Products

the latest products to help you improve your manufacturing process

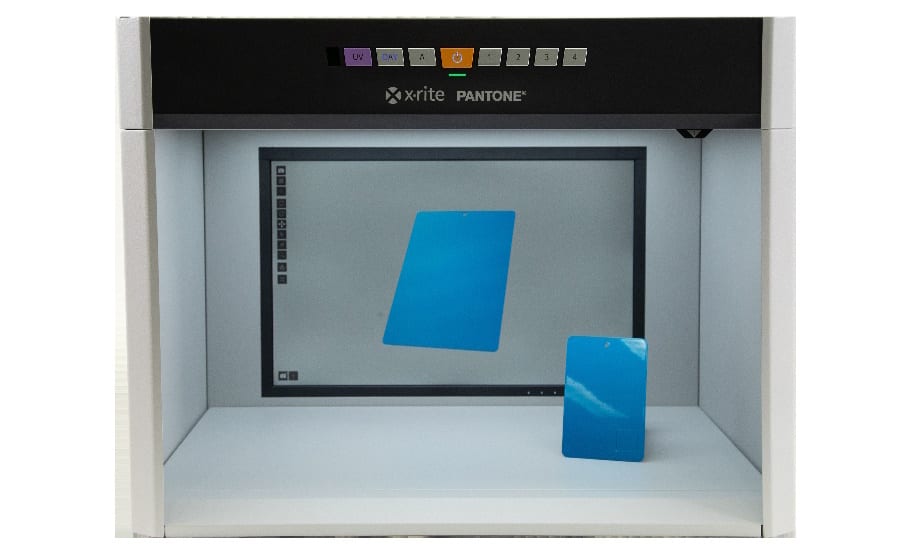

X-Rite Judge LED Light Booth

X-Rite Incorporated announced the Judge LED light booth, designed for precise visual color evaluation as industries shift from fluorescent to energy-efficient LED lighting. Building on 60 years of lighting innovation, this new light booth incorporates advanced LED technology to ensure compliance with environmental regulations and helps brands and suppliers transition smoothly to LED-based color assessments, maintaining quality without operational disruptions.

The global shift to LED lighting, driven by energy efficiency mandates and governmental regulations, presents a new challenge for industries such as textiles, automotive, paint and coatings, plastics, and packaging that depend on color accuracy. Fluorescent and LED illuminants have distinct spectral power distributions (SPD) that can dramatically impact color perception. To maintain color consistency across the supply chain – from design to production to retail – visual evaluation programs must integrate LED standards into their color workflows.

“The Judge LED light booth is a future-proof solution for brands and manufacturers transitioning from fluorescent lighting to comply with new energy regulations,” said Albert S Laforet, Director of Strategic Projects, X-Rite. “Our custom-designed LEDs are optimized to offer the best SPD match for legacy fluorescent tubes, including U30, U35, CWF and TL84, ensuring a seamless integration into color workflows. This allows companies to meet regulatory requirements, ensure color consistency, and prevent color discrepancies before final product assembly.”

“The Judge LED light booth is ready for use immediately and allows for faster and more consistent color assessments. Our goal is to make color management more efficient across our global supply chain,” said Carmen Keim, Colorist and Digital Pioneer at Sympatex Technologies, a pioneer for high-tech functional materials in clothing, footwear, accessories and technical fields.

The Judge LED light booth delivers precise and consistent color evaluation with seven distinct light sources that simulate a variety of lighting conditions. The seven light sources can be selected from a wide range of industry-leading standard illuminants, including LED D50, D65, LED-B2 3000K, LED 3500K, LED-B3 4000K, UV, A, CWF LED, TL84 LED, U30 LED, and U35 LED.

Key features of the Judge LED light booth include:

- Instant Warm-Up: Eliminates waiting time to improve daily efficiency.

- Stabilized Illuminants: Ensures color evaluation consistency by delivering calibrated illuminants that offer fixed intensity levels and stable chromaticity.

- Directional D65 Daylight: Facilitates defect inspection and surface evaluation for characteristics like orange peel to ensure superior product quality on complex finishes.

- Digital Evaluation: Offers an optional integrated calibrated monitor, allowing for the comparison of physical samples with digital material twins to ensure consistency between digital prototypes and physical products.

- Energy Efficient: Operates quietly, produces minimal heat, consumes less energy, and has longer lasting illuminants than fluorescent light booths.

- Standards Compliance: Meets ISO, ASTM, AATCC, and BSI visual assessment requirements.

“The Judge LED light booth integrates visual and digital workflows, allowing designers, material suppliers, and marketers to compare digital renderings or material twins with physical samples under precise LED lighting. Paired with X-Rite's end-to-end digital color solutions—including color specification, measurement, PANTORA virtual material creation, and color formulation and quality control software—companies can improve decision-making, streamline approval cycles, and accelerate time to market while ensuring consistent quality," continued Laforet.

X-Rite

https://www.xrite.com/categories/light-booths/judge-led-light-booth

Nikon NEXIV VMF-K Series Video Measurement System

Nikon Corporation (Nikon) has launched the NEXIV VMF-K Series, a next-generation video measuring system designed to meet the increasing semiconductor and electronic component inspection demands.

Building upon the success of the VMZ-K Series, the NEXIV VMF-K Series offers significant benefits to a wide range of industries in addition to semiconductor manufacturing, including advanced packaging, substrate production, wafer inspection, and probe card inspection.

As semiconductors become smaller and more integrated, inspection processes are increasingly crucial for quality maintenance. The NEXIV VMF-K Series addresses this challenge by providing stable measurements of micron-level dimensions while significantly improving throughput, thereby supporting stringent quality control in semiconductor device manufacturing.

The new NEXIV VMF-K Series consists of the VMF-K3040, which replaces the VMZ-K3040, and the VMF-K6555, which replaces the VMZ-K6555.

Key benefits of the NEXIV VMF-K Series include:

- Enhanced measurement throughput: The VMF-K Series achieves 1.5 times higher measurement throughput compared to the previous VMZ-K model (according to Nikon’s standard measuring conditions), significantly reducing measurement time and boosting productivity.

- Advanced optics: Equipped with a confocal optical system, the VMF-K Series enables simultaneous 2D and height measurement within the field of view, achieving significantly higher throughput compared to height measurement using only bright-field images.

- Improved light source: The confocal light source has been changed from a xenon lamp to an LED, increasing lifespan from 3,000 hours to 30,000 hours. This enhancement improves operational efficiency and reduces the need for lamp replacements.

- Expanded model lineup: The series now includes a standardized 45x objective lens model, supporting advanced semiconductor measurement demands for even finer measurements.

- SEMI S2/S8 compliance: The VMF-K Series meets industry safety standards for semiconductor manufacturing equipment when installed appropriately according to the SEMI S2/S8 guidelines.

- New software function: The series offers the ability to display the remaining time during measurement.

- New exterior design: The series features a sleek factory design with black and silver tones.

“We are delighted to introduce the NEXIV VMF-K Series, an industry-leading solution that addresses the growing needs for high-speed, finer measurement in semiconductor and electronic component manufacturing,” said a Nikon spokesperson.

“By significantly improving measurement throughput and maintaining high accuracy, our new system empowers manufacturers to enhance their quality control processes and accelerate product development in the face of increasing miniaturization and integration of semiconductor devices.”

Nikon Corporation

https://industry.nikon.com/en-us/products/video-measuring-systems/nexiv-vmf-k-series/

Siemens Guided Safety Acceptance Test for SINAMICS

With its SINAMICS Startdrive commissioning software, Siemens is supporting machine builders in the validation of safety functions for SINAMICS variable frequency drives with a guided acceptance test. With SINAMICS Startdrive, Siemens offers a tool for the integration of drive hardware into the TIA Portal engineering framework. This integrated guided acceptance test for safety functions is available for SINAMICS G- and S-series drives and complies with EN ISO 13849-2 and IEC 62061.

The safety acceptance test is extremely user-friendly. A wizard guides the user step-by-step through the acceptance process and checks whether safety functions have been parameterized and executed correctly in the relevant application. For documentation purposes, a standard-compliant acceptance report is then created automatically. With the safety acceptance test integrated into SINAMICS Startdrive, Siemens helps machine builders carry out the legally required validation of safety functions easily and safely.

LK Metrology Extends Eco-Friendliness of CMMs

A new innovation, EcoAir, has been introduced by British co-ordinate measuring machine (CMM) manufacturer LK Metrology to lower the carbon footprint of its products. The technology is optionally incorporated into new machines built at the firm's Castle Donington factory in Derbyshire, UK, or may be retrofitted to CMMs already carrying out measurement and inspection duties in factories, quality control rooms and metrology bureaux. Any make of CMM may be upgraded, provided that it is fitted with an LK NMC300 controller, which is also available from the manufacturer as a retrofit.

Connected to the machine's air filter set, the EcoAir automatic shut-off unit interrupts the supply of compressed air to the CMM's air bearings when the machine is idle, reducing consumption by up to 95% and leading to substantial energy and cost savings. The period of inactivity that triggers shutdown can be adjusted to as little as one minute. The CMM remains ready for action, however, and when it is next used in either manual or CNC mode the flow of compressed air resumes automatically.

Such power saving devices help manufacturers to meet regulatory requirements for energy efficiency and support corporate social responsibility initiatives, while reaping the financial benefits of reduced consumption of electricity. Other ecological measures introduced over the years by LK include a reduced thickness of the air bearing film needed to maintain smooth, accurate movement of the machine elements over their guideways. This not only cuts air consumption when the CMM is in use, but also offers three and a half times higher stiffness than standard air bearings due to their wrap-around design. The major benefit is improved accuracy of measurement due to higher resistance to dynamic forces, particularly when tactile scanning or using long probes.

Likewise, LK has for many years incorporated advanced motor control and intelligent power management into its CMMs. The drive motors are programmed to power down automatically when they are not actuating axis motions. Additionally, the design of the machines themselves is environmentally friendly, as they are constructed with moving elements of lightweight materials, such as the ceramic bridge and spindle, which helps to minimise the energy required to set them in motion.

LK Metrology

www.lkmetrology.com

Mahr Precimar SM 60-V Small Length Measurement Model

Mahr Inc. announced the expansion of its Precimar® SM 60 length measurement product line with the introduction of the Precimar SM 60-V small-length measuring bench. This new version of the SM-60 has the ability to use Mahr’s standard contact inserts with 3.3mm mounting. These inserts enable the SM-60 to be individually adapted to a wide range of measuring tasks. For example, it can measure recesses, external gears, the pitch diameter of external threads, and perform many other measuring tasks. It is also ideally suited for precise measurements at the point of manufacture or in a measurement center.

The Precimar SM 60 family features a measuring range of 60 mm, with a 25 mm sensitive contact and a fixed reference jaw with a 35 mm adjustment to obtain the total 60 mm measurement capacity. Equipped with a 5 N measuring force, the Precimar SM 60-V includes a robust construction for use in the production environment, designed to meet the demand for high-performance gaging at the point of manufacture. It also offers a simple setup for fast adaptation to new workpieces.

The Precimar SM 60-V is highly-flexible. It is configurable with various Mahr readouts to provide a system tailored to the performance level required for the specific measurement application, including:

- MarCator 1086R or 1087R digital indicators

- Millimess® 2000 high-performance digital comparator

- Millimar® P2004 LVDT with +/-2mm range and C1200 bench amplifier

- Incremental probes: P 1530 V using Millimar® C 1202 and the N 1702 VPP-module, providing long-range and high-resolution capabilities

Interchangeable measuring inserts provide hardened steel or carbide surfaces in a wide variety of shapes, along with numerous thread measuring options. An adjustable support table is positioned up or down to ensure proper part location and then locked into place. Retraction of the sensitive contact is accomplished with a simple lever that is easy to use by right- or left-handed operators.

"The expansion of the Precimar SM 60 family with the new SM 60-V model demonstrates Mahr's commitment to delivering innovative solutions that meet the evolving needs of manufacturers," said Nick Russo, product manager at Mahr. “The flexibility, accuracy, and durability of the Precimar SM 60-V make it an ideal choice for manufacturers seeking to perform precise measurements in a production environment, enhancing their measurement capabilities and driving productivity.”

Mahr Inc.

www.mahr.com