Products

the latest products to help you improve your manufacturing process

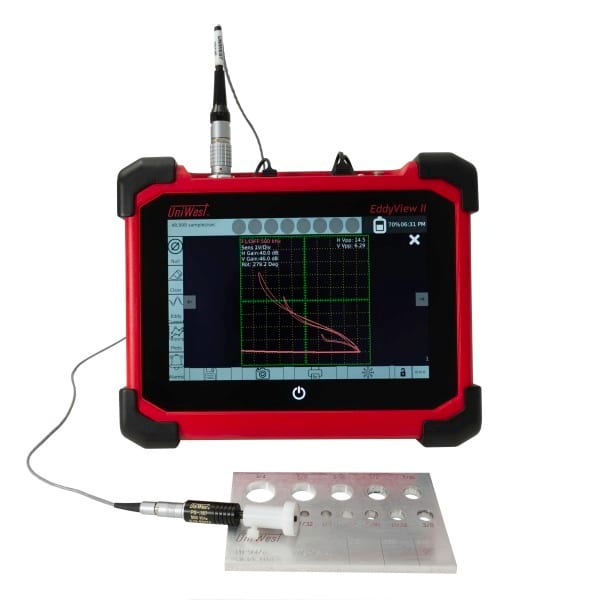

UniWest EddyView II Portable Eddy Current Flaw Detector

UniWest announced the introduction of the new EddyView® II portable eddy current flaw detector at the ASNT Annual 2022 Conference on October 31, 2022.

The innovative EddyView II features a large 8-inch touch screen display with gesture adjustments for key parameters such as gain and rotation, ability to drive conventional probes or array probes, an independent channel that monitors probe to part coupling (liftoff), and UniWest’s industry-leading signal performance with extremely low signal-to-noise.

The EddyView II also includes multi-frequency probe drive and signal mixing, digital conductivity & non-conductive coating thickness, and compatibility with UniWest’s ECS-1S & JF-15 rotating bolt hole scanners. In addition, the EddyView II can be connected to the internet for remote diagnostics and calibration, as well as export raw eddy current data for post-processing flexibility.

While using the EddyView II in demanding and often dirty NDT environments, its rugged housing is designed to meet the standards of Ingress Protection (IP) rating IP-65.

Designed for use by NDT professionals, the EddyView II includes all the advanced features and functionality to allow both standard eddy current measurements and complex inspections, including use of eddy current array (ECA) probes up to 32 elements as well as large-scale automated and robotic production applications. System features include multi-frequency with mixing, split-screen for both impedance plane and O-scope/sweep modes, digital conductivity measurement, non-conductive liftoff digital measurement, rotating scanner support for high-speed bolt hole scanning, Ethernet connectivity, alarm outputs, and USB flash drive support. Ideal for field, laboratory, or production settings, the EddyView II’s fast data acquisition rate facilitates smooth system integration.

UniWest

www.uniwest.com/eddyview2

Teledyne Genie Nano 10GigE Cameras

Teledyne DALSA announced the all-new Genie™ Nano-10GigE M/C8200, and M/C6200, based on Teledyne e2v’s 67M and 37M monochrome and color sensors. The new Genie Nano-10GigE series delivers a futureproof and scalable solution with significantly higher interface speeds and resolutions, offering system designers an easy integration path for application upgrades requiring higher speed data capture and transfers.

The new Genie Nano-10GigE 67M camera is the smallest 10GigE Vision camera in the industry achieving full resolution image transfer at up to 15 fps. Both the M/C8200 and M/C6200 offer wider operating temperature ranges, PTP synchronization and commonality of sizes with other Genie Nano cameras, enabling versatility of applications and ease of integration or upgrades. Coupling a compact 59 mm x 59 mm form factor, system designers can transition from 1, 2.5, 5GigE to 10GigE Vision without the need for software changes. Genie Nano-10GigE cameras are engineered to deliver high-speed, dependable results for applications such as electronics manufacturing inspection, industrial metrology, intelligent traffic systems, aerial imaging and sports and entertainment.

Key Features:

- Industry’s smallest 67M 10GigE Vision camera

- Four new models offered in 37M and 67M, monochrome and color versions

- Trigger-to-Image Reliability (T2IR) framework improves the reliability of your inspection system and protects from data loss

- GenICam, GigE Vision 2.0 compliant

- Multi ROI with up to 16 x Region of Interest (ROI)

- All-metal body with 3-year warranty

Teledyne DALSA

www.teledynedalsa.com/imaging

Smart Vision Lights JWL150 External Light

Smart Vision Lights (SVL) announced the release of its JWL150, the first in the new Camera-to-Light (CTL) series. Unlike other external illumination products designed for machine vision cameras and smart cameras with built-in illumination that falls short, the JWL150 delivers an intense, compact light source with an integrated camera mount.

Compatible with most major machine vision cameras, the JWL150 can be directly connected and controlled through a camera’s trigger output. Systems integrators often deploy external bar lights or use built-in camera lights, but external lighting takes up valuable space and built-in lights often provide insufficient lighting. In machine vision systems that are tight on space, the JWL150 delivers an intense yet compact lighting option.

The IP65-rated bright field light features a working distance of 500 mm up to 2000 mm; 10-, 14-, and 30-degree lens options; and built-in Multi-Drive™ technology, which offers both continuous operation and OverDrive™ mode. In continuous operation mode, the JWL150 can provide constant light or be triggered following the camera’s exposure signal. OverDrive™ mode delivers up to 6 times the continuous power with a low-latency response and fast strobe durations down to 10 ms.

The JWL150 features a batwing design that illuminates a larger area than built-in lighting systems and produces a greater light output that easily combines with polarizers, diffusers, and other optical elements that reduce light output. The new JWL150 targets disparate machine vision applications, with a particular focus on high-speed conveyors that require bright illumination at long, stand-off distances.

Smart Vision Lights

www.SmartVisionLights.com

JAI 8.1-megapixel UV Camera

JAI introduced the Go Series GO-8105M-5GE-UV, a new 8.1-megapixel, UV-sensitive camera with a high performance 5GBASE-T (5 GigE) interface. The new camera surpasses JAI’s three other UV (ultraviolet) camera models by providing both increased resolution (8.1 megapixels vs. 5 megapixels) and a higher spectral sensitivity covering UVA, UVB, and extending well into the UVC range.

The GO-8105M-5GE integrates the Sony Pregius S IMX487-AAMJ CMOS sensor into a compact form factor of 29 x 29 x 68 mm and produces full resolution 8.1-megapixel images at up to 66 frames per second over the 5 GigE interface. The camera’s interface features an auto-negotiation function that adjusts the camera's output to match the capabilities of the network or host PC, including 2.5GBASE-T (2.5 Gbps) or 1000BASE-T (1 Gbps), depending on the available bandwidth.

The camera has a compact 2/3” C-mount optical format thanks to the 2.74 µm pixel size of the Pregius S sensor. Pregius S sensors feature backside illumination to support this smaller pixel size without sacrificing imaging performance. 8-bit, 10-bit and 12-bit output formats are supported.

The GO-8105M-5GE-UV is offered in two configurations. The standard model features a double-AR-coated quartz glass cover over the sensor to protect the sensor from dirt and damage while maximizing light transmission. A glassless version (GO-8105M-5GE-UV-GL) is shipped with a protective glass cover on the sensor that can be removed by the user for applications where no interference from light passing through a cover glass can be tolerated.

The new camera’s resolution, frame rate, and ultraviolet sensitivity make it suitable for a range of complex applications in the fields of semiconductor mask inspection, wafer processing, sorting of waste materials, fluorescence analysis, high voltage technology, microscopy, dermatology, and more. Among the built-in camera features to support such applications are a horizontal/vertical image flip function, blemish compensation, shading correction, a sequencer function, multiple binning/rescaling modes, and an automatic level control (ALC) function that links auto-shutter and auto-gain functions to control exposures under changing light conditions.

The GO-8105M-5GE-UV becomes the 25th model currently available in JAI’s Go Series of compact industrial cameras. Other models include monochrome and color machine vision cameras with resolutions of 2.35 or 5 megapixels and with GigE Vision, USB3 Vision, or Camera Link interfaces, as well as two models equipped with on-sensor polarizer grids to support polarization imaging applications.

JAI

www.jai.com