Speaking of Quality

Jane D. Keathley

Speaking of Quality | Jane D. Keathley

Using new information, technology, and/or knowledge is the distinguishing factor for innovation.

Process Innovation or Innovation Process?

When talking about processes and innovation it’s easy to confuse ‘process innovation’ and ‘innovation process.’ Both are important elements of a thriving organization, and it’s important to understand the differences and utilize each of them effectively.

Innovation Process: How does Innovation Get Done around Here?

One way to think about the innovation process is that it is an overarching system. Your organization must establish a common methodology that lets people know how innovation will get done across the organization and sets the expectations for innovation.

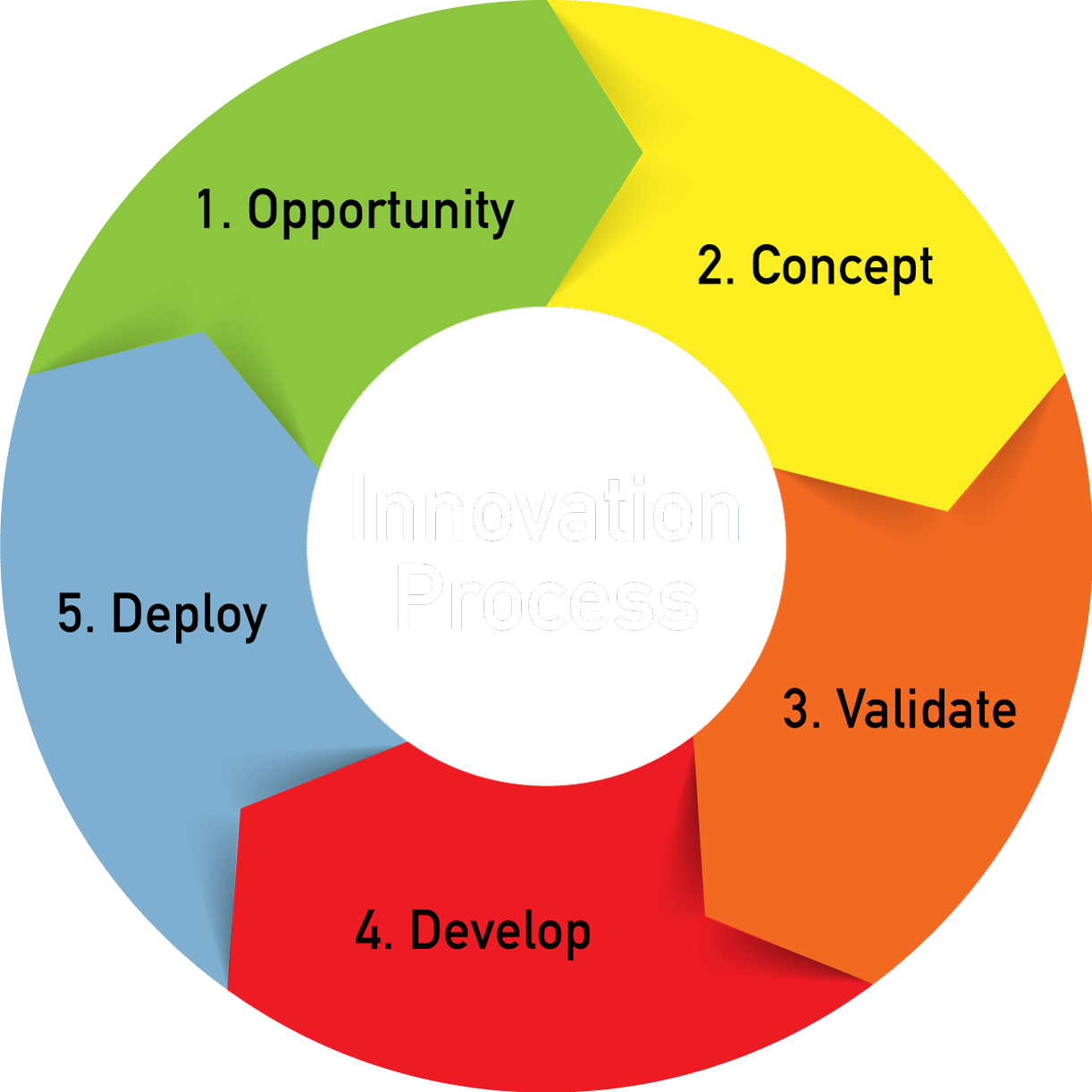

The primary steps of the innovation process are relatively consistent across various models (1), and are shown in Figure 1. Developing insights into a problem or need and identifying the opportunity inherent in solving it is the first step. Note that this is almost always a process problem, where there is an issue that gets in the way of optimal performance. It could be a customer experiencing an issue with a product, a group of people whose ability to accomplish a common endeavor is constrained, or an organizational restriction that limits performance. Innovation must start with a clear understanding of the problem.

Figure 1. Innovation Process (Source: Peter Merrill, 2020, used with permission)

As the problem is being clarified, the innovation process moves forward to the creative, problem-solving phase. Connecting new knowledge and potential resources together with a feasible solution is the objective here. The process needs to have clear decision points to ensure progress and to focus resources as the solution matures through multiple iterations. A step to narrow the list of solutions is sometimes included as a formal step in the process.

From the short list of solutions, the next step is to refine and ready the selected solution for prime time. While major changes should be complete by this point, there may be final adjustments, syncing up of components, and cosmetic touches to be made before the official launch.

Now the refined solution is ready to move into its intended environment for use. The business model around its execution must be developed, to include, as applicable, communication to customers, availability and access, and training and services.

By this time, new problems will have emerged, as well as new opportunities, and a new round of creative problem solving will begin. Ideally, there will be multiple innovative endeavors underway at any one time, at various stages within the innovation process.

Process Innovation: How do Innovative Changes to Processes Get Done?

The innovation process is applied to any type of innovation, including operations. In terms of process innovation, the desired outcome is to resolve the issue: process inefficiencies? Poor quality outcomes? Resource intensive? Using old technology? The list could go on and on, but the first step is always to define the problem, then move on to creative solutions. Using new information, technology, and/or knowledge is the distinguishing factor for innovation. Connecting knowledge from multiple sources, both external and internal, is key to making the breakthrough changes that set an organization apart from its competitors.

A few tips on innovating processes:

- Keep the end user as the focal point – even if the process is deep inside the organization, consider the ultimate customer’s perspectives at each organizational level. For example, in the automotive sector, research has shown that the customer experience – the end-to-end experience including purchasing and ownership options, services, add-on products, etc., as well as vehicle performance – has superseded engineering capabilities as the primary competitive driver (2). Operations processes need to be transformed to align with the overall customer experience.

- Risk tolerance – are the risk criteria too restrictive? Wider tolerance ranges may be necessary, especially in the early stages of identifying creative solutions. Also, consider basing risk evaluation on factors such as complexity and ambiguity rather than failure modes (3).

- Embrace new technologies – invest in necessary technologies and upskilled resources to develop a deep understanding of the information related to the process. Manufacturers are increasingly using data analysis, artificial intelligence, and automation for optimizing processes (4).

- Leverage traditional quality tools – Deming taught that process innovation needed to be part of a continuous improvement foundation (5). Continuous improvement models such as lean and Design for Six Sigma are applicable and, in combination with new technologies and tools, can be powerful enablers of process innovation.

In conclusion, a well-designed innovation process is the bedrock of innovative changes to processes. Process innovation developed via the innovation process will focus on the end user, tolerate greater risks early in development, use new information and technology, and leverage traditional continuous improvement models.

References:

1. Keathley J and HJ Harrington; Structuring Your Organization for Innovation; ©2020, ASQ Quality Press

2. Grūntges, V, A Matthey, F Peter, J Stober; The new key to automotive success: Put customer experience in the driver’s seat; Nov 2021; McKinsey & Company, https://www.mckinsey.com/business-functions/marketing-and-sales/our-insights/the-new-key-to-automotive-success-put-customer-experience-in-the-drivers-seat?cid=other-eml-alt-mip-mck&hdpid=a7fe45e7-66e6-4ef0-9358-db75491d919c&hctky=1767404&hlkid=6c61a8709d574aeaa59cc5491ad30522

3. Merrill, P; ISO 56000 Building an Innovation Management System; ©2020, ASQ Quality Press

4. American Productivity and Quality Center; Report K011533-AI is Driving New Skills in Manufacturing; April 2021; (https://asq.org/quality-resources/articles/ai-is-driving-new-skills-in-manufacturing?id=086fb5843d2a44e187e5cac84469db53)

5. The W. Edwards Deming Institute; accessed November 2021; https://deming.org/quotes/there-are-four-prongs-of-quality-and-four-ways-to-improve-quality-of-product-and-service