Verisurf Software Partners With Open X to Close Skills Gap

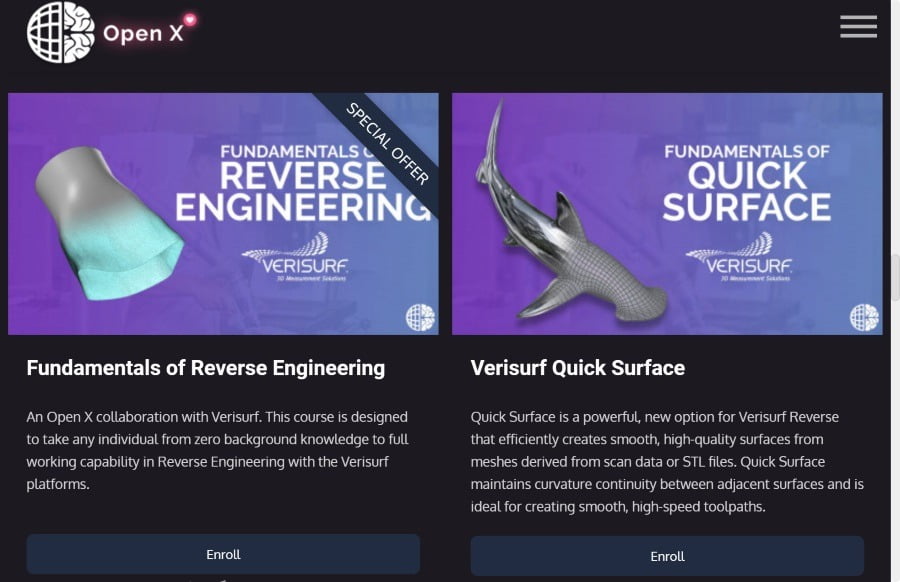

Verisurf Software has partnered with Open X, an interactive learning platform, to provide comprehensive education courses to those looking to pursue a career in dimensional metrology or expand their skills in specific application areas. Current courses include Reverse Engineering (which includes Fast 3D Scanning to 3D Printing Workflows) and powerful 3D Surface Modeling. Future courses will include Portable Inspection, and Programmable CMM Inspection.

“Technology continues to grow exponentially in today’s manufacturing environment. In its wake, skilled workforce development struggles to keep up, with many considering access to advanced training inaccessible, which can cause confusion for some about the viability of their career paths or career trajectory,” said Cody James, CEO of Open X.

Verisurf Software has long been a leader in the development and support of metrology software solutions rooted in Model-Based Definition (MBD). At the heart of the MBD is the CAD Model, it is the absolute authority to define a part or entire product providing a defined 3D data set, including all necessary GD&T annotations for inspection, measurement, analysis, tool building and reverse engineering. MBD is the undisputed source of definition for all of these applications and more.

One technical skill set that is quickly emerging from the increased dependency on MBD is dimensional metrology, the measurement science of length, size and dimension measurement in 2D and 3D real world and digital space. To compare, analyze and verify the physical real part to the Original CAD-Model of the part. Over the last two decades, dimensional metrology technicians have been in high demand, with the trend line growing exponentially higher, especially within tier one aerospace entities and their supply chains, including DOD, NASA, Boeing, Northrop, Lockheed and others.

“At Verisurf we have always maintained a philosophy of developing practical metrology solutions. Our software is one of the easiest to learn and use; it is also the most compatible and open platform on the market, supporting all CAD file formats and virtually any new or legacy CMM in use, today,” said Ernie Husted, president and CEO of Verisurf Software. “We feel it is our responsibility to support our customers and manufacturing employees at large with high-quality training and support. This is the driving force behind our partnership with Open X,” added Husted.

Verisurf training, using the Open X online platform, is available 24/7 to any organization or individual seeking to learn dimensional metrology skills needed in today's technology-based and automated manufacturing environments. Courses can be accessed using desktop computer, laptop, tablet, or smartphone.

Ames Appointed President, CEO of Tekscan

Tekscan, Inc. announced that its board of directors has appointed Jeff Ames as president and CEO, effective immediately. Ames will lead all strategic and operational initiatives to position Tekscan for successful growth and value creation. Tekscan was acquired by Artemis Capital Partners (Artemis) earlier this year.

He brings more than 25 years of experience in engineered product businesses, with past roles spanning commercial, technical, and operational responsibilities. Before joining Tekscan, Jeff led the Industrial Automation business unit of Kaman Distribution Group, a leading integrator and distributor of automation and motion control solutions. Ames previously held roles of increasing responsibility at Eaton Corp., including leading Eaton's Notification and Wright Line businesses and directing Eaton's uninterruptible power supply offerings. Jeff earned a BS in Electrical Engineering from Syracuse University and an MBA from Marist College.

Peter A. Hunter, managing director for Artemis and Chairman of Tekscan's Board of Directors, said, "We are thrilled to bring Jeff onto the Tekscan team and are confident that his skills will help Tekscan build on their leadership position in the tactile force and pressure sensing market space. Jeff shares Artemis' passion for leading companies with highly differentiated product offerings in growing niche markets."

Ames commented, "I am honored and excited to join the Tekscan team. I have been impressed by Tekscan's innovative technology offerings, and I look forward to working closely with Tekscan's employees, partners, and customers to bring unique solutions to these markets. I am also excited to partner with Artemis, whose focus on manufacturers with differentiated technology and a culture of innovation will perfectly complement Tekscan's business."

Teledyne Imaging Concludes Successful Virtual Technology Showcase

Teledyne Imaging announced the successful conclusion of its multi-session virtual event held recently to introduce its newest and most innovative imaging solutions for machine vision. Online sessions led by subject matter experts from across the Teledyne Imaging group covered topics such as AI and embedded vision, extreme high-resolution and high-speed imaging, 3D sensing, non-visible and multi-spectral imaging, and high-volume, low-cost CMOS sensors.

With more than 2,200 registrations over three days and six sessions, the event included attendees from North America, Europe, and Asia Pacific. “We couldn’t be more pleased to offer these sessions, proving that even with the temporary closing of trade shows, individuals are keen to spend time online learning about the newest technology,” commented Dale Deering, director of market development, Teledyne Imaging. “With such resounding success, we are planning on offering this showcase again in 2021.”

Recordings of all sessions are available now:

- Clarity at High Speed – Performance Imaging

- Connection is everything – Camera/Data Interfaces

- AI & Embedded Vision – Driving System Innovation

- New Advances in 3D Sensing

- Beyond Sight! Non-Visible and Multi-Spectral Imaging

- Evolving CMOS Sensor Technology

Automate Postponed Until June 2022

The Association for Advancing Automation (A3) announced it has made the difficult decision to postpone Automate, North America’s leading automation trade show and conference, until June 6-9, 2022, at TCF Center in Detroit, Michigan, USA.

A3 also announced Automate Forward, a virtual conference and trade show for the robotics and automation industry, which will be held March 22-26, 2021. The conference will feature more than 80 speakers on robotics, machine vision, motion control, artificial intelligence, and smart automation technologies.

Automate Forward will include a virtual exhibit hall and networking center where attendees can connect directly with companies and experts to solve their automation solutions. Registration for Automate Forward is open now. Exhibiting and sponsorship opportunities are available.

“The pandemic has taken a major toll on people all over the world,” said Jeff Burnstein, president of A3. “While we expect that vaccines will have a positive impact in 2021, we don’t believe it would be in the best interests of our exhibitors, attendees, speakers, and staff to hold an in-person Automate in May of 2021. Coming out of the pandemic, companies in every industry will be looking for automation products and solutions to help them become more successful in an increasingly automated world. Automate Forward and Automate 2022 will be critical to that growth.”

More than 20,000 attendees and 600 exhibitors are expected in Detroit for Automate 2022. The Automate Show in 2021 was on pace to be the largest ever, with nearly 300,000 square feet of exhibits. Exhibitors for the postponed 2021 show are currently being notified about how they can lock in their participation in Automate 2022.

In 2019, A3 announced Automate’s move to its new home in Detroit, after more than 25 years in Chicago. After 2022, Automate will return to its normal odd-year cycle with the next shows being held in Detroit on May 22-25, 2023 and May 12-15, 2025.

SME Announces Willig New CEO

SME announced that Robert “Bob“ Willig has been named as its executive director and CEO. His employment with SME began January 1.

Willig, who has more than 30 years’ experience in the manufacturing industry, has held multiple leadership positions for global divisions within major manufacturing companies, most recently at Stoneridge Inc. where he was president of the Control Devices Division. Prior to Stoneridge, Willig served as president and CEO of Plasan Carbon Composites; before that, he was president, Americas, for GKN Driveline, an automotive industry supplier focused on drive system technologies. Earlier in his career, Willig was president of both Power Transmission and Powertrain at The Gates Corp. He has also served on various boards, including Plasan's Board of Directors, GKN's Chief Executive Council and Gates Corp. Asia’s Board of Directors.

Willig has extensive experience leading teams across multiple cultures, languages, locations and disciplines, which made him an additionally attractive candidate as SME conducted its search.

“Bob’s extensive experience and insights into the manufacturing industry make him an ideal leader for SME during this time of disruptive change in manufacturing,” said 2020 SME President Susan Smyth, PhD, FSME, NAE. “Bob’s ability to focus on long-term strategy even during a challenging economy, his track record of business development success and his values-based leadership will help SME pursue its mission of advancing manufacturing while building a culture for continued success. We're very excited to have him as our new CEO.”

Willig will succeed Sandra Bouckley, FSME, P.Eng., 2017 SME president, who was appointed SME’s executive director and CEO in July 2018. Bouckley, whose exit was long intended, will remain with SME as a leadership transition consultant through March 31.

“I’m passionate about manufacturing and its people,” said Willig. “For nearly 90 years, SME has been a consistent resource for knowledge, connections and supporting the next generation of manufacturing talent. I’m looking forward to working to protect that legacy while charting a new course for this organization as our industry adapts to advanced technology and a post-COVID economy.”

Willig earned his bachelor’s degree in mechanical systems design from Lawrence Tech University and an MBA from Wayne State University. He will be based at SME’s headquarters in Southfield, Michigan.

U.S. Manufacturing Technology Orders Totaled $383.8M in October, Up 3.7% from September

U.S. Manufacturing Technology Orders totaled $383.8 million in October 2020, an increase of 3.7% from September 2020, and the highest dollar value since December 2019, according to the latest U.S. Manufacturing Technology Orders report published by AMT – The Association For Manufacturing Technology.

October 2020 orders decreased 1.9% from October 2019; however, this was smallest year over year difference in 2020 and a stark contrast to the 43.1% year over year decrease seen in May 2020. Total orders through October reached $3.07 billion, a decrease of 20.2% from 2019.

“All metrics point to a continuation of economic recovery in the manufacturing technology sector,” said Douglas K. Woods, president of AMT. “Industrial machinery orders were strong in many industries relative to this time last year. The mold and die sector experienced strong growth for the second straight month, with orders being multiples of typical numbers and strongly indicating that mold and die manufacturing is being reshored. Pandemic-related needs for secure supplies of medical equipment, as well as continued strong growth for consumer products such as appliances, also contributed to this growth. Consumer products grew due to a continued strong housing market; housing starts in the last two months have been higher than any time since 2007.”

“Additionally, we’re seeing large investments in capital equipment in the automotive sector with substantial investments going to EVs and hybrid vehicles, while some traditional manufacturing lines are just being refurbished versus replaced. The rail industry is also investing – largely to refurbish both rail cars and infrastructure – as transport of goods by rail to centralized warehouses for home delivery continues to grow as a consequence of the pandemic.”

“Unfortunately, the news is still not promising in the lagging aerospace and oil & gas sectors, as these sectors are still experiencing weak growth, and we do not foresee any significant uptick in growth in either sector in the foreseeable future.”