Products

the latest products to help you improve your manufacturing process

EMUGE-FRANKEN N.A. Line of Ring Gages

EMUGE-FRANKEN N.A. has expanded its thread gaging solutions to include a new line of thread ring gages to complement its thread gage offering. The new line comprises UNC and UNF Go and No-Go ring gages, in addition to metric and metric fine Go and No-Go ring gages, a total of 152 new gages.

The new EMUGE Ring Gages accompany the comprehensive line of EMUGE Fixed Limit Thread Gages, consisting of Go/ No-Go Plug Gages and Thread Depth Plug Gages that inspect the pitch diameter and functional thread for internal-threaded components.

EMUGE Go and No-Go Ring Gages are manufactured with hardened tool steel for exceptional durability and feature a fully knurled circumference for maximum gripping ability and safety. No-Go gages are clearly marked with a red ring. UNC and UNF gages have a 2A tolerance. UNC gages are available in 19 sizes from #2-56 to 2-4 ½ and UNF gages are available in 19 sizes from #0-80 to 1 ½ -12. Metric and metric fine gages have a 6g tolerance. Metric gages are available in 19 sizes from M2x.4 to M68x6 and metric fine gages are available in 19 sizes from M8x1 to M48x1. Additional sizes are also available upon request and all gages (UNC, UNF, metric and metric fine) are furnished with a short form gage certificate at no additional charge. Upon request, long form certificates are also available.

EMUGE-FRANKEN N.A. (Emuge Corp.)

www.emuge.com

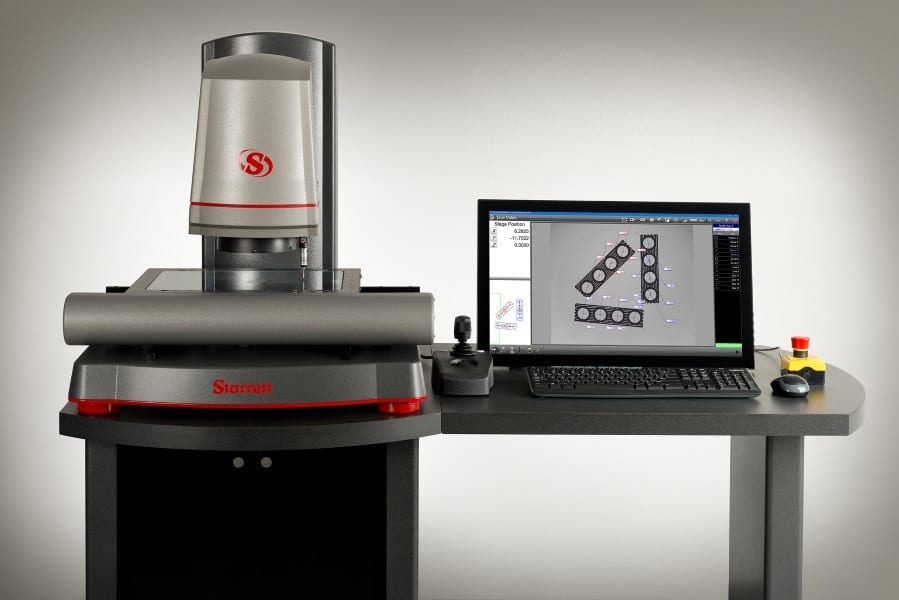

The AVR-FOV 0.14X automated part programs deliver accurate results to the micron level in a matter of seconds with “Go/ No-Go” tolerance zones, and data are provided in one easy-to-interpret report. These features allow metrology users in manufacturing facilities or QC labs to produce accurate, fast, and repeatable results.

Equipped with the M3 software package from MetLogix, a traditional mouse as well as a touchscreen monitor make user interaction easy and intuitive. Auto part recognition enables creating a part measurement program that comprises the desired features of a part for inspection, which can automatically be saved in the system or to a network. Programmable light output options can be built into the program as defined steps, including being called up as the part recognition program initiates. Once the program is created, placing that part within the camera’s field-of-view allows for the saved program to initiate and run the inspection. A Renishaw Touch Probe may also be utilized for quick acquisition of discrete points along a part’s profile as well as Z-axis measurements.

The AVR-FOV 0.14X has an X-Y-Z travel of 12 in. x 8 in. x 8 in. (300mm x 200mm x 200mm). The Starrett AVR-FOV 0.14X Multi-Sensor Vision System is made in the United States.

The L.S. Starrett Company

https://www.starrett.com

Starrett Large Field of View Multi-Sensor Vision System

The L.S. Starrett Company has enhanced its AVR300 Multi-Sensor Vision System with a 0.14 magnification lens featuring the largest field of view to date for Starrett on the AVR Series at 2.36 in. x 1.90 in. (60 mm x 48 mm). For greater efficiency and accuracy, more of the part can be viewed in every image on the new AVR-FOV 0.14X system. Due to “superimage” technology, which allows multiple images to be stitched together to form one larger image, together with the system’s touch probe technology, the AVR-FOV 0.14X can accurately inspect a wide range of features on large or complex parts, as well as on multiple small parts.