and community just as much as it’s about education and technology! The welding and fabrication industry is like no other–we are a very close family,” commented Barbie Parsons, welding influencer also known as Barbie the Welder.

During FABTECH, the American Welding Society hosted judges from Netflix’s new series, Metal Shop Masters. Making its Netflix series premiere on September 10, 2021, just days before FABTECH 2021, Metal Shop Masters features a group of metal artists who will torch, cut and weld epic creations from hardened steel in a competition to win a $50,000 prize and the Metal Shop Master title. Attendees enjoyed hearing from judges Stephanie Hoffman and David Madero at FABTECH’s Careers in Welding Trailer as they discussed what it was like to be on the show and meet talented competitors.

“With everything that the industry has been through over the last year and a half, it was great to bring everyone together to do business, learn, and connect in person,” said John Catalano, SME senior director US events and strategic partnerships, FABTECH. “Nothing compares to being able to make those face-to-face connections and see the newest advancements and products in action. FABTECH 2021 was a success, and we hope everyone who joined us gained new business and insights into current and future manufacturing trends.”

For more information, visit www.fabtechexpo.com.

Scroll Down

Scroll Down